CS-Lab CSMIO/IP-A User manual

Hardware version: v2

Firmware version: v2.030

Rev: 1.1

© copyright 2015 – CS-Lab s.c.

INDEX

1. General......................................................................................................................................... 6

1.1 Signs used in this guide.................................................................................................................. 6

1.2 Content .......................................................................................................................................... 7

1.3 Standards compliance.................................................................................................................... 8

1.4 Specification .................................................................................................................................. 8

2. Safety........................................................................................................................................... 9

2.1 Example of direct E-Stop signal connection .................................................................................. 10

2.2 Example of E-Stop Signal connection using PILZ module.............................................................. 11

3. Recommendations for mechanical installation ................................................................................ 12

3.1 Examples of components arrangement in a control cabinet. ......................................................... 12

3.1.1 Block scheme pictorial view .............................................................................................. 12

3.1.2 Control cabinet made by CS-Lab Company......................................................................... 13

4. Connectors, controls and electrical installation of the device............................................................ 14

4.1 Connectors arrangement on the device......................................................................................... 14

4.2 Analog inputs/outputs connector.................................................................................................. 15

4.2.1 Signals on a Terminal Block connector .............................................................................. 16

4.2.2 Example – connection and configuration of FRO and SRO potentiometers........................... 17

4.3 Encoder inputs connector (0 / 1 / 2).............................................................................................. 18

4.3.1 Signals on a Terminal Block connector .............................................................................. 19

4.3.2 Example - connection of an encoder to Ch0 channel........................................................... 19

4.4 Encoder inputs connector (3 / 4 / 5).............................................................................................. 21

4.4.1 Signals on a terminal block connector ............................................................................... 21

4.5 Digital inputs connector (0-11) ..................................................................................................... 22

4.5.1 Input circuits construction ................................................................................................ 23

4.5.2 Signals on a terminal block connector ............................................................................... 23

4.5.3 Examples - input signals connection.................................................................................. 24

4.6 Digital inputs connector (12-23) ................................................................................................... 26

4.6.1 Signals on a terminal block connector ............................................................................... 26

4.7 Digital outputs connector (0-15) ................................................................................................... 27

4.7.1 Output circuits construction.............................................................................................. 28

4.7.2 Signals on a terminal block connector ............................................................................... 28

4.7.3 Example – spindle activation signal................................................................................... 29

4.8 Expansion modules connector...................................................................................................... 30

4.9 Power connector .......................................................................................................................... 31

4.10 Communication connector – Ethernet .......................................................................................... 31

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 2

4.11 Recommended cables................................................................................................................... 32

4.12 LED lights meaning....................................................................................................................... 33

4.12.1 Types and location of the LEDs.......................................................................................... 33

4.12.2 LEDs state description - STATx.......................................................................................... 34

4.13 Example - a scheme view of a 3-axis plotter (XYZ) ........................................................................ 35

4.13.1 Power supply.................................................................................................................... 35

4.13.2 Servo drives connection.................................................................................................... 36

4.13.3 Limit switches and E-STOP signal...................................................................................... 37

4.13.4 Inverter connection using analog output. ........................................................................... 38

4.13.5 Automatic control of drives power supply (HV)................................................................... 39

5. Recommendations and drives selection (motors drives)................................................................... 40

6. Precise homing with encoder INDEX signal ..................................................................................... 41

6.1 Homing on "index" enable ............................................................................................................. 41

7. LAN connection and configuration ................................................................................................. 42

7.1 Direct connection to the PC .......................................................................................................... 42

7.1.1 Windows®XP configuration ............................................................................................... 42

7.1.2 Windows®7 configuration................................................................................................. 43

7.2Local network with router and DHCP............................................................................................. 46

8. Mach3 program – general information ........................................................................................... 47

8.1 Recommended PC configuration................................................................................................... 49

9. Software installation.................................................................................................................... 50

9.1 Mach3 installation........................................................................................................................ 50

9.2 Microsoft®.Net installation (older operating systems).................................................................. 51

9.3 Installation of CSMIO/IP firmware................................................................................................. 51

9.4 Administrator rights in Windows® Vista and Windows® 7 ............................................................ 53

10.Mach3 program configuration ....................................................................................................... 54

10.1 Configuration profile creation ....................................................................................................... 54

10.2 The first run.................................................................................................................................. 55

10.3 Configuration of axes used in a machine....................................................................................... 57

10.4 Configuration of digital input signals ............................................................................................ 58

10.5 Configuration of digital output signals.......................................................................................... 60

10.6 Configuration of spindle and cooling............................................................................................. 62

10.6.1 Analog output configuration.............................................................................................. 62

10.6.2 Problematic PWM Control function.................................................................................... 63

10.7 Configuration of resolution, speed and acceleration...................................................................... 64

10.8 Configuration of directions, homing and software limits................................................................ 65

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 3

10.9 Configuration functions in a plug-in window ................................................................................. 67

10.9.1 Axes special functions...................................................................................................... 67

10.9.2 Spindle configuration........................................................................................................ 70

10.9.3 Override sources – feed speed and spindle revs corrections source selection...................... 71

10.9.4 Plasma – additional functions for plasma cutters .............................................................. 72

10.9.5 Misc IO – Special functions related to I/O .......................................................................... 72

10.9.6 Other – other plugin functions........................................................................................... 73

10.10Selection of inch/mm units........................................................................................................... 75

10.11Some parameters in the General Config window ........................................................................... 75

11.PID controller (regulator).............................................................................................................. 77

11.1 What is PID controller................................................................................................................... 77

11.2 PID controller terms (parameters) operation................................................................................. 78

11.2.1 The proportional term – P................................................................................................. 78

11.2.2 The integral term – I ......................................................................................................... 78

11.2.3 The Derivative term – D .................................................................................................... 79

11.2.4 The „sixth” sense – the mysterious KVFF parameter ............................................................ 79

11.3 The actual controller in CSMIO/IP-A.............................................................................................. 80

11.4 The order of controllers tuning...................................................................................................... 80

11.5 „PID Regulator Tuning” window..................................................................................................... 81

11.6 Manual PID regulator tuning procedure in CSMIO/IP-A.................................................................. 83

11.7 PID tuning – practical tips ............................................................................................................ 85

11.7.1 Slave axis......................................................................................................................... 85

11.7.2 An axis with toothed racks (straight toothed)..................................................................... 85

11.7.3 Laud noises at standstill ................................................................................................... 86

11.7.4 Cannot start tuning because an axis does not move. .......................................................... 86

11.7.5 An axis after activation jerks or starts to move with max. speed.......................................... 86

11.7.6 Cannot tune an axis .......................................................................................................... 86

11.8 Autotuning – Automatic PID tuning .............................................................................................. 87

12.First tests ................................................................................................................................... 89

12.1 Checking the input signals............................................................................................................ 89

12.2 Verification of axes scaling and motion directions........................................................................ 90

12.3 HOMING and software limit switches test..................................................................................... 91

12.3.1 First homing..................................................................................................................... 91

12.3.2 SoftLimit switches............................................................................................................ 91

12.4 Test of spindle and cooling........................................................................................................... 92

13.Sample treatment step by step...................................................................................................... 93

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 4

13.1 Project and G-Code files preparing................................................................................................ 93

13.2 Preparing machine and Mach3 program........................................................................................ 97

13.3 We begin the treatment ................................................................................................................ 99

14.A few practical notes about Mach3 program and CSMIO/IP-A ..........................................................101

15.VisualBasic® macros ...................................................................................................................104

15.1 Automatic tool-length measurement........................................................................................... 104

15.1.1 Configuration ................................................................................................................. 105

15.2 Automatic tool change macro..................................................................................................... 106

Addition A – Slave axis configuration example....................................................................................107

Defining axes used in Mach3 program ................................................................................................. 107

Axis scaling and configuration............................................................................................................. 107

Activation and choice of slave axis....................................................................................................... 107

LIMIT and HOMING switches................................................................................................................ 108

Axis direction settings ......................................................................................................................... 108

Manual feed test.................................................................................................................................. 108

Automatic reading of HOME switches position difference .................................................................... 108

Geometry correction mode activation .................................................................................................. 109

Addition B – –CSMIO/IP-A firmware update .......................................................................................110

How to check your current firmware version ........................................................................................ 110

Update application (uploader).............................................................................................................. 110

Plugin file update................................................................................................................................. 111

Update verification .............................................................................................................................. 111

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 5

1. General

The CSMIO/IP-A product was designed for professional customers, who want to equip their machine tool

with an efficient, stable and flexible CNC control system for a reasonable price.

The main designing assumption was working stability – hence the PC connection via Ethernet (its physical

layer is galvanically isolated and protocols we use ensure reliable and fast transmission even in tough

industrial environment). Practically any others interfaces do not provide the continuity and reliability of

transmission on such a high level as the ETHERNET. That is why it is currently the worldwide standard for

high-speed digital communication.

Another important assumption was simplicity of installation. CSMIO/IP-A does not require any external

electronics for proper operation. Inputs/outputs signals are inside optically isolated, filtered, protected

against short circuit, overheating etc. Of course, all I/O signals are adjusted to industry standard 24V. The

device is enclosed in a compact cover, mounted on a DIN-rail, what makes that mechanical and electronic

installation in a control cabinet takes less time and is even simpler.

CSMIO/IP-A product works with Mach3 program because of its low price, popularity and enormous ability

to adapt to specific requirements. To meet customers' needs, who prefer +/- 10V servo drive control

standard, the CSMIO/IP-A was equipped in such an interface, and very fast encoder inputs allow for taking

full advantage of encoders with large number of pulses per rotation, and the same let you to achieve such

a precision and speed, which previously were unavailable in this price sector.

1.1 Signs used in this guide

________________________________________________________________________________________________________

Potential danger, possible injury risk

________________________________________________________________________________________________________

Useful information, tips

________________________________________________________________________________________________________

Warning, failure to comply with these warnings may lead to inappropriate functioning or damage of

the device

________________________________________________________________________________________________________

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 6

1.2 Content

The CSMIO/IP-A device is placed in a cartoon box with DB->Terminal Block adapters for easier wires con-

nection in a control cabinet. More content details below:

•CSMIO/IP-A - CNC controller

•3x DB25Terminal block (2 pcs.)

•Ethernet connection wire

•DB25 connection tape (6 pcs.)

•„Phoenix” 3pin power plug

•CD with electronic version of the user guide and software

(always check if there is a newer version on http://www.cs-lab.eu )

In case of lack of any elements listed above, please contact your distributor.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 7

1.3 Standards compliance

The CSMIO/IP-A controllers were designed and made in accordance with the national and international

standards for industrial control systems based on electronic components:

•Detailed requirements for programmable controllers: working characteristics, shock resistance,

safety etc. EN61131-2 (IEC1131-2), CSA 22.2, UL508

•Compliance with European Guidelines (low voltage, level of electromagnetic interference

Electromagnetic Compatibility), the CE marking.

•Electrical and non-combustible properties of insulation materials: UL 746C, UL 94, etc.

•The Product made in lead-free technology, RoHS compliant.

1.4 Specification

Parameter

Value

Digital inputs number

24

Digital outputs number

16

Analog inputs number

4

Analog 0-10V outputs number

2

Analog +/-10V outputs number

6

Encoder inputs number

6

Supply voltage

24VDC +/-10%

Power consumption

5W

Maximum voltage on the in/out lines

30VDC

Maximum load of an output line

250mA

A voltage range of analog inputs

0-10VDC

Maximal load of analog outputs

50mA

Axis drives control type

Analog +/-10V

Maximum frequency of an encoder signal

6MHz

Encoder type

Incremental TTL

Encoder signal kind

Differential

PC connection

Ethernet 10/100Mb

Ambient temperature range

0oC do +60oC

Relative humidity

10% to 95%

(without condensation)

„KernelSpeed” a configuration parameter in Mach3 has no influence on CSMIO/IP working speed.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 8

2. Safety

CSMIO / IP-A device is powered by 24V safe voltage. I/O control lines are optically isolated also PC con-

nection is galvanically isolated. The device does not constitute direct threat to health and life of a user.

Designing a complete control system (control cabinet), you should draw attention to several issues, so

that the entire system does not pose any hazard during use.

Always use NC contacts (Normal Closed) for limit switches and safety switch. Thanks to it - a wiring mis-

take or i.e. plug-ins disconnection will stop the machine.

Pay special attention to an emergency stop circuit. Control system must be designed in such a way that

when you press an emergency stop mushroom, controlled machine stops immediately in all axes. You

should also take into account the possibility of failure of particular system components such as main

controller, or axis drives.

For that purpose you can use (not required) a standard safety relay (i.e. from PILZ Company). The safety

switch mushroom, FAULT signals of drives and inverter and eventually other alarm signals – you should

connect to input circuits. Output or outputs - depending on a used module - should be connected to

CSMIO/IP-A controller, and defined as emergency stop. Outputs of security module should be also

connected to axis drives, inverters, etc. This way we get double protection – if, by inappropriate

configuration or CSMIO/IP-A controller failure - the emergency would not work, then information goes to

axis drives, which can properly respond to it. It works both sides: if drives would not react, you always

have the controller.

The CSMIO/IP-A controller in active state on the input line - defined as an E-Stop stops the motion on all

output channels within 1ms.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 9

2.1 Example of direct E-Stop signal connection

In example above we used direct emergency signals connection. Such a connection is very easy and at the

same time it ensures satisfying safety level. Of course the easiest way is to connect the E-Stop only to

CSMIO/IP-A but then we lose double protection and it’s no longer so safe solution.

As a switch (mushroom) of emergency stop always use special switchers, specially designed for that. They

have different construction and you can be actually 100% sure that the circuit will be disconnected after

pressing the mushroom. Using common NC contacts is dangerous. It’s worth to use contacts from repu-

table companies. They are a little bit more expensive but their quality is much, much better.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 10

2.2 Example of E-Stop Signal connection using PILZ module

Above you can see an example of E-Stop signal connection to the CSMIO/IP-A controller and to the axis

drives, using Pilz company safety relay (PNOZ X7 24V symbol). S1 is a reset button (switching on the safe-

ty relay), S2 is the emergency stop.

This module has one input, and due to it, all the alarm sources are connected to this input (A1). In addition

to the mentioned emergency stop (S2) there are NC contacts - NC1 and NC2, which may be, e.g. opening

sensors for a cover and a control cabinet. Moreover, there are drives FAULT signals connected in series.

Two outputs of the safety relay were used as the E-Stop signal for the CSMIO/IP-A controller and axis

drives.

This combination assures that machine stops in case of failure on any axis (FAULT signals of the drives),

by pressing the emergency stop mushroom and opening the cabinet or the cover. Separation of the safety

relay output channels gives double protection to a system and significantly increases reliability of the

entire system.

PILZ

PNOZ X7 24 V

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 11

3. Recommendations for mechanical installation

CSMIO/IP-A controller and DB->Terminal block connection modules were designed to be installed on a

standard DIN-rail. It’s the quickest and the best way of installation.

The controller uses a small amount of electricity and creates a negligible amount of heat. Aluminum

housing provides adequate cooling for electronics inside, even if an ambient temperature reaches 40OC.

As for the controller, there are no special precautions for ventilation and minimum distances. However,

usually, next to the controller in a control cabinet, there are also inverters, power supplies, motor drives -

these components emit a lot of heat, so you should always remember about their proper location and

proper ventilation of the cabinet.

3.1 Examples of components arrangement in a control cabinet.

3.1.1 Block scheme pictorial view

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 12

3.1.2 Control cabinet made by CS-Lab Company

Caution is advised during mechanical and electrical installation. Poorly tightened cable may cause many

problems it’s also very difficult to find such a defect while launching/using the system.

In the picture above there is also CSMIO/IP-S controller placed (right side). It is a picture of the control

cabinet we use for testing new firmware versions. The wiring is doubled so we can easily switch between

CSMIO/IP-A and IP-S models.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 13

4. Connectors, controls and electrical installation of the device

4.1 Connectors arrangement on the device

Detail description of signals on each connector is placed in the next sections.

DB->Terminal block connectors have the same pin numbers as DB connectors in CSMIO/IP-A device.

In example: 15 pin of DB25 connector match with the 15 pin on the terminal block.

Analog I/Os

Encoders signals

(axes 3 / 4 / 5)

Encoders inputs

(axes 0 / 1 / 2)

Expansion modules

connector

Power connector

Digital inputs 0-11

Digital inputs 12-23

Communication con-

nector (ETHERNET)

Digital outputs 0-15

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 14

4.2 Analog inputs/outputs connector

Axes by default are assigned to following channels: XCh0 / YCh1 / ZCh2 … CCh5. It can be

changed in plugin's configuration.

PIN number

Description

1

Analog output Ch0 (+/-10V)

2

Analog output Ch1 (+/-10V)

3

Analog output Ch2 (+/-10V)

4

Analog output Ch3 (+/-10V)

5

Analog output Ch4 (+/-10V)

6

Analog output Ch5 (+/-10V)

7

Analog output 0 (0-10V)

8

Analog output 1 (0-10V)

9

Analog input 0

10

Analog input 1

11

Analog input 2

12

Analog input 3

13

10V (max. 50mA)

14

GNDCh0

15

GNDCh1

16

GNDCh2

17

GNDCh3

18

GNDCh4

19

GNDCh5

20

GND

21

GND

22

GND

23

GND

24

GND

25

GND

Pay attention to not exceed the

permissable 10V voltage on the analog

inputs. It may cause damage of the de-

vice.

Analog outputs for servo drives (Ch0,

Ch1, Ch2, Ch3, Ch4, Ch5) always connect

with dedicated GND (GND Ch0, GND

Ch1…). Otherwise a servo drive will not

work properly.

Pay attention to not overload 10V volt-

age output. Its permissable load is 50mA.

Connecting the analog signal to a plasma generator you should remember that it should be

galvanically isolated signal.

The connection with use of a simply voltage divider does not protect against surges and may

cause damage of the controller.

There is 50mA max. permissable load on

analog outputs. Exceeding this value may

damage the output circuits.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 15

4.2.1 Signals on a Terminal Block connector

Axes by default are assigned to following channels:

XCh0 / YCh1 / etc.

Pin numbers Entered in Mach3 program in

Port&Pins” on „Motor Outputs” tab do not matter.

If you want to assign other STEP/DIR channels

numbers to an axis you should do it in the plugin's

configuration: menu „ConfigConfig

PlugInsCONFIG”.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 16

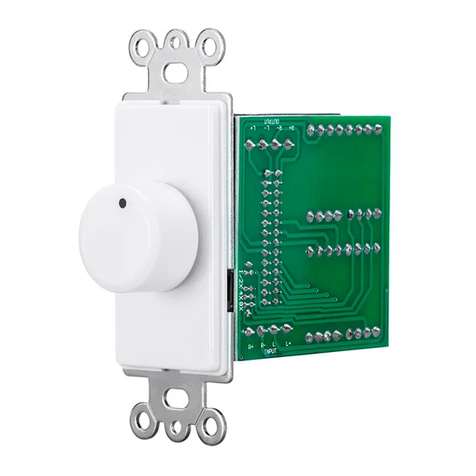

4.2.2 Example – connection and configuration of FRO and SRO potentiometers

Below you can see example of connection and configuration of potentiometers for feed rate correction

and spindle revs regulation.

As you can see in the scheme, 10V placed on the analog con-

nector is very convenient and useful - thanks to it we do not

need any external power supply for the potentiometers. The

Potentiometer 1was connected to the analog input no. 0, and

potentiometer 2 to analog input no 1. After the connection you

can check it by viewing analog inputs in the diagnostic window

– menu „PlugIn ControlCSMIO_IP plugin”, „Analog IO” tab.

If values on the analog inputs change with the position of the potentiometers' knobs, then only what left is

to configure the plugin. Open configuration window–

menu „ConfigConfigPlugInsCONFIG”. Choose

„OverrideSrc.”.

Select „CSMIO-IP AIN 0” for „Feedrateoverride” – so for

feed rate regulation we use POT.1 potentiometer.

For „Spindlespeedoverride” select „CSMIO-IP AIN 1”, so

for spindle revs regulation we use POT.2 potentiometer.

At the end click „Save” to keep this settings.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 17

4.3 Encoder inputs connector (0 / 1 / 2)

Oz

Axes by default are assigned to the following channels: XCh0 / YCh1 / ZCh2 … CCh5. It can be

changed in plugin configuration.

While "A, B" signals signage is quite standard, the "I" index signal is signed by encoder manufacturers in

different ways: "Z, C, … etc."

PIN number

Description

1

Enc. Ch0 A+

2

Enc. Ch0 B+

3

Enc. Ch0 I+

4

+5V

5

Enc. Ch1 A+

6

Enc. Ch1 B+

7

Enc. Ch1 I+

8

+5V

9

Enc. Ch2 A+

10

Enc. Ch2 B+

11

Enc. Ch2 I+

12

+5V

13

GND

14

Enc. Ch0 A-

15

Enc. Ch0 B-

16

Enc. Ch0 I-

17

GND

18

Enc. Ch1 A-

19

Enc. Ch1 B-

20

Enc. Ch1 I-

21

GND

22

Enc. Ch2 A-

23

Enc. Ch2 B-

24

Enc. Ch2 I-

25

GND

Pay attention to not exceed the per-

missible voltage (5VDC) on the input

lines.

The encoder inputs of CSMIO/IP-A

require differential signal. If connect-

ed encoder has a common output

then you should use special convert-

er. Connection of A-, B-, I- to GND

causes axis position will be distorted.

Max. PINs load is +5Vto 200mA / pin.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 18

4.3.1 Signals on a Terminal Block connector

4.3.2 Example - connection of an encoder to Ch0 channel

As you can see below, although an encoder requires many wires, the rule is easy and the connection is not

that hard. However the connection should be done carefully to avoid any unpleasant surprises later.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 19

In the example above there is a situation where to encoder input there is a motor encoder connected di-

rectly. In case we use AC servo drives - to encoder input of CSMIO/IP-A you should connect encoder out-

put of a servo amplifier. So connection for AC servo looks as following:

[Motor encoder][servo amplifier (input)]

[servo amplifier(output)][CSMIO/IP-A controller]

Encoder cable shielding should be connected as close to CSMIO/IP controller and should be connected

only in one point.

"Cables" colors on the scheme above are random so please do not be influenced by that.

Please note so the signals connection is made using twisted-type cable and also to not mix the signals in

cable pairs, so to not connect e.g. A+, B- signals etc. in one pair. It cause irregularities in a machine work -

also later it may be difficult to find a reason of the problems.

CS-Lab s.c. –CSMIO/IP- A - CNC controller

Page 20

Other manuals for CSMIO/IP-A

1

Table of contents

Other CS-Lab Controllers manuals

Popular Controllers manuals by other brands

Johnson Controls

Johnson Controls VA-7010 Series Product/Technical Bulletin

Mitsubishi

Mitsubishi MELSEC iQ-F FX5 series user manual

SkyAzúl

SkyAzúl qSCALE maestro Service manual

Mitsubishi Electric

Mitsubishi Electric MELSEC-F FX-16E-TB user guide

Emerson

Emerson RSTi-EP CPE200 Series quick start guide

HUST CNC

HUST CNC H6D-T manual

Monoprice

Monoprice 38171 Quick install guide

Sunricher

Sunricher SR-2400P quick start guide

Honeywell

Honeywell 7800 SERIES RM7895A installation instructions

Termal

Termal Hokkaido XRV Mobile BMS Installation & user manual

Rockwell Automation

Rockwell Automation Allen-Bradley Logix 5000 Series Programming manual

RMG

RMG DFAWLC-044 installation manual