5

2012-10

For safe operation

ETAbox Operation

For safe operation

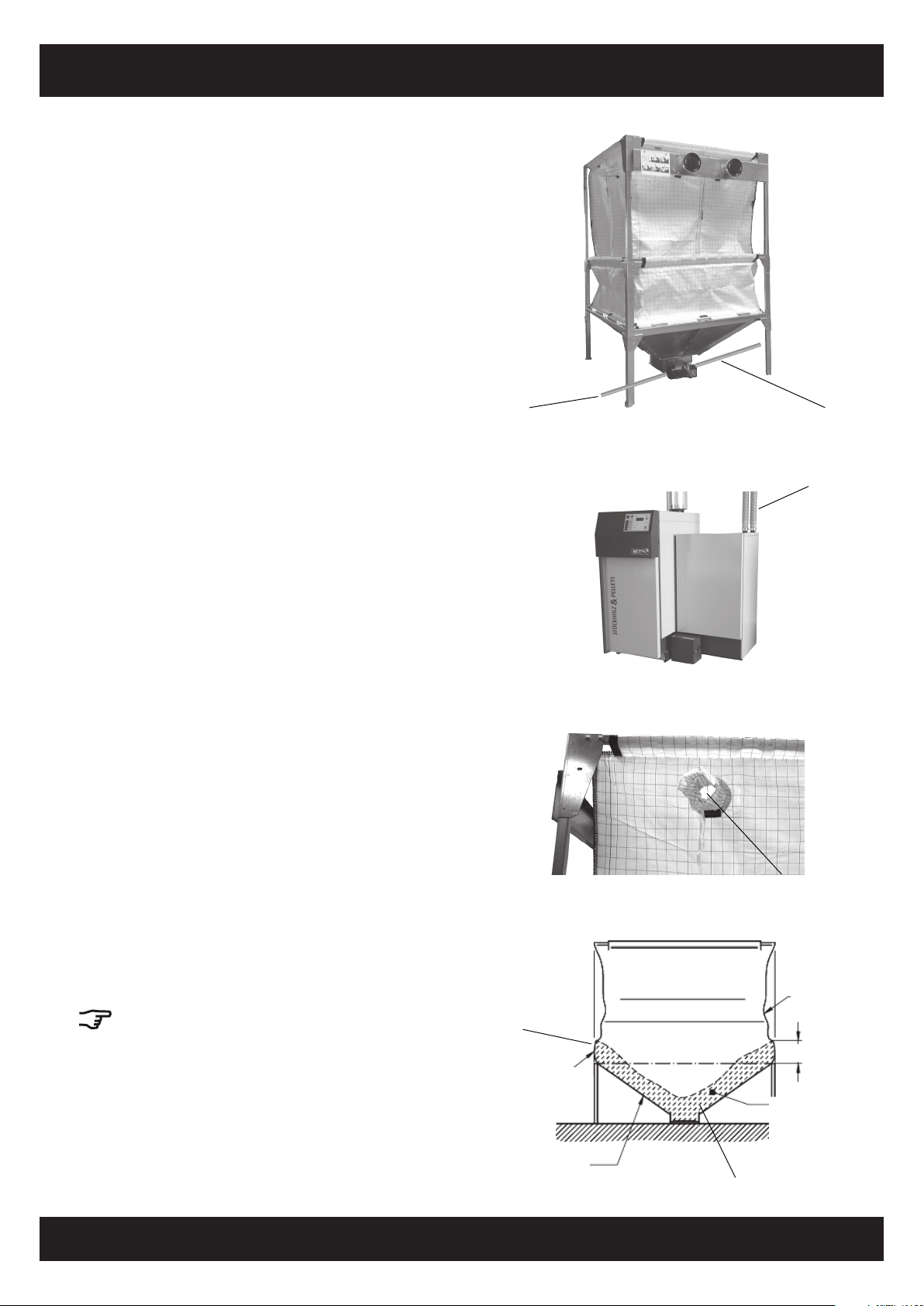

Ventilation

The store must be ventilated through windows,

doors or air inlets and outlets as carbon monoxide

can form where pellets are stored.

Container wall across from couplings must be 200

mm from wall

to cushion the impact of the pellet stream during

injection and avoid damage to the pellets while

filling.

ETAbox may not be in contact with damp walls

Rooms with the dampness of a normal cellar do

not pose a problem, but the ETAbox may not come

into contact with damp walls.

No sharp or pointed objects

No sharp or pointed objects that could damage the

fabric are permitted in the vicinity of the ETAbox.

No UV light

Do not allow the ETAbox to be exposed to UV light

under any circumstances. No fluorescent lamps

in the room. Cover cellar windows with dark

foil or use UV protective film if they must remain

transparent.

Outdoor set-up possible with rain shelter

In the event of outdoor set-up, the ETAbox must be

protected against weathering (rain, wind, exposure

to sunlight and UV light). A watertight roof and

side walls are an absolute requirement. The pellet

hoses must also be protected against UV light and

sunlight.

Official permits and fire safety

Official permits (building authorities, trade autho-

rities) may be needed for operation.

Local building and fire safety regulations must be

observed. Consult your local authorities.

Switch off heating system during maintenance

Switch off the main switch on the boiler before

any work on the ETAbox and the pellet conveyor

system. If the ETAbox has a power supply separate

from that of the boiler, switch that power supply

off as well. If there is no switch, isolate the ETAbox

from the mains using the trip switch (RCD).

Switch off 3 hours before filling?

If no ETA boiler is being used, switch off the

heating system at least 3 hours before filling the

ETAbox to avoid back-burning.

If the ETAbox is being used with an ETA pellet

boiler, the heating system may remain switched

on. An ETA boiler is equipped with a draught fan

and ventilated rotary valve to protect against

back-burning.

Use back air hose while filling

The ETAbox must be filled at underpressure. While

pellets are being blown in, air must be simultane-

ously removed through a second hose, ensuring

nearly dust-free fill-up.

Open door or window while filling

To minimize the amount of dust escaping from

the container during filling, more air should be

extracted than is blown in. To ensure the necessary

air supply for the room, open windows and/or

doors while filling.

Do not operate conveyor screw without vacuum

motor

Without removal of pellets, the conveyor screw

will jam. If the boiler's vacuum motor fails, the

conveyor screw will draw more current and the

fuel conveying system will be switched off before

the screw can jam.

Setting for current monitoring

To protect against jamming, current monitoring

must be correctly set on the boiler, for the ETAbox

2.1 A nominal current and 3.0 A maximum

current.

Prevent unauthorized access

Lock the room where the ETAbox is installed in

order to keep out children and pets.