CRX 680 User manual

Table of contents

Languages:

Other CRX Engine manuals

Popular Engine manuals by other brands

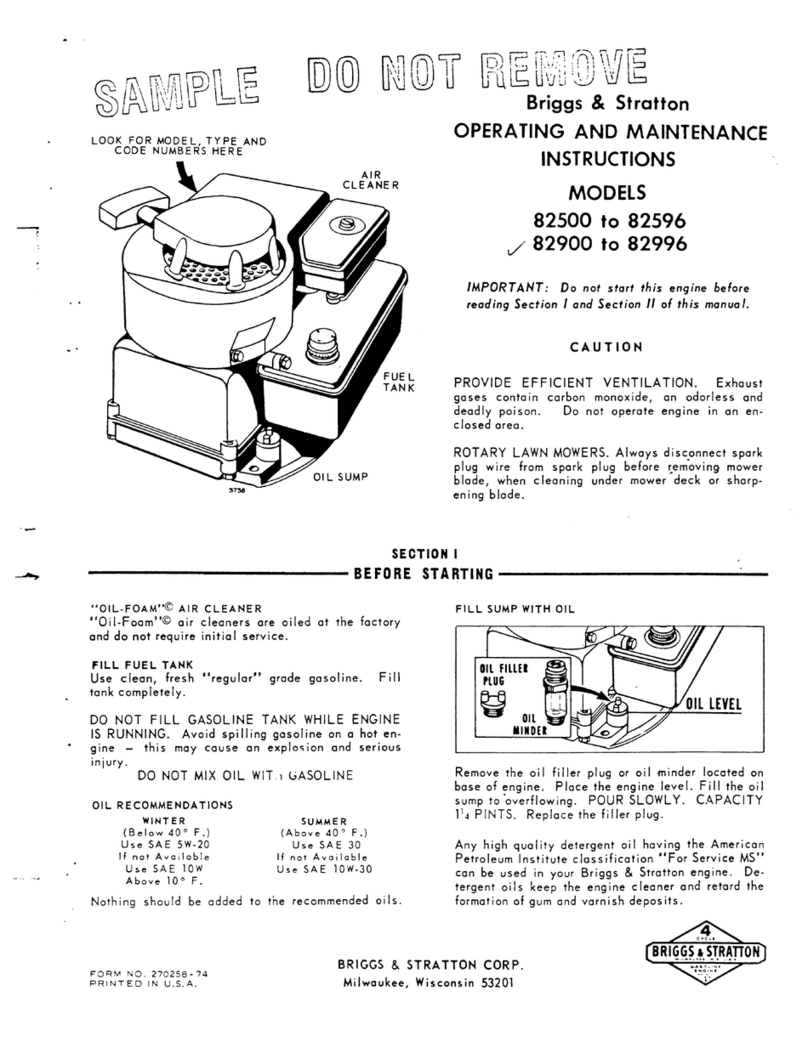

Briggs & Stratton

Briggs & Stratton 82500 Operating and maintenance instructions

SOMFY

SOMFY Sonesse 40 PA manual

RADEMACHER

RADEMACHER RolloTube Comfort 2360 20 80 installation instructions

Sears

Sears 143.994006 Operator's manual

Evolution

Evolution 15GX2 user manual

rojaflex

rojaflex ELFIM-45M Original assembly and operating instructions

Briggs & Stratton

Briggs & Stratton 80200 Series Operating and maintenance instructions

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SL Series Service manual

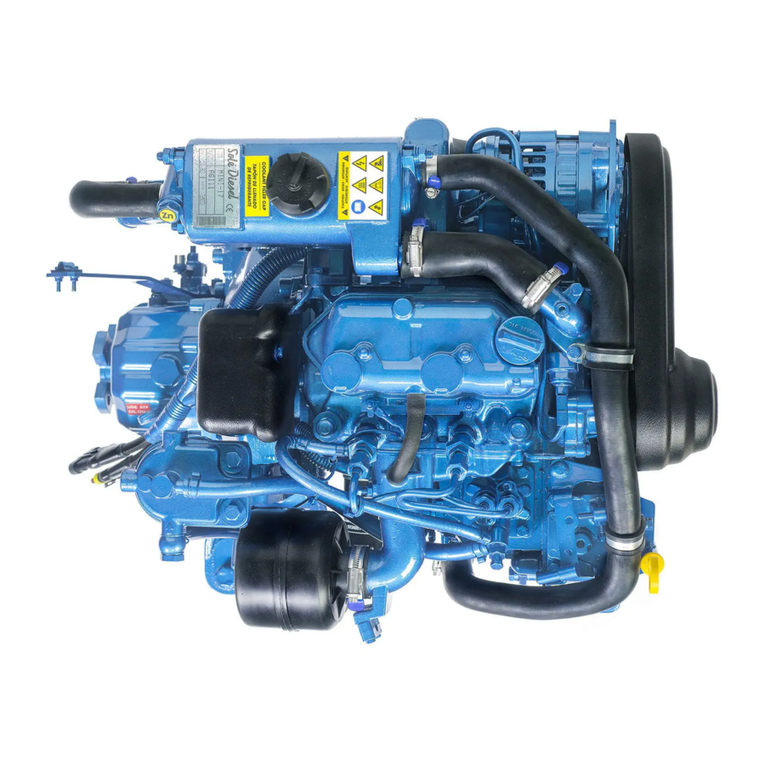

Sole Diesel

Sole Diesel MINI-17 Operator's manual

Emerson

Emerson Bettis WO Installation, operation and maintenance manual

Becker

Becker P9-16-E01 Assembly and operating instructions

Perkins

Perkins New 1000 Series Workshop manual