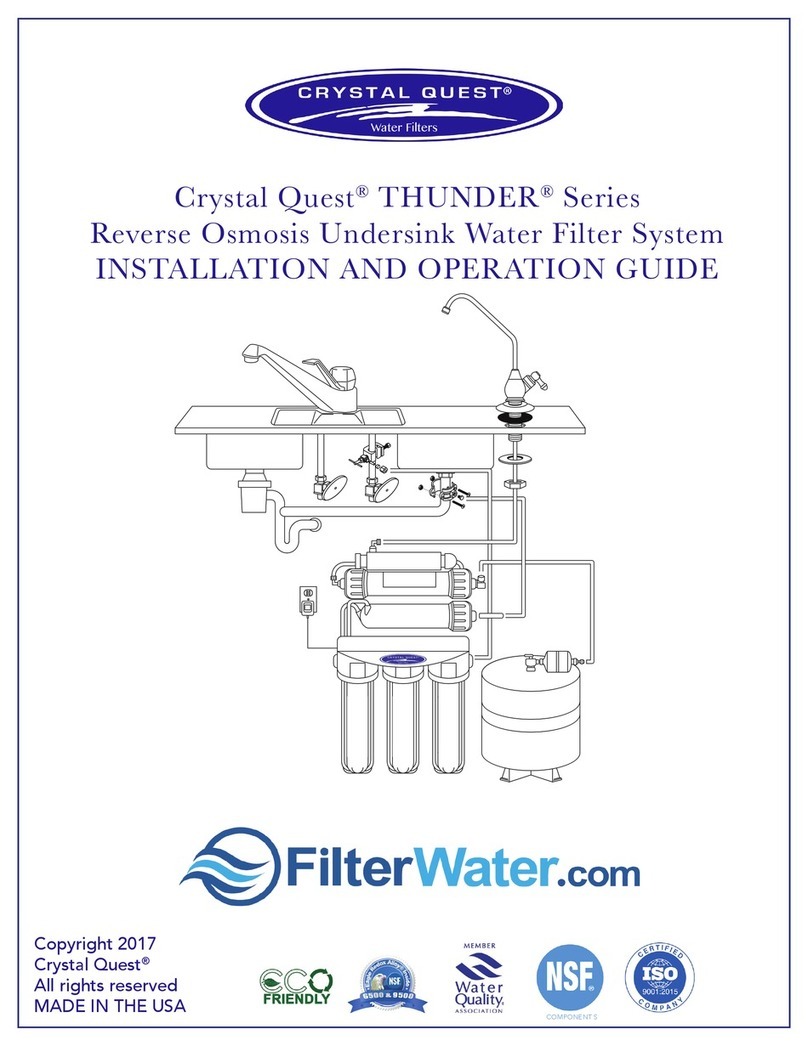

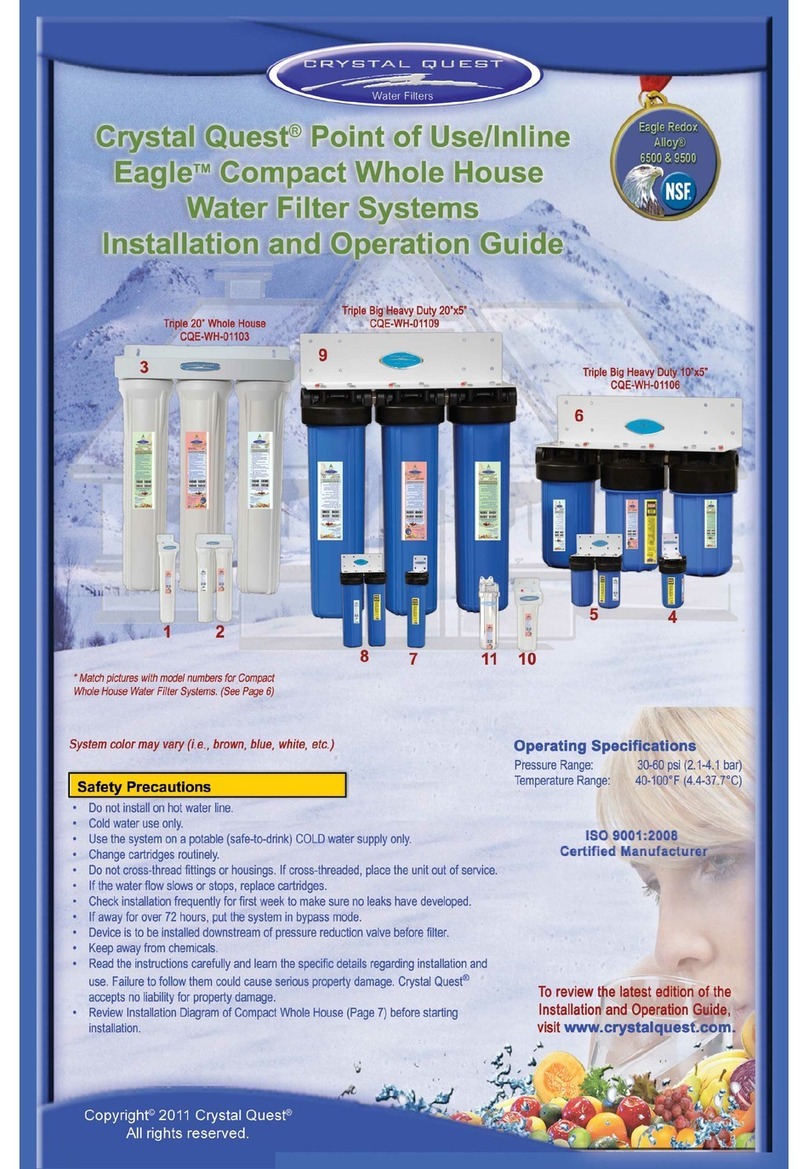

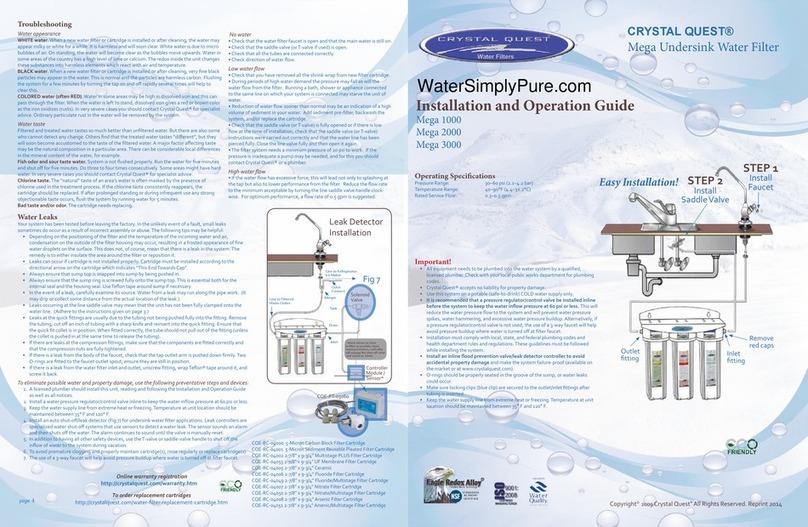

Crystal Quest Whole House Operating instructions

Crystal Quest® Point of Entry (POE) Whole House Water Filter System

INSTALLATION AND OPERATION GUIDE

OPERATING SPECIFICATIONS

Pressure Range: 30-60 psi (2.1-4.1 bar)

Temperature Range: 40-100ºF (4.4-37.7ºC)

Optimum Service Flow: 8-13 gpm (30.28-49.21 lpm)*

*Depending on the size of the system Read all instructions, specifications, cautions, and warnings

before installing and using your water filter system.

All drawings, pictures, colors and sizes are approximate for illustrative purposes only and may not exactly resemble the end product.

Components

REMEMBER, YOUR PURCHASE IS AN INVESTMENT AND NEEDS TO BE MAINTAINED PROPERLY.

• Do not run ½” I.D. semi-rigid drain tube more than 20 running feet. If over 20 ft., increase

drain line tubing size to ¾” I.D. for the entire length of tube.

• Have control valve set correctly for your specific water needs.

• If more than one unit is being installed, the regeneration/backwash times should be

staggered.

• A pressure regulator, such as a slow-flow regulator, must be installed in front of the unit’s

water inlet if the water pressure (including any possible pressure spikes) could exceed 60 psi.

The most common operating water pressure range is 35-65 psi. Failure to comply will void the

warranty. Crystal Quest® assumes no liability for damage caused by excessive water pressure.

• Check all the connections (i.e., water hose/tubing, connectors/fittings) to ensure proper

connection and to avoid leaks.

• The filter cartridges used with this system have a limited service life. Changes in taste, odor,

color, and/or flow of the water indicate that the cartridge should be replaced. Change

cartridges routinely.

• After prolonged periods of non-use (such as during a vacation), it is recommended that the

system be flushed thoroughly. Let water run for 10-20 minutes before using.

• Check plumbing inlet and outlet to ensure the proper flow of water through the system.

• Plug system into a 110-volt outlet which contains a fuse or circuit breaker of 20 amps.

• Locate the system near a cold water supply line. Do not set the system farther than 15 ft. from

the cold water line.

• Do not use the system on cold water supply line with less than 20 psi.

• Do not use the system where water is microbiologically unsafe or with water of unknown

quality.

• All water treatment installations must conform to local plumbing, electrical and sanitation

codes. These codes are established for your protection. Check with your local public works

department for current plumbing codes.

• Installation errors can cause property damage. Crystal Quest® assumes no liability

whatsoever for systems improperly installed or those installed by someone other than a

licensed plumber or qualified contractor. A leak detector valve is recommended to avoid

accidental property damage. See page 13.

• The contaminants or other substances removed or reduced by the selected cartridge(s) are

not necessarily in your water. Ask your local water municipality for a copy of their water

analysis, or have your water tested by a reputable water lab.

IMPORTANT INFORMATION

Installation must be made within an area protected from the elements and freezing.

The unit must be protected from rain, dust, flooding, snow, freezing, and direct sunlight

(the system’s exposure to direct sunlight may cause algae growth). Failure to comply

will void the warranty.

SAFETY PRECAUTION

Read all instructions, specifications, cautions, and warnings before

installing and using your water filter system. Learn the specific

details regarding installation and use. Failure to follow them could

cause serious property damage.

Installation errors can cause property damage. All equipment

needs to be plumbed into the water system by a licensed plumber.

These guidelines must be followed during system installation:

• Use the system on a potable, safe-to-drink, COLD water supply

only.

• The system is for indoor use only.

• Turn the cold water line off while installing the system.

• When installation is completed, re-check the system to ensure

there are no leaks or drips.

• The outlet must be within reach of the power cord. Do not use an

extension cord. Extension cords that are too long or too light do not

deliver sufficient voltage to the unit and could present a safety

hazard.

• The rubber O-ring provides a watertight seal between the cap and

the bottom of the housing. Make sure the O-ring is properly seated

in the groove below the threads of the housing or a water leak could

occur.

• Do not cross-thread fittings or housings. If cross-threaded, place

the unit out of service.

Water testing by an independent third-party lab will attest to

contamination removal and validity of toxicology testing. California

residents are advised to have their water tested to ensure the water

filter system is in compliance with Proposition 65.

2

TABLE OF CONTENTS

Important Information and Safety Precautions................................................................................................................ 2

Arrival, Unpacking, and Inspection...................................................................................................................................4

System Location................................................................................................................................................................4

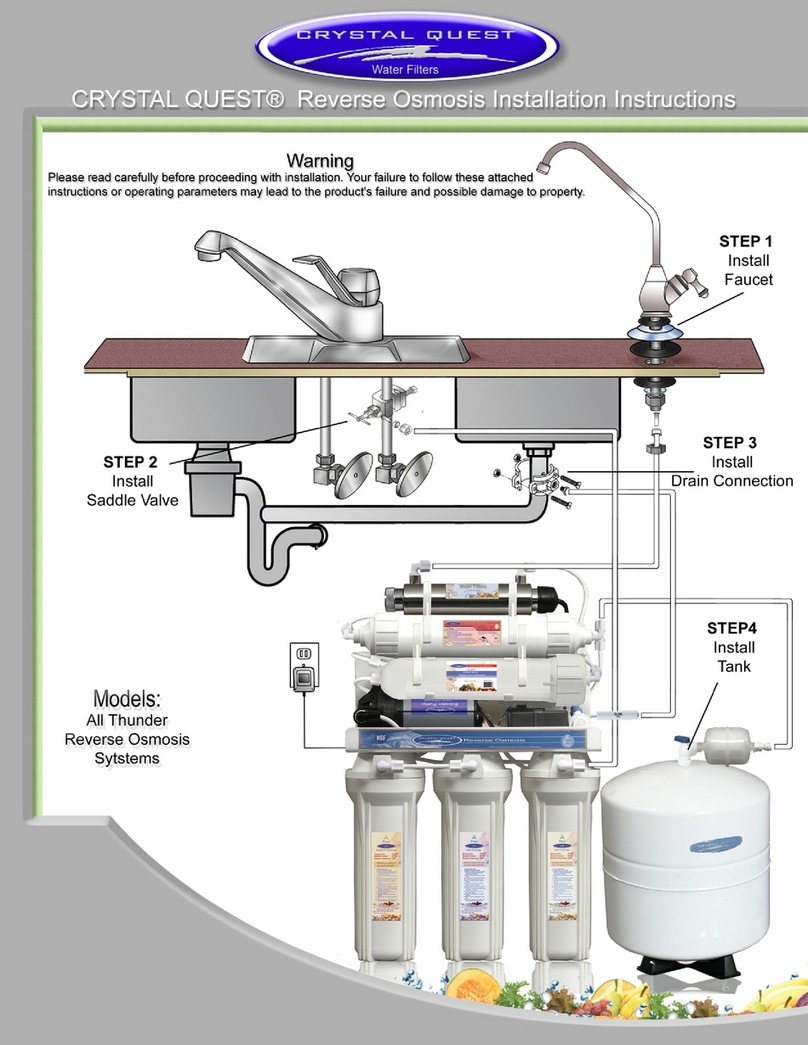

Installation Diagrams........................................................................................................................................................5

Installing Optional UV Lamps...........................................................................................................................................6

Assemble Water Filter System with Control Valve and Brine Tank (Mechanical and Automatic)......................................7

Programming Automatic Control Valve............................................................................................................................8

Connecting Water Filter System to Water Supply............................................................................................................9

Connecting Pre- and Post-Filters to Water Supply.........................................................................................................10

Connecting Tubing to Control Valve..............................................................................................................................11

Connecting Tubing to Brine Tank...................................................................................................................................12

How to Avoid Accidental Property Damage..................................................................................................................13

Installing the Leak Detector Valve..................................................................................................................................13

Guide for Replacing Media.............................................................................................................................................14

Replacing Filter Cartridges and Maintenance.................................................................................................................15

Maintenance for Water Softeners....................................................................................................................................15

Troubleshooting..............................................................................................................................................................16

Frequently Asked Questions...........................................................................................................................................17

One Year Limited Warranty..............................................................................................................................................18

Ordering Replacement Cartridges .................................................................................................................................18

ALL POINT OF ENTRY SYSTEMS MUST BE INSTALLED BY A LICENSED PLUMBER TO AVOID PROPERTY DAMAGE.

*Specifications are subject to change

without notice.

INFORMATION & ASSISTANCE

WWW.CRYSTALQUEST.COM

CUSTOMER SERVICE

1-800-934-0051

Hours of Operation:

Monday to Friday

9 AM to 5 PM EST

SUPPORT@CRYSTALQUEST.COM

Contact us for questions about your order,

technical support and product information,

or general comments or questions.

The system needs to be installed by a licensed plumber in any state or country. Specifically, the

following states require a licensed plumber OR allow a state-registered installer or contractor to

install your water filter system: AR, CA, GA, KS, MA, MI, MN, OK, RI, SC, SD, TX, VT, and WI.

3

ARRIVAL, UNPACKING, AND INSPECTION

• Inspect the carton and water filter for evidence of rough handling and concealed damages.

If contents appear damaged, ask driver or contact the carrier for a damage claim form to fill

out. Notify shipper immediately.

• Remove components from the shipping carton. Check that all installation parts are present,

which includes the unit and installation hardware.

• Make a complete inspection of the system to ensure that:

a) there are no physical damages to the system,

b) all accessories are present,

c) and the system is clean and dust free.

• Pipe, shut-off valves, and fittings are not provided by Crystal Quest®.

CHECK LIST WATER FILTER SYSTEM

• Unpack the water filter from the shipping box.

• Unpack the control valve from the shipping box.

• Unpack the water softener, tannin, or nitrate

water filter system from the shipping box.

• Check the entire water filter system for any loss

of parts.

• Parts needed to install the water filter (control

valve and softener) are packaged in a plastic bag.

To avoid loss of the small parts, keep them

packaged until you are ready to use them. Be sure

not to discard components hidden in packaging.

All Point of Entry Whole House models with

backwashing and regeneration/backwash

programming

All Point of Entry Whole House models with

regeneration/backwash programming

All Point of Entry Whole House models with

regeneration/backwash programming

ALL MODELS SUBJECT TO CHANGE WITHOUT NOTICE.

Read all instructions carefully to learn the details for installing and using your

P.O.E. water filter system. Failure to follow the Installation and Operation Guide

could cause injury and/or property damage.

SYSTEM LOCATION

Select the location of your water filter system with care.

For correct installation, refer to the appropriate diagram.

Various conditions which contribute to proper location

are as follows:

• Do not locate the system where the environment

would offer any risk of water contamination.

• Do not put any liquid other than water into the

system.

• Position the water filter near main water supply line,

drain and electrical outlet. Position so that main water

supply shut-off valve is between water filter and main

water source.

• Turn off the water flow to the house while installing

system.

• Select location where floor is level. If floor is rough

and/or uneven, you can level by placing tanks on 3/4”

plywood, and shim to level as needed.

• Install the water filter by positioning it BEFORE the

water heater

• Water temperatures above 100°F (38°C) will damage

the water filter. Use on cold water line only.

• Allow sufficient space around the installation area for

easy servicing.

• Provide a non-switched 110/120V, 60Hz power source

for the control valve (automatic/softener system).

4

The system needs to be installed by a licensed plumber in any state or country. Specifically, the following states require a licensed plumber OR

allow a state-registered installer or contractor to install your water filter system: AR, CA, GA, KS, MA, MI, MN, OK, RI, SC, SD, TX, VT, and WI.

TYPICAL INSTALLATIONS AND SYSTEM LOCATIONS

COMBO SYSTEMS CAN BE CUSTOMIZED BASED ON WATER CONDITIONS/LAB REPORTS.

*ORIENTATION OF TANKS ARE BASED ON WATER REPORTS/CONDITIONS *IN SOME CASES, DIRECTION OF WATER FLOW IS FROM LEFT TO RIGHT.

Mechanical System/Polyglass Water Filter System Automatic System/Polyglass Water Filter System Softener, Tannin or Nitrate System/

Stainless Steel Water Filter System

BYPASS

COLD WATER

WATER

HEATER

SHUT OFF

VALVE

SHUT OFF

VALVE

SHUT OFF

VALVE

FLOOR DRAIN

WATER METER

WATER SUPPLY

HOT WATER

OUTSIDE TAP

WATER

COLD WATER

HOT WATER

SHUT OFF

VALVE

SHUT OFF

VALVE

SHUT OFF

VALVE

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

WATER

HEATER

WATER

HEATER

COLD WATER

HOT WATER

SHUT OFF

VALVE

SHUT OFF

VALVE

SHUT OFF

VALVE

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

Automatic System/Polyglass Water Filter System

BYPASS

SHUT OFF

VALVE

SHUT OFF

VALVE

COLD WATER

HOT WATER

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

Softener, Tannin or Nitrate System/

Triple Stainless Steel Water Filter System

Softener, Tannin or Nitrate System/

Quad Stainless Steel Water Filter System

BYPASS

SHUT OFF

VALVE

COLD WATER

HOT WATER

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

BYPASS

SHUT OFF

VALVE

COLD WATER

HOT WATER

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

(WITH BACKWASH OR REGENERATION FEATURES)

5

WATER

HEATER

WATER

HEATER

WATER

HEATER

SHUT OFF

VALVE

SHUT OFF

VALVE

SHUT OFF

VALVE SHUT OFF

VALVE

SHUT OFF

VALVE

DOWNFLOW WITH NO BACKWASH WATER FILTER SYSTEMS

This system is ideal for acidic water conditions or as a post-filter for a

reverse osmosis system to remineralize and enhance pH. This design will

allow quick and easy media refill.

CONNECTING TO GALVANIZED PIPE

CONTROL VALVE

GALVANIZED PIPE

OR NIPPLE

CONNECTING TO PLASTIC PIPE

CONTROL VALVE

PLASTIC PIPE

SOLVENT BOND

FITTING

• Electronic ballast must be connected to a grounded

outlet, and the lamp connector ground wire must be

connected to the stainless steel reactor chamber.

• This disinfection system is designed to be mounted

horizontally or vertically at the point of use or point of

entry, depending on the specific flow rate of the unit.

• The UV disinfection system is intended for indoor use

only.

• Do not install disinfection system where it may be

exposed to the weather or temperatures above 100ºF.

UV INSTALL

HINTS

Refer to section

"CONNECTING

WATER FILTER

SYSTEM TO WATER

SUPPLY" for detailed

instructions.

ULTRAVIOLET WATER STERILIZER SYSTEM

This system is great for well water and as an add-on to any

whole house water filter. For detailed installation instructions,

refer to the UV Installation and Operations Guide.

6

CONNECTING UV TO GALVANIZED PIPE* CONNECTING UV TO PLASTIC PIPE

INLET

OUTLET

ULTRAVIOLET

INLET

OUTLET

ULTRAVIOLET

GALVANIZED PIPE

OR NIPPLE PLASTIC PIPE

OR NIPPLE

SOLVENT

BOND

FITTINGS

(UV PLACEMENT IS OPTIONAL BASED ON WATER FEED SOURCE.)

BYPASS

SHUT OFF

VALVE SHUT OFF

VALVE

COLD WATER

HOT WATER

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

OPTIONAL

SHUT OFF

VALVE

SHUT OFF

VALVE SHUT OFF

VALVE

ULTRAVIOLET

BULB

OPTIONAL

SHUT OFF

VALVE

PRE-FILTER

POST-FILTER

ULTRAVIOLET

BULB

WATER HEATER TANNIN SOFTENER

BRINE TANK

To change the UV

bulb, follow

instructions provided

in the UV Installation

and Operation Guide.

Pipe and shut-off

valves are not

provided by

Crystal Quest®

ASSEMBLE WATER FILTER SYSTEM WITH CONTROL VALVE AND BRINE TANK

CAUTION - DO NOT OVERTIGHTEN COMPRESSION NUT! HAND TIGHTEN AND ADD A HALF TURN WRENCH.

Unpack the control valve from the shipping box. It is recommended that you keep the original boxes

and packing materials.

1 2 34

5 6 7

Unscrew and remove the top

cap from unit.

Unplug slip cap from the

distributor/riser tube (also referred

to as a PVC tube).

To prevent leaks, lubricate the

inner and outer O-rings on the

bottom of control valve with food

grade silicone lubricant.

Twist and lock top distributor to the

bottom of control valve. Ensure it is

fully locked in place.

Attach control valve to the tank by sliding distributor tube into top

distributor. Turn control valve clockwise to tighten. Distributor tube

needs to be equal to the top of the resin tank (not more than 1/4"

above). Lubricate the inner O-ring prior to attaching the control

valve to the tank.

Attach bypass valve to the back

ports of the control valve by

sliding the bypass over the

O-rings and tighten (it is held in

place by two metal clips and

two screws).

Attach drain line hose barb and

compression nut of the brine tank

by turning clockwise to tighten

until snug. To prevent leaks, wrap

threads of hose barb and

compression nut with Teflon® tape

clockwise, approximately 3 times

around.

TOP

DISTRIBUTOR

CONTROL

VALVE

CONTROL

VALVE

TOP

DISTRIBUTOR

DISTRIBUTOR

TUBE

O-RING

TANK

DRAIN LINE

HOSE BARB

COMPRESSION NUT

OF BRINE TANK

CONTROL VALVE

(BACK VIEW)

CONTROL VALVE

(FRONT VIEW)

DRAIN CONNECTOR

CLAMP

TANK

TOP DISTRIBUTOR

DRAIN

BOTTOM

DISTRIBUTOR

DOWN-FLOW SYSTEM

DISTRIBUTOR/

RISER TUBE

7

SLIP CAP

DISTRIBUTOR/

RISER TUBE

PROGRAMMING AUTOMATIC CONTROL VALVE

1) Use the up or down arrows to set the time to 12:01

PM. Once the time is changed to 12:01 PM, push the

Recycle button (refer to Figure A1) to lock it in.

2) Push and hold both arrow buttons until screen

changes to read “GAL”.

3) Push Recycle button. Screen will read “DF 1b”. This

is set at factory and will not need to be changed.

4) Push Recycle button. Screen should read “tc”. If not,

use up/down arrow buttons to set to “tc”.

5) Push Recycle button. Screen will read “NT ---1”. This

is the number of tanks the timer is controlling (one

tank). Do not change this.

6) Push Recycle button. Screen should read “DO 7”. If

not, use up/down arrow buttons to set number to 7.

7) Push Recycle button. Screen should read “RT 2:00”.

* If not, use up/down arrow buttons to set to 2:00.

8) Push Recycle button. Screen should read “BW 10”. If

not, use up/down arrow buttons to set to 10.

9) Push Recycle button. Next screen will be “BD 60”.

Use up/down arrow buttons to change screen to read

“OFF”.

10) Push Recycle button. Screen will change to time

display and programming is locked in.

*If more than one tank is being used, regeneration

time (RT 2:00) should be staggered for each tank.

Programming to backwash non-regeneration

systems once every 7 days:

1) Use the up or down arrows to set the time to 12:01

PM. Once the time is changed to 12:01 PM, push the

Recycle button (refer to Figure A1) to lock it in.

2) Push and hold both arrow buttons until screen

changes to read “GAL”.

3) Push Recycle button. Screen will read “DF 1b”. This

is set at factory and will not need to be changed.

4) Push Recycle button. Screen should read “tc”. If

not, use up/down arrow buttons to set to “tc”.

5) Push Recycle button. Screen will read “NT ---1”.

This is the number of tanks the timer is controlling (one

tank). Do not change this.

6) Push Recycle button. Screen should read “DO 7”. If

not, use up/down arrow buttons to set number to 7.

7) Push Recycle button. Screen should read “RT 2:00”.

* If not, use up/down arrow buttons to set to 2:00.

8) Push Recycle button. Screen should read “BW 10”.

If not, use up/down arrow buttons to set to 10.

9) Push Recycle button. Screen should read “BD 60”.

If not, use up/down arrow buttons to set to 60.

10) Push Recycle button. Screen should read “RR 10”.

If not, use up/down arrow buttons to set to 10.

11) Push Recycle button. Screen should read “BF 12”.

If not, use up/down arrow buttons to set to 12.

12) Push Recycle button. Screen will change to time

display and programming is locked in.

*If more than one tank is being used, regeneration

time (RT 2:00) should be staggered for each tank.

Programming to backwash Softener, Nitrate, or

Tannin systems to regenerate once every 7 days:

Programming to Backwash and Regenerate

using an Automatic Valve

Programming to Backwash

using the Mechanical Control Valve

• When programming the mechanical valve to backwash, firmly grip

the handle, turning it counterclockwise from the service FILTER (M1)

position.

• Lock the handle to the BACKWASH (M2) position.

• Allow the water to run through the unit for five minutes or until the

water becomes clear and free of dust or media fines.

• Manually turn the control knob clockwise to the service FILTER (M3)

position. Your unit is back in service and ready to operate.

CAUTION - FAILURE TO FULLY LOCK DISTRIBUTOR WILL CAUSE IMPROPER OPERATION.

A1 A2

M1 M2

M3

BACKWASH

FILTER

8

(Refer to instructions for programming Automatic Control Valve)

(See Instructions Below)

*For more about automatic valve settings please refer

to our "Frequently Asked Questions" on Page 17.

CAUTION - IF COPPER PIPING WITH SWEAT FITTINGS IS USED, DO NOT SWEAT DIRECTLY INTO THE IN/OUT MANIFOLD

OF SOFTENER VALVE OR BYPASS VALVE. HEAT WILL DAMAGE PLASTIC PARTS.

CONNECTING WATER FILTER SYSTEM TO WATER SUPPLY

• Turn off the main water shutoff valve.

•Open all plumbing fixtures in the house

including all outside faucets in order to drain the

lines of all water.

• Cut and remove a section of the main incoming

water line near where the system is to be

installed. Allow this line to drain thoroughly (Fig

8).

• If copper piping is used and soldered, remove

the bypass from the valve assembly and attach

your plumbing adapters to the bypass away from

the valve. This simple step will ensure that you

are not applying heat as you solder, or pressure

as you tighten the adapters onto the bypass

while they are mounted on the valve body itself.

•Solder a 3" to 5" piece of copper pipe into

each of the two pipe adapters away from the

valve, then let them cool before threading each

one onto the yoke or bypass valve (Fig 9).

• Apply Teflon® tape onto the male adapters for

the brass bypass valve when cool, and securely

tighten them to the bypass valve. This is done

before reattaching them onto the rear of the

valve/meter body assembly.

• Close main water supply shutoff valve.

•Open nearest faucet to relieve pressure and

drain plumbing lines.

• ¾" or 1" male thread adapters to plumb the

system

• Wrenches, either open end or adjustable jaw, sized

to fit compression adapters

• Pipe cutter

• Teflon® tape

• Sandpaper or emery cloth

• Before installing ¾" or 1" fittings to the inlet and

outlet of the bypass valve or manifold, wrap the

threads 3 times around with Teflon® tape. Install ¾"

or 1" fittings.

• Soldering is no longer required to plumb with

copper pipe. Instead, use ¾" or 1" compression

fittings. Connect plumbing as shown below (Fig 10),

choosing appropriate connection for

mechanical/automatic control valve.

CAUTION: Do not overtighten or cross-thread.

CAUTION: Install water filter in direction of arrows.

MINIMUM MATERIALS NEEDED

89

Cut out section of main water

supply line downstream from

the supply shut off at position

water filter is to be installed.

Using a pipe cutter, sand (file)

cut ends of pipe to ensure that

they are square and smooth.

Check plumbing inlet and outlet

to ensure the proper flow of

water through the unit. Match

plumbing inlet and outlet with

arrows located on the sides of

the valve head and on the

bypass valve.

10 Connecting to galvanized pipe Connecting to plastic pipe Connecting to copper pipe

X

OUTLET

INLET

AUTOMATIC

CONTROL

VALVE

INLET

OUTLET

GALVANIZED PIPE OR NIPPLE

INLET

OUTLET

AUTOMATIC

CONTROL

VALVE

SOLVENT

BOND

FITTING

PLASTIC PIPE

AUTOMATIC

CONTROL

VALVE

INLET

OUTLET

SOLVENT

BOND

FITTING

COPPER PIPE

GALVANIZED PIPE OR NIPPLE

MECHANICAL

CONTROL VALVE

PLASTIC PIPE

MECHANICAL

CONTROL VALVE SOLVENT BOND

FITTING

9

(Choose appropriate connection below)

MECHANICAL/AUTOMATIC

13 POLYPROPYLENE FILTER - Choose appropriate connection below

Connecting to plastic pipe Connecting to copper pipe Connecting to galvanized pipe

MINIMUM MATERIALS NEEDED

• Tape measure or ruler

• 4 hex washer-head screws

• Anchors

• Pipe cutter

• Teflon® tape

• Sandpaper or emery cloth

• Before installing ¾" or 1" fittings to the inlet and outlet

of the bypass valve or manifold, wrap the threads 3 times

around with Teflon® tape. Install ¾" or 1" fittings.

• Soldering is no longer required to plumb with copper

pipe. Instead, use ¾" or 1" compression fittings. Connect

fitting as shown below (Fig 13).

• Select a secure location surface to install filter and mounting bracket. The location

should align the filter system with inlet and outlet pipe and should not cause the

pipes to bend or get damaged. Mark the distance "X" on the pipe.

• The bracket can be used as a template for marking the location of the mounting

screws (Figures 11 & 12).

• Use four hex washer-head screws to mount bracket firmly to wall. Use proper

anchors on wall. Anchors and screws are NOT included.

• Apply 4 or 5 wraps of Teflon® tape, in a clockwise direction, to the pipe threads

of each fitting. DO NOT use joint compound on any parts connecting to filter

housing.

• Turn fittings clockwise to tighten. Do not overtighten.

Connecting to copper pipe Connecting to galvanized pipe

TURN FITTING CLOCKWISE TO TIGHTEN. DO NOT OVERTIGHTEN. DO NOT CROSS-THREAD.

IMPORTANT: A copper or galvanized cold water pipe is often used to ground electrical outlets

in the home. Grounding protects you from electrical shock. The water filter housing may have

broken this ground path. To restore connection, install an 18” long, 6-gauge copper wire across

the filter, tightly clamped using UL ap-proved 1/2”-1” bronze grounding clamps at both ends as

shown. Zinc clamps should not be used on copper plumbing. Wire and clamps may be

purchased separately from your local hardware store. With emery cloth, clean copper pipe and

ends of wire. Bare wire is recommended. If insulated wire is used, it should be stripped 3/4” at

each end before cleaning with emery cloth.

• Attach bronze clamps to pipe. Tighten screws.

• Attach wire to clamps as shown. Tighten screws.

11 12

13 STAINLESS STEEL FILTER - Choose appropriate connection below INSTALLING GROUND WIRE

Turn off the water supply and open a

nearby faucet to drain the water out of

pipes. Using a tape measure or ruler,

measure the distance "X" as shown.

Using a pipe cutter, cut pipe. Sand (file)

cut ends of pipe to assure that they are

square and smooth.

X

X

INLET

OUTLET

PLASTIC PIPE

SOLVENT

BOND

FITTINGS

INLET

OUTLET

COPPER PIPE

SOLVENT

BOND

FITTINGS

INLET

OUTLET

GALVANIZED PIPE

INLET

OUTLET

COPPER PIPE

SOLVENT

BOND

FITTINGS

INLET

OUTLET

GALVANIZED PIPE

CLAMP CLAMP

GROUND WIRE

10

CONNECTING PRE- AND POST-FILTERS TO WATER SUPPLY

Pre-filter: Sediment Cartridge

Post-filter: Carbon Block (for EAGLE systems, the UltraFiltration Cartridge is Post-filter 2)

CONNECTING TUBING TO CONTROL VALVE - MECHANICAL AND AUTOMATIC

Press 1/2" I.D. semi-rigid or non-collapsible plastic tubing onto drain line hose barb until

snug and secure with a hose clamp (Figs 14 and 15).

• Plug cord from control valve into

110V electrical outlet. Make certain

that outlet is supplied with power at all

times. Make sure area is dry before

plugging the unit in (Fig 16). Open

main water supply shutoff valve.

• CHECK FOR LEAKS! Close previously

opened faucet.

NOTE: Do not run 1/2" drain line over

20'. If over 20', increase tube size to

3/4".

CONNECTING TUBING TO BRINE TANK

• Connect tubing to control valve as shown in Figures

14 and 15 for the mechanical and automatic water

filter systems.

• For connecting tube to brine tank (softener, nitrate

and tannin systems), see Fig 17 below:

(1) Slide the brass insert into brine tube and slide

compression nut onto brine tube.

(2) Turn compression nut clockwise with wrench to

tighten. DO NOT OVERTIGHTEN.

14 15

16 17

TRANSFORMER OUTLET

BRASS INSERT

11

PLASTIC TUBING

PLASTIC TUBING

CONNECTING TUBING TO BRINE TANK

CAUTION - DO NOT OVERTIGHTEN COMPRESSION NUT! HAND TIGHTEN AND ADD A HALF TURN WITH A WRENCH.

• Install 1/2" I.D. semi-rigid or non-collapsible tubing (not included) to the overflow

hose barb located on the side of the softener brine tank and run to a suitable drain.

Do not connect to drain line off of softener (Figs 22 & 23).

• Plug cord from control valve into 110V grounded electrical outlet. Make certain

that outlet is supplied with power at all times. Make sure area is dry before plugging

the unit in (Fig 25).

• Open main water supply shutoff valve. CHECK FOR LEAKS! Close previously

opened faucet.

• Pour the 5-gallon bucket of water into the brine tank.

• Pour 1-1/2 oz. of chlorine bleach solution directly into the brine tank or

salt/potassium permanganate compartment.

• Pour salt or potassium permanganate into brine tank component (not included).

Fill tank 1/2 - 3/4 full (do not pack full) and add water until it is just above the salt

level. To read more about brine tanks and where to buy salt, refer to our

"Frequently Asked Questions" on page 17. If any red rust stains are apparent, mix

iron control agents (Super Iron Out®) with the salt or potassium permanganate.

18 19 and 20 21 22 & 23

Remove the black brine tank lid. Remove the small white lid from the inside of the brine tank.

Lift out parts inside and unscrew bolt. Thread the screw through the pre-made hole,

and use the bolt to secure in place.

Remove the black plastic screw on opposite side and

thread the hose through the tank.

Place the black screw and additional parts around the hose

and then screw securely into place.

24

TRANSFORMER

25

OUTLET

12

INSTALLING A LEAK DETECTOR VALVE

Crystal Quest Point-of-Entry Water Filters use the latest

technologies available to ensure and prevent water rupture.

However, if manufacturing guidelines are not followed, water

damage can occur. Causes of flooding include excessive water

pressure, spikes in water pressure, human tampering, and

negligent installation.

To eliminate possible water and property damage, use the

following preventative steps and devices:

1. A licensed plumber should install this unit, reading and

following the Installation and Operation Guide as well as all

notices.

2. Install a water pressure regulator/control valve inline to keep

the water inflow pressure at 60 psi or less.

3. Keep the water supple line from the extreme heat or

freezing. Temperature at unit location should be maintained

between 35F and 120F.

4. Install an inline flood prevention valve/leak control (available

at CrystalQuest.com) – instructions at right.

5. In addition to having all other safety devices, use a ball valve

to bypass the inflow of water to the system during vacation.

13

Leak Controllers are specialized water alarm and shut-off systems that use sensors

to detect a water leak. The sensor sounds an alarm and then shuts off your water. The

alarm continues to sound until the valve is manually reset. By preventing continuous

water flow, mold and property damage are restricted.

FEATURES

- 1” full port ball valve with auto shut-off

- Programmable service reminder indicator

- Water detection sensitivity down to 2ppm TDS (total dissolved solids)

- 4 AA alkaline batteries

- Automatic daily valve management

- Available port sizes (inlet/outlet) 3/4 “, 1”, 1-¼” and 1-½”

BYPASS

SHUT OFF

VALVE

SHUT OFF

VALVE

COLD WATER

HOT WATER

FLOOR DRAIN

WATER METER

WATER SUPPLY

OUTSIDE TAP

WATER

WATER

HEATER

SHUT OFF

VALVE

SENSOR*

CONTROLLER

MODULE

FULL

PORT

VALVE

1) INSTALL LEAK DETECTOR VALVE INTO INLET WATER LINE

2) MOVE SENSOR AS CLOSE TO FILTER AS POSSIBLE.

UPON SENSING MOISTURE, CONTROLLER WILL ENGAGE THE

SHUT-OFF VALVE AND SOUND AN ALARM.

3) SECURE CONTROLLER MODULE TO WALL

HOW TO AVOID ACCIDENTAL PROPERTY DAMAGE

GUIDE FOR REPLACING MEDIA

1. Turn off the water to the unit and unplug from the power source.

2. Disconnect the unit from your plumbing.

3. Carefully unscrew the control valve off the top of the tank.

4. Remove the riser tube from inside the mineral tank.

5. Lay the tank on its side or lay over a trash can to remove media.

6. Rinse the inside of the tank clean with a garden hose, discard old resin, and save the old gravel.

7. Stand media tank upright. Plug a slip cap or put a piece of tape over the top of the distributor/riser tube to prevent media from

entering the tube while loading the media.

8. Place the media funnel in the top of the media tank with the riser tube still inside and centered.

9. Begin replacing media by putting gravel into the tank first. Make sure the riser tube is firmly on the bottom of the tank. If the riser

tube is pulled out of the gravel once the media is added, it is impossible to put it back in without removing the other media from the

tank.

10. Pour resin/media into the funnel, slowly letting it fall down inside the media tank around the riser tube. If you have a twin

alternating system, divide the resin/media equally between the two tanks. The media tank should be approximately 3/4 full. The

media tank should be approximately ¾ full but this can vary based on the media for your specific system.

11. Remove the funnel and the slip plug or tape from the top of the riser tube.

12. Brush any loose resin/media off the top opening of the tank. Clean the top edge with a cloth so the O-ring can seal securely to

the valve base. Lubricate o-ring with clean food grade silicon grease.

13. Look at the bottom of your control valve and locate the upper basket. Inside the basket, the control valve has O-rings that will seal

on the riser tube. Install the valve on top of the media tank, making sure the top of the riser tube inserts inside the opening of the

upper basket. Guide the riser into the O-ring seal and tighten gently. Be careful not to over-torque the valve as the threads are plastic.

14. Screw the control valve back onto the top of the tank. Be sure to hold the control valve where there will be no damage to the valve

from the pressure you exert from tightening the valve back onto the tank.

15. Reconnect your plumbing to your unit and plug the control valve back in, making sure to set the correct time of day. Turn on the

water to the unit and check for leaks.

16. Leave all faucets turned off inside the house, and open a single faucet (such as an outside faucet), letting the water run for 3-5

minutes. This rinses the new resin/media inside the tank, and any particles or color will rinse out through the one open faucet, and not

throughout your home plumbing system.

17. Manually turn your regeneration/backwash control knob slowly through a complete cycle, allowing the water to run through the

unit for a minute or so in each position.

18. Once the regeneration/backwash knob is back in the service position, your unit is in service and ready to operate!

For details on replacement media or to order replacement media, visit http://www.crystalquest.com/whole-house-water-filters.htm

FUNNEL

DISTRIBUTOR/

RISER TUBE

SLIP CAP

14

REPLACING FILTER CARTRIDGE AND MAINTENANCE

• You should change your filter cartridge when the water flow is

noticeably reduced and/or between 12-18 months.

• Turn off water to filter. Water must be shut off from an upstream

valve or bypass.

• Unscrew the filter sump and discard used cartridge.

• Wash the filter sump with mild soap and water. Do not use harsh

cleaners or hot water.

• Inspect the filter sump O-ring. Make sure it is lightly lubricated

with clean food grade silicone grease. Be sure the O-ring is seated

in the groove.

• It is recommended that you replace the O-ring as needed or if it

becomes damaged.

• Place a new filter cartridge into the sump, making sure it is

centered and completely seated on the bottom seal.

• Reinstall the filter sump to the unit. Use the sump wrench to

tighten the sump. DO NOT OVERTIGHTEN.

• Slowly turn on water to the filter by using the upstream shut-off

valve or bypass.

• After installation, flush the cartridge for 10 minutes, wait one

hour, and then flush again for 10 minutes before using the water.

Water softeners work using a process called ion exchange.

Your water softener replaces harmful calcium and

magnesium ions with neutral sodium chloride / potassium

chloride ions. The mineral exchange takes place in one tank

as water passes over plastic beads coated with sodium

chloride / potassium chloride ions. A second tank (called a

brine tank) replenishes the sodium chloride / potassium

chloride as it is used up during the mineral exchange

process. Here's how to keep your water softener in top

shape:

• Inspect the sodium chloride / potassium chloride level in

the brine tank at least once a month. If your water softener

has recently been installed, check more frequently until you

can gauge how much sodium chloride / potassium chloride

your unit will require. Fill tank about ¾ full. Do not pack full.

Do not use block salt or block potassium chloride.

•Sodium chloride / potassium chloride in your water

softener's brine tank can form solid cakes that inhibit the

proper operation of the unit. As you inspect your brine tank,

look for large clumps of solidified sodium chloride /

potassium chloride. As a temporary measure, caked salt can

be broken up with a broom handle or other long, solid

object. Bridged salt will bridge again at a much faster rate

and should be removed as soon as possible.

• If iron is present in the water supply, the softener will

eventually become iron fouled, resulting in reduced

softening capacity and rust stained fixtures. Mixing one or

two ounces of Super Iron Out® or similar resin bed cleaner

with every 80 Ibs. of sodium chloride / potassium chloride

added to the brine compartment will minimize these

problems.

• Periodically check time setting. Power outages will cause

timer/meter setting to become incorrect. To reset, refer to

"Setting the Control Valve".

• Once a year, your brine tank should be drained, emptied

and cleaned with soap and water. The tank should be rinsed

well and refilled.

• Should your family size, your water usage habits or your

water quality change, the regeneration program setting may

have to be adjusted. Do not lower salt setting.

MAINTENANCE FOR WATER SOFTENERS

For assistance with installation and maintenance, contact Service/Technical Support at service@crystalquest.com or toll-free 1-800-934-0051.

MAINTENANCE

• Periodically check time setting. Power outages will cause time of day setting to become

incorrect. To reset, refer to "Programming Automatic Control Valve."

• Should your family size, your water usage habits or your water quality change, the

regeneration/backwashing program setting may have to be adjusted. Do not lower salt setting.

FILTER

CARTRIDGE

HEAD

O-RING SEAL

SUMP

15

TROUBLESHOOTING

PROBLEM CORRECTION WATER FILTER SYSTEM

No water flow

Media discharging during

backwash/regeneration

Mechanical, Automatic, Water

Softener or Nitrate and Tannin

Filter Systems

Mechanical, Automatic, Water

Softener or Nitrate and Tannin

Filter Systems

Mechanical, Automatic, Water

Softener or Nitrate and Tannin

Filter Systems

Water Softener or Nitrate and

Tannin Filter Systems

Water Softener or Nitrate and

Tannin Filter Systems

Water Softener or Nitrate and

Tannin Filter Systems

Water Softener or Nitrate and

Tannin Filter Systems

Water Softener or Nitrate and

Tannin Filter Systems

Water Softener or Nitrate and

Tannin Filter Systems

System does not

backwash/regenerate

properly or regularly

• Re-read the instructions to install the system properly.

• Check the in and out arrows on the bypass valve to ensure the

system is not piped backwards.

• Make sure the bypass valve is in the "Service" position.

• Make sure top distributor has been installed properly.

• Control valve not programmed properly. Check

programming and re-program as needed.

• Check the well float in the brine tank. The well float

should be able to move up and down, and the hose should

be able to inject water into the tank and siphon it out again.

Poor performace

(filtration/softening ability)

• Check the resin media level in the tank. System should be 2/3

full.

• Check sodium chloride / potassium chloride level in brine

tank. This should be 3/4 full.

• Check the frequency and period of backwashing.

System uses too much

sodium chloride/potassium

chloride and excessive

water in brine tank

• Brine draw not functioning. Clean injectors. Check and

reset sodium chloride / potassium chloride settings.

Softener fails to regenerate • Electricity to system has been interrupted.

• Check the power source and programming of control valve.

Iron build up in water

conditioner and loss of

water pressure

• Clean control and add resin cleaner. Increase regeneration

frequently.

• Check the pre- and post-filters for timely replacement.

• Clean control and add resin cleaner. Increase regeneration

frequently.

Put the system in bypass position and depressurize* the unit by

putting into “Backwash" position. There are 2 screws on neck of

valve where the salt rinse line goes into softener. Remove the 2

screws and clean screen to remove any chunks of salt, etc.

Injector or injector screen

plugged

Leak in distributor tube

After prolonged periods of non-use

(such as during a vacation), it is

recommended that the system be

flushed thoroughly.

1. First put the system in bypass by

turning the bypass valve to the

"BYPASS" position.

2. Let water run for 10-20 minutes by

opening all faucets to flush the pre- and

post-filters and all water supply lines.

3. Turn handle on bypass valve to

"SERVICE" position to backwash* the

system.

*To backwash or depressurize the

system, refer to "Programming

Automatic Control Valve" in manual.

To review the latest edition of the

Installation and Operation Guide, visit

www.crystalquest.com.

!

16

17

FREQUENTLY ASKED QUESTIONS

What is shocking a well, is it necessary, and how do I do it?

• ‘Shocking a well’ refers to disinfection by means of chlorine to rid bacteria and other contaminants from

a well. It is definitely suggested if there is iron or sulfur in the well, if it a newly constructed well or an old

well that hasn’t been disinfected in a while. There are 3 techniques that can be used to shock a well

depending on your preference.

• Chlorination Techniques for Well Water:

1) Shocking a well with bleach: This is the cheapest and quickest way to shock a well. For shallow wells

(40 ft. or less) add a ½ gallon of bleach. For deep wells (40 ft. and over) add a gallon of bleach.

2) Using chlorination tablets: Similar to adding bleach, only specifically made to put into wells. Sold

through Crystal Quest®. Please call 1-800-934-0051.

3) Chlorine Injection Systems: A separate device to be tied straight into the line and set to automatically

pump a certain amount of chlorine into the water each day. Sold through Crystal Quest®. Please call

1-800-934-0051.

When is the ideal time to change the pre- and post- filters?

• Between 12-18 months. Please visit CrystalQuest.com for replacement cartridges.

What salt is used in the brine tank, where do I buy it, and how much of it will be used?

• Sodium chloride or potassium chloride, which can be bought at your local hardware store. Because of the

high costs associated with shipping these solutions, it is best to buy locally.

• The brine tank should be filled up about ½ to ¾ of the way with the salt and topped off with water (just

above the salt level). The user should attempt to maintain the level of solution around the halfway point in

the brine tank. It will slow decrease over time. When it reaches around 1/3 or ¼ of the original salt level,

add more to the halfway point.

Will my whole house system affect water pressure?

• As long as the appropriate sized system was installed for the house-size and water demand, there should

be very little change, or none at all. If you think you may have purchased the wrong sized system, please

contact us at 1-800-934-0051.

How do I reset an automatic head?

• Refer to page 8 in the manual and re-do steps under “Programming Automatic Control Valve”.

How often do you need to backwash a manual system?

• Generally, once a week for 10 minutes. In some conditions, it can be adjusted based on water conditions.

How can you do a manual backwash with an automatic head?

1) Press the Regeneration button and hold until it says ‘BW’

2) It will automatically begin a 10 minute backwash

Can I change my valve head?

• A new valve head can always be purchased if you find yourself wanting a different functioning head.

Please call us 1-800-934-0051.

I'm having issues with my media working properly, what should I do?

The answer most likely is too high of water pressure, resulting in ineffective media because there is not

enough contact time. The prime fix is to slow down incoming water by installing a pressure regulator which

allows the water more contact time with the media, thus allowing the media to do its job more effectively.

The same fix is for customers with very high native pressure that need to bring it down to a constant 50-60

psi(recommended) in order to use our systems. 1” & ¾” Pressure Regulators are available for purchase

through Crystal Quest®. Please call 1-800-934-0051 to order. If water pressure is not the issue and your

media is failing due to old age (older than 5-10 years depending on water conditions and consumption),

please visit CrystalQuest.com or call to buy new replacement media.

What do some of the pop-up acronyms mean on my automatic valve head?

•[Parameter Display - Data Display] Brief explanation of what the setting

controls and recommendations for correctly setting it.

•[Parameter Display - ****] A setting that should not be shown if setup correctly.

If you are seeing this setting check to ensure other settings are set correctly.

•[TD - 11:08] Time of Day, tells the system what the current time is. To change the

time, press and hold the up OR down arrow until the service icon is replaced with

the programming icon. Use the up and down arrows to set the time of day (PM is

indicated in the upper right corner of the screen). Once the time is set, press the

extra cycle button or don't press anything for 5-10 seconds to return to normal

operation.

•[DO - 7] Day Override, this setting will cause the system to backwash after the set

number of days. Typically set no higher than 3 to ensure the media gets lifted and

cleaned off.

•[RT - 2:00] Regen Time, this is the time of day the system will backwash. This

process typically takes 30 minutes - 2 hours depending on system size, so schedule

it when water will not be used. It is common to set to run when everyone is asleep,

and ensure it does not conflict with any other systems you may have.

•[DF - GAL] Display format, shown settings is gallons. Liters [Ltr] and Cubic Meters

[Cu] are alternative settings, however, all instructions are written on the basis of the

[Gal] display format.

•[VT - dF1b] Valve type, set to the downflow single backwash setting shown.

•[CT - tc] Control Type, sets the opereration of the controller. Backwashing systems

use the time clock [tc] setting where backwash is based on time (days) passed.

•[NT --- 1] Number of tanks holding media for treatment.

•[BW - 10] Backwash, the length of time used for the backwash part of the cycle,

actual setting varies depending on system size.

•[BD-60] Brine Draw for 60 minutes. This means that salt will be pulled from the

brine tank to the system to regenerate. Regenerating with brine draw backwashes

the media and puts water back into the brine tank.

If you still did not find your solution here, please contact our Service Department at

[email protected] or 1-800-934-0051.

*For any specific chemistry related questions about your water and/or the media

used, please call one of our water specialists at 1-800-934-0051.

?

ONE YEAR LIMITED WARRANTY

CRYSTAL QUEST® warrants your CRYSTAL QUEST® Point of Entry Whole House Water Filter System* for one year from

the date of purchase against all defects in materials and workmanship when used in compliance with the manual. This

warranty does not include replacement cartridges unless defective upon receipt. CRYSTAL QUEST® disclaims all implied

warranties including, without limitation, warranties of merchantability and fitness for a particular purpose. If for any reason

the product proves to be defective within one year from the date of purchase, please call for assistance. This warranty gives

you specific legal rights and you may have other legal rights which vary from state to state. CRYSTAL QUEST® assumes no

responsibility for incidental or consequential damages, for damages arising out of misuse of the product, or the use of any

unauthorized attachment. Some states do not allow the exclusion or limitation of implied warranties or incidental or

consequential damages; therefore, the above limitations or exclusions may not apply to you. Should service be required

during or after the warranty period or should you have any questions regarding how to use your CRYSTAL QUEST® Point

of Entry Whole House Water Filter System, please contact our Technical Support Department at [email protected],

Monday through Friday, 9 AM to 5 PM Eastern Time.

*Warranty varies on components of the whole house water filter system. Contact your Crystal Quest® Dealer or

Email [email protected] for more information.

Installation and Maintenance

Instructions

KEEP THIS MANUAL FOR FUTURE

REFERENCE

AND UNIT MAINTENANCE

Online warranty registration

http://crystalquest.com/warranty.htm

PRODUCT DESIGN IS SUBJECT TO

CHANGE WITHOUT NOTICE.

For further assistance, contact your

Crystal Quest® Dealer or email us at

To review the latest edition of the Installation and Operation Guide, visit www.crystalquest.com.

ORDERING REPLACEMENT CARTRIDGES

To order replacement cartridges or replacement media,

contact your Crystal Quest® Dealer or visit us online at

http://www.crystalquest.com

YOUR PURCHASE INFORMATION

Please record the information below for your future reference

Plumber’s Name Plumber’s Address Plumber’s Telephone

18

2-7/8” x 20” Carbon Block

Filter Cartridge

12-18 months lifetime expectancy

2-7/8” x 20” Sediment Reusable Pleated

Filter Cartridge

12-18 months lifetime expectancy

2-7/8” x 20” UF Membrane

Filter Cartridge

18-36 months lifetime expectancy

2-7/8” x 20” SMART

Filter Cartridge

12-18 months lifetime expectancy

2-7/8” x 20” Fluoride

Filter Cartridge

12-18 months lifetime expectancy

2-7/8” x 20” Nitrate

Filter Cartridge

12-18 months lifetime expectancy

2-7/8” x 20” Arsenic

Filter Cartridge

12-18 months lifetime expectancy

(Optional cartridges for use with Compact Whole House Systems.

Refer to Compact Whole House Installation and Operation Guide

for more details.)

CQE-RC-04014

CQE-RC-04015

CQE-RC-04056

CQE-RC-04016

CQE-RC-04019

CQE-RC-04020

CQE-RC-04021

AUTHORIZED DISTRIBUTOR

19

Should service be required during or after the warranty period or

should you have any questions regarding how to use your

Commercial Water Purification System, please contact manufacturer’s

Technical Support Department Monday through Friday, 9 AM to 5 PM Eastern Time,

or your authorized CRYSTAL QUEST dealer:

Mailing Address:

FilterWater.com

P.O. Box 968

Southampton, PA 18966

USA

http://www.FilterWater.com

Tel. +1 (800) 439-0263

Fax +1 (215) 354-0304

Email: [email protected]

Table of contents

Other Crystal Quest Water Filtration System manuals

Crystal Quest

Crystal Quest 200 User manual

Crystal Quest

Crystal Quest 5600 Operating instructions

Crystal Quest

Crystal Quest 1,000 C Operating instructions

Crystal Quest

Crystal Quest CQE-PI-00601 Operating instructions

Crystal Quest

Crystal Quest Voyager Series Operating instructions

Crystal Quest

Crystal Quest Thunder Series User manual

Crystal Quest

Crystal Quest CQE-SP-00809 Operating instructions

Crystal Quest

Crystal Quest CQE-WH-01103 Operating instructions

Crystal Quest

Crystal Quest Mega 1000 Operating instructions

Crystal Quest

Crystal Quest CQE-WH-01101 Operating instructions