Cryomech Cryocooler PT410 User manual

CP.PT410 - CPA289C(C)

Cryocooler

PT410 - CPA289C

INSTALLATION and OPERATION

MANUAL

CP-1

The information contained in this document is belie ed to be accurate and reliable as of the time of its publication.

Howe er, Cryomech, Inc. cannot accept any responsibility (financial or otherwise) that may result from the use or

misuse of the information contained in this document. Except as expressly contained in this document, there are

no other warranties granted or extended by the manufacturer.

Cryomech, Inc. reser es the right to add, change, modify or delete any or all information contained herein without

prior written notice. Re isions to this document may be issued at the time such changes and/or deletions occur.

Any duplication of this manual or any of its parts without expressed written permission from Cryomech, Inc. is

expressly prohibited.

Correspondence concerning this document should be forwarded to:

Customer Ser ice Department

Cryomech, Inc.

6682 Moore Road

Syracuse, NY 13211 USA

Telephone (315) 455-2555

FAX: (315) 455-2544

Email: support@cryomech.com

Website: www.cryomech.com

CP-2

Content

Section 1

O er iew

Section 2

Warranty

Section 3

Safety

Section 4

Inspection and Unpacking

Section 5

Specifications

Section 6

Installation

Section 7

Operation

Section 8

Routine Maintenance

1.100(D)

Section 1

Overview

Overview

1

-

1

Section 1: Overview

This section provides a general overview of a cryocooler, the organizational structure of

this anual, and a glossary of defined ter s and acrony s.

1.1 Cryocooler system

1.1.1 General description

The operation of a Cryo ech cryocooler is based on a closed-loop heliu expansion cycle.

The cryocooler consists of a heliu co pressor package, cold head, flex lines and cold

head otor cord.

The co pressor package receives low pressure heliu fro the cold head, pressurizes

the heliu gas and returns high pressure heliu gas to the cold head via flex lines. The

cold head reaches cryogenic te peratures through adiabatic expansion by using the high

pressure heliu gas fro the heliu co pressor package and discharging low pressure

heliu gas and returning it to the co pressor package.

1.1.2 Organization of the manual

This anual is divided into eight section that provide the infor ation needed to install,

operate and perfor aintenance on a Cryo ech cryocooler. It is i portant to note that

bulleted list ay be perfor ed in any order but nu bered lists (labeled 1, 2, etc.) are

representative of sequential actions that ust be perfor ed in the order listed.

1.2 Glossary

1.2.1 Definitions

eroquip Couplings:

The ter "Aeroquip couplings" is used generically to describe the self-sealing fittings that

connect co ponents, e.g. heliu flex lines are connected to the heliu co pressor

package and to the cold head via Aeroquip couplings.

Category II Installation:

Category II refers to the potential for transient over-voltage conditions in the ains power

connection to the equip ent. See IEC 664, Sub-clause 5.6 for further details.

Closed Loop System:

This refers to a cryogenic syste that has no heliu loss.

Cold Head:

The cold head is an expansion device which is capable of reaching cryogenic

te peratures.

Cold Head Motor Cord:

The cold head otor cord provides electrical power fro the heliu co pressor package

to the cold head otor.

Overview

1

-

2

Cold Head Heat Exchanger:

The heat exchanger(s) on the cold head provide cooling at cryogenic te peratures by

transferring heat to the heliu within the syste .

Cryogenic Temperatures:

Te peratures lower than 120 K or -153 °C.

Cryocooler:

A cryocooler is a cryogenic refrigeration syste based upon a closed loop heliu

expansion cycle. It consists of a heliu co pressor package, heliu flex lines, and a cold

head (expansion device).

Gifford-McMahon (GM):

A cold head which expands the heliu using a displacer.

Helium Compressor Package:

Provides syste safety controls, houses the co ponents that co press, cool and purify

the heliu gas and provides electrical interface controls.

Helium Flex Lines:

The heliu flex lines are corrugated, stainless steel hoses that transport heliu between

the heliu co pressor package and the cold head.

Pollution Degree 2:

Pollution degree 2 refers to the extent to which the local environ ental conditions could

affect the electrical safety of the syste . See EN 61010 or UL 61010A for further details.

Pulse Tube:

A cold head that does not use a displacer or piston.

System:

The ter "syste " is used as a synony for cryocooler. It consists of a co pressor

package, heliu flex lines and cold head.

1.2.2 cronyms

The following acrony s are used in the text and provided here for convenient lookup:

FPT Fe ale Pipe Thread

GPM Gallons per Minute

LPM Liters per Minute

MPT Male Pipe Thread

psig Pounds per Square Inch Gauge

2.100(C)

Section 2

Warranty

Warranty

2-1

Section 2: Warranty

2.1 Statement of warranty

Provided the customer installs, operates and maintains this cryocooler in accordance with

the specifications and procedures set forth in this manual, Cryomech, nc. extends a limited

warranty on parts and workmanship. This warranty covers all non-user serviceable

components of the compressor package, cold head and helium flex lines. The warranty

does not cover user-serviceable electronics (such as fuses).

f found to be defective and in accordance with the terms of the limited warranty, Cryomech,

nc. will provide warranty replacement parts at no cost to the customer. Cryomech, nc.

does not cover onsite service. Defective components must be returned to Cryomech, nc.

for service. Customers are responsible for all shipping and handling charges associated

with each warranty repair.

GM cryocoolers have a warranty period of three (3) years or 8,000 operating hours,

whichever comes first. The GM cold head is warranted for the same three (3) years or

8,000 operating hours to deliver the specified temperatures and cooling capacities.

Pulse tube cryocoolers have a warranty period of three (3) years or 12,000 operating hours,

whichever comes first. The pulse tube cold head is warranted for the same three (3) years

or 12,000 operating hours to deliver the specified temperatures and cooling capacities.

2.2 Conditions that can void the warranty

Operation of this cryocooler in situations that do not meet the specifications in this

manual will void the warranty. f you intend to operate the cryocooler outside any of the

specified conditions, prior written authorization from Cryomech, nc. must be granted.

nstalling any software on a Cryomech, nc. product that was not provided by

Cryomech, nc. will void the warranty. See Section 5

See Section 6 for installation guidelines. Failure to follow these guidelines will void the

warranty.

Exceptional care must be used when handling the cold head. The warranty will not

cover dented or bent tubes.

Heating any part of the cold head above 325 K (125 ºF, 52 ºC) will cause damage and

void the warranty.

With the cold head oriented vertically, the maximum allowable load cannot exceed the

value specified in Section 5. Excessive loading will damage the cold head. This type

of damage is not covered by the warranty. f your application requires a load heavier

than the weight specified in Section 5, prior written authorization from Cryomech, nc.

must be granted.

Mounting the cold head in an orientation other than vertical will void the warranty

without prior written authorization from Cryomech, nc.

Alterations to the cryocooler are prohibited without prior written authorization from

Cryomech, nc. Modifications without prior written approval will void the warranty.

Cooling water must meet the specifications in Section 5. f non-conforming cooling

water is introduced into the system, even for cleaning purposes, the warranty will be

void.

Warranty

2-2

The mains supply voltage to the cryocooler must be within 10% of the nominal voltage

specification in Section 5. Operating the cryocooler outside the voltage specification

will void the warranty.

Do not allow the flex lines to contact any corrosives or commercial cleaning agents.

Flex line damage caused by exposure to corrosives or commercial cleaning agents will

not be covered by the warranty.

Applying extreme bend stress to a flex line will cause permanent damage. Bending a

flex line to less than a 12 in (30 cm) radius will void the warranty. See Section 6.

Operating the cold head in a magnetic field of greater than 500 gauss will void the

warranty.

Attempting to disassemble the cold head will void the warranty. Contact Cryomech,

nc. if the cold head needs to be serviced. See Section 8.

When adding helium to the cryocooler, the helium must be at least 99.999% pure.

Adding helium that is less than 99.999% pure will contaminate the cryocooler and void

the warranty. See Section 8.

Consumable, non-electrical, items such as adsorbers must be replaced with parts

provided by Cryomech, nc. Replacing consumable items with third party produced

products will void the warranty for all parts of the cryocooler, including the helium

compressor package, flex lines and cold head. See Section 8.

Excluding the designated water cooling circuit, never allow water to contact any of the

components of the system. Exposing the helium compressor package, flex lines or cold

head to water will void the warranty.

3.100(B)

Section 3

Safety

Safety

3-1

Section 3: Safety

3.1 Safety and information symbols

3.1.1 Equipment symbols

The safety and information symbol stickers placed on Cryomech, nc. cryocoolers are defined below.

Alternating current. The symbol signifies that alternating current is present.

nternal ground. This symbol represents an internal protective grounding terminal.

Such a terminal must be connected to earth ground prior to making any other

connections to the equipment.

Warning con. Refer to the documents that accompany the equipment.

The CE label is placed on a product if the product has been tested for and meets the

safety standards set by the European Community. CE stands for Conformité

Européenne. All pressure equipment bearing the CE label has a maximum

temperature of 94 °C (200 °F) and a maximum pressure 29 barg (425 psig).

The TUV label is placed on a product if the product has been tested for and meets the

safety standards set by the US and Canada. The cTUVus mark is officially recognized

as an equivalent and direct replacement of the UL and CSA marks. Nation Recognized

Testing Laboratories (NRTL) like TÜV Rheinland can test to the same standard and

specifications as those defined by UL and CSA.

Power switch. This symbol designates an in/out or push/push switch.

Read the manual or handbook sign. When this symbol is found on a piece of

equipment, the user should read the whole manual before starting installation or use.

This symbol is found on the compressor package.

3.1.2 Icons in the manual

Definitions of Warning and Caution and nformation icons in the manual

Warning con. A warning message is used when failure to observe instructions or

precautions could result in injury or death to humans.

Electrical Warning con. An electrical warning message is used when failure to observe

instructions or precautions could result in electrical shock or burns to humans.

Caution con. A caution message is used when failure to observe instructions or

precautions could result in significant damage to equipment and/or facilities.

nformation con. The accompanying message contains information to aid the operator

in obtaining the best performance from the equipment or other important information

that does not involve danger to equipment or humans.

Safety

3-2

3.2 Warnings and cautions

The warnings and cautions for the Cryomech cryocooler are listed here by section. The same warnings

and cautions appear in each respective section.

3.2.1 Section 5: Specifications

Section 5.2 echnical specifications

CAU ION

Operation of the cryocooler in any situation that does not meet the specifications in this section will void

the warranty. f you plan to operate the system outside any of the specified conditions, contact Cryomech,

nc.

CAU ION

The use of D (De- onized) water is prohibited. D water causes damage to the compressor package and

will not be covered under warranty.

3.2.2 Section 6: Installation

Section 6.1 Cold head installation

CAU ION

Failure to follow these installation guidelines will void the warranty.

CAU ION

Special care must be taken when handling the cold head. The warranty will not cover dented or bent

tubes.

CAU ION

Operating the cold head in a magnetic field of greater than 500 gauss will void the warranty.

Section 6.1.2 Initial preparation of the cold head

CAU ION

Heating any part of the cold head above 325 K (125 ºF, 52 ºC) will cause damage and void the warranty.

CAU ION

With the cold head oriented vertically, the maximum allowable load cannot exceed the value specified in

Section 5. Excessive loading will damage the cold head. This type of damage is not covered by the

warranty. f your application requires a load heavier than the weight specified in Section 5, prior written

authorization from Cryomech, nc. must be granted.

Safety

3-3

CAU ION

Mounting the cold head in an orientation other than vertical will void the warranty without prior written

authorization from Cryomech, nc.

CAU ION

Alterations to the cryocooler are prohibited without prior written authorization from Cryomech, nc.

Modifications without prior written approval will void the warranty.

Section 6.1.6 Connect the remote motor assembly’s flex line- Remote Motor Cold Heads Only

CAU ION

Follow this procedure carefully when connecting and disconnecting the helium flex lines. Failure to follow

the procedure will void the warranty.

CAU ION

Do not allow the flex lines to contact any corrosives or commercial cleaning agents. Flex line damage

caused by exposure to corrosives or commercial cleaning agents will not be covered by the warranty.

CAU ION

Applying extreme bend stress to a flex line will cause permanent damage. Bending a flex line to less than

a 12 in (30 cm) radius will void the warranty.

Section 6.2 Compressor installation

CAU ION

Failure to follow these installation guidelines could result in voiding the warranty.

Section 6.2.1 Prepare the compressor package location

WARNING

The helium compressor package must be positioned to provide easy access to the front panel mounted

circuit breaker.

Section 6.2.2 Connect the water lines to the compressor

CAU ION

Cooling water must meet the requirements in Section 5. ntroduction of cooling water that does not meet

the specifications in Section 5, even for cleaning purposes, it will void the warranty.

CAU ION

Do not apply heat to the cooling water inlet and outlet connectors located on the front panel of the helium

compressor package.

Safety

3-4

Section 6.2.3 Connect the compressor package to the main power

CAU ION

The mains supply voltage to the helium compressor package must be within 10% of the nominal voltage

specification in Section 5. Operating the helium compressor package outside the voltage specification

will void the warranty.

WARNING

Follow all local electrical codes and guidelines when during installation.

WARNING

One lead of the helium compressor package is grounded. Never bypass this ground or attach the helium

compressor package to an ungrounded circuit. A dangerous electrical hazard will develop.

Section 6.2.4 Connect the helium flex lines to the cold head or remote motor assembly and the

compressor package

CAU ION

Follow this procedure carefully when connecting and disconnecting the helium flex lines. Failure to follow

the procedure will void the warranty.

CAU ION

Do not allow the flex lines to contact any corrosives or commercial cleaning agents. Flex line damage

caused by exposure to corrosives or commercial cleaning agents will not be covered by the warranty.

CAU ION

Applying extreme bend stress to a flex line will cause permanent damage. Bending a flex line to less than

a 12 in (30 cm) radius will void the warranty.

3.2.3 Section 7: Operation

Section 7.1.1 Checks before operating

CAU ION

A voltage deviation of more than 10% above or below the voltage rating can cause helium compressor

motor overheating and possible failure. ndications of voltage operation outside that range will void the

helium compressor warranty.

CAU ION

Operating the cold head in a magnetic field of greater than 500 gauss will void the warranty.

Safety

3-5

Section 7.1.2 Startup procedure

WARNING

The system operates in a closed loop cycle at pressures higher than 200 psig (12.8 bar) and at

temperatures below 120 K.

Section 7.6 Disassembling the system for transport or storage

WARNING

Do not touch the cold end of the cold head until it has warmed to room temperature. f there is frost on

the cold head, it is too cold to touch.

3.2.4 Section 8: Routine maintenance

Section 8.3 Cold head

CAU ION

The Pulse Tube style cold heads contain no user-serviceable parts. Attempting to disassemble the cold

head will void the warranty. Contact Cryomech, nc if the cold head needs to be returned for servicing.

CAU ION

Service to Gifford-McMahon style cold heads must be performed using Cryomech, nc parts and the

appropriate work instructions. Contact Cryomech, nc. before servicing the cold head.

Section 8.4 Replace the adsorber

CAU ION

At no time should the Aeroquip couplings be removed from the adsorber. Replacement can be completed

without relieving system pressure, since the adsorber is equipped with Aeroquip couplings for sealed

removal.

WARNING

The input power must be disconnected from the helium compressor package before removing any helium

compressor package panels.

Section 8.5 Vent excess helium from the helium compressor package

CAU ION

Venting more than 5 psig (0.34 bar) of helium per minute will lead to improper oil migration within the

system. f this condition occurs, factory service will be required.

Safety

3-6

Section 8.6 Recharge helium to the helium compressor package

CAU ION

When adding helium to the helium compressor package, the helium must be 99.999% pure.

Contamination of the helium by other gases is a common cause of premature failure and is not covered

by the warranty.

CAU ION

No more than 5 psig (0.34 bar) of gas should be added per minute to prevent improper oil migration within

the system. f such contamination occurs, factory service will be required.

Section 8.7 Cleaning

CAU ION

Excluding the designated water cooling circuit, never allow water to contact any of the components of the

system. Exposing the system to water will void the warranty.

WARNING

Never remove an Aeroquip coupling from the helium flex lines, cold head, adsorber, or helium compressor

package without first relieving the helium charge. Pressure in any of the components can cause the

coupling to become a projectile that may cause injury.

4.100(B)

Section 4

Inspection and

Unpacking

Inspection and Unpacking

4-1

Section 4: Inspection and Unpacking

IMPORTANT

If there is any visible damage to the packing crates or any components contact ryomech, Inc.

immediately.

4.1 Inspection of crate

Be sure to note on the shipping documents any visible damage to the crate, including tip

indicators that have been activated.

4.2 Unpacking

The system is shipped in a secure packing crate. The base of the packing crate is a wooden

pallet, to which the system is strapped. The walls of the crate are placed around the system,

attached to the pallet, and to each other with tension clips (Klimp fasteners) and screws.

After adding packing material, the top is clipped onto the packing crate.

4.2.1 Directions for npacking:

1. After ensuring there is no visible damage to the packaging, remove the top of the

packing crate by unfastening the Klimp fasteners that join the top to the sides.

2. heck for tip indicators on the inside and outside of the packing crate.

3. heck for any visible signs of damage besides activated tip indicators.

4. Locate and remove items that can easily be lifted out of the crate.

5. Remove the sides of the packing crate by unfastening the Klimp fasteners and

screws that join the sides to the pallet.

6. Remove packing material and any straps that anchor items to the pallet. Retain

the packing materials and crate for use in the future, to ship the equipment to

ryomech, Inc.

7. Ensure that adequate space is prepared for the equipment (see Section 6 for

installation directions) before continuing.

4.3 Inspection of eq ipment

4.3.1 Packing list

There is a packing list included with the system. heck that all parts listed on the packing

list are included in the crates. Then, check for any signs of damage to the parts.

4.3.2 Cold head

1. See weights and dimensions of the cold head in Section 5 to ensure components

can be moved safely.

2. Inspect the box that contains the cold head for any signs of physical damage.

3. Remove the screws holding the cover to the box and lift the cover.

4. arefully remove packing material to expose the cold head. Retain the packing

material for use in the future, to ship the equipment to ryomech, Inc.

5. Use all equipped eyebolts for lifting the cold head. Follow local regulations while

lifting or hoisting the cold head.

6. arefully remove the cold head from the box and place on a clean, secure work

surface.

Inspection and Unpacking

4-2

7. Inspect the cold head for any damage, in particular, small dents on the tubes and

any scratches, especially on the mounting surface of the base plate.

8. Retain the cold head box and packing material to use in the future if you need to

store the cold head or ship it to ryomech, Inc.

4.3.3 Heli m flex lines

1. See weights and dimensions of the flex lines in Section 5 to ensure components

can be moved safely.

2. Inspect the helium flex lines for any signs of damage.

4.3.4 Cold head motor cord

Inspect the cord for any signs of damage.

4.3.5 Tool kit

ryomech, Inc. systems are shipped with a box of tools. The label on the box lists the

contents included inside.

4.3.6 Heli m compressor package

1. The helium compressor package should not be tipped more than 5 at any time.

See weights and dimensions of the helium compressor package in Section 5 to

ensure components can be moved safely.

2. Inspect the helium compressor package for any signs of damage such as dents,

scratches or any signs of oil leaks.

3. heck the pressure readings on both pressure gauges. If either gauge reads 5 psig

(0.34 bar) lower than the static pressure listed in Section 5, contact ryomech, Inc.

4.4 Ret rning a system to Cryomech, Inc.

1. ontact ryomech, Inc. for a Return of Material Authorization (RMA) number, and

for additional detailed instructions on how to properly return system components.

2. Repackage the system:

IMPORTANT

Use the original crate and packaging materials to minimize the likelihood of damage during

shipping.

a) Using the original packing material, rewrap the cold head and place in the original

cold head box.

b) Place the helium compressor package on the pallet on top of sufficient vibration

dampening material to prevent the wheels from touching the pallet.

c) Strap the helium compressor package to the pallet, making certain that there is

sufficient insulating material between the helium compressor package and the

straps so the straps will not scrape any paint off the helium compressor package.

d) Use protective wrap to secure the helium flex lines and place them in the container.

3. Include shipping labels on the crate showing which side is up and make clear that

the shipment is fragile.

4. ryomech, Inc. highly recommends using “tip and tell” indicators. These indicators

are helpful in determining whether your package was handled properly. Replace

used “tip and tell” indicators with new ones (three per crate).

5. When the system has been completely packaged, contact ryomech, Inc. for

shipping instructions.

05.PT410 – CPA289C(B)

Section 5

Specifications

This manual suits for next models

1

Table of contents

Other Cryomech Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Hydrotech

Hydrotech HSF2200 Series Operation & maintenance manual

Lippert Components

Lippert Components Power Gear 82-L0356 owner's manual

U-Line

U-Line H-1843 instructions

SCHUNK

SCHUNK VERO-S NSE3 138 Assembly and operating manual

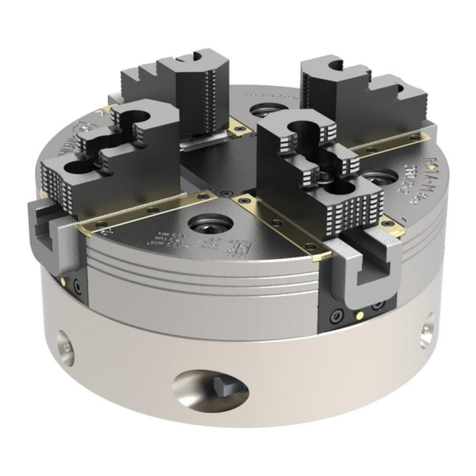

SAMCHULLY

SAMCHULLY PHD instruction manual

SCHUNK

SCHUNK ROTA-M flex 2+2 Series Assembly and operating manual