Lippert Components Power Gear 82-L0356 User manual

Hydraulic Motorized

Leveling (82-L0356)

OWNER'S MANUAL

Rev: 09.05.19 Page 2 CCD-0002565

TABLE OF CONTENTS

Introduction 2

Safety 3

Operation 4

Operating Conditions 4

Selecting A Site 4

Leveling Procedures 4

Jack Retract Procedures 5

Troubleshooting 6

Automatic Safety Shuto Feature 6

Drive Away Protection System 6

Troubleshooting Table 6

Maintenance 6

Fluid Recommendation 6

Preventative Maintenance 7

Introduction

NOTE: Information for this document was based on Power Gear document 82-L0356, with a revision date

of June 2003.

The Power Gear manual leveling system on the coach is designed and built to provide years of trouble-free

leveling and stabilizing operation.

The Power Gear manual leveling system consists of several components, including spring return jacks rated

at a lifting capacity appropriate for the coach. Each jack has a large diameter shoe for maximum surface area

on soft surfaces. Each jack is powered from a central 12V DC motor/pump assembly, which also includes the

hydraulic oil reservoir tank, control valve manifold and solenoid valves. The system is controlled by the solid

state control panel assembly, which is located by the driver.

Additional information about this product can be obtained from lci1.com/support or by downloading

the free myLCI app. The app is available on iTunes® for iPhone® and iPad® and also on Google Play™ for

Android™ users.

iTunes®, iPhone®, and iPad® are registered trademarks of Apple Inc. Google Play™ and Android™ are

trademarks of Google Inc.

For information on the assembly or individual components of this product, please visit:

https://support.lci1.com/hydraulic-leveling-support-motorized-leveling.

NOTE: Images used in this document are for reference only when assembling, installing and/or operating

this product. Actual appearance of provided and/or purchased parts and assemblies may differ.

Rev: 09.05.19 Page 3 CCD-0002565

Safety

Please read and study this manual before operating the leveling system.

This manual provides general instructions. Many variables can change the circumstances of the instructions,

e.g., the degree of difficulty, operation and ability of the individual performing the instructions. This

manual cannot begin to plot out instructions for every possibility, but provides the general instructions,

as necessary, for effectively interfacing with the device, product or system. Failure to correctly follow the

provided instructions may result in death, serious personal injury, severe product and/or property damage,

including voiding of the LCI limited warranty.

The use of the Lippert Components, Inc. Hydraulic Motorized Leveling to support the coach for any reason

other than which it is intended is prohibited by the Lippert Limited Warranty. The system is designed as

a leveling system only and should not be used for any reason to provide service under the coach, e.g.

changing tires or servicing the leveling system.

Lippert Components, Inc. recommends that a trained professional be employed to change the tires on the

coach. Any attempts to change tires or perform other service while the coach is supported by the leveling

system could result in damage to the coach and/or cause serious injury or death.

The “WARNING” symbol above is a sign that a procedure has a safety risk involved and may cause

death or serious personal injury if not performed safely and within the parameters set forth in

this manual.

Failure to follow instructions provided in this manual may result in death, serious personal injury

and/or severe product and/or property damage, including voiding of the component warranty.

The coach MUST be supported per manufacturer's recommendations before working underneath.

Failure to do so may result in death or serious personal injury, severe product and/or property

damage, including voiding of the LCI limited warranty.

The “CAUTION” symbol above is a sign that a safety risk is involved and may cause personal injury

and/or product or property damage if not safely adhered to and within the parameters set forth

in this manual.

Always wear eye protection when performing service, maintenance or installation procedures.

Other safety equipment to consider would be hearing protection, gloves and possibly a full face

shield, depending on the nature of the task.

Moving parts can pinch, crush or cut. Keep clear and use caution.

Rev: 09.05.19 Page 4 CCD-0002565

Operation

Operating Conditions

The leveling system should only be operated under the following conditions:

1. The coach is parked on a reasonably level surface.

2. The coach parking brake is engaged.

3. The coach transmission is in park (or neutral for a diesel coach).

4. The coach engine is running.

5. Make sure all people, pets and property are clear of the coach while the leveling system is in operation

Selecting A Site

When the coach is parked on an excessive slope, the leveling requirements may exceed the jack lift stroke

capability. The coach must be moved to a more level surface before the leveling jacks are deployed.

Leveling Procedures

1. Press the ON/OFF button (Fig. 1A) to turn on the system. The ON/OFF light will illuminate.

2. Check to see if the ENGAGE PARK BRAKE light (Fig. 1I) is not flashing. If light is flashing, engage the

parking brake.

3. Check to see if the ON/OFF (Fig. 1A) and WAIT (Fig. 1H) lights are flashing. If both lights are flashing,

put the coach into park or neutral for a diesel engine.

4. Push the appropriate jack buttons to level the coach (Fig. 1C, Fig. 1D, Fig. 1E and Fig. 1F).

5. Push the ON/OFF button to turn off the system.

Do not use the leveling jacks to support the coach while under the coach or changing tires. The

hydraulic leveling system is designed only as a leveling system. It is recommended that a trained

professional change tires. Attempts to change tires while supporting the coach with the hydraulic

system could result in death or serious personal injury, severe product and/or property damage.

Keep people and pets clear of the coach prior to turning on the leveling system and while the

system is in use.

Check that potential jack contact locations are clear of obstructions or depressions before

operation. Park coach on reasonably solid surface or jacks may sink into the ground. On extremely

soft surfaces, use load distribution pads under each jack.

Never lift wheels o the ground when leveling the coach. Lifting the wheels o the ground during

leveling may result in death or serious personal injury, severe product and/or property damage.

Rev: 09.05.19 Page 5 CCD-0002565

Fig. 1

Callout Description

AON/OFF - Turns leveling system on and off. The LED will be on if the system is operational.

If flashing with the WAIT LED, it signals the coach transmission must be placed in park.

B RETRACT JACKS - Retracts all jacks.

C FRONT JACKS - Extends both front jacks.

D LEFT REAR JACK - Extends left rear jack.

E REAR JACKS - Extends both rear jacks.

F RIGHT REAR JACK - Extends right rear jack.

G JACKS DOWN - Illuminates when jacks are down.

HWAIT - If flashing by itself, the control is busy and jacks cannot be operated. After 5 to 30

seconds, the WAIT LED will go off again and operation can be resumed.

I ENGAGE PARK BRAKE - Flashes if parking brake is not engaged.

A

B

C

D

E

F

H

G

I

Jack Retract Procedures

NOTE: Coach ignition must be on.

1. Press the ON/OFF (Fig. 1A) button to turn on the system. The ON/OFF and JACKS DOWN (Fig. 1G) lights

will be illuminated.

2. Push and release the RETRACT ALL JACKS button (Fig. 1B).

NOTE: All the jacks will retract and automatically return to the full retract position. As the jacks approach

the full retract position the WAIT light (Fig. 1H) will flash for about 30 seconds. This is to ensure the

jacks retract all the way. During this 30-second period, the control panel cannot be turned off. When

the jacks return to the full retract position, the JACKS DOWN light (Fig. 1G) will turn off.

3. When the JACKS DOWN light (Fig. 1G) turns off, push the ON/OFF button (Fig. 1A) on the touchpad to

turn off the system.

4. Visually inspect underneath the coach to verify all of the jacks are fully retracted.

5. The coach is ready for travel.

Table of contents

Other Lippert Components Industrial Equipment manuals

Lippert Components

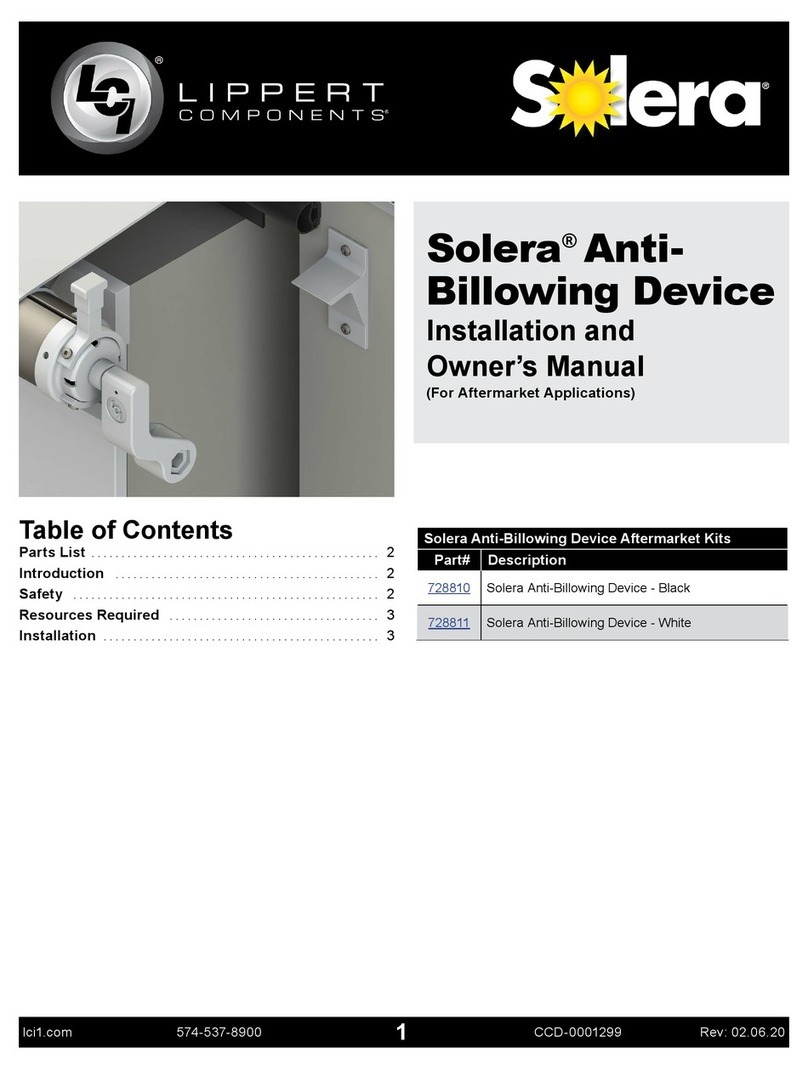

Lippert Components Solera 728810 Installation instructions

Lippert Components

Lippert Components Level Up LCD Travel Trailer User manual

Lippert Components

Lippert Components Equa-Flex Triple Axle Installation instructions

Lippert Components

Lippert Components Happijac User manual

Lippert Components

Lippert Components SOLIDSTEP 2.0 User manual