CrustBuster Seed Box Tote User manual

P.O. Box 526 - Spearville, Kansas 67876 - (620) 227-7106

crustbuster.com

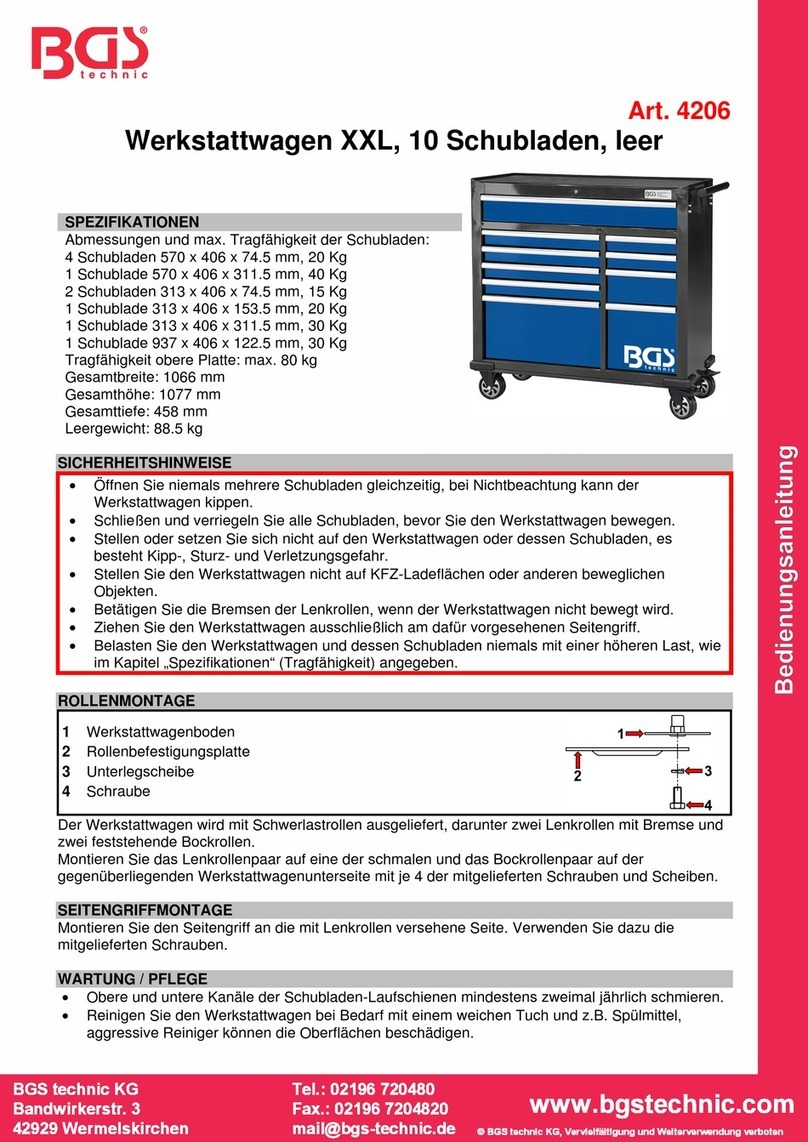

Seed Box Tote

Back Load Unit

OWNER'S MANUAL

#04175600 UPDATED 04/2021 (2013)

Table of Contents

Warranty Information . . . . . . . . . . . . . . . . . 1

Operator Qualifications. . . . . . . . . . . . . . . . 2

Safety and Warnings . . . . . . . . . . . . . . . . 3-6

FuelValve ......................... 7

Loading Seed in Tote Boxes . . . . . . . . . . 8-9

Wiring Diagram . . . . . . . . . . . . . . . . . . 10-11

Belt Assembly . . . . . . . . . . . . . . . . . . . . . 12

Operation, Maintenance, Belt Training . 13-14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . 15

Repair Parts:

Stand - Gas with Telescoping Tube and

Remote (Prior 2021) . . . 16-17

Stand - Gas with Standard Tube and

Remote (Prior 2021) . . . 18-19

Stand - Electric with Standard Tube

(Prior 2021) . . . . . . . . . . . . . . . . . . . 20-21

Stand - Gas with Telescoping Tube and

Remote . . . . . . . . . . . . . 22-23

Stand - Gas Hardwire w/ Actuator . . 24-25

Stand - Gas Remote w/ Actuator . . . 26-27

Stand - Electric w/ Actuator . . . . . . . 28-29

Standard Tube -Gas . . . . . . . . . . . . . 30-31

Standard Tube -Electric . . . . . . . . . . 32-33

Standard Tube -Gas w/ Actuator . . . 34-35

Standard Tube -Electric w/ Actuator . 36-37

Telescoping Tube Assembly

Gas w/ Actuator . . . . . . . 38-39

Gas................ 40-41

Support Frame. . . . . . . . . . . 41

Top and LowerTubes . . . . . . 42

Wind Guard . . . . . . . . . . . . 43

Upper Roller Bracket . . . . . . 43

S-wrap Roller . . . . . . . . . . . . 43

Electric Winch . . . . . . . . . . . 44

Shaft & Sprocket Assy . . . . . 44

Handle Assy. . . . . . . . . . . . . 44

SeedSpouts...................... 45

Flexible Tube Spouts . . . . . . . . . . . . . . . 46

Engine Assemblies . . . . . . . . . . . . . . . . . 47

DryTalc ...................... 48

Trailer ................... 54-56

Options:

Remote Enclosure Assy . . . . . . . . . . 48-51

Remote Control . . . . . . . . . . . . . . . . . . . 52

Identification

Your Seed Tender is identified by a Serial Number and Model Number. Record these numbers in the

spaces provided in this manual and refer to them when ordering parts or requesting service.

Serial Number Model Number

Warranty

CrustBuster/Speed King, Inc. of Spearville, Kansas, warrants consumer products, so far as

the same is of our own manufacture, against defects in material and workmanship under

normal and reasonable use for a period of one (1) year after date of delivery to the original

purchaser. Our obligation under this warranty is limited, however, to furnishing a replacement

part for a defective part, or at our option to repair the defective parts without charge, either

method F.O.B. our works, provided the consumer gives CrustBuster/Speed King,Inc. written

notice within ten (10) days after said part appears to be defective and affords

CrustBuster/Speed King,Inc. an opportunity to inspect. Unless otherwise expressly agreed

to by CrustBuster/Speed King,Inc., the consumer shall bear the expense of installation.

CrustBuster/Speed King, Inc. will not be liable for consequential damages where the loss is

commercial, including but not limited to loss of profit, delays or expenses.

This warranty sets forth the extent of our liability. The foregoing is in lieu of all other

warranties, expressed or implied, including any warranties that extend beyond the description

of the product.

1

Operator Qualifications

Operation of this Seed Tote shall be limited to competent and experienced persons. In addition,

anyone who will operate or work around this equipment must use good common sense. In order to

be qualified, he or she must also know and meet all other requirements, such as:

1. Some regulations specify that no one under the age of 16 may operate power

machinery. It is your responsibility to know what these regulations are in your

area or situation.

2. Current OSHA regulations state in part: "At the time of initial assignment and at

least annually thereafter the employer shall instruct EVERY employee in the

safe operation of servicing of all equipment with which the employer is, or will

be involved."

3. Unqualified persons are to STAY OUT of the work area.

4. A person who has not read and understood all operating and safety instructions

is not qualified to operate the machinery.

FAILURE TO READ THIS SEED TENDER MANUAL AND ITS

SAFETY INSTRUCTIONS IS A MISUSE OF THE EQUIPMENT.

Sign Off Sheet

As a requirement of OSHA, it is necessary for the employer to train the employee in the safe operation

and safety procedures with this Seed Tender. We include this sign off sheet for your convenience and

personal record keeping.

DATE EMPLOYER EMPLOYER'S SIGNATURE

2

BE ALERT!

Your Safety is involved.

General Safety Statement

WATCH FOR THIS SYMBOL. IT POINTS OUT IMPORTANT

SAFETY PRECAUTIONS. IT MEANS "ATTENTION ))) BECOME

ALERT!"

YOUR SAFETY IS INVOLVED.

It is your responsibility as an owner, operator, or supervisor to know and instruct everyone

using this Seed Tender at the time of initial assignment and at least annually thereafter, of the

proper operation, precautions, and work hazards which exist in the operation of this Seed

Tender in accordance with OSHA Regulations.

Safety Is No Accident

The following safety instructions, combined with common sense, will save your equipment

from needless damage and the operator from unnecessary exposure to personal hazard. Pay

special attention to the caution notes in the text. Review this manual at least once each year

with new and/or experienced operators.

1. Read and understand the operator's manual before operating this Seed

Tender. Failure to do so is considered a misuse of the equipment.

2. Make sure Seed Tender is secure before operating.

3. Always keep children away from Seed Tender when operating.

4. Make sure everyone that is not directly involved with the operation is out of

the work area before beginning the operation.

5. Make sure all safety devices, shields, and guards are in place and are

functional before beginning the operation.

6. Shut off power to adjust, service, or clean.

7. Keep hands, feet, and clothing away from moving parts. It is a good idea to

remove all jewelry before starting the operation.

8. Visually inspect the Seed Tender periodically during operation for signs of

excessive vibration, loose fasteners, and unusual noises.

9. Before transportation unit, make sure tube assembly is locked into place and

safety strap is on and secure.

10. Keep box tote on level surface.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

NOTICE: Used to address practices not related to physical injury.

3

Safety Decals

REMEMBER: If Safety signs have been damaged, removed, become illegible or parts replaced without

decals, new decals must be applied. New decals are available from your authorized

distributor or factory. Individual decals shown below.

#05326400 #05303300

#05312400

#05328000

#05316500

#05310800

4

Danger

BE ALERT! YOUR PERSONAL SAFETY IS INVOLVED.

ALWAYS PARK TENDER ON LEVEL SURFACE TO UNLOAD.

Before releasing safety strap that secures tube assembly, make

sure tender is sitting on a level surface.

If parked on an unlevel surface, and the tube assembly is not

restrained, it could swing rapidly and out of control to one side or

the other.

The rope attached to the tube is to assist in guiding the tube. If

tube is swinging out of control, the rope may not control the tube.

If parked on an unlevel surface with the spout side down, (See

illustration A)the tube could rapidly swing out.

5

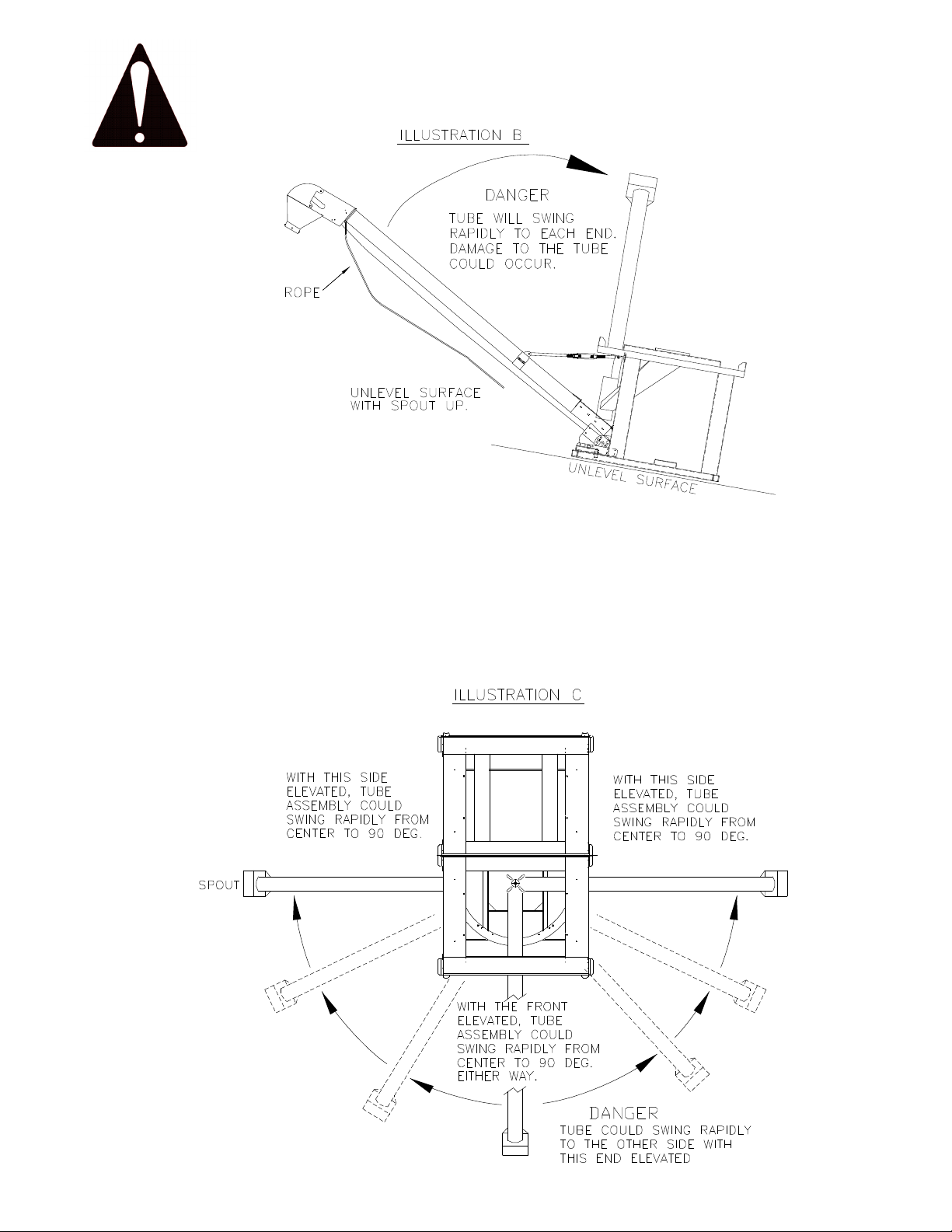

If parked on an unlevel surface with the spout

side up, (See illustration B)the tube will rapidly

swing to one end or the other depending on

which side the gravity pulls it. This could be

very hazardous for anyone standing in its path.

Be very cautious of situation.

If parked on an unlevel surface with the spout

side up, (See illustration C)the tube could

rapidly swing from one end to the other.

This could be very hazardous for anyone

standing in its path. Be very cautious of this

situation. This could also cause damage to the

tube assembly.

Danger

6

FUEL VALVE

When engine is not in use, leave the fuel

valve lever in the OFF position to prevent

- carburetor flooding

- fuel in the oil crank case because of

transporting vibrations

- the possibility of fuel leakage.

See engine owner’s manual to help you avoid

other damage to your engine.

CAUTION

NOTE: CrustBuster recommends fuel

valve be shut off and the motor

run completely out of fuel before

transporting.

7

NOTE:

For proper seal to hopper,

container should be lowered

straight down as shown. Make

sure there is no debris on hopper

top. Make sure rubber skirtboard

deflector is not bent under and

preventing a good seal.

CAUTION

FAILURE TO EXTEND FORKS UNDER

OAK INSERTS WILL CAUSE DAMAGE

TO SLIDE DOOR ON THE UNDER

SIDE OF CONTAINER. THIS IS A

DANGEROUS SITUATION ALSO.

Assembly

CAUTION

ALWAYS LIFT THE CONTAINER FROM THE BOTTOM. NEVER USE STRAPS OR

LIFT BY TYING ANYTHING TO THE SIDES OF THE CONTAINER. REQUIRES

MINIMUM 3000 LB. FORKLIFT TO PICK UP FULL CONTAINER. OAK INSERTS,

LOCATED IN THE BASE OF THE CONTAINER, REDUCE LIPPAGE ON FORKLIFT

FORKS AND PROVIDE STRUCTURAL SUPPORT.

8

TO LOAD SEED BOXES, THE

TOTE SHOULD BE ON LEVEL

GROUND OR SURFACE AS

SHOWN.

IF IT IS NOT POSSIBLE TO

LOAD ON A LEVEL SURFACE,

LOAD THE DOWN HILL

CONTAINER FIRST, AS

SHOWN.

THIS IS THE RIGHT WAY!

IF YOU LOAD THE UP HILL

BOX FIRST, IT WILL BE VERY

DIFFICULT TO GET THE

SECOND BOX LOADED.

THIS IS THE WRONG WAY!

Seed Box Loading

9

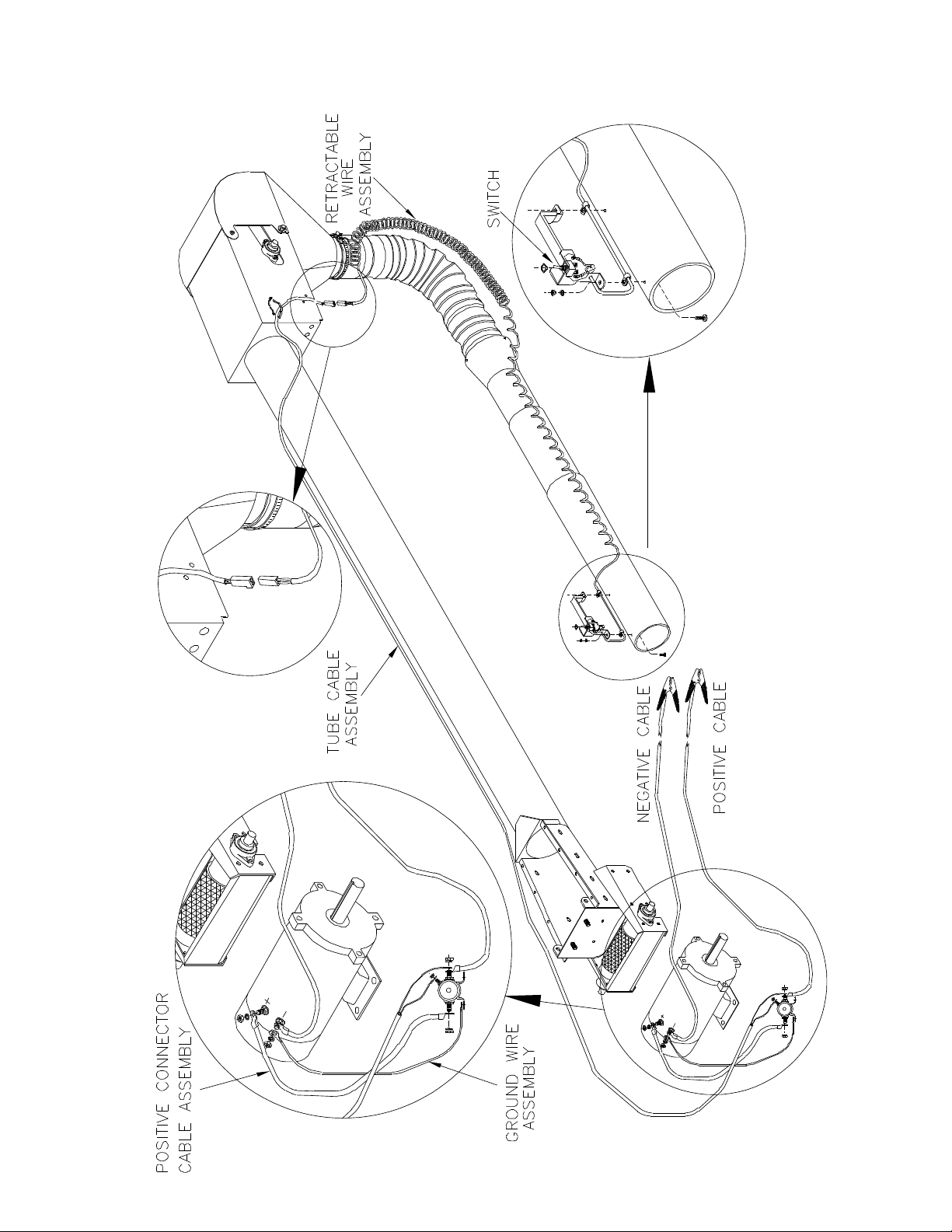

Wiring Diagram

For Electric Units

10

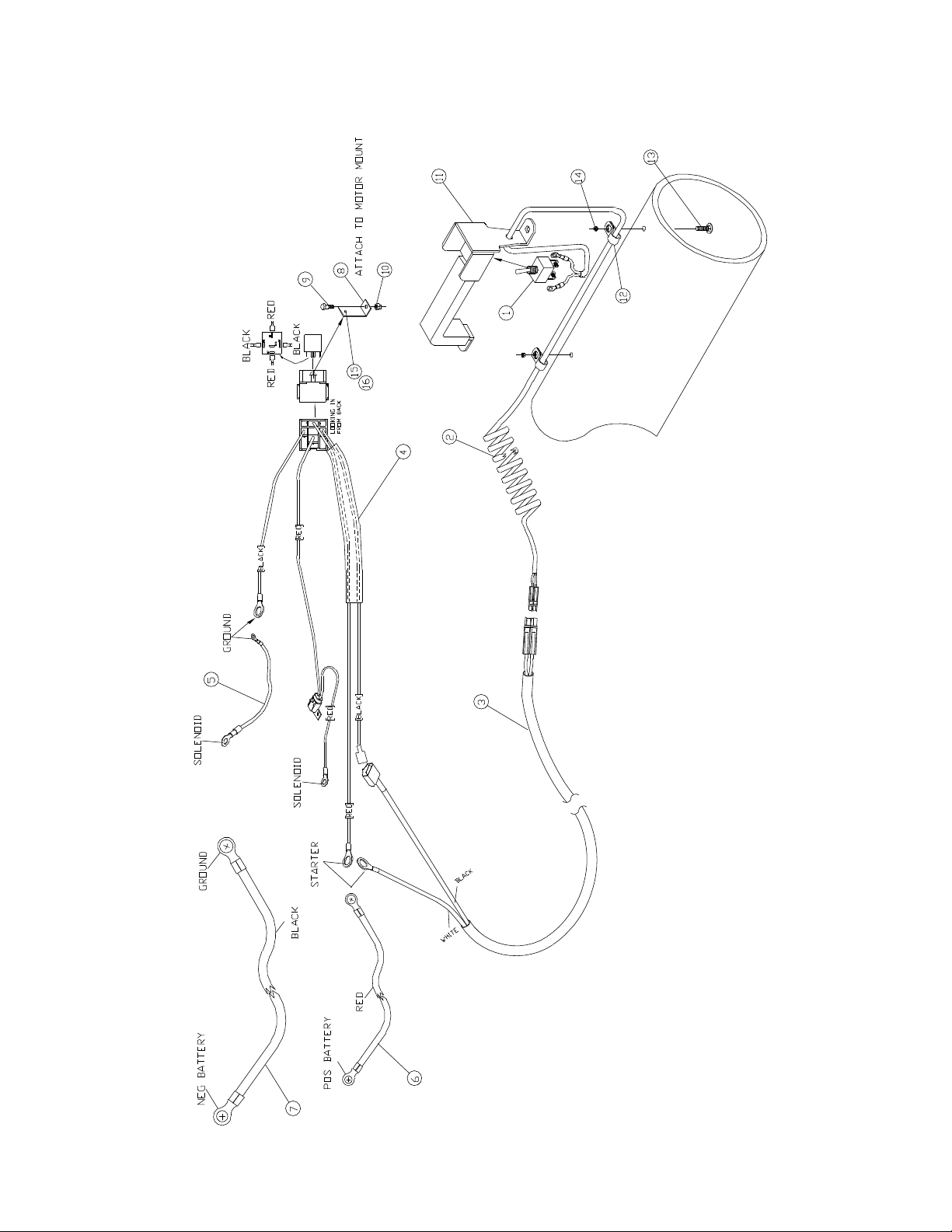

Wiring Diagram

For Gas Units (without remote)

11

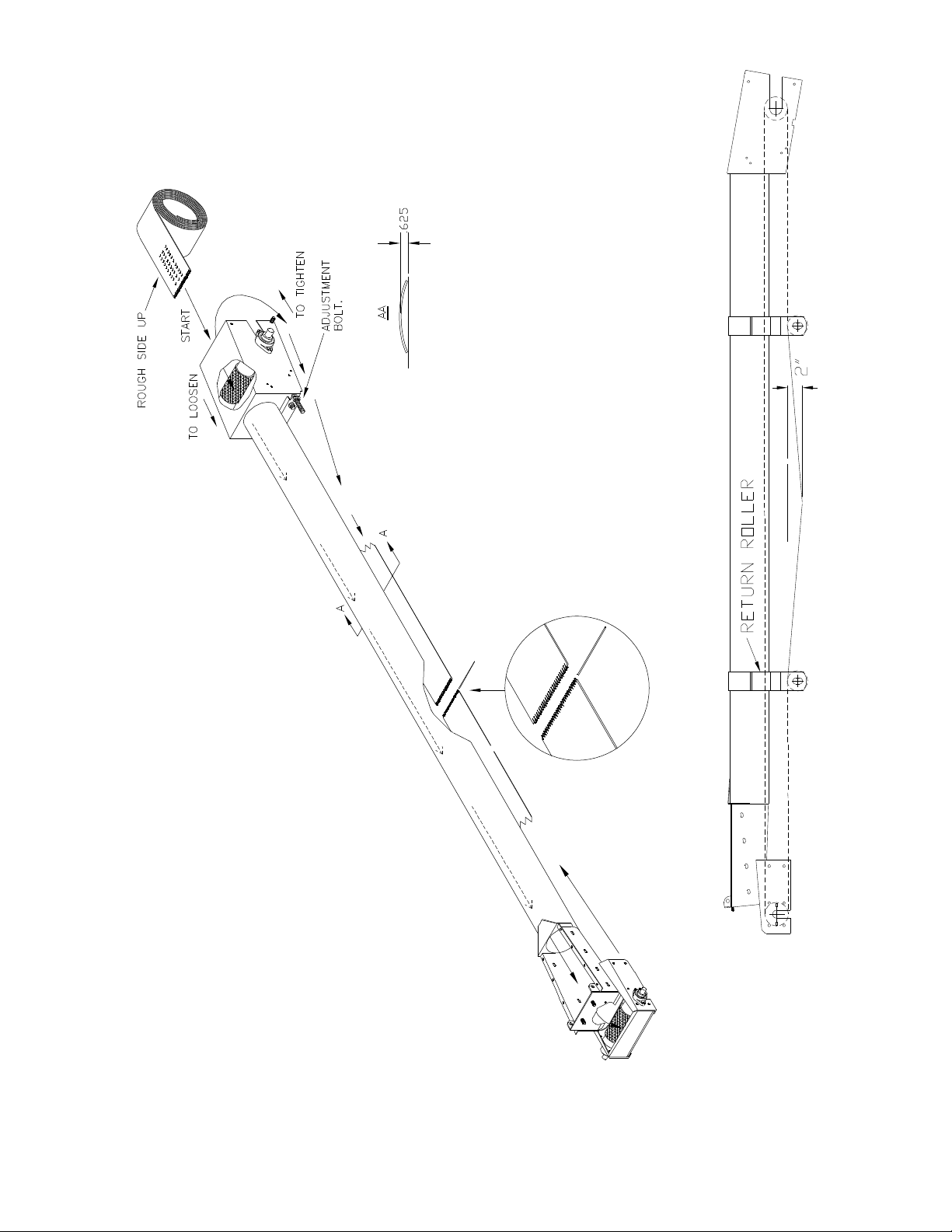

BELT TIGHTENING

INSTRUCTIONS

Belt should be tightened before

you train the belt. Tightening the

belt is done on the head roller by

tightening the take up bars

evenly. Belt is tight when

applying 25 lbs. of force,

centered between the return

rollers, there is no more than 2

inches of deflection.

BELT ASSEMBLY INSTRUCTIONS

At the start point, see view of head and tail assembly.

Drop belt over the top of head roller and gravity feed belt

down the tender tube to the bottom. Guide the belt over

the top of the tail roller. Make sure rough side is UP and

the smooth side is DOWN against the inside of wall of the

tube.

Route both ends around head and tail rollers and over all

return idlers mounted under the tube. Slide belt forward

or back through tube so the ends of the belt meet at a

convenient location between return idlers to facilitate

joining.

Align and interlace belt and clipper lacings. Slip splice pin

(Plastic covered cable) through clipper lacings to secure.

Belt Assembly

12

Pre-Operation Check List

1. Check all bearings for proper lubrication.

2. Check the tube for foreign material.

3. Check belt for proper tension.

4. Start unit and check tender belt alignment while unit is empty.

BELT CARE ………

It is suggested that the unit be run every two to three days or more often if possible. This tends to

keep the belt alive and stops any forming of the belt to the curvature of the tube while the unit is

not in use.

NOTE: Belt may deteriorate if not in use and exposed to weather conditions for any prolonged

period of time.

Operation Sequence

1. Check drive chain for proper tension.

2. Make sure tender belt is properly tensioned.

3. Allow unit to run empty for a few minutes to flex tender belt.

4. Check tender belt for proper alignment.

5. Before shutting power off, be certain head and tail unit is empty.

STORAGE ………

Temporary Storage

1. Relieve tension on tender belt.

2. Store all belt equipment in a dry place. If equipment cannot be stored out of the weather,

cover engine and mechanical parts with waterproof material.

Prolonged Storage

1. Remove all belts and store in a cool, dark, dry place.

2. Wash tender belt thoroughly.

3. Wash tender tube both inside and out.

4. Lubricate all bearings.

5. Store in a dry shelter.

Maintenance

Preventive maintenance is the key to the long life of any mechanical device.

Careful and systematic inspection of the Seed Tender will result in maximum, trouble-free service.

BELT REPLACEMENT ………

To replace the belt, cut it into and hand rotate the head roller until belt has been removed. Install

appropriate belt as outlined in assembly instructions.

HEAD ASSEMBLY TAKE-UP ………

After extended use, the tender belt may stretch to the point that there is not sufficient take-up in

the head assembly to tighten it. Obtain additional take-up by cutting a 6" to 8" section from the

belt. A new splice lacing may be ordered from your CrustBuster/Speed King distributor or from the

factory.

PERIODIC CLEAN-OUT ………

Due to the characteristics of certain materials, residue sometimes collects between the tender belt

and the tube. Check the unit periodically for any material build up in this area. If residue appears

excessive, remove the tender belt and thoroughly wash the belt and tube. Allow belt and tube to

dry before reinstalling the belt.

When the tender is not being used, secure belt to the tube to prevent belt from flopping in the wind,

possibly breaking return idlers or ripping belt.

LUBRICATION ………

All bearings which are fitted with grease zerks should be lubricated at the conclusion of each

operating day. Before greasing the bearings, make certain the zerks are free of dirt, otherwise this

will be passed into the bearing race. If the unit will be out of service for a period of time, purge the

bearings.

BELT TRAINING PROCEDURE ………

A tender belt correctly installed and trained will run straight and true. The belt must run centered

on all terminal rollers, take-up rollers, and return idlers throughout the entire belt length.

Incorrect installation and training can result in severe edge damage, material spillage, material

leakage through the skirt rubber at the loading point, and excessive power demands. Material

spillage is the usual reason for belt carcass ruptures and pulley cover gouging and stripping, while

leakage at the skirt rubber results in excessive conveyor cover wear under the skirts.

13

Maintenance - (cont’d)

ALIGNMENT ………

All rotating parts -head roller, tail roller, and return idlers- must be at a 90 degree angle to the

direction of belt travel, must be level, and the midpoint of each centered on a line when properly

aligned.

Alignment is checked by running a tight wire from the center of head roller to center of the tail roller.

Level all rotating parts. If a part is not level, the belt will run to the lower side.

BELT SPLICING ………

A belt must not run out at the splice area. Runout will occur if the belt is not cut square or splice

is not installed square.

Operation

1. Prior to the start-up, check to see that belt is free from any objects that would bind or tear.

2. On starting for the first time, with no load on belt, apply power for a few seconds only to see

that the tender belt is well centered in the tube and on the return.

3. It should be noted at this time that too much tension on the tender belt will make adjustment

or training much more difficult, shorten the life of the belt, and waste power. The belt should

be tensioned tight enough so the drive roller does not slip. The belt is tight when applying 25

pounds of force, centered between the return rollers, there is no more than 2 inches of

deflection.

BELT TRAINING ………

It is essential that the tender belt be properly trained at all times. For this reason, all rotating parts

should always be at right angles to the tender belt.

Slight adjustment of roller shafts may be required to keep belts centered on them i.e., if the belt

runs to one side of the roller - apply more tension to this side of the belt by advancing the roller

shaft on this side. This can be done on the head section as long as adjustment bolt does not vary

more than 1/4". If it does, and belt will still not center on both rollers, the tail section is probably out

of square.

To square tail section roller, even out the head roller until adjustment bolts are equal. On tail

section, loosen bearing bolts on opposite side the belt is off. CAUTION: LOOSEN BEARING

BOLTS JUST ENOUGH SO IT TAKES A BLOCK OF WOOD AND A SMALL HAMMER TO MOVE

THE BEARING. To adjust tail section, 1/32" in most cases, will move the belt. Tail roller bearings

only have about a 1/16" to 3/32" movement total. Tighten the bearing, and go to the head section

and retrain the belt.

If the belt tends to veer to one side of the return strand, the belt can be centered by "knocking"

ahead (in the direction of belt travel) the end of the return idler to which the belt runs. A belt

correctly installed will usually train well both empty and loaded, except as noted:

1. One or more rotating parts not in alignment.

2. Belt tensions in some part of system (usually at tail section) are below minimum

recommended.

3. Belt not loaded centrally.

When a belt is initially started, it should be jogged around the system to determine if a major runout

occurs which could damage belt and belt edges. If runout occurs at some point of the system, the

reason is usually a return idler or roller out of alignment before the runout. Alignment should be

rechecked before restarting.

After the belt can be safely run without damage, final training should begin with the head roller.

The belt must enter the head roller in the center without movement from side to side. If the belt

is not centered on the tail pulley, the return strand of belt should be observed for any section which

is not centered on the return idlers. If the belt is not centered at some point, move return idlers

starting before this point to correct centering of belt. Movement of idler bracket should be gradual

and only 1/16" to 1/8" remembering that the belt will move in the direction that it first contacts the

idler. The same corrective action should be taken at the tail roller.

After the belt is trained empty, the belt should be trained with a load. The take-up adjustments are

made to prevent belt slip and keep tensions at all points above minimums recommended when belt

is operating with a load.

If slip occurs under load, additional belt tension should be adjusting the take-up only enough to

prevent slip from occurring under load, and when started with a load.

14

Seed Box Tote

Dimensions

15

Seed Box Tote

Stand Assembly -Telescoping Tube

Gas Drive (Prior 2021)

16

Seed Box Tote

Stand Assembly -Telescoping Tube

Gas Drive (Prior 2021)

#63164800

Item Qty Part No. Description

1 1 975326 Tote Stand

2 1 879072 Telescoping Conveyor

3 1 878793 Spout Assembly

4 2 241133 Spout Gate

5 1 123448 Pivot Lock Collar

6 1 04255600 Sheave 1B 8 x 1 w/keyway

7 1 975464 Belt Guard

8 8 330894 Flat Washer 3/8"

9 21 330837 Nylock 3/8"

10 1 276337 Pivot Plate Center

11 2 276329 Pivot Plate Ends

12 12 01047000 Carriage Bolt 5/16" x 1"

13 2 242529 Insulator Bracket

14 2 03651700 Insulator

15 2 01034800 U-bolt 3/8" x 1 1/4" x 2 1/4"

16 1 63046700 Engine Assembly

17 2 975425 Load Bar

18 1 01429000 Battery Box

19 1 82099300 Conveyor Hopper

20 1 474304 V-Belt B-46

21 3 434456 Chain #4 x 17 links w/pin

22 2 03818200 Plug 1 1/4" Square

23 2 608596 Metal Loom Clamp 1/4"

24 1 607416 Manual Holder

25 1 04175600 Owners Manual

Item Qty Part No. Description

26 2 605659 Grommet

27 1 03895000 Remote Fob Box

28 1 00694000 Serial Plate

29 2 600577 Serial Plate Drive Screws

30 1 17375700 Key 1/4" x 1"

31 33' 01467000 Nylon Rope

32 1 03439700 Decal Patent #

33 1 05303300 Decal Cautions

34 2 05310800 Decal Debris Center Flow

35 1 05312400 Decal Shield Caution

36 1 05326400 Decal Tip-Over Warning

37 1/8 00843300 Silicone Caulk

38 1 976498 Belt Guard Rear

39 26 01057900 HHCS 1/4" x 3/4"

40 15 02016400 Flat Washer 1/4"

41 26 330522 Nylock 1/4"

42 4 01144500 HHCS 5/16" x 3/4"

43 4 335448 HHCS 5/16" x 1½”

44 10 330852 Flat Washer 5/16"

45 22 331611 Nylock 5/16"

46 10 330548 Carriage Bolt 3/8" x 3/4"

47 2 334847 Wing Nut 3/8"

48 8 01017300 HHCS 3/8" x 1"

49 1 330886 HHCS 3/8" x 3"

50 2 976902 Spout Assembly Mount

17

Seed Box Tote

Stand Assembly -Standard Tube

Gas Drive (Prior 2021)

18

Table of contents

Other CrustBuster Outdoor Cart manuals

Popular Outdoor Cart manuals by other brands

Knurr

Knurr Dacomobile Extension shelf Assembly instructions

Rockler

Rockler Material Mate instructions

JohnDow Industries

JohnDow Industries GAS & GO GG-25PFC-D Operator's manual

fetra

fetra 3191 Operation manual

MedViron

MedViron Height Adjustable Medical Carts Operation & maintenance manual

Sauder

Sauder Studio RTA 408343 Instruction booklet