Crystal Clean 2734 User manual

USER GUIDE

MODEL

2734

Ultrasonic Cleaning System

www.crystal-clean.com

Heritage-Crystal Clean LLC · 2000 Center Drive Suite East C300 Hoffman Estates, IL · 60192

877-938-7948 · contact@crystal-clean.com

2

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

INDEX

GENERAL VIEW..............................................................................................................................................................................3

SAFETY WARNINGS.......................................................................................................................................................................3

SET UP.............................................................................................................................................................................................4

BEFORE START UP........................................................................................................................................................................4

CONTROL PANEL AND FUNCTIONS ............................................................................................................................................5

START UP AND CLEANING PROCEDURES .................................................................................................................................6

WATERFLOW SYSTEM ......................................................................................................................................................9

AIR PRESSURE REGULATOR ............................................................................................................................................9

ADJUSTING THE SPEED OF THE PNEUMATIC CYLINDER .............................................................................................9

BAG FILTER TTF1 AND TTF2 .............................................................................................................................................9

MAINTENANCE.............................................................................................................................................................................10

POSSIBLE DISFUNCTIONS .........................................................................................................................................................11

TECHNICAL SPECIFICATIONS....................................................................................................................................................12

ELECTRICAL AND PNEUMATICS SCHEMES.............................................................................................................................13

RISK ASSESMENT........................................................................................................................................................................18

3

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

GENERAL VIEW

You have just purchased a CRYSTAL CLEAN ultrasonic

cleaning system. We appreciate the confidence shown by

purchasing a CRYSTAL CLEAN equipment.

Each CRYSTAL CLEAN machine has been carefully tested

and has passed our quality controls. However, the lifetime of

the machine depends largely on you, so we recommend you

to consider the information contained in this manual at the

start up and use of your ultrasound equipment. Give special

attention to the instructions that we detail below.

FORESEEN USE

Motor clean range equipment is specially designed for

cleaning engines, engine parts and accessories.

This equipment is designed to cover the needs not only

of car repair shops but also for marine and cogeneration

engines, aeronautic industry and grinding and

remanufacturing engine workshops.

Crystal Clean products achieve a high cleaning quality,

effectively removing any kind of dust: greases, oil or

carbon deposits. Since cleaning is carried out by

immersion, the ultrasonic cleaning achieves a high quality

result in every hard-to-reach areas.

SAFETY WARNINGS

1. Use protective equipment against thermal, chemical

and splashes risk (gloves, goggles, protective clothing,

mask) according safety data sheet of the chemical

product. Gloves and clothes must be thermal

and chemical protective and glasses completely cover

both eyes and the mask should cover both the mouth

and the nostrils.

2. Use safety boots to prevent injury from possible falls of

parts to be cleaned.

3. Perform cleaning and maintenance while the machine

is off.

4. Do not transport the machine with water in the tank.

5. Do not work with the machine if damages are detected.

6. Do not introduce in the machine parts larger than

those indicated as useful measures in the technical

specications.

7. When draining the tank for cleaning, wait until the

temperature lowers befor pouring cold water for

cleaning.

8. Keep the lid open while tank is being drained.

9. Use the machine only for ultrasonic cleaning of parts. It

is not designed for any other applications.

10. Introduce softly the load and center on platform against

rear side (if equipment has platform).

11. Do not place the machine against direct sunlight,

nor next to a heat source. In such cases the internal

temperature of the machine increases and may result

in a malfunction.

12. This machine is designed for indoor use only. In case

of outdoor use, the equipment can be damaged or an

electrical failure may occur.

13. Do not use power wires or plugs in bad condition.

14. Make sure you have a good grounding and appropriate

supply voltage according to the specications of

the ultrasound machine. The electrical installation

where the machine is connected must comply with

current regulations and must be installed by qualied

technicians.

15. Do not touch or unplug the power wire with wet hands.

16. Do not access to the control registers. These areas are

indicated on the machine with this symbol.

In case of disassemble any guard ensure to cut the

electrical and pneumatic supplies before. All the guards

must be assembled again before start the machine

again. Do not work with the guards removed.

17. Disconnect the equipment from the electric network or

in case of a long inactivity

18. During the test and maintenance of transducers,

generator y or any other electric element, it is required

to check that the main switch (which is blocked with a

lock) is on the OFF position or “switched off”, and also

it’s advisable to unplug the machine. This way, we

make sure that the main energy source is switched off.

Otherwise, there is a risk of electric shock.

19. When handling the machine without taking the measures

mentioned in the previous point, the corresponding

personal protective equipment against electrical

hazards must be used.

20. Do not drop any heavy bodies in the tank or press

buttons with sharp objects. It can cause serious damage

to the equipment or electric shock.

21. The transducers are located at the bottom of the tank.

It is very important to avoid hitting the transducers box

and avoid placing parts directly on it.

22. ALWAYS OPEN THE LID before activating the rise of

the platform.

23. Do not spill liquids such as water, acid or alkaline liquids

near the control panel.

24. If a acid cleaning liquid is used the machine may be

damaged, depending of how corrosive the used product

is. Therefore consult us about the product you will

use if it does not belong to those recommended by

CRYSTAL CLEAN®. In any case, it is always necessary

to consider the measures of use and safety of the

product itself, especially those relating to the volatility

and the volume of product to use.

25. The equipment is designed to work with neutral and

basic products (pH above 6,5).

26. Do not use products with a pH lower tan 6,5. In case

of doing so, the machine could be seriously damaged.

27. Do not use ammable products.

28. The working area must be properly ventilated and

workers must be aware of the posible hazards of the

cleaning products that are used. It’s necessary to read

4

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

the safety data sheets before using the product.

Trapping hazard with the machines:

1. Work clothes should t the body and the operator must

not wear any clothing or hanging rings, bracelets,

chains... which may be caught with the moving parts of

the machine causing an injury to the operator.

2. Do not modify nor remove the coverings and protections

of the machine.

3. Do not activate the plataform while there is any body part

inside the tank.

Risk of electrical accidents:

1. Check that the machine, equipments and instalations

are in good condition

2. Stick to the guidelines given in the manuals regarding

disconnection and maintenance of electrical appliances.

3. Do not use equipment when wet, when the operator

is wet or in the presence of water or moisture. The

electrical equipment will be deposited in dry places and

should never get wet.

4. If a fault or malfunction is detected, the operator must call

the Maintenance Service (phone number is indicated in

last page) and he should never try to repair it by himself.

5. In case of malfunction, the operator must inform the rest

of his coworkers, stop using the equipments and prevent

the rest of the workers from using them.

6. Equipment and individual protections used must be

certied.

If you have to work in electrical installations, please remember:

1. Cut off all voltage sources.

2. Block breaking devices (switches, circuit breakers, etc.).

3. Verify the voltage absence.

4. Ground and short-circuit all possible voltage sources.

5. Demarcate and mark out the working area.

This list of safety warnings do not include all possible

misuse of the machine, but it describes the most

predictable. The person responsible for the safety at

the machine owner company must be commissioned to

assess, monitor and control the use of this machine.

SET UP

1. The machine is supplied packed. Check that the

packaging is in good condition before removing it. When

removing the packaging, do not use sharp elements such

as scissors or cutters to avoid marking the machine.

2. Use a forklift to move the machine and make sure that

you use the red points of support when using a pallet and

the blue ones when lifting the machine directly.

3. Distance the unit 300mm / 11.81”. or more from the

walls or from other machines, since the semiconductors

integrated into the generator make it temperature

sensitive. The high temperature may cause malfunction.

4. Connect to a power source of appropriate voltage as

indicated on the equipment. Always ensure the machine

is properly grounded. See equipment specifications.

5. The cleaning tank must be placed horizontally on a firm

surface and leveled.

6. The equipment must be placed in a dry place.

7. The air connection must maintain a constant pressure of

6 bars. (Recommended operating pressure).

8. The size of the water connection for filling and emptying

the tank will depend on the model (See technical

specifications). If there are security overflows, they

must remain open.

BEFORE START UP

Personnel in charge of handling and operating the machine

must have training in handling it and its inherent risks. This

machine carries risks due to chemical substances, electrical

elements and tires.

IMPORTANT: READ THE MANUAL

BEFORE DOING ANY TASK WITH THE

MACHINE.

1. Connect to a suitable electrical outlet (IMPORTANT:

See equipment specifications and check the type

label on the machine).

2. Ensure that the drain valve is closed.

3. Do not operate the ultrasonic equipment without

water. When the machine is started without fluid the

transducers, the heating element and other components

get damaged immediately.

Ensure the tank is full before operating the

equipment.

4. Fill the main tank to its maximum water level. In model

with WFS up to the top of the separator connecting the

main tank with the auxillary tank (see image). Fill the

auxiliar tank by overflowing over the separator.

5

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

Setting up and initial operations must only be carried

out by CRYSTAL CLEAN personnel. At the time of

installation, a representative of CRYSTAL CLEAN will

conduct a demonstration and give all the explanations

deemed appropriate.

Installation and commissioning carried out by

unauthorized personnel can cause damage to both

operators and the machine.

THE USE AND MISMANAGEMENT

The machine is designed for the operator to work at the front,

except for maintenance works where you can access the

machine where necessary.

When the cleaning is done,the pieces will be at an elevated

temperature, it is necessary to use thermal protection gloves

for handling.

Do not put into the machine parts with a higher volume than

30% of the total tank volume.

Do not insert parts whose measures and/or weight are greater

than described in the specications.

You should not work without adequate water level.

To drain the machine it is necessary to wait until the cleaning

liquid has decreased in temperature in order to avoid thermal

contact damage.

Insert the parts to be cleaned in the tank free of ammable

liquids.

IMPORTANT: Always exceed the minimum level

marked. If not so, transducers and heating elements

may get damaged.

5. WFS fill the auxiliary tank through the main tank

(overflowing over the separator).

6. Turn on ultrasounds.

7. Turn on heating element (recommended temperature:

68ºC / 155ºF to 74ºC / 165ºF). Be careful with the hot

parts of the machine, specifically the valves located on

the left side, the cleaning liquid and the parts cleaned

when removed from the liquid.

8. Before cleaning any part, and every time you change the

water of the tank, it is necessary to DEGAS the water.

For this we must let ultrasounds work for 2 to 3 hours,

depending on water hardness. We will know when

the water is degassed when it stops leaving out small

bubbles (oxygen molecules).

When the diluted product is added to the tank, an abrupt

change in water cavitation can be appreciated for about

two minutes. Then the bath is ready to work. Whenever

we add water by accumulated losses when parts are

taken out or by evaporation, it is important to add the

product in the same proportion.

The percentage of the product to be mixed with

the water will depend on the type of product (see

technical data sheet of the product purchased).

9. The ultrasonic unit comes with built-in programming.

However, it can be changed.

10. Do not place parts, cleaning baskets, or cups directly on

the bottom of the tank (on top of transducer box). This

is a common cause of defects in vibration, and also

shortens the life of the transducer.

11. Immerse the parts to be cleaned in the cleaning tank

gently, taking special care not to hit the base or other

components. These incidents can damage the parts or

shorten the life of the transducer.

12. The bath will be effective for longer if we carry out oil

extractions and water filterings. There is no provisions

for water and product exchange as it depends on the

quantity of cleaning performed and the degree of

contamination of parts washing time.

13. Performing extractions of oil and filter the water bath

will last longer. As with changing the bath, there is not a

stipulated periodicity of the filterings and oil extractions

because it depends on the parts to be washed and dirt.

This frequency should be assessed by the staff in

charge of the equipment.

14. When the platform is down, the cover must be closed

before proceeding to the cleaning process.

15. When the cleaning is finished, let the piece drain to

avoid risks of dripping. Make sure it does not drip before

removing from the platform.

6

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

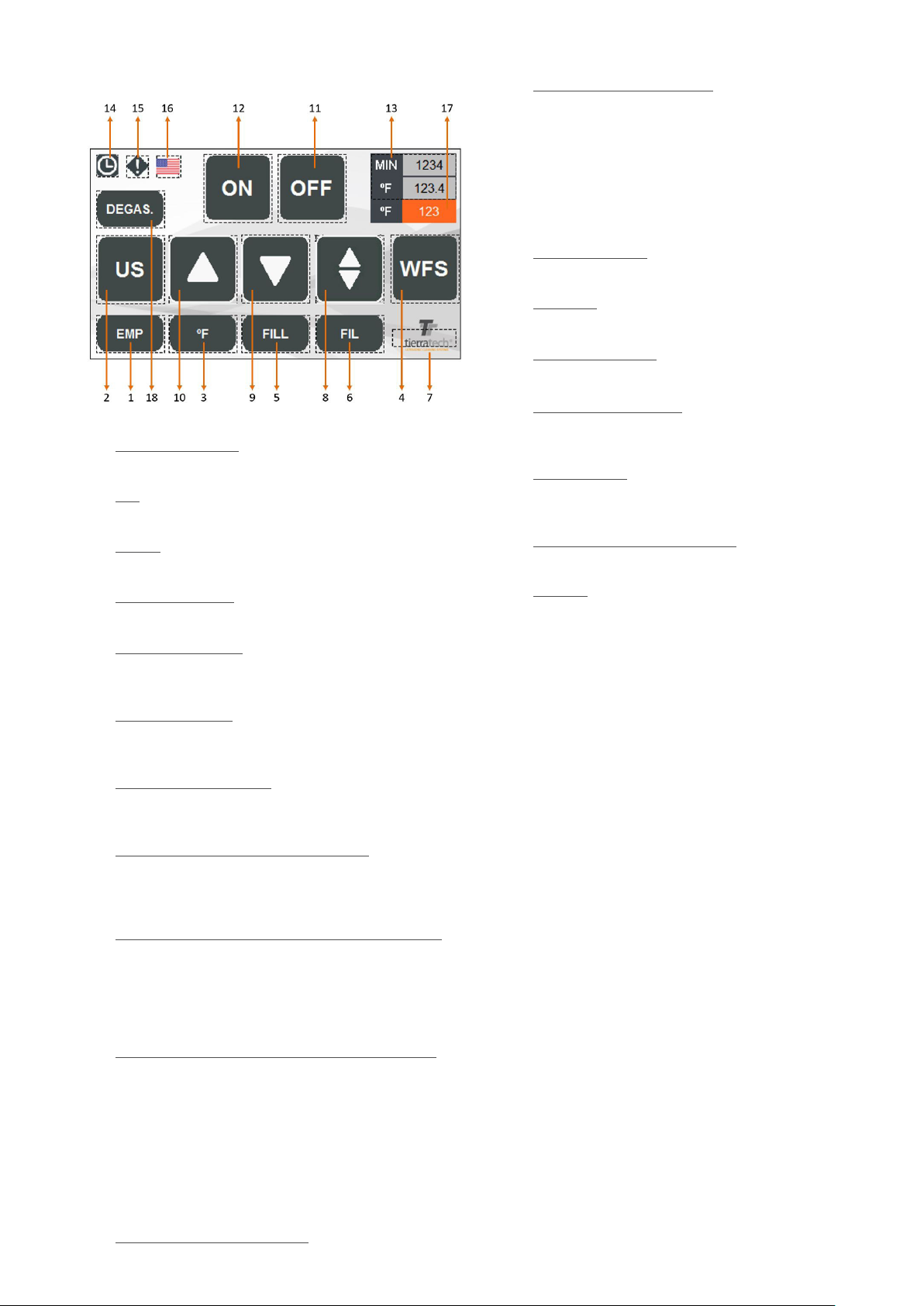

CONTROL PANEL AND FUNCTIONS

1. EMP (if installed): On/Off drain tank function. If this

function is On, the button is highlighted in white.

2. US: On/Off ultrasound function.

If this function is On, the button is highlighted in white.

3. ºC / ºF: On/Off heating function. If this function is On, the

button is highlighted in white.

4. WFS (if installed): On/Off WFS function. If this function

is On, the button is highlighted in white.

5. FILL (if installed): Enables or disables lling tank

function.If this function is On, the button is highlighted

in white.

6. FIL (if installed): Enables or disables tank ltering

function.If this function is On, the button is highlighted

in white.

7. SETTING UP SCREEN:Private access to set up the

machine programming . This option is only available for

the manufacturer.

8. MOVEMENT FUNCTION (if installed): Activates or

deactivates an oscillating movement of the platform

during the cleaning process. If this function is On, the

button is highlighted in white.

9. PNEUMATIC LOWERING PLATFORM FUNCTION (if

installed): Lowers platform for pieces immersion. If this

function is On, the button is highlighted in white.

Movement is activated pressing simultaneously both

buttons “dead man”. If there is only one button you

should press simultaneously the one on the screen.

10. PNEUMATIC LIFTING PLATFORM FUNCTION (if

installed): Raises the platform for loading and unloading

of parts. If this function is On, the button is highlighted

in white.

The movement is accomplished exactly the same way

than the lowering platform.

Any movement (8,9 and 10) that we select it will disable

any other which is ON. Also, if we press an activated

button, we will disable it immediately.

11. AUTOMATIC CYCLE “OFF”: When automatic cycle

is ON this button turns in red. Allows to disable the

12. AUTOMATIC CYCLE “ON”: Automatic cycle activated

(this button turns in green). Once the automatic cycle is

ON all the manual functions will be off. Automatic cycle

connects and disconnects all the consecutive functions.

The timer and the working temperature for each function

will set up in each recipe.

If the platform is installed , it will make a first down

movement automatically, afterwards it will start to make

a continuous movement automatically.

13. MIN FUNCTION: Time left for automatic cycle

(

countdown).

ºC / ºF : Current tank temperature. Pressing on this

button we enter in the recipe screen for automatic cycle.

14. PROGRAMMING: This function allows you to set up a

weekly program.

15. HISTORICAL ALERTS: This button allows you to check

the alarms or warnings . The button will blink and turns in

blue, if there are alarms.

16. LANGUAGES: It allows to change the language on the

screen (If you change to USA it will change to degrees

Fahrenheit).

17. TEMPERATURE SET VALUED: It shows you the target

temperature and pressing on it you can modify.

18. DEGAS: Activates or deactivates ultrasound operating

mode for degassing water (additionally it is required to

activate the US function, button 2). If this option is

active, the border is highlighted in white.

7

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

•RECIPE NUMBER: Set up the recipe number which

you would like to modify. It can be realize until ve

recipe.

•AUT. MIN: Time (minutes) for automatic cycle.

•ºC / ºF : Working temperature.

•WFS SEG: Time (seconds) during the WFS pump is

working.

•FILT MIN:Time (seconds) during the FILTER pump

is working.

•MOVEMENT: Selecting “1”, you will activate the

movement (in platform) on automatic cycle. If “0” is

selected the movement will be disable.

Once a recipe is modied the changes will be released

below. To upload a recipe to the machine you should

select a recipe and press the button HMI>PLC.

To return to main screen press on right below arrow

button.

3. If it´s required, you are allowed to set up a weekly

programming. You must be press the function (14) on

the main screen.

On this screen, it shows a temperature program on a

weekly schedule. To start up this function you should

introduce a “START TIME” ( press ENTER to conrm)

and minutes ( press ENTER to conrm) and active the

weekday button. After, you have to introduce the hours

and minutes in “FINAL TIME” to stop the program.

Once the programming days are selected the buttons

turns in green and you should press the PROGRAM

ON function to release. This function will be disabled if

we selected PROGRAM OFF.

This function will always work with the previous xed

temperature. To set up our cleaning program we press

on the number which is showed the temperature. On

this screen appears a numeric board and you should

press the desired temperature for working. Conrm with

ENTER ( It is not allowed to fix the temperature higher

than 90ºC / 194ºF).

4. The rst program must be to DEGAS the water, applying

ultrasound long enough to stop small bubbles emerge.

The process will last at least 3 hours (it depends on water

hardness). The water must be degassed whenever the

whole bath is changed.

WHEN RUNNING ULTRASOUND, KEEP

TRANSDUCER BOXES UNDER REQUIRED

LIQUID LEVELS. IMPORTANT FAILURE

MAY RESULT IN THE EQUIPMENT IF YOU

DO NOT FOLLOW THESE INSTRUCTIONS.

IMPORTANT:

If, for any reason, the date and time are reseted (because

the touch screen battery is damaged, because the

machine takes a long time off, etc.) you need to follow

the protocol below:

1. Click on the main screen ,option (14) and press on the

following area to set up the date and time:

2. Click on arrows to move along the date and time. Press

on + (to increase number) or press on - ( to decrease

number). Click on SAVE to release the changes. If you

wish to cancel the changes or to exit of the screen, click

on QUIT.

START UP AND CLEANING PROCEDURES

Setting up and initial operations must only be carried

out by CRYSTAL CLEAN personnel. At the time of

installation, a representative of CRYSTAL CLEAN will

conduct a demonstration and give all the explanations

deemed appropriate.

Installation and commissioning carried out by

unauthorized personnel can cause damage to both

operators and the machine.

1. Turn on the switch located on the rear / on the right side

of the equipment (it depends on the model).

2. Select the function (13) to set up the information for the

recipe.

Press on white gaps to set the numeric data for the

following options

8

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

5. Add the recommended amount of cleaning product. The

dosage of the product generally varies between 3% and

5% of the equipment capacity (consult CRYSTAL CLEAN

before adding cleaning product, as it depends on the soil

to be removed and material of parts to be cleaned).

6. Once the liquid has reached the right temperature and

the product is mixed properly, proceed to immerse the

parts.

Press the function (12) and it will activate the automatic

cycle with the recipe which has been uploaded before

in PLC. However, if it requires a manual mode it will able

and disable the different manual functions.

7. During the cleaning process we can activate the

movement function (if installed)(8). This function will

start immediately during all automatic cycle.

8. WFS and FILTER (If included):

• WFS

The WFS system cannot be used when the auxiliary tank

is empty.

The pump has 3 speeds. The fastest one is selected

by default. After a cycle of cleaning, the pump will run

automatically during one minute and it is important to

maintain the security level of the uid for the pump not

to break. In case of manual activation start the cleaning

cycle immediately and before of taking out the pieces

from the tank.

• FILTER

In this function, it activates the lter pump following

the WFS pump. In the manual option it should start

immediately after de WFS function

9. Automatic filling system (5) (if included).

This system allows the machine to maintain a constant

water level in the tank.

Connect a water supply hose to the fill-in solenoid valve.

Once connected, open the fluid flow. A level sensor will

automatically maintain a constant fluid level in the tank.

10. Drained system (if included): The draining will be

always manually when it requires empty the tank for

maintenance task or replacing the bath. Once this

function is ON it will drain the tank until the

minimum security level. To drain the left liquid you must

be press the button in 10 seconds pulses.

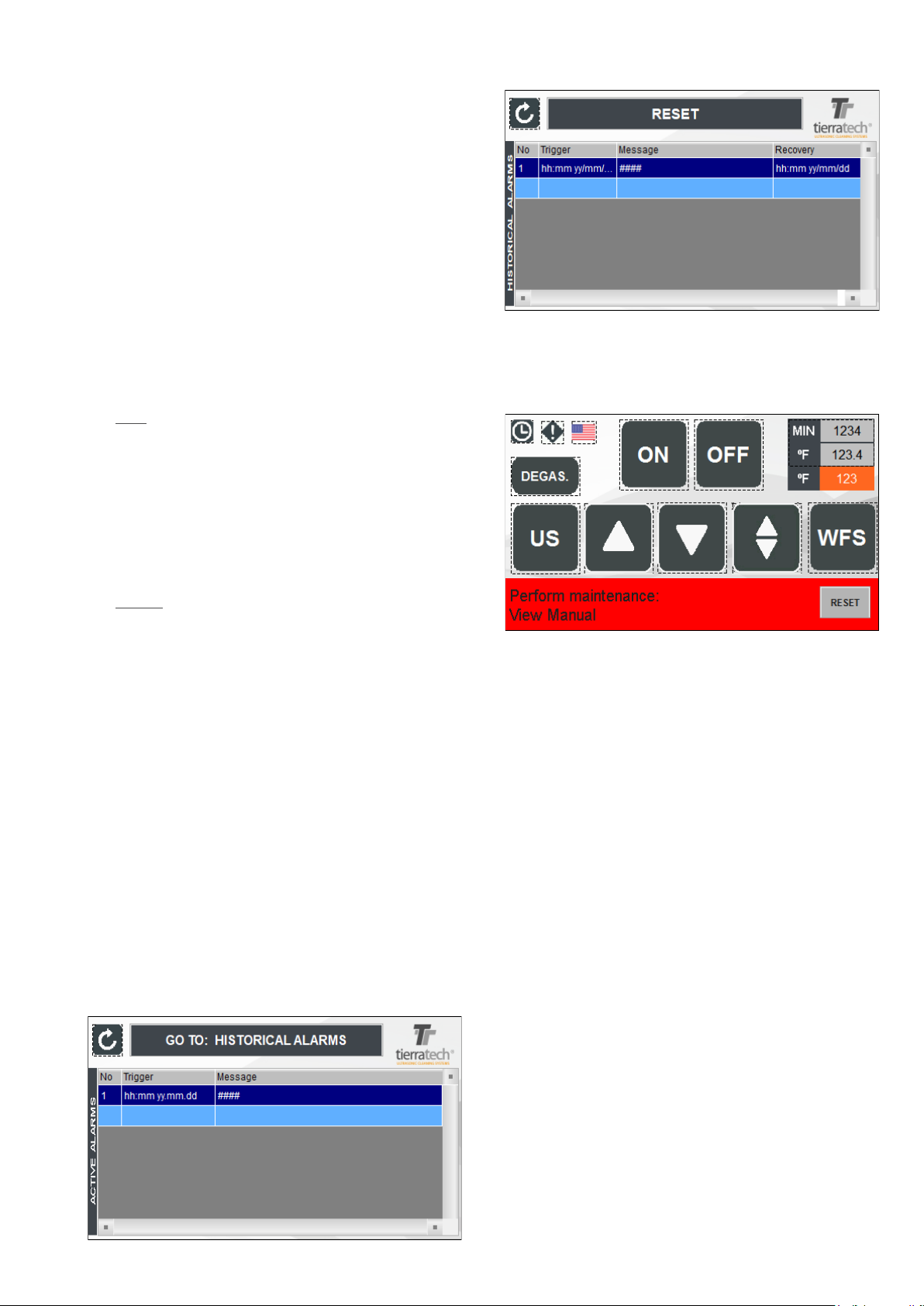

11. Alarms Screen (15): When the icon is blinking it means

there are warnings. If we pressed on , it will show

historical alarms of the machine.

If you press on “HISTORICAL ALARMS” will show a

RESET button which remove all the showed alarms.

ATTENTION: WHEN THE WORKING HOURS ESTIMATED

HAVE BEEN ACCOMPLISHED , IT WILL APPEAR A MES-

SAGE ON THE MAIN SCREEN WARNING ABOUT THE

MAINTENANCE TASK TO FOLLOW. SEE MAINTENANCE

SECTION.

9

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

By adjusting the regulators it is possible to change the

movement speed of the plataform.

This zone indicates the maximum weight that can be raised

with this machine.

BAG FILTER TTF1 AND TTF2

(IF INCLUDED)

Filtering process of the cleaning liquid to reduce contamination.

Regular checking and emptying of the lter bag and its

cleaning are recommended. When the lter gauge exceeds

1 bar, empty the reusable bag.

Every time the lter is opened, to return to operation it must

be purged through the valve located next to the manometer.

Orient the valve hose to the main tank or a can.

To change the lter bag, you must open the lter cover, close

the outlet (to the tank) and inlet (to the lter) valves and

drain it through the drain valve. Replace the bag and leave

everything as at the beginning and purge.

Do not drop small objects into the tank, they may reach

the pump and damage it.

Attention: do not open the lter when hot to avoid injuries.

WATERFLOW SYSTEM

(IF INCLUDED)

With this system, through the pump (described in section 8 of

the previous section), a circulation is created in the uid that

entrains all the oil and other residues that are on the surface

to an auxiliary tank.

With the valves in the open position the pump works to remo-

ve the oil from the main tank to the auxiliary tank. This is the

normal position that the machine should always have.

To extract the oil from the auxiliary tank, proceed as follows:

- Open the drain valve and install a bucket for the drainage of

the oil. This operation is most effective by applying it with low

ow rate in the injection. (This valve must always be closed

in case it is not performing this operation)

- Inject water (very slowly) through the valve located in the

lower part of the equipment (The amount of oil that comes out

will be smaller the less the injection of water into the tank).

AIR PRESSURE REGULATOR

(IF INCLUDED)

In the equipment there is the possibility of regulating the

pressure of the compressed air (see the manometer) of the

pneumatic system of the platform or any other system that

requires air.

ADJUSTING THE SPEED OF THE PNEUMATIC

CYLINDER

(IF INCLUDED)

10

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

MAINTENANCE

Maintenance of the machine should only be carried out by

CRYSTAL CLEAN personnel. If the machine requires fur-

ther cleaning or shortening service intervals, please contact

your CRYSTAL CLEAN delegation. Any incidents or break-

downs should only be repaired by a CRYSTAL CLEAN

sales and service representative.

CLEANING LIQUID

It is necessary to periodically replace the used cleaning

liquid. It may happen that particles deposited on the bottom

of the cleaning tub will clog transducers, resistance and

other components, thus causing losses in the quality and

intensity of cleaning and reduction of the life of the

transducers. This interval for water change depends on the

intensity of use of the machine, both in time and in the

degree of dirt of the parts to be cleaned.

IT IS RECOMMENDED TO CLEAN THE

TANK PERIODICALLY

ULTRASOUND EMITTERS

The surface of the emitter erodes after many years. It is

necessary to examine it with each change of water before

use. When it is seriously eroded, holes appear on the surface,

which in case of penetrating the plate will allow water to enter

the interior of the emitter and will generate a fault.

Clean periodically by taking advantage of water changes.

The inside of the tank is cleaned using a water hose.

It is necessary to use the cleaning products recommended

by CRYSTAL CLEAN , in order not to cause damage to

the parts to be cleaned or to the ultrasound equipment itself.

Each machine will use a product adapted to the specific

application that is needed. CRYSTAL CLEAN will supply

the data sheet of the products to be used.

IMPORTANT: NEVER clean them if they are at high

temperature. Allow to cool and rinse together with the

bottom of the tank. If you want to expedite the process,

empty the hot water tank while mixing with cold water

so that the temperature gradually drops. This is done to

avoid a sudden change of temperature in the emitters

(Ultrasound boxes).

GENERATORS

Clean it once a month with a compressed air gun using the

safety glasses. If the dirt that is generated at the site where

the equipment is located is extreme (eg suspension of

particles such as chip powder, paint suspension, polishing

powder in suspension, etc.). They will be cleaned more often.

DO NOT clean with organic solvents such as solvent,

alcohol, or kerosene since the paint coat of the generator

may deteriorate or even deform the plastic components of

the equipment.

Way of acting:

• Open the back of the unit. Remove the lters from the

generators (in the case of models with lters), located at the

rear. Blow with air gun (make sure no water gets out with air).

• Blow the generators.

• Mount the lters of the generators.

• Replace the rear panel that has been removed to access

the generator.

ELECTRICAL CABINET

Clean the inside of the cabinet with air gun every 1-3 months

depending on the accumulated dirt. If the work environment

is too dirty, do so at shorter intervals. Whenever the air gun is

used it is necessary to use the safety glasses.

HEATING ELEMENT

Check cleaning at each water change.

If it is covered by sludge, a fault can occur. It can be cleaned

using a water hose.

LEVEL PROBE (if included)

Check the cleaning of the level probe every water change.

Sludge or other types of dirt may be present in the probe

housing. Be sure to remove any items and clean using a

water hose.

SCREEN

Do not use with wet hands or chemical residues.

Clean with a cloth and mild soap when necessary.

Cleaning with other more aggressive chemicals can cause

irreparable damage to the screen.

PNEUMATICS (if included)

Bleed the regulator lter if necessary

Check that the air supply is free of moisture.

If moisture enters the pneumatic circuit, the solenoid valve

and cylinder can be damaged.

WATERFLOW SYSTEM (if included)

Cleaning the auxiliary tank with each change of water.

It is often impregnated with oil that in some cases is dried and

accumulated both in the bottom and in the extraction bowl.

Clean the lter inside the tank in turn. This can be unscrewed

to clean outside of the machine.

FILTERING SYSTEM (if included)

Verify the pump is operating properly taking advantage of the

water changes.

Clean the lter periodically using the drain valve.

Check that the lter bags are in good condition, not broken.

Check the gasket.

All these operations must be done at a temperature below

104 ° F.

Maintenance periods for standard cleaning:

•Cleaning liquid change: When poor or longer cleaning

is observed.

•Check surface emitter status: Each water change

•Emitters cleaning: Each water change.

•Generator cleaning: 1-3 months depending on

environmental conditions.

•Electrical cabinet cleaning: 1-3 months depending on

environmental conditions.

•Check heat resistance condition: Every change of water.

•Check level probe condition: Every change of water.

•Screen cleaning: When required.

•Purge air lter: When necessary (each case will be

different).

•Check air circuit humidity: Daily

•Auxiliary tank cleaning: Every change of water.

11

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

POSSIBLE DISFUNCTIONS

1. No power:

-Check the power cord and plug.

-Check the switch and the main supply is possible.

-Check the fuse located on the power plug.

-Replace the fuse if necessary.

2. Indicators do not work.

- Call Service.

3. Ultrasonic cavitation weak:

-Clean the base of the tank of dust and particles.

-Change the water level.

-Empty the tank and rell with clean water.

4. Touch screen (if included)

1. Touch screen does not work.

- Call Service.

2. A warning of low battery appears on the screen.

- Change the battery.

5. High temperature warning.

- In the case of the equipment exceeds 90ºC / 194ºF,

ultrasounds and the heating elements will stop. For them

to operate again, the temperature should drop at least 5.

This may happend whe the lid is not open for a long time

due to the transducer boxes generate heat that can not

dissipate.

6. Communication failure.

- Call Service.

7. Generator (if included)

1. It does not emit US.

- Check that the partial automatic of the ultrasounds is on.

- Check for voltage to the generator.

- If any of the above is correct, call Service.

8. Heating element

1. It does not heat.

- Check that the partial automatic is on.

- Check that the setpoint temperature is correct on the

display.

- Check that temperature sensor is in touch with the tank.

9. Pneumatic system (if included)

1. No aire in the system.

- Check that the external air system works.

- Check that the tap of the lter regulator is the right one for

the working pressure.

- Check that the tap is opened.

- Check the circuit for leacks.

- Check that the ow regulator is in the correct position.

10. Movement function (if included)

1. Movement function failure.

- Check that the cylinder sensors switch on the LED.

- Check that the ow regulator is in the correct position and

cot completely closed.

- Any other disfunction, call Service.

11. WFS and lter (if included)

1. No water movement is appreciated in the system.

- Check that the supply voltage reaches the pump.

- The pump is not working. Call Service.

- Check that the system is clean both at the suction area of

the auxiliary the tank, and at the intake of the main the tank.

- Check That the rotor of the pump is not blocked.

12. Transducer boxes (if included)

.

1. They don’t emit.

- Call Service.

2. They don’t clean properly.

- Call Service.

SITUATIONS AND PLACES WHERE THE MACHINE CAN

NOT BE USED.

Never use the machine outdoors or in areas with an

excessively dirty environment. In case you can not avoid

working in dirty environment, proceed to maintenance works

more frequently.

12

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

TECHNICAL SPECIFICATIONS

1. Power Supply: 230V Monophase + Neutral + Earth.

2. Capacity: 220 liters / 60 gallons

3. Tank built in AISI 304, 2mm / 0,078”. thick, Stainless-

Steel.

4. Integrated auxiliary tank for lubricants and oil separation,

with 40 liters / 10 gal. of capacity.

5. 1 ultrasonic generator with 2000Wp (4000Wp-p) total

output power. Working frecuency: 40 KHz sweep system

±2%.

6. 1 submersible emitter, 2000Wp. Working frecuency: 40

KHz. The emitter is equipped with 34 PZT (lead zirconate

titanate) transducers with an aluminum alloy body. The

emitters are made of 2.5mm / 0,098” INOX AISI 316 steel

thick, with a mirror polished finish.

7. 1 heating element 3750 W.

8. Outside panel in 1mm / 0,039” thick fingerprint-resistant

steel.

9. ½” BSP auxiliary tank drain draining ball valve, and 1”

BSP draining ball valve.

10. 20mm / 0,78” thick K-Flex Duct Net thermal-acoustic

insulation.

11. Pneumatic lifting platform for loading, oscilating

movement and unloading with a capacity of

200Kg /440Lbs. Air requirements is 85 PSI / Reads 6 bar

on Regulator

12. Insulated tank cover in Stainless-Steel.

13. Air blow-gun for drying parts.

14. Compressed air connection: Ø 8mm / Ø 0,314”

15. 4.3” Touch screen, functional and intuitive access to

ultrasound time setting, temperature and peripheric

or optional systems; and programmable with weekly

calendar. 6 outputs & 8 inputs temperature module PLC.

16. DIMENSIONS (large x wide x high):

- Internal: 760 x 520 x 590 mm / 29.92 x 20.47 x 23.23 inch.

-Useful: 730 x 465 x 350 mm / 28.74 x 18.31 x 14.96 inch.

- External: 1330 x 930 x 1590 mm / 52.36 x 36.62 x 62.60 inch.

17. Filtration system for waste and sludge (optional).

The noise emissions in this machine are less than 65dB.

There are two regulators, the upper one controls the speed

of raising the platform while the lower one controls the speed

of lowering.

The maximum weight that can be lifted with this machine is

indicated in this area.

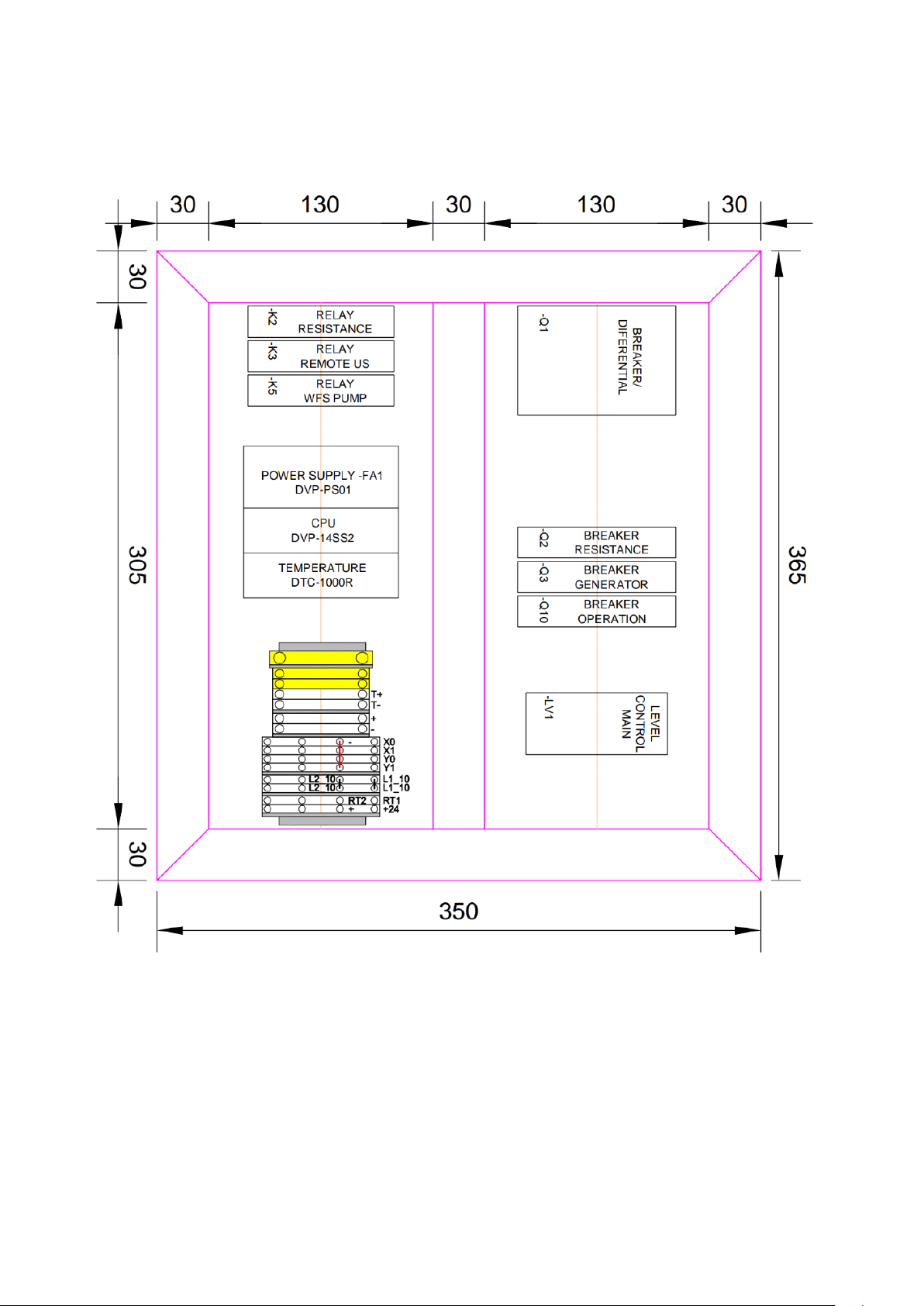

REGISTERS

At the rear of the machine: access to the heating element,

solenoid valve, temperature sensor, cylinder, cylinder

detector..

At the front of the machine: access to the pump.

On the left side of the machine: electrical cabinet.

On the rigth side of the machine: ultrasonic generator.

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS 13

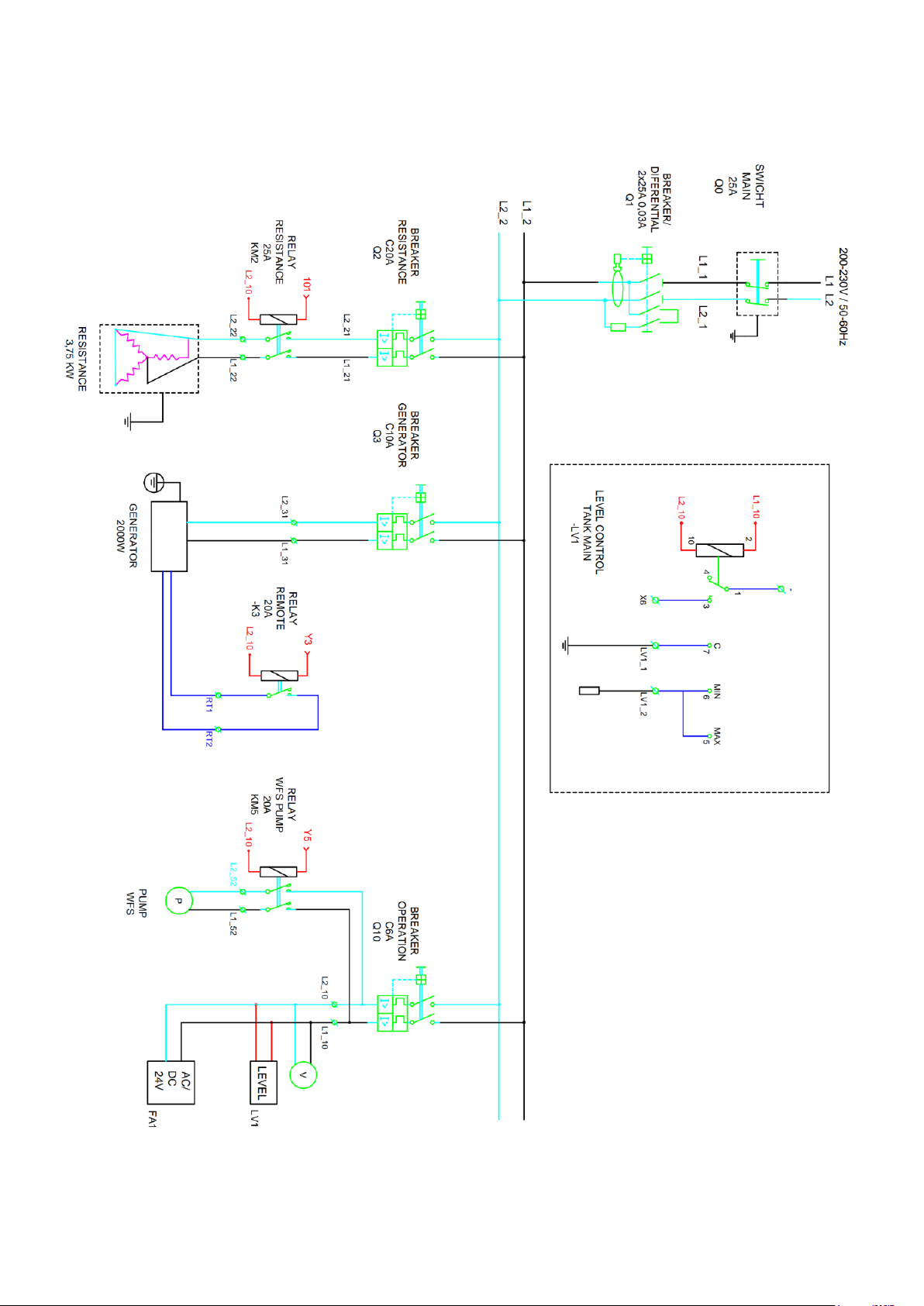

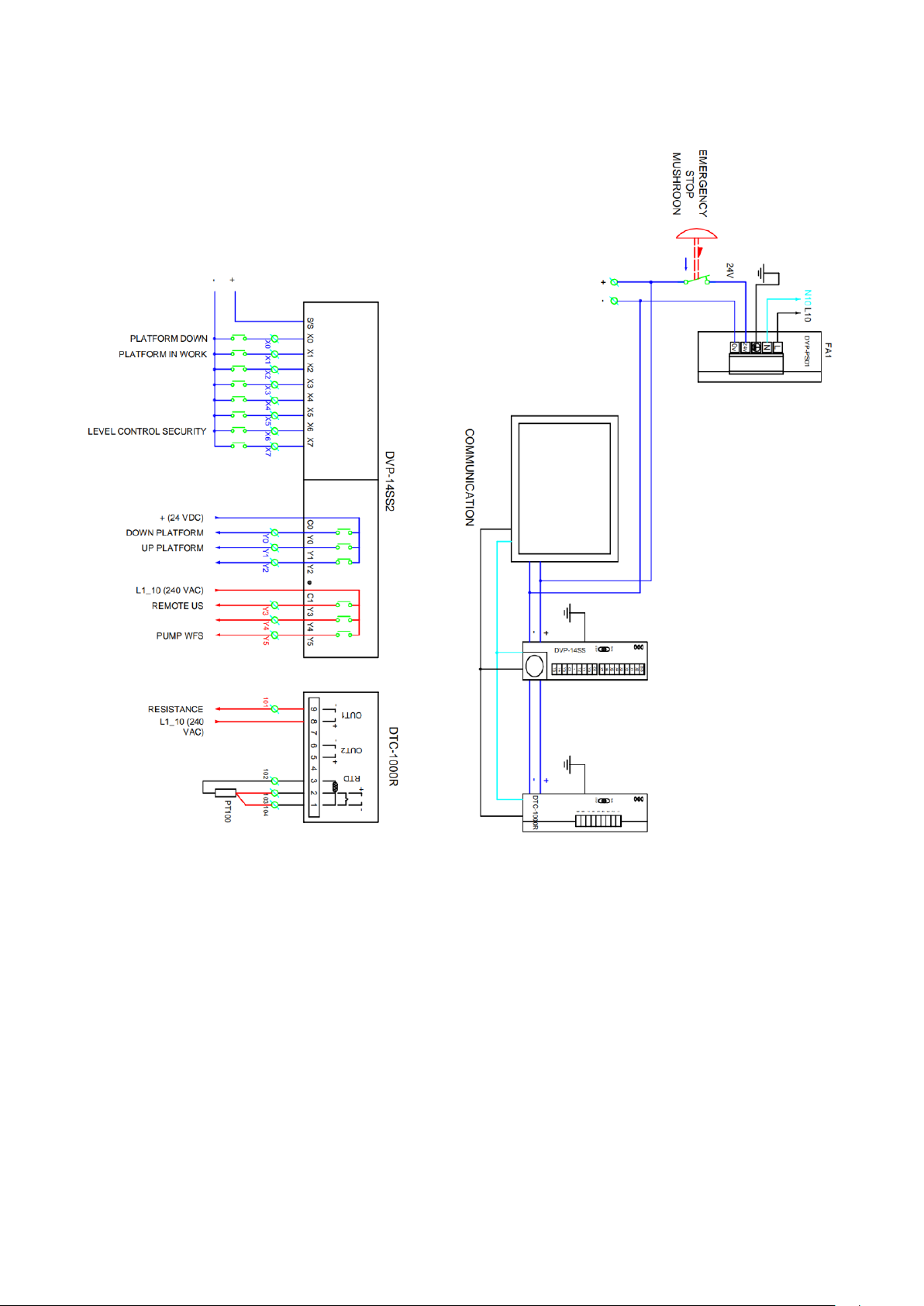

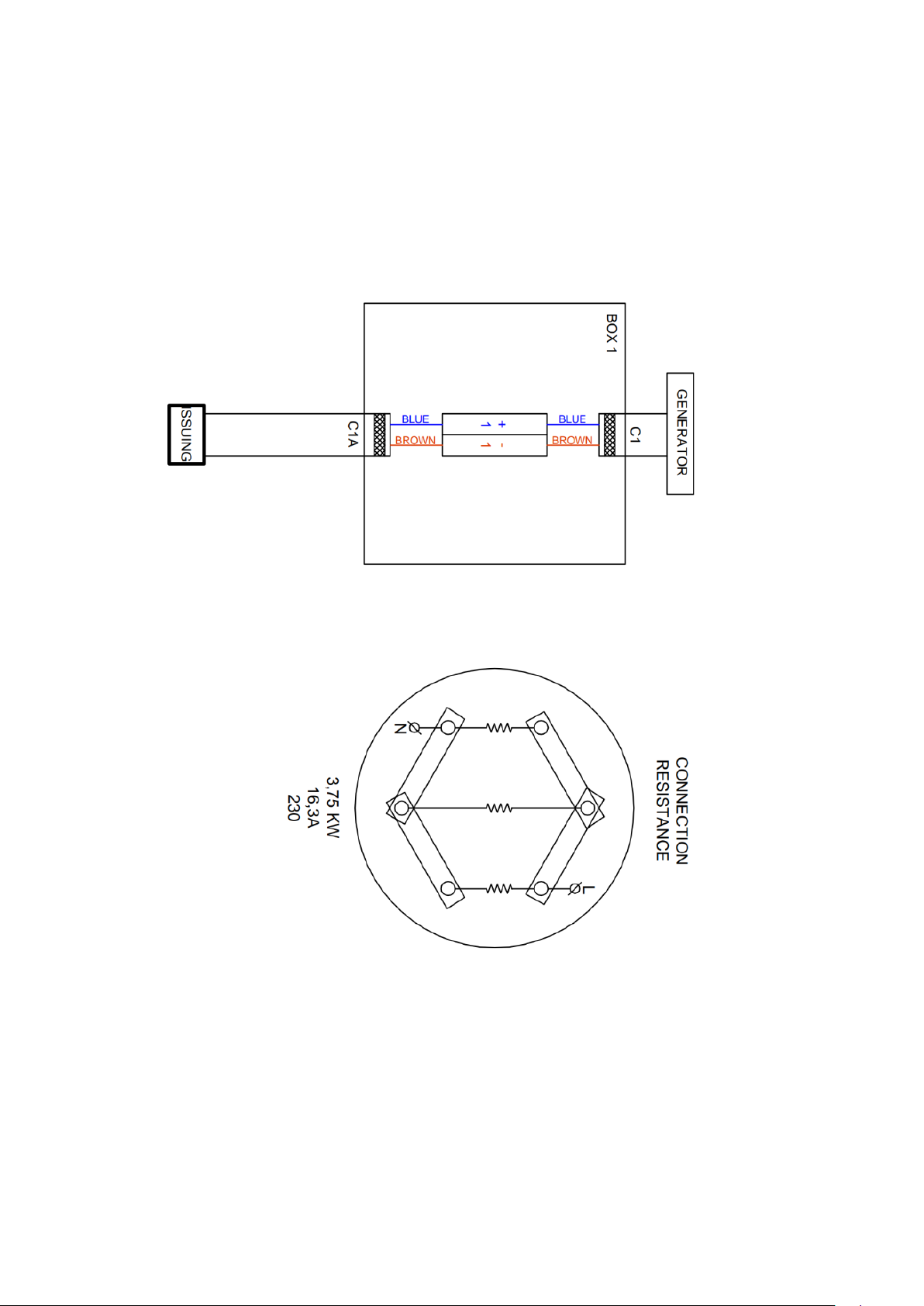

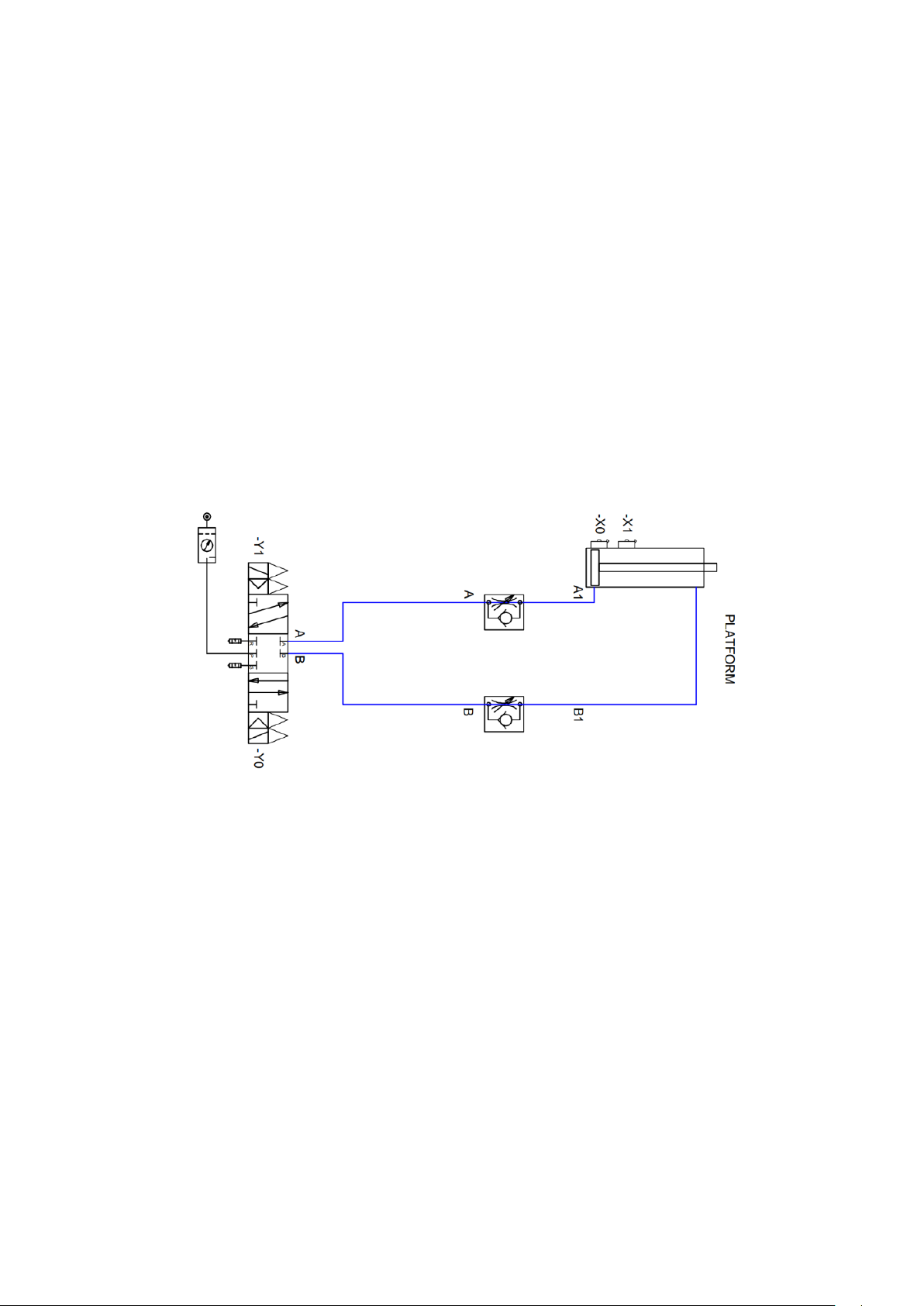

ELECTRICAL AND PNEUMATICS SCHEMES

14

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS 15

16

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS 17

18

ULTRASONIC CLEANING SYSTEMS ULTRASONIC CLEANING SYSTEMS

RISK ASSESMENT

This equipment has built-in ultrasound emitters inside the tanks. Ultrasound are acoustic waves whose frequency is

above the hearing capacity of the human ear (approximately 20,000 Hz). Ultrasonic cleaning is a method that uses ultrasounds

(generally 15-2000 kHz) and an appropriate cleaning solution. The ultrasonic frequency in this type of work is low.

The health effects of ultrasound, as included in the Technical Note of Prevention 205 are the following:

By contact: mainly manifested in the hands, in cleaning and degreasing operations. There is no such exposure, since the

transmission medium is aqueous, that is, the water acts as a shield, with which the transmission of ultrasounds is practically

non-existent.

By air: same as the previous point.

Every cleaning operation with this equipment is made with the lid closed, so there is no exposure to ultrasound.

In case of auditory discomfort it would be advisable to use adequate protection (plugs, etc.), although the noise

emission values are below the maximum admissible.

Risks that could not be eliminated are analyzed below:

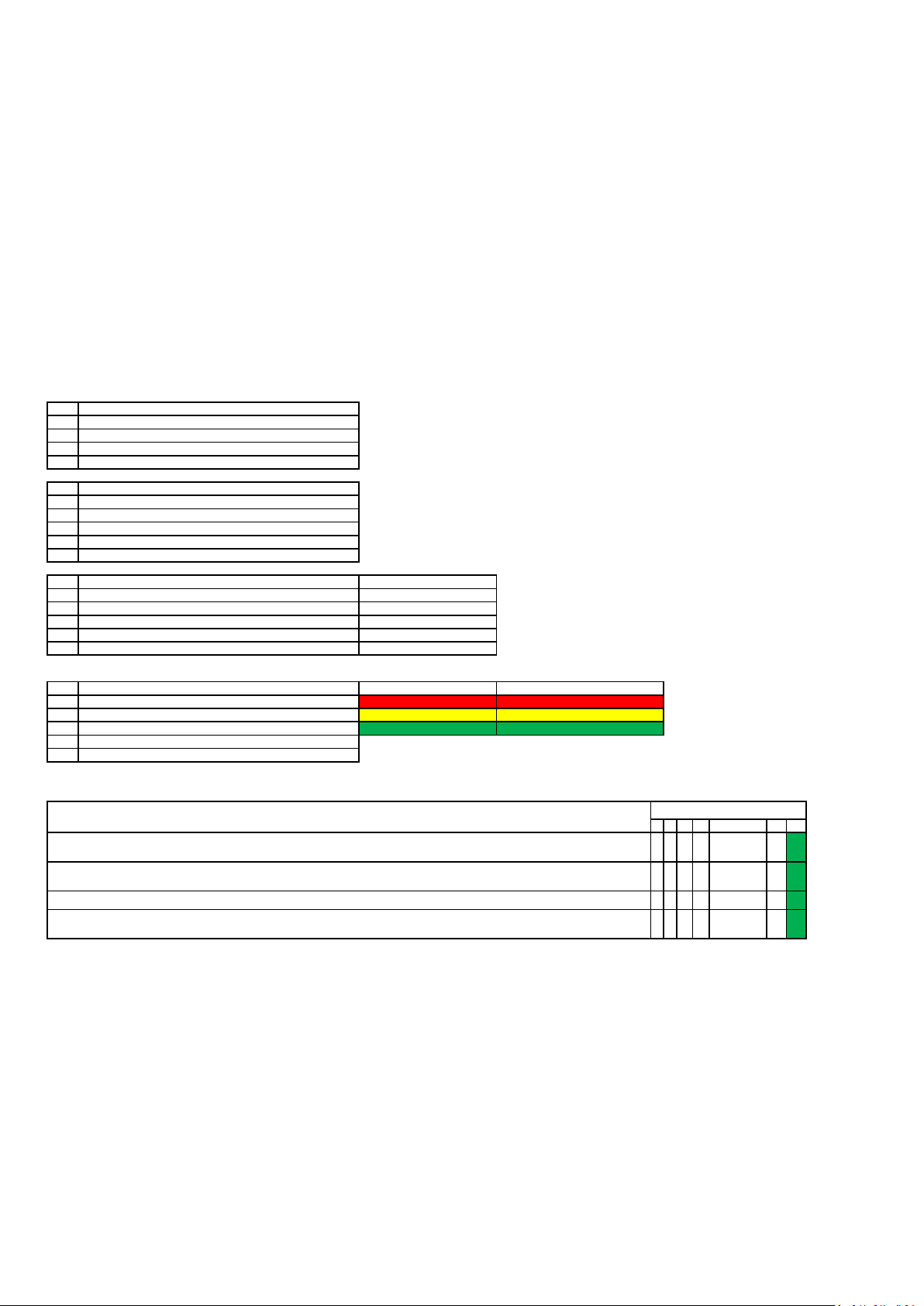

CLASS SEVERITY (S)

1Minor injuries. 3 Days maximum of sick leave. First aids.

2Reversible damages. Between 3 and 30 days of sick leave.

3Permanent damages. More than 30 days of sick leave.

4Death. Permanent disability.

CLASS FREQUENCY (Fr)

2 Never / Almost never / More than 1 year

3Rarely / More than two weeks and up to 1 year

4Occasionally / More than 1 day and up to a week

5Regularly / More than one hour and up to a day

6Often / Less than one hour

CLASS PROBABILITY (Pr) Avoidable (Av)

1Unlikely, not known or in any case Avoidable

2Unlikely to occur

3Posible Likely avoidable

4Probable

5Frequently Impossible to be avoided

NGrade (N1) Class

14-15 56-8

11-13 44-5

8-10 31-3

5-7 2

3-4 1

SFr Pr Av N=Fr+Pr+Av N1 (P)

1 2 1 1 4 1 1

1 2 1 1 4 1 1

1 2 1 1 4 1 1

1 2 1 1 4 1 1

In the user manual it is indicated that the piece, once cleaned, is left in the basket until the liquid is drained.

Risk generated by the transfer of flammable liquids to the cleaning liquid. The users manual indicates that it is necessary to make sure that the part to

be cleaned is free of flammable liquids.

Risk assesment

Risk profile (P)=S+N1-1

High risk. Correction neded

Medium risk

Low risk

RISK DESCRIPTION. CORRECTIVE ACTION

Risk of thermal contact with hot parts of the machine, the cleaned part or the cleaning liquid. The risk is duly signposted on the machine at the exit of

the cleaning liquid and the use of heat protection gloves is indicated in the users manual.

Risk of contact with chemical products (cleaning fluid). In the users manual, is indicated that it should be considered the cleaning products safety data

sheets and the use of chemical protective gloves.

Table of contents

Other Crystal Clean Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Garten Meister

Garten Meister 94 60 24 Original instructions

Good Way

Good Way VAC-EX-120-9-SS Operation and maintenance manual

Drieaz

Drieaz DriForce XL owner's manual

e.ziclean

e.ziclean Cyclosteam P310 manual

Flow Medic

Flow Medic U-sonic instruction manual

Omegasonics

Omegasonics PowerLift 4560 Operation & instruction manual