AFM GS 75 User manual

GS 75 & 100

Radial Heat Shrink Tunnel

User Guide

GS 75 & 100

Radial Heat Shrink Tunnel

Model

User Guide

Revised 11/8/2018

P/N 4510008 Rev A

Copyright and Trademarks

Copyright ©2018 American Film and Manufacturing.

All rights reserved. All trademarks and brand names

are the property of their respective owners.

AFM

7041 Boone Avenue North

Brooklyn Park, MN 55428

Phone: (714) 974-9008; Fax (763) 795-8867

www.afmsleeves.com

Contents:

Safety.........................................................................................................6

WARNINGS

................................................................................................................. 7

Safety Notes:................................................................................................................. 8

Introduction ...............................................................................................9

General System Description ......................................................................................... 9

System Components..................................................................................................... 9

System Specifications ................................................................................................. 10

Options........................................................................................................................ 11

Installation and Setup.............................................................................12

General Recommendations ........................................................................................ 12

Unpacking and Placement .......................................................................................... 13

Check for shipping damage.................................................................................................13

Mounting ..................................................................................................................... 14

Electrical Connection .................................................................................................. 16

Sleever Placement ..............................................................................................................17

Control Cabinet Overview ........................................................................................... 18

Operation .................................................................................................19

Power Up .................................................................................................................... 19

Shutdown .................................................................................................................... 22

Part Replacement....................................................................................23

Electrical box parts..............................................................................................................23

Replacing Sheaf Heaters ....................................................................................................24

Replacing Fan Assembly.....................................................................................................30

Troubleshooting ..................................................................................................................32

Maintenance ............................................................................................33

Mounting Hardware and Connections .................................................................................33

Cleaning External................................................................................................................33

Schematics..............................................................................................34

Wiring Diagram ...................................................................................................................34

Exploded Diagram...............................................................................................................35

Exploded Diagram Fan........................................................................................................36

Inside of Power Box ............................................................................................................37

Parts List .................................................................................................38

Recommended Replacement Parts.....................................................................................39

Component Dimensions ..........................................................................40

Warranty Statement ................................................................................41

Warranty Verification ...........................................................................................................42

Limited Warranty .................................................................................................................43

Customer Support ...................................................................................44

6Safety

Safety

The GS Heat Shrink Tunnel is easy to install, operate and maintain. Please follow these

safety steps to insure smooth and safe operation:

All operators should study this manual thoroughly before operating the machine.

•Always follow GMP (Good Manufacturing Practices) when operating this machinery.

•The machine is heavy. While unpacking and setting up the unit, always take care to

use proper lifting techniques. Avoid over-reaching and leaning over while handling the

machine and accessories. Use more than one person to lift and move the tunnel.

•Wear safety shoes and work gloves when moving the machine.

•Beware of uneven spots on the factory floor when moving the unit.

•Make sure the electrical power source is properly wired and grounded. The power

source should comply with all safety regulations and codes applicable to the

installation location.

•Before attempting any service or repair, make sure that the power is turned off and

power cable is disconnected from the power source.

•Before connecting the air supply, make sure that the pressure gauge is closed and

that the pressure indicator reads zero.

•The equipment generates heat, so make sure the area is properly ventilated.

•Do not place any body parts or tools into a running machine!

•Turn off and unplug the machine while servicing and performing maintenance

procedures.

CAUTION

TEAM LIFT

7 Safety

WARNINGS

Every effort has been taken to insure safety while operating this machine, however,

there are certain risks remaining. Do not allow this machine to be

operated before

informing all personnel of the attached warnings:

•

Do not tamper with electrical wiring. Use only licensed electricians for

maintenance. Always disconnect electrical power before attempting

maintenance to any electrical or moving parts.

•

To prevent injury to machinery and/or personnel, DO NOT INCREASE

SETTINGS ON EITHER ELECTRICAL OR MECHANICAL OVERLOAD

SAFETY DEVICES.

•

KEEP HANDS AWAY FROM MOVING CONVEYORS AND ASSEMBLIES.

Conveyor belts that have become worn or frayed can be hazardous and should

be replaced promptly.

•

NEVER OPERATE THIS OR ANY MOVING EQUIPMENT WITHOUT ALL

COVERS

AND GUARDS IN PLACE. The internal mechanism of most

packaging machinery contains numerous

shear, pinch, and in-running nip

points, many of which are capable of causing severe injury and permanent

disfiguration.

•

To minimize potential for personal injury, always be sure that machine

operators and others working on machinery are properly

trained in the

correct usage of the equipment and properly instructed

regarding the safety

procedures for operation.

•

DO NOT MAKE ANY MODIFICATIONS TO EITHER THE ELECTRICAL

CIRCUITRY OR THE MECHANICAL ASSEMBLIES OF THIS

MACHINERY. Such modifications may

introduce hazards that would not

otherwise be associated with this machinery. American Film & Machinery will not

be responsible for any consequence resulting from such unauthorized

modification.

•

The use of certain types of plastic films in sealing and/or shrinking equipment

may result in the

release of HAZARDOUS FUMES due to the degradation of

the film at high temperatures. Before using

any plastic film in this equipment,

the manufacturer or supplier of the film should be contacted for specific

information concerning the potential release of hazardous fumes. ADEQUATE

VENTILATION

SHOULD BE PROVIDED AT ALL TIMES.

•

Keep combustible and explosive materials away from this equipment. The

equipment may be a source of ignition.

8Safety

•

Do not use with pressurized containers. Exposure to high temperatures can

cause pressurized containers to burst, and could cause injury to operators

and other personnel nearby.

•

Take care when clearing product jams inside the heat tunnel. Do not use

anything that could potentially puncture a container. Use the hand crank to

raise the tunnel from the conveyor before clearing product from inside the

heat tunnel. If containers remain in the heat chamber, turn off power and

allow the temperature to drop below 100

F

before clearing. Temperature

inside the tunnel can easily cause burns.

Safety Notes:

Electrical Hazard-do not open cover. No user-serviceable parts inside.

Ensure that unit is properly grounded.

Fumes may be harmful to the environment.

Do not tamper with electrical equipment.

Keep the equipment dry and indoors.

Some fumes may be a health hazard if exposed to for too long.

Insure the area has adequate ventilation.

Introduction 9

Introduction

General System Description

The intended use of AFM heat shrink tunnels, is for the shrinking of heat shrink

film (labels, tamper bands, multi-pack), on containers over which they have been

applied. Containers with labels are to enter the tunnel, on a conveyor, for a

duration of between a minimum of 3 seconds, to a maximum of 6 seconds. This

dwell time of 3-6 seconds is necessary to achieve proper coverage without

overheating the containers. Operators must make sure that every container that

enters the AFM tunnel exits within this maximum time of 6 seconds.

AFM shrink tunnels are intended for industrial use only.

System Components

•Stainless Steel Brackets with Height Control

•IR Heat Tunnel

•Operator Controls

2207

Tunnel

External

Cover

Controls

Blower Motor

Wiring Enclosure

Mounting

Rod

10 Introduction

System Specifications

Power: A.C. 1-Phase, 220 Volt, 50/60Hz

Machine Dimensions : 75-185mm W (7.28”) x 565mm L (22.24”) x 530mm H (20.86”)

100-185mm W (7.28”) x 565mm L (22.24”) x 530mm H (20.86”)

Tunnel Dimensions : 75mm W (2.95”) x 565mm L (22.24”) x 95mm H (3.75”)

100mm W (3.94”) x 565mm L (22.24”) x 95mm H (5.90”)

Temperature: 250C

Heater: 2.5KW x 2

Introduction 11

Options

Conveyor Conveyor is supplied by customer. For conveyor

options, please consider an AFM conveyor system.

Accumulator Accumulator is supplied by customer. For Accumulator

options, please consider an Eastey Accumulator

system.

Feed Screw Feed Screw is supplied by customer. For Feed Screw

options, please call the AFM Customer Service

department for details.

Unwind Unwind is supplied by customer. For Unwind options,

please call the AFM Customer Service department for

details

Sleever Sleever is supplied by customer. For Sleever options,

please consider one of our many quality AFM Sleever

systems.

Brushdown Brushdown unit is supplied by customer. For

Brushdown options, please call the AFM Customer

Service department for details.

Tamp down Tamp down unit is supplied by customer. For Tamp

down options, please call the AFM Customer Service

department for details.

External Controls Call the AFM Customer Service department for details.

For any Sales-related questions, please call us at 763-398-1743.

We would be happy to assist in any way possible!

12 Installation and Setup

Installation and Setup

General Recommendations

Material Handling

The most critical item for consistently achieving superior quality shrink applicating is

material handling. This is an area controlled by the customer and the installer. It is

imperative that adequate conveyor product guides be provided, and that they are installed

and maintained properly. Incorrect or inconsistent product handling will cause quality

problems, maintenance issues, and could lead to product damage. The customer is

responsible for maintaining proper material handling equipment.

Work Area

The GS may require cleaning from time-to-time due to environmental contaminants.

Maintenance Access

When planning the installation, allow for easy access to the tunnel so that cleanup can

be done conveniently.

Important! Turn off power and allow tunnel to cool before doing any

cleaning/maintenance.

Installation and Setup 13

Unpacking and Placement

Open the box and lift out the tunnel assembly by its cage. BE CAREFUL-UNIT IS HEAVY.

Attention! Use only the supplied mounting hardware to attach the

tunnel to the Bracket assembly. Using hardware other

than that supplied by AFM can result in damage to the

assembly.

Check for shipping damage

14 Installation and Setup

Mounting

After unpacking the Bracket Assembly, assemble it per the illustration, if required.

Find a spot to mount to Conveyor approximately 1” down from top of Conveyor.

Measure the distance to the Sleever (if used), and drill though one side of Conveyor.

Mount the Bracket to the Conveyor using the enclosed ¼-20 hex bolts. Tighten bolts and

nuts until snug. Fender washers may be used.

2208

Mount this angle to

Conveyor

approximately. 1”

lower than top of

Conveyor,

depending on

container size

Mounting

slots

2209

Installation and Setup 15

After Bracket has been mounted and tightened, use two (2) people to lift and attach the

Tunnel to the Bracket. Aim the two Mounting Rods on the Tunnel Assembly toward the

Mounting Collars on the Bracket. Slide Tunnel into the Collars.

Center the Tunnel parallel to the Conveyor and tighten the collars with an Allen wrench.

Collars (2)

2210

Rods (2)

2212

16 Installation and Setup

Electrical Connection

There is a power cord connected to the GS Tunnel. Plug this into a clean 220Volt AC

power source. DO NOT HOT-PLUG. Ensure that Tunnel has all switches turned to

“OFF” before plugging into any power source.

Place the correct male AC plug onto the end of the power wire. Check the connections,

and plug the male cord end into AC power.

2213

Power

Installation and Setup 17

Sleever Placement

Line up the Sleever to the existing Tunnel (if applicable). Insure that all controls on the

unit are easily accessible. Hook up the ventilation equipment, if required (It is a good

idea to have the exhaust ports vented outside of the building).

If not using a Sleever, make sure that the operator has enough room to move and is not

in danger of getting caught in moving mechanisms. Ensure availability of a trip cord or

other safety shutoff mechanisms.

2217

Sleever

2218

18 Operation

Control Cabinet Overview

Important! The control cabinet is not a watertight enclosure- do not

splash the cabinet with liquid.

The front face of the Control Cabinet has the following:

1. Power

2. “HEATER” switch

3. “FAN” switch

4. Left-and-Right Temperature Controls.

2224

Temperature

Controls

Heat

Power

Fan

Operation 19

Operation

Power Up

When all the components have been properly mounted and connected, the GS tunnel is

ready to power up and begin production.

Tip! Before powering up, double-check your installation. Make

a quick inspection to ensure all the components have been

securely mounted and all data and power cables are

properly seated and connected.

To power up the GS Tunnel, plug into power outlet. Push the power switch located on the

front of the controller to the ON (I) position.

Power Switch

2219

Airflow Control

20 Operation

Turn on FAN Switch

Turn on HEATER Switch

2224

Fan

Switch

Heater Switch

This manual suits for next models

1

Table of contents

Other AFM Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Loepfe

Loepfe YARNMASTER 1N1 instruction manual

Eaton

Eaton Airflex WCBD Series Installation, operation and maintenance manual

Stober

Stober K38-03 operating manual

bon

bon E-30 instruction manual

Georg Fischer

Georg Fischer MULTI/JOINT 3000 Plus user manual

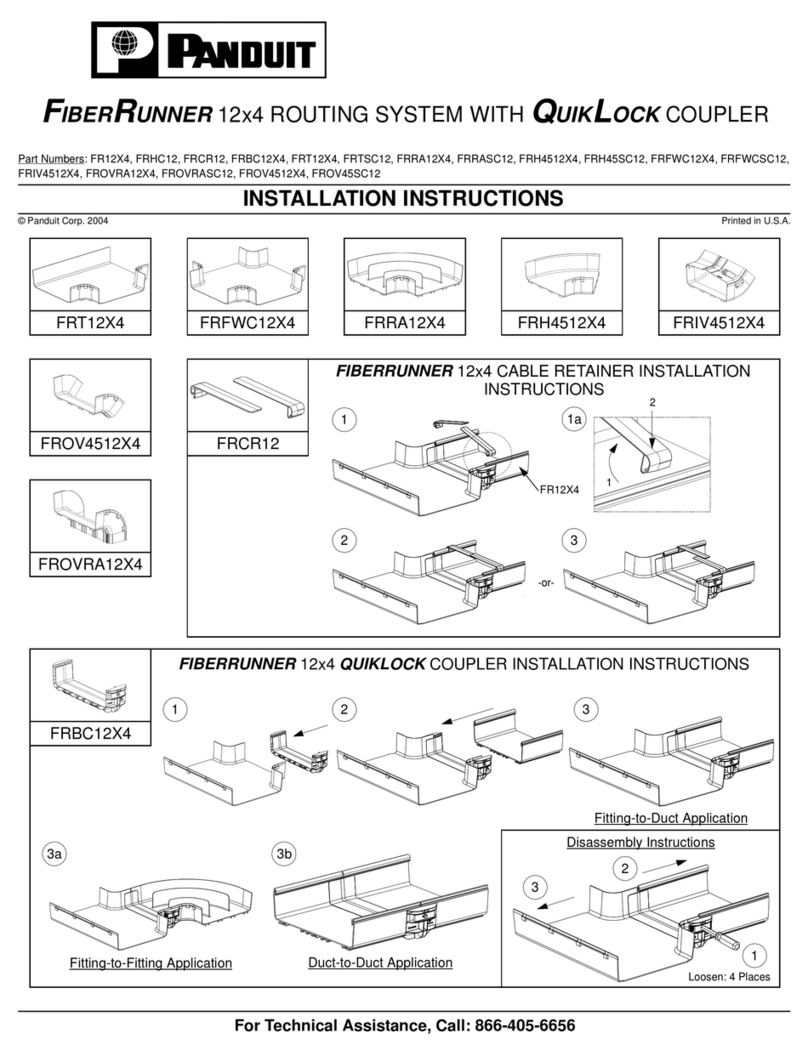

Panduit

Panduit FiberRunner QuikLock FR12X4 installation instructions