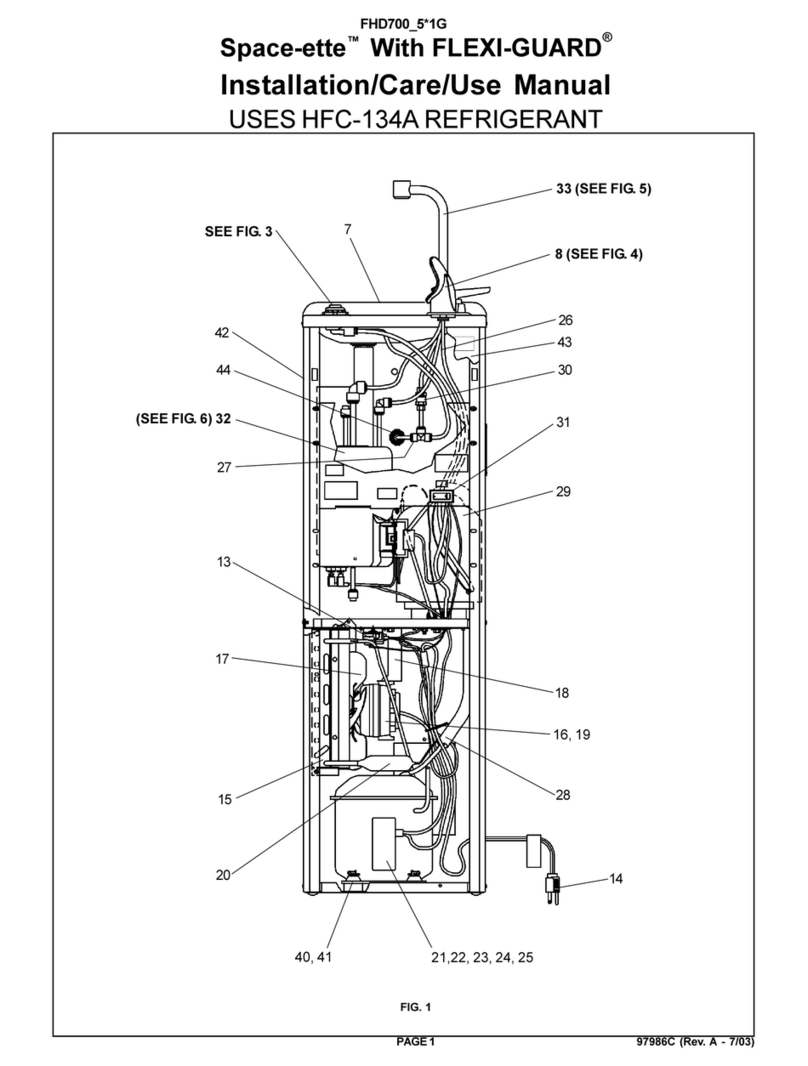

Inlet

Outlet

Connecting Tubing into Filter (Figs 3, 4, and 5)

PLASTIC TUBING

• Cut tube ends square and straight. Do not deform tube (i.e., cause tube to compress its diameter so it is

no longer round).

1. Remove red end caps from unit’s water inlet/outlet connections.

Changing Filters (Fig 6)

NOTE:THIS MEGA UNDERSINK SYSTEM CONTAINS CARTRIDGES WHICH MUST BE REPLACED AT REGULAR

INTERVALS TO MAINTAIN PROPER PERFORMANCE. USE ONLY FACTORY APPROVED CARTRIDGES.

• Release any pressure in the line by turning on the cold- and hot-water faucets.

water.

(Cartridges may be recycled. Visit www.crystalquest.com/crystal quest

policies.htm under Preventive Routine Mintenance instructions.)

you're working on.)

directional arrow on the cartridge which indicates “This End Towards Cap”.

• Check O-ring(s). Lubicate with cooking oil if needed. Position O-ring(s) properly in the groove of the sump and tighten

by turning it clockwise. Do not overtighten. Do not cross-thread at the sump or inlet/outlet ports. If cross-threaded, do

not put or keep unit in service.

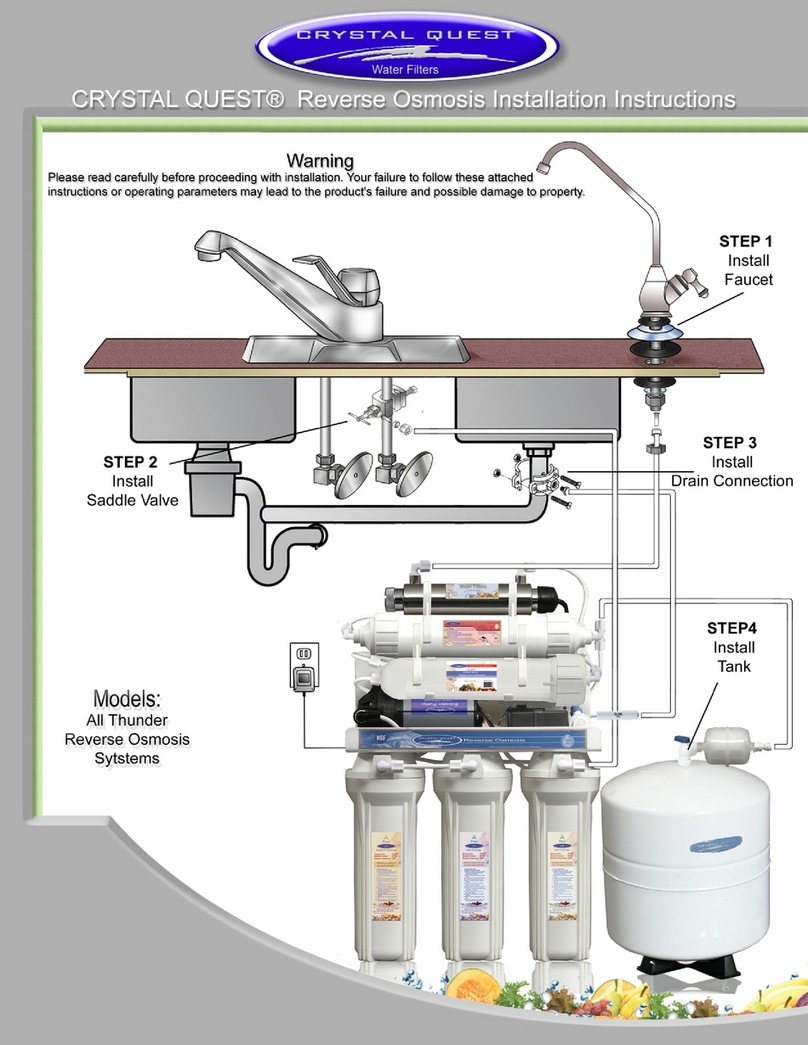

STEP 2 – Install the Saddle (Feedwater) Valve and Tubing (Fig 2)

CHOOSE THE VALVE LOCATION

• Choose a location for the valve that is easily accessible. It is best to connect into the side of a vertical water pipe. When it is necessary to connect into a horizontal water

• Disconnect the cold water supply line. Attach and tighten the saddle valve connector assembly, being careful not to pinch or crimp any tubing or water supply line while

NOTE: The saddle valve clamps onto hard tubing or pipe. It will make its own hole in copper tubing but not in iron or brass.

For brass or galvanized iron pipe, drill a 1/4” hole in pipe before mounting saddle valve. If possible, use a hand or cordless drill

when drilling water pipe. If using an electric drill, be sure that drill, cord and outlet are all properly grounded.

NOTE: If water supply line is soft tubing, it is recommended to use aT-valve installation.

NOTE: Do not turn handle before installing or while installing saddle valve.To prevent damage to piercing needle,make sure

NOTE:

1. Hold backplate against tube.

2. Hold saddle valve against tubing in a position directly opposite backplate.

3. Tighten screw enough so saddle valve and backplate are held securely against tube.

CONNECT SOURCE WATER FEED TUBING TO VALVE BODY USING COMPRESSION FITTING

1. Slide nut and sleeve onto tubing (in that order).

2. Install insert into tubing.

3. Install tubing with insert and sleeve into valve body.

4. Thread compression nut onto valve body. Tighten.

CAUTION: When the supply line is pierced, the valve should be closed. Do not open valve until system is activated. Turn on

cold water supply. Check saddle-tapping valve installation for leaks. Allow water to run from faucet for a few

minutes to clear any debris in the line caused by installation.

NOTE:

Tightening

Screw

Reversible

Plate

Compression

Nut

Tubing

Cold water

supply line

Sleeve

Insert

Valve

Handle

Valve

Body

CONNECT USING QUICK-CONNECT

FITTINGS

• Fittings consist of three parts: a body, collet, and

a locking clip. Make sure outer surface of tube is

clear of marks or scratches for a length equal to

twice tube diameter. This allows O-ring to seat

properly against tube.

• Remove locking clip from body collet (A).

• Push tube through collet into body until it seats

clip around the collet. Not replacing the locking

damage (A, B).

BODY

LOCKING CLIP

COLLET

TUBE

A

B

REMOVE FITTINGS

•

locking clip.

• Push and hold collet against body (ring of the

tube out.

• To reinsert a tube, cut 1/2” of tube from the end.

This will help prevent leaking. Replace the locking

clip around the collet.

CONNECT USING COMPRESSION

FITTINGS

• Slide compression nut over the end of

tubing.

• Connect compression nut to compression

adapter and tighten the compression nut

securely.

Fig 3

Fig 2

Fig 4A Fig 4B Fig 5

Fig 6

Sump

Sump

Wrench

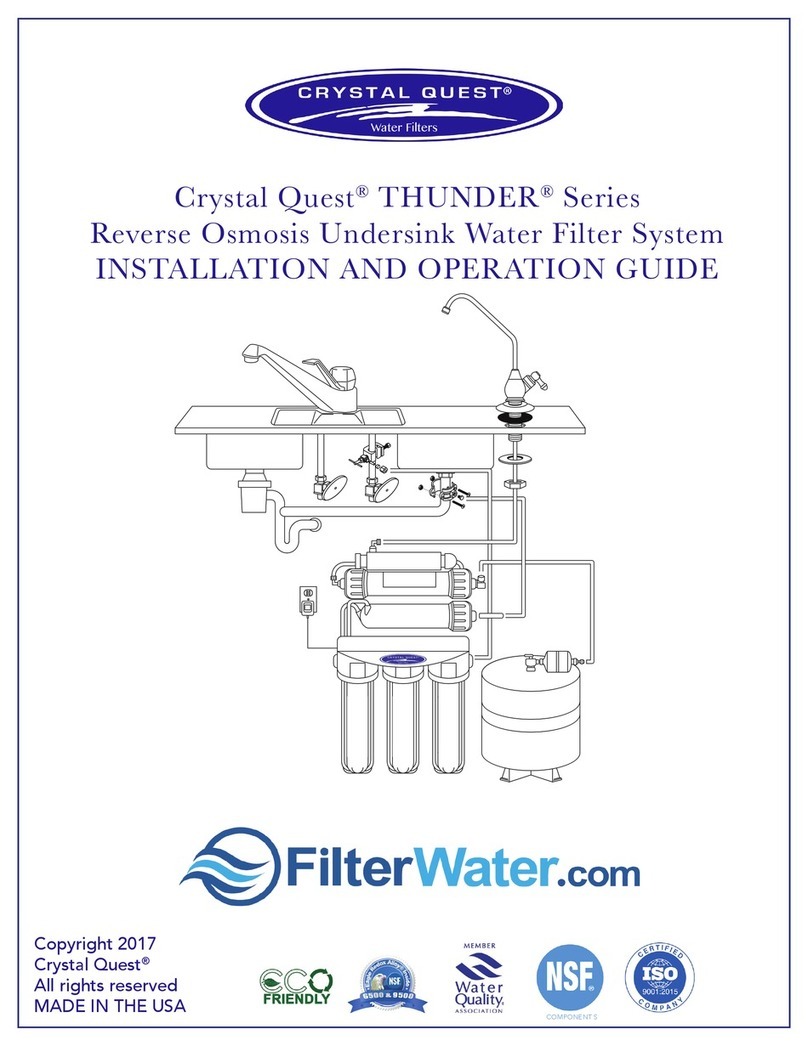

Mounting the Faucet:

Disassemble hardware from the threaded

nipple, except for chrome base plates and

rubber washers. (Rubber washers may be

replaced with a bead of plumber's putty

for neater appearance.) Feed the threaded

nipple through sink or counter mounting

hole and position the faucet. From below

sink or counter, assemble the white spacer

toward air gap). After checking faucet ori-

entation, tighten with a wrench until secure

(Fig 1).

Important Notice

licensed plumber. Not using the service

of a plumber will void warranty. Crystal

for systems improperly installed or those

licensed plumber.

Porcelain, Enamel, Ceramic on Metal or Cast Iron:

Precautions must be taken to penetrate the porcelain through to the metal

base and prevent it from chipping or scratching.

Tools required:

• Variable speed drill • Relton porcelain cutter tool set (7/8" or

• Plumber’s putty alternative size, 9/16”)

Procedures:

1. Mark the center for the 7/8" hole.

lubricate carbide drill bit.

3. Carefully drill pilot hole through all layers (use light pressure and slow

speed).

4. Insert pilot tip of spring-loaded porcelain cutter into pilot hole.

5. Drill porcelain/enamel using spring-loaded porcelain cutter, making

certain a complete ring has been cut through the porcelain/enamel to the

metal base.

6. Cut away the inner porcelain/enamel disc down to the base metal. Make

certain the cutter does not touch outer rim of the cut porcelain/enamel.

Continue with this bit to cut through metal until sink has been completely

penetrated.

Note: Always use sharpened porcelain cutter to eliminate chips and

cracks.

Stainless Steel Sinks:

Recommended tools:

• Center punch

• Variable speed drill

• High speed drill bits

• Greenlee chassis punch 7/8" (9/16" for

non air gap faucets)

• Protective gloves and eye protectors

Procedures:

1. Center punch small indent for hole.

2. Drill the required pilot hole.

3. Set-up the chassis punch per

instructions and tighten nut to cut

the desired hole size.

• 1-1/4" wood bit

• Household bleach (liquid)

• Crescent wrench

• Air pump (hand)

• Safety glasses

• 3/8” variable speed electric drill, 1/8” and 1/2” bits

• 1-1/4” porcelain hole cutter (if hole for second faucet is not provided)

• Plastic anchors and screws

• Plastic tube cutter

• Air pressure gauge (low pressure)

• Pliers

Tools and Material Recommended for Installation

Easy To Install

STEP 1 – Install the Faucet (Fig 1)

Faucet should be placed near the sink where drinking/cooking water is normally required.

mount the faucet if an existing hole for a second faucet is not available. The mounting thickness should not exceed 1-1/4". If

the sink has a sprayer, it may be disconnected for faucet installation. A pipe cap or plug will be necessary to seal the sprayer

connection. If making the faucet mounting hole (if sprayer or second hole is not used), check to make sure the drill does

not exceeding 1-1/4" in thickness). Drill the required pilot hole of the chassis punch and tighten nut to cut the desired hole

size. Clean up sharp edges. The faucet should be positioned so it empties into the sink and the spout swivels freely for

convenience. If sink has a hole that can accommodate the faucet, no drilling is required. Proceed with mounting the faucet.

Preparing for Installation

to follow them could cause serious property damage.

• Inspect the carton and unit for evidence of rough handling and concealed damages. If

that all installation parts are present, which includes the unit, faucet, installation hardware

contact customer support for replacement parts at (800) 934-0051.

All drawings, pictures, colors, and sizes are approximate for illustration purposes only

and may not reect the end product. All models are subject to change without notice.

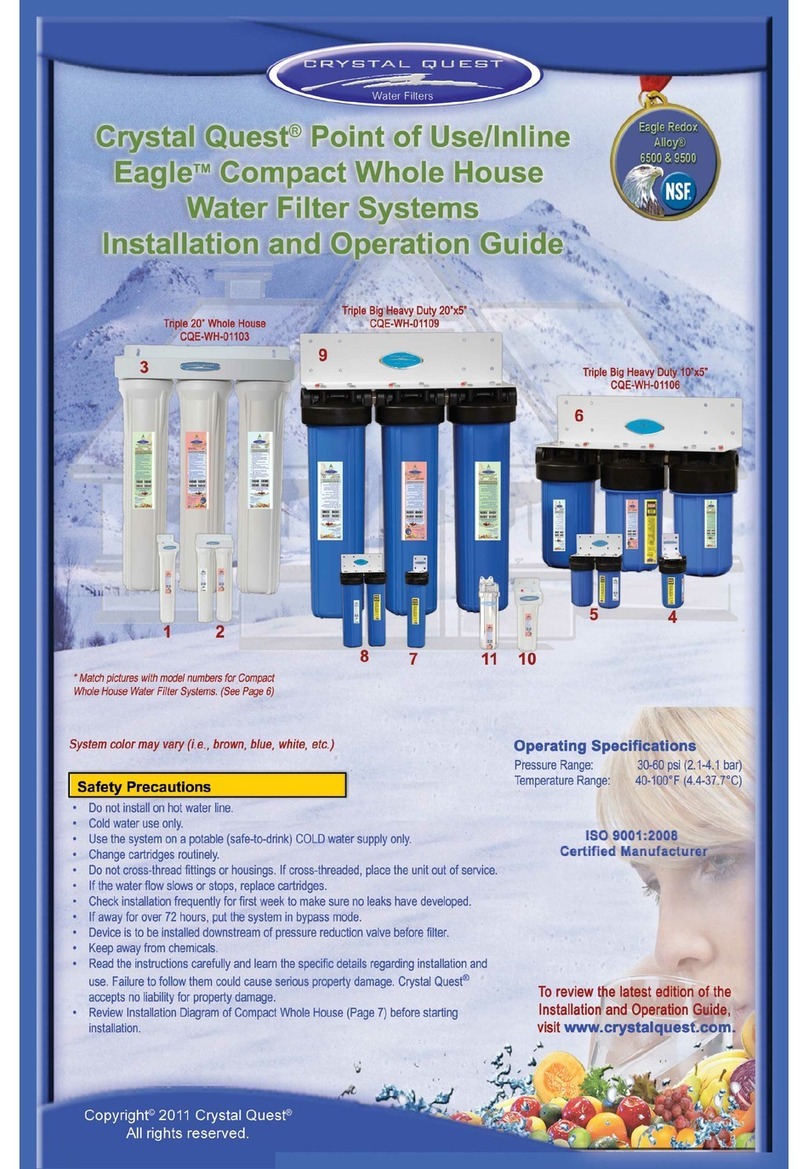

Mega 1000

6-Stage Filtration

CQE-US-00303

CQE-US-00304

CQE-US-00305

Mega 2000

7-Stage Filtration

CQE-US-00306

CQE-US-00307

CQE-US-00308

Mega 3000

8-Stage Filtration

CQE-US-00309

CQE-US-00310

CQE-US-00311

Important!

undersink units.

page 2page 3

WaterSimplyPure.com 859-336-3246