CS Unitec 5 1217 0020 User manual

Translation of the original manual,

compiled: 20.04.16

512170020_BA_en_Version_CSU_07.doc

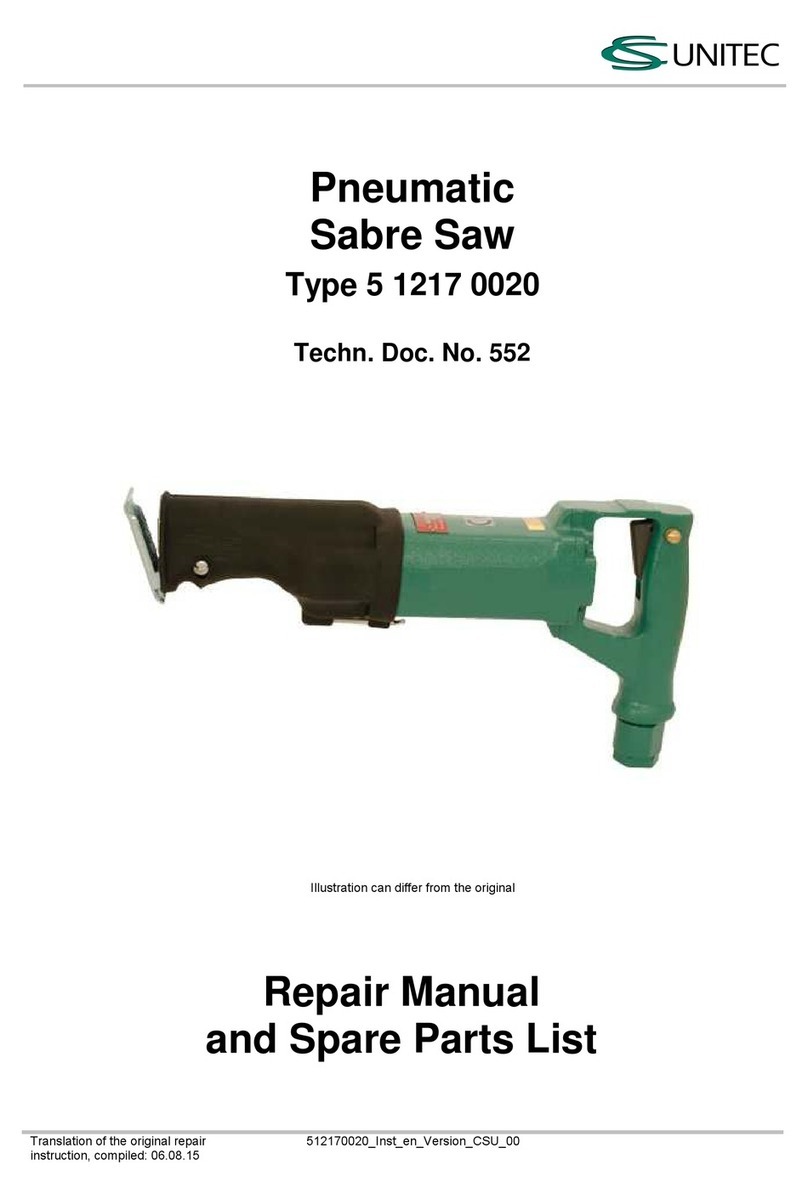

Pneumatic Sabre Saw

Type 5 1217 0020

ATEX Tool

Illustration can differ from the original

Translation of the original manual,

compiled: 06.02.23; from serial no. 231016

Techn. Doc. No. 552

Operation

and Maintenance Manual

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 1 of 18

Directory

Page

Signal Word and Symbol Definition

2

Technical Specification

3

Use

3

Product Description

4

Accessories

4

Identification

5

Installation

6

Startup

7-8

Explanation of Symbols for Protective Equipment and for Accident Prevention

9

Basic Safety Instructions

9

Employer‘s Obligations

10

Operator‘s Obligations

10

Safety Instructions for avoiding Safety Hazards

11-14

Service and Maintenance

15

Disassembly –Re-assembly

16

Storage

16

Disposal

16

Environmental Regulations

16

Troubleshooting

17

Warranty and Liability

17

Scope of delivery

17

Declaration of Conformity

18

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 2 of 18

Signal Word and Symbol Definition

The signal words and symbols used in the technical documentation (safety instructions, operating booklet,

etc.) have the following meaning:

WARNING –Read the operation and maintenance manual

It is imperative to familiarize with this operation and maintenance manual and its safety

instructions before starting your SPITZNAS machine. Stick to the operating processes and

avoid accidents due to improper use of the machine.

This symbol has

the following

meaning:

DANGER –Indicates an immediate danger, which causes serious injuries to any person

or even death, if not avoided.

WARNING –Indicates a threatening danger, which can cause serious injuries to any

person or even death, if not avoided.

CAUTION –Indicates a danger or unsafe procedure which can cause injuries to any

person or material damages, if not avoided.

NOTICE –Indicates a potentially dangerous situation which can cause damage to the

product or its surroundings, if not avoided.

WARNING –explosive atmosphere

Air and flammable substances can mix and result in an explosive atmosphere. In areas

exposed to explosion hazards, supplementary instructions and directives apply. Observe

the safety instructions of the employer as well.

WARNING –explosive material

Caution should be exercised when working with explosive material or in its surrounding

area.

PROHIBITION –No naked flame, fire, or ignition source and no smoking

Prevent from fire and explosion hazards, which can be caused by naked flame, open

ignition source or by smoking.

Eating and drinking forbidden –The prohibition sign forbids the consumption of food.

This symbol has

the following

meaning:

NOTICE –Gives recommendations and important hints for handling the product

IMPORTANT –Indicates application advice and other particularly useful information.

REMARK:

In each case the used symbol does not replace the safety text. The text must always be read fully. In some

cases other symbols will be used with the signal words.

WARNING

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 3 of 18

Technical Specification

Operating pressure

6 bar

Power

1.25 kW

Number of strokes (free speed)

2300 1/min

Stroke of saw blade

28 mm

Air consumption

1.45 m³/min

Air connection

½”- 14 NPT female

Weight approx.

4.5 kg

Sound pressure level LpA(1)

101 dB (A)

Sound power level LWA

112 dB (A)

Vibration (2)

Cutting of chipboard

Cutting of wooden beams

15.3 m/s²

19.3 m/s2

ATEX Classification

II 2G Ex h IIB T5 Gb

(1) Remark: Measurement acc. to DIN EN ISO 15744

(2) Remark: Measurement acc. to DIN EN ISO 28927-8

Measurement uncertainty K: 3 dB (A)

Measurement uncertainty K: 1.5 m/s2

The performance specifications are guide values only, they depend basically on the application, the

working pressure and the accessories used.

Intended Use

SPITZNAS machines are designed for industrial use only.

Only trained, skilled personnel are allowed to operate the machine. The pneumatic sabre saw is designed for

cutting pipes and profiles made of:

metal, plastic, fibre glass, hard rubber, wood, etc.,

for the special application areas:

old building renovation,

fitting of sanitation/pipe repair,

car body building,

pipe construction,

in all areas difficult to reach and in areas exposed to explosion hazards.

Improper Use

Any use deviating from the intended use as described is considered to be improper use.

Working without personal protection equipment.

Using the machine in an inadmissable area.

Cutting self-flammable material.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 4 of 18

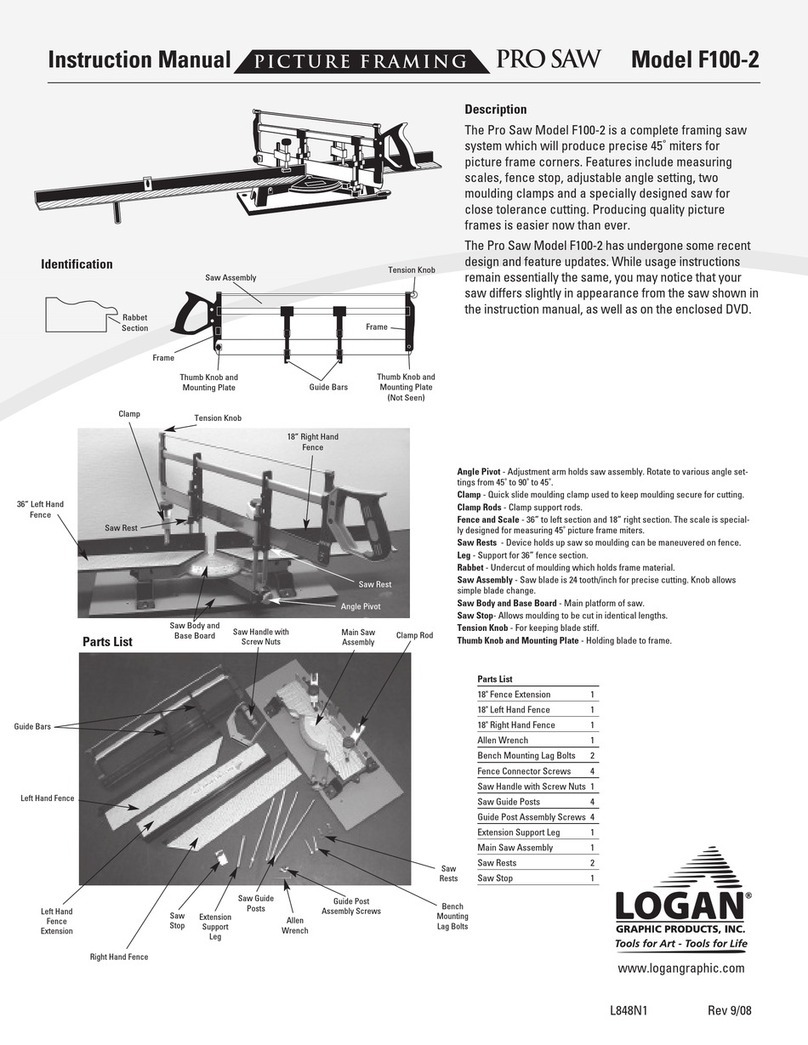

Product Description

Fig. 1

1 Release button

2 Valve trigger

3 Air connection

4 Pneumatic motor

5 Saw blade

6 Support shoe

7 Gear head

8 Sound absorber

9 Holder for clamp

10 Quick clamp

Accessories

Overview: Saw blades:

Order no.

Length

in mm

Tooth pitch

in mm

Application and materials, etc.

9 2505 0020

280

2.5

Wood with nails, steel, non-ferrous metal, alu up to 5.0 mm,

plastics, stainless steel

9 2505 0040

280

4.0

Wood, plastics, fast and rough cuts

9 2505 0060

100

0.7

high-strength steel, non-ferrous metal, alu up to 1.5 mm, steel

plates up to 5.0 mm

9 2505 0080

150

1.2

Non-ferrous metal, alu up to 3.0 mm, pipes and profiles from 1.5

mm

9 2505 0100

150

2.5

Wood with nails, steel, non-ferrous metal, alu up to 5.0 mm,

plastics, stainless steel

Overview: Clamps

Order no.

Description

5 1217 9500

Clamp up to 100 mm for rectangular cuts

5 1217 9910

Clamp for pipes up to 150 mm diameter

5 6035 9400

Clamp for pipes up to 200 mm diameter

2

6

5

3

8

4

1

9

7

10

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 5 of 18

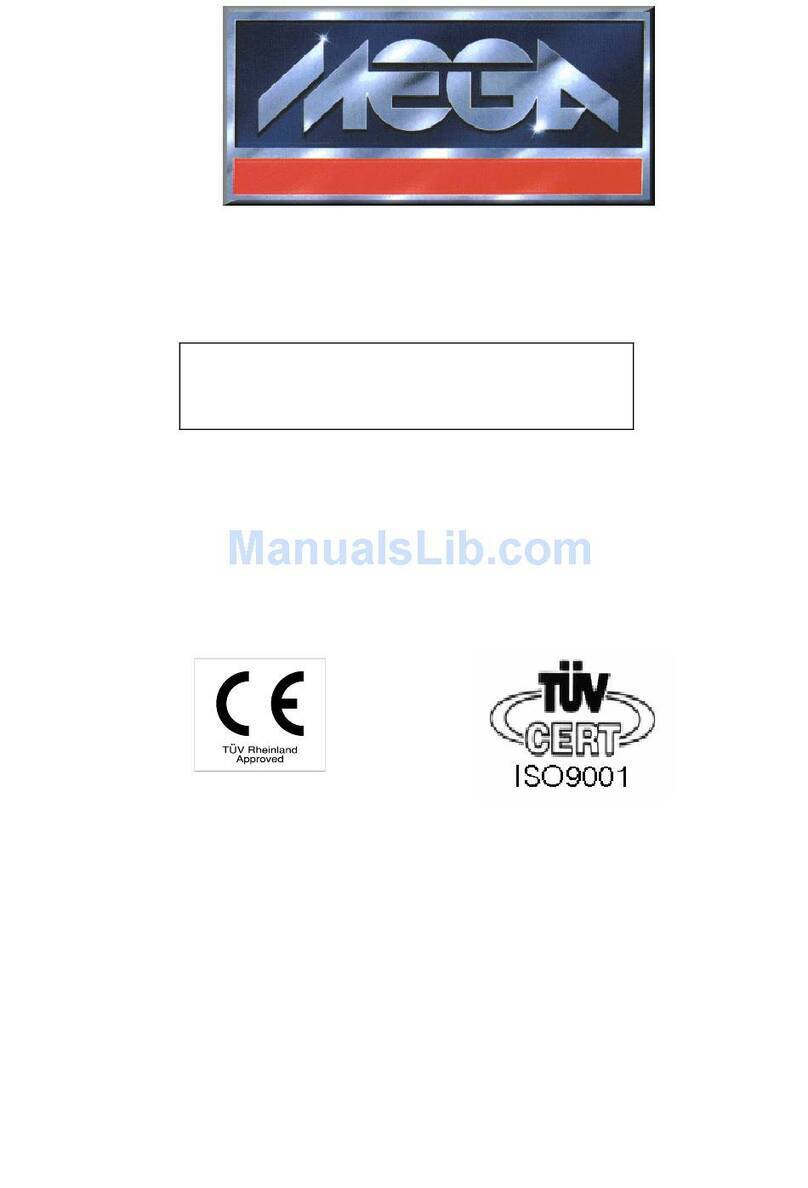

Identification

Type sign Explanation of ATEX Identification

CE specification

Specification

acc. to 2014/34/EU

Address

Technical specification

ATEX Identification

Serial number (1. and 2. figure BJ = refer to

the year of manufacture/ following figures

Sr = refer to the series)

Type description

Company name

Machine group II

Explosive atmospheres

e. g. Industry

Category 2

Very high level of safety

High level of safety

Normal level of safety

1

2

3

Ex-Atmosphere G

Gas, vapor and mist

Marking according to

standard - Ex-Symbol

Ignition protection category h

Code letter h for all

non-electrical equipment

Explosion group IIB

e.g. Methane, Propane

e.g. Ethylene, Town gas

e.g. Hydrogene, Acethylene

IIA

IIB

IIC

Temperature class T

Surface limit temperature

450°C

300°C

200°C

135°C

100°C

85°C

T1

T2

T3

T4

T5

T6

Equipment Protection Level

Group II EPL Gb

Category 2 (usable in category 3 as well) Explosion group IIB usable in explosion group IIA as well.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 6 of 18

Installation

Requirements to the air supply

The pneumatic sabre saw works optimally at an operating pressure of 6 bar, measured at the air inlet.

The distance from the air supply to the machine has to be adjusted to the application conditions on site.

We recommend installing an oiler or a maintenance unit upstream the machine for compressed air

preparation. Use acid and resin-free lubricating oil, like SAE 5W - SAE 10W, for proper functioning of the

pneumatic sabre saw. Attention! Do not use viscous oil.

Use an antifreeze lubricant, e.g.:

“Kilfrost”

or “Kompranol N74” in winter and if the compressed air is very moist.

The supplied compressed air has to be free of:

Foreign particles,

humidity.

Pay attention that all hoses:

Have a cross section being large enough,

do not have any restrictions or buckles,

are designed for a minimum operating pressure of 6 bar,

are replaced regularly at preventative maintenance,

have an oil resistant inner surface and an abrasion-resistant outer surface,

are proved and specified to be non-conductive when being used next to electric conductors.

When operating the machine in areas exposed to explosion hazards, always use antistatic hoses, lubricating

oil and antifreeze lubricants, which meet the local safety requirements.

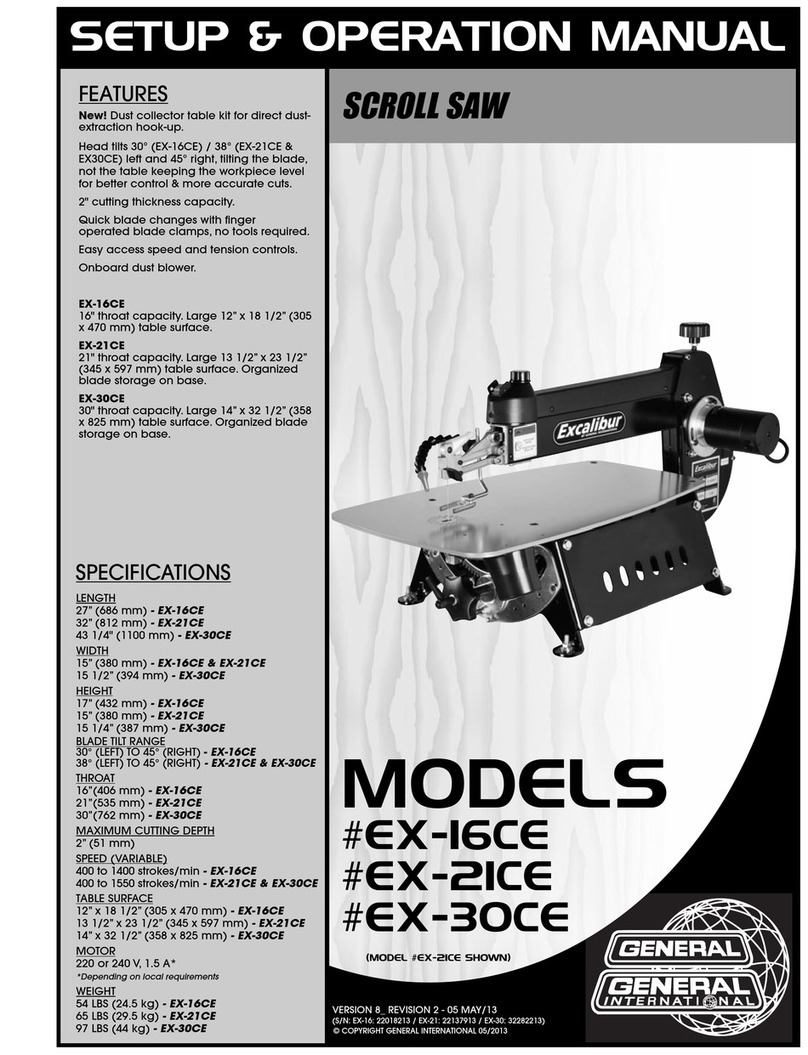

Connecting the air supply to the pneumatic sabre saw

Remove the locking cap from the air connection 3 (see fig. 2). Connect the pneumatic hose (not contained in

the scope of delivery).

Air inlet

Fig. 2

Exhaust (sound absorber)

3

8

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 7 of 18

Startup

The size of the saw blade depend on the material of the work piece (refer to accessories on page 17).

During cutting, the saw blade has to be cooled, respectively lubricated, with water, drilling emulsion, oil or

cutting paste.

Mounting the saw blade

WARNING –Disconnect the machine from pneumatic supply before mounting the saw blade.

Observe the following for mounting the required saw blade to the saw:

Turn (see fig. 3).

Insert the saw blade to its stop.

Release (see fig. 4).

Fig. 3 Fig. 4

Do not lubricate the blade clamp.

Important–Before cutting an assembly, make sure that no electric lines of this

assembly are damaged or cut. If they are energized, there is danger to life due to

electrocution.

Cutting

Follow all safety precautions.

Install the correct saw blade, see „Mounting the saw blade”.

Connect the machine to the air supply (blow out the hose before connecting).

Actuate the air supply.

Actuate the valve (ref. to fig. 5).

Start cutting.

Cool sufficiently the saw blade.

Useful tips: refer to fig.6

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 8 of 18

Steel wire

Profile

Plunge cutting

Start and stop

Use of sticky tape

Use of wedge

with without

Press or release

prevents from

splicing

prevents from

pinching

Fig. 5

Fig. 6

Fig. 7

Plunge cutting

The sabre saw can also be used for plunge cutting:

Wood, plywood, wall boards and plastic material.

Mark clearly line of cut on the work piece.

Place the tip of the saw blade on the cutting point, while resting the saw on the lower edge of the

support shoe.

Start the saw and plunge the saw blade in the material while cutting carefully (see fig. 7).

Press the support shoe against the material to be cut.

Notice: Do not use plunge cutting for metal sheet.

Sawing metal

When cutting angle iron, H-beam, I-beam, tubes, pipes etc., start the cut on the surface where the greatest

number of teeth will contact the work.

Useful tips: Select thoroughly the length of the saw blade (see fig. 8 and 9).

(Length of blade (free hand cutting) = max. section + 30 mm.)

Fig. 8 Fig. 9

Procedure for handheld cutting

For straight or curved cutting, place the support shoe on the work piece and start the saw.

Use only sharp and faultless blades. Take care to cut at a uniform feeding speed. This will reduce the risk of

accidents and wear on blade and saw. Always keep the connecting line (air hose) towards the rear of the saw.

After finishing the sawing work

Shut valve.

Shut compressed air supply and disconnect air hose.

Clean saw.

Inspect machine for damages.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 9 of 18

Explanation of Symbols for Protective Equipment and for Accident Prevention

Ensure that the operator is familiar with the symbols for accident prevention and that he sticks to the

following safety instructions, in order to avoid accidents.

Use protective clothes –Protective clothes are necessary for diverse applications, e.g.

protection against chemicals, heat and cold. Provide appropriate protective clothes to your

staff and identify this requirement by convincing signage.

Use head protection –Keep staff and visitors from head injury. Provide enough safety

helmets and identify the obligation for using safety helmets by appropriate mandatory signs.

Use eye protection –whether goggles, laser safety goggles or etc. –

identify areas where eye protection has to be used, by appropriate mandatory signs.

Use ear protection –Capsule hearing protectors or hearing protectors have to be used for ear

protection, depending on the sound intensity at the work place. Provide appropriate ear

protection and identify the obligation for using ear protection by appropriate mandatory signs.

Use foot protection –Foot injuries by vehicles, objects, hot material or hazardous

substances can be avoided by appropriate protective shoes. Equip your staff with

appropriate protective shoes and identify those requirements properly.

Use hand protection –Identify convincingly the safety requirement „Use hand protection“

by a gloves sign, respectively a gloves symbol.

Use respiratory protection –Ensure that the specified protection equipment is available

and that it is used. Identify by mandatory signs, where and when respiratory masks are

required.

Basic Safety Instructions

NOTICE –Before working on or with the tool, read the safety instructions and follow the

instructions during operation.

Do not modify the machine or the machine tools and accessories after receipt. Any constructive changes or

modifications need the manufacturer`s acceptance and have to be in compliance with the safety

instructions. Use the machine only for its determination.

Consider the technical data of the equipment and the ambient temperatures. Pay attention to labels,

restrictions of use and special instruction notes on the machine tools and the machine itself.

Check regularly that the type plate and symbols on the machine are legible.

If necessary, contact the manufacturer to replace them.

Only operators with technical knowledge, trained by authorized responsible technical personnel, may

install, start, operate, maintain and repair, transport, disassemble and re-assemble, store and dispose of

the machine.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 10 of 18

Employer’s Obligations

Generally, the employer is responsible for the faultless condition/operation of the machine and the

adherence to the safety regulations.

The machine is designed and manufactured in accordance with state-of-the-art technology and the

recognized safety rules and regulations.

However, using it, there is still a risk of accidents to the operator or third parties or damage to the machine or

other objects.

All current regulations and specifications, which apply to the site of operation in regards to accident

prevention, installation of electrical and mechanical systems as well as radio interference must be

considered.

IMPORTANT - The employer must make sure that…

risk assessment is carried out for the specific risks, which can occur due to any operation of the machine,

the function of the safety equipment is regularly checked,

the safety symbols and safety notes on the machine/ device and the operating instruction booklet are

considered,

the safety instructions and the operating instruction booklet are available completely and in legible

condition on site with the machine.

The employer is obliged to allow personnel to work on the machine only, who:

Are familiar with the basic work environment safety rules and accident preventing regulations. Also,

those persons must have been instructed in the correct use of the machine,

have read and understood the safety and warning notes in the operating instruction booklet as well as all

the other documentation pertaining to the machine,

have been tested at regular intervals in regards to their safety-conscious operation.

Safety-conscious working

Additionally to the safety instructions in this manual and the intended use, the following safety regulations

have to be considered:

Accident prevention instructions, safety and operation regulations,

explosion protection directives,

safety regulations for the operation with hazardous material,

effective norms and laws.

Operator’s Obligations

All persons who are assigned to work with the machine are obligated to:

Pay always attention to the basic safety and accident preventing regulations,

read always and follow the safety and warning notes in the operating instruction booklet.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 11 of 18

Safety Instructions for Prevention of Workplace Hazards

WARNING –The following applies unless otherwise stated in the machine’s operating

instructions booklet:

The machine is not insulated to protect against an electrical power surge.

CAUTION –risk of injury!

Hands may be crushed, seized or otherwise injured. Keep your hands away from areas which

are marked with

this symbol.

CAUTION –risk of injury!

Remove all sources of danger which could lead to slipping, tripping or falling (e.g. slippery

surface, hoses, cables). Keep the work area clean and tidy.

PROHIBITION –Eating, drinking and smoking are forbidden during operation.

WARNING –Explosion hazard!

Operate the machine only according to the intended use. The machine is designed for the use

in areas exposed to explosion hazards as well. The generation of heat and –eventually- sparks

is characteristic for cutting. Therefore cool continuously.

Consider the following:

Valid local explosion protection directives.

Technical specification of the machine.

Markings on the machine.

Avoid the generation of sparks.

When operating the machine, do not push or beat against other material and hold the

machine firmly and safely by hand, respectively fix it in a clamping device.

Do not slide the machine over the ground.

If heat generation exceeds the specified surface temperature, the machine has to be

stopped instantly. It may be re-started only after having eliminated the cause for the fault.

The work area and the other close working areas should always be protected from sparks.

All dust deposits from the machine have to be removed regularly.

Consider that there must be no flammable dusts at the place where the machine is operated.

Flammable and explosible material has to be removed from the work area before starting

work. Among others, this relates to dust deposits, cardboard, packing material, textile, wood

and wooden splints, but also flammable fluids.

Ensure adequate lighting.

Be extra careful in unfamiliar surroundings. There is a risk of hidden hazards such as electric lines or other

supply lines. Make sure when operating the machine that no electrical cables, gas pipes or similar could be

damaged. Use suitable and personal protective equipment.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 12 of 18

Safety Instructions for Prevention of Hazards caused by Compressed Air

WARNING –Compressed air can cause severe injury. Before working on the tools (e.g.

installation, changing accessories or machine tools, prior to a long standstill, maintenance,

etc.) depressurize pneumatic equipment.

CAUTION –Risk of injury by whipping pneumatic hose.

Check pneumatic hoses, connection components and fittings regularly for any damages and

proper fixture.

When connecting / disconnecting the machine to / from the pneumatic supply, please pay attention not to

actuate the valve while doing so. Never remove a pressurized pneumatic hose. Always switch the power

supply off first and then depressurize the machine. The maximum operating pressure (flow pressure)

according to the technical specification must not be exceeded.

A pressure regulator should be installed, which regulates the pressure before it reaches the machine.

Never direct a pneumatic hose at yourself or anyone else. Never clean your clothes with compressed air.

Direct cold air away from your hands. Do not pull or carry the machine by the pneumatic hose. When using

claw couplings make sure that they are fitted with a suitable lock mechanism (e. g. lock pin) and a safety

chain.

Safety Instructions for Prevention of Operating Hazards

Before starting work make sure that the hands are protected against: impacts, crushing, hits, cuts,

abrasions and heat. The operating and maintenance personnel must be physically able to handle the bulk,

the weight, the power and/or the torque of the machine. Do not use the machine if you have taken any

medication or drugs, after drinking alcohol or with any other constraints on your vision, reaction time or

judgment. Work in the best possible position so that you can react with both hands to any normal or

unexpected movements of the machine. Maintain a balanced body position and secure footing in order to

avoid improper strain and to be able to support the reaction torque of the machine.

Additionally, observe the following:

Operate the machine only after having carefully read the operation manual.

If the machine shows any signs of abnormal operation and performance, work must be stopped instantly

and the machine has to be serviced or repaired.

Do not employ the sabre saw by excessive force.

Before using the machine, all parts or protective devices should be carefully checked to make sure they

are working correctly and fulfil the designated function.

Damaged or malfunctioning protective devices and valves to be replaced and repaired by qualified

personnel.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 13 of 18

Safety Instructions for Prevention of Entanglement Hazards

CAUTION –Loose clothing, personal jewellery (e.g. necklace), scarves/ ties, long hair or

gloves can get caught up in the machine tool or accessories and thus cause severe injuries

(lack of breath by throttling, abrasions, skin injuries and/ or cuts and lacerations).

Wear suitable, close fitting work clothing!

Wear a hair net, if you have long hair. When handling the machine, jewellery, necklaces, etc.

have to be removed or are forbidden, respectively.

Safety Instructions for Prevention of Noise Hazards

Always wear hearing protection –This refers to the operator, as well as to any other

person within the vicinity of the machine. Observe the instructions of the employer and of the

professional association.

During operation high noise levels can cause permanent hearing problems such as tinnitus (ringing, buzzing,

whistling or humming in the ears), hardness of hearing or even deafness.

Before starting work, ensure that the provided, respectively the factory-made, sound absorbers are

mounted and in proper condition.

If possible, use sound absorbing material, in order to avoid ringing noise at the work pieces.

Safety Instructions for Prevention of Vibration Hazards

Vibrations can cause damage of nerves and blood vasculares in hands and arms, therefore observe the

following:

Wear warm clothing and keep your hands warm and dry when working in cold conditions. Exercise

hands and fingers regularly.

Use stands and/or weight balancers, if possible.

When using a support (e.g. stand) make sure the machine is securely fixed. If no support is used, hold

the machine with light but safe grip in order to support the tool’s reaction torque. The tighter the grip the

greater the risk of vibrations.

Mount the machine as described in the operating instruction booklet in order to avoid unusually high

vibrations.

Stop work immediately, if you feel any numbness, tingling, pain or whitening of fingers or hands. Inform

the employer and consult a doctor.

Safety Instructions for Prevention of Dust and Fume Hazards

Wear respiratory protection - Use respiratory protection as instructed by your employer

and as required by occupational health and safety regulations. Potentially generated or

disturbed dust and fumes in the working environment or from using the machine can cause

illness (e.g. cancer, birth defects, asthma and/ or dermatitis).

Carry out risk assessment regarding dust and fume hazards and implement appropriate measures.

Keep the working place clean.

Keep in mind that working in certain materials may create dust and fumes causing a potentially

explosive atmosphere.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 14 of 18

Remark: Some types of metal may have toxic coatings.

Please pay particular attention to avoid skin contact and breathing in, when working with those materials.

Always use a protective mask. Ask your material supplier about special safety instructions and stick to them.

Safety Instructions for Prevention of Projectile Hazards

Wear impact-resistant safety goggles –This refers to the operator, as well as to the persons

within the vicinity of the machine. Assess and determine the grade of protection required

depending on the individual case. The risks to others should also be assessed at this time.

On overhead work, wear a safety helmet. If a work piece, accessories, inserted tools, or the

tool itself breaks, there is danger from high velocity projectiles.

Check all parts for damages before using the machine.

Replace damaged parts immediately.

When working on brittle material make sure that you are protected against harmful splinters.

Safety Instructions for Prevention of Accessory Hazards

Use only machine tools, accessories and consumables, which are recommended by the manufacturer. Make

sure choosing the correct size and the correct type. Use only accessories, which are in proper condition.

CAUTION –Injury due to carelessness!

If the machine is fixed to suspension equipment make sure that it is secure. Never hang the

machine onto the supply line.

Separate the machine from any external energy source before changing the machine tool

or any accessory.

Avoid direct contact with the machine tool during and after use as it can be

hot or sharp.

Wear protective gloves when changing a tool or an accessory!

Notice: Defective/ inappropriate gloves can lead to injury. Wear only proper hand protection,

adapted to the work place requirements.

WARNING –Explosion hazard!

When operating the machine in areas exposed to explosion hazards, use only accessories,

respectively devices, which are ATEX approved and specified.

Safety Instructions for Prevention of Transport Hazards

ATTENTION –Improper Transport, injury due to parts falling down!

Damage of the machine!

Separate the machine form any external energy source before transportation.

Check that the machine is undamaged and in proper condition.

Never carry the machine at the supply line.

Wear worker’s protective shoes!

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 15 of 18

Service and Maintenance

Basic Safety Instructions:

WARNING –Maintenance and repair work on pneumatic equipment.

Compressed air can cause severe injury. Observe legal regulations. Take precautions for

persons and environment. Additionally, observe the following:

Secure machine against unintentional starting and let the machine cool down to the

ambient temperature.

Protection against tipping, tumbling or falling down when assembling/ disassembling the

machine/parts.

CAUTION –Skin exposure to hazardous dusts may cause severe dermatitis. Dust present

at the work place could be disturbed during the maintenance procedure and inhaled. Clean

machine and work place before maintenance work.

WARNING –Danger of explosion! Generation of sparks during maintenance work!

Observe local safety regulations. Avoid use of force when disassembling and assembling the

machine. Always do maintenance work outside areas which are not exposed to explosion

hazards.

PROHIBITION - Eating, drinking and smoking are forbidden during maintenance and repair

work.

NOTICE –Use only original SPITZNAS spare parts, in order to avoid damages.

Otherwise you risk a decrease in machine performance and an increase in maintenance

work. Check the adherence to the technical specifications according to the operation manual

after each maintenance work.

IMPORTANT –There is no warranty for damages and liability is disclaimed, if non-original

spare parts are used.

Maintenance Instruction

Generally, pneumatic machines need little maintenance. If the following rules are observed, the machine

will have the expected long life-time and high reliability. Service life and performance of the machines are

decisively determined by:

The air purity,

the lubrication conditions and maintenance,

the regular control of the compressed air filter, as well as the regular checking of the machine

with regards to external damages.

Disassembly and re-assembly of the machine have to be executed by qualified staff only. Incorrect assembly

can lead to danger of accident for the operator and to defects on the machine. Furthermore we recommend

giving the pneumatic sabre saw a general overhaul by the supplier once a year.

After completing maintenance and repair work and before restarting production make sure that…

all materials, tools and other equipment which are required for maintenance or repairs have been

removed from the work area of the machine,

any fluid leaks have been removed,

all safety devices on the machine have proper function,

the oil level was checked,

fixtures of screw connections are tight,

removed covers, screens or filters were reinstalled.

The employer ensures that all maintenance, inspection and assembly work is done by authorized and

qualified experts.

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 16 of 18

Disassembly- Re-assembly

Maintenance and repair

Disassembly and re-assembly should be done according to the exploded views, respectively the sectional

drawings (see repair instruction).

All work regarding disassembly and re-assembly, have to be executed by SPITZNAS or skilled staff only.

DANGER –Working with the machine without appropriate preparation and disregarding of

instructions. Shut down the machine properly and let it cool down to the ambient temperature.

NOTICE –Special instructions apply for the repair of explosion-proof machines.

Retrofits or modifications of the machine need the manufacturer’s acceptance.

The explosion-proof machine is designed in the type of protection „c“ constructive safety.

All work executed on the machine, influencing the explosion protection, e. g. repairs with

mechanical machining, require an approval of an authorized expert or have to be done by the

manufacturer.

The internal structure must remain unmodified.

Storage

Unused machines and machine tools should be kept in a dry, closed room.

Keep them free from damaging influences such as damp, frost or large temperature fluctuations as well as

mechanical damage. Always store the machine in a way that important machine instructions, e. g. on

stickers and signs, are legible.

Disposal

Dispose of machine and worn out/defective machine tools according the local/national regulations. Fully

disassemble the machine for the necessary disposal. Separate materials according to local environmental

specifications. Dispose of environmentally hazardous greasing, cooling or cleaning agents in order to avoid

environmental contamination.

Environmental Regulations

When working on or with the equipment, it is imperative to observe all legal requirements in regards to

waste-disposal and proper recycling. In particular during installation, repair and maintenance work, water

damaging agents, such as

lubricating grease and oil,

coolant,

solvent containing cleaning agents

must not leak into the ground or reach the sewage system.

These materials must be stored, transported, contained and disposed of in suitable containers!

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 17 of 18

Troubleshooting

The following table shows possible problems and their causes:

Problem

Cause

Remedy

a

Sabre saw does not start

Not connected to compressed

air supply

Connecting and opening of the

compressed air supply

b

Low stroke rate

Operating pressure too low

Hose diameter too small

Flow rate too low

Increase operating pressure

Choose larger hose diameter

Increase flow rate

c

Stroke rate too high

Operating pressure too high

Flow rate too high

Consider max. operating pressure acc.

to technical specification

Reduce flow rate

d

Sabre saw comes to a stop

during cutting

Feeding pressure too high

Blunt saw blade

Unsuitable saw blade

Reduce feeding pressure

Replace saw blade (new)

Replace saw blade (appropriate for the

cut)

Increase operating pressure to 6 bar

e

Centre pin shears off,

saw blade cannot be

adequately clamped

Clamp screw worn/

hexagonal socket wrench worn

Replace clamp screw/ hexagonal

socket wrench

f

Sabre saw runs slower

during cutting

Compressed air is not

lubricated –dry run

Fill the line oiler with oil.

Check oiler setting (approximately 2-5

drops per m³/min air consumption)

g

Other problems

Contact authorized expert company

We ask you to send the machine to the manufacturer, if necessary.

Warranty and Liability

Unless otherwise specified, our „General Sales Terms” apply. Warranty and liability claims in regards to

persons or equipment damages are invalid, if one or more of the following causes apply:

Improper use of the machine,

improper assembly, startup, operation or maintenance of the machine,

operation of the machine with defect safety devices or improperly fixed or non-functioning safety and

protection devices,

not considering of the instructions in the operating instruction booklet concerning transport, storage,

assembly, startup, operation, maintenance and setting up of the machine,

independent structural alterations or settings on the machine beyond the intended purpose,

inadequate supervision of wear parts,

improperly carried out repairs, inspections or maintenance,

catastrophic cases due to foreign objects, acts of god or other reasons which are beyond our control.

Scope of Delivery

Check, if the scope of delivery is complete:

1 Operation and Maintenance Manual, 1 pneumatic sabre saw, accessories, if applicable

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Pneumatic Sabre Saw

5 1217 0020

Translation of the original manual,

compiled: 06.02.23

512170020_BA_en_Version_CSU_07.doc

Page 18 of 18

EC-/ EU-Declaration of conformity

as defined in the Machine Directive 2006/42/EC, according to Annex II 1. A

We,

SPITZNAS Maschinenfabrik GmbH, declare with the sole responsibility

that the following product in the version supplied by us

Description:

Pneumatic Sabre Saw

Type:

5 1217 0020

meets the fundamental requirements of the EC Machine Directive 2006/42/EC.

Furthermore we declare the conformity of the product as defined by the EU-Directive 2014/34/EU

with the specification: II 2G Ex h IIB T5 Gb

According to section 13 (1) b) ii) of the Directive 2014/34/EU the technical documentation is

deposited under reference No. 557/Ex-Ab 2232/14 at the following office:

TÜV Rheinland Industrie Service GmbH

Am Grauen Stein, 51105 Köln

(Notified body number 0035

with the identification of the scope of Directive 2014/34/EU)

Applied harmonized norms are:

EN ISO 12100: 2010

Safety of machinery - General principles for design

Risk assessment and risk reduction

EN ISO 11148-12: 2012

Hand-held non-electric power tools

Safety requirements - Part 12: Circular, oscillating and reciprocating saws

EN IEC 60079-0: 2018

Explosive atmospheres - Part 0: Equipment

General requirements

EN ISO 80079-36: 2016

Explosive atmospheres - Part 36:

Non-electrical equipment for explosive

atmospheres - Basic method and requirements

EN ISO 80079-37: 2016

Explosive atmospheres - Part 37:

Non-electrical equipment for explosive

atmospheres - Non-electrical type of protection constructional safety "c",

control of ignition sources "b", liquid immersion "k"

Name of the authorized person for documentation: Mr. Simon Witt

Address of the authorized person for documentation: see manufacturer’s address

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Translation of the original manual,

compiled: 20.04.16

512170020_BA_en_Version_CSU_07.doc

CS Unitec, Inc.

22 Harbor Ave, Norwalk, CT

06850

USA

Toll-free: 1-800-700-5919

(USA & Canada)

Phone: 203-853-9522

(outside USA & Canada)

Fax: 203-853-9921

E-Mail: info@csunitec.com

Internet: www.csunitec.com

1-800-700-5919 (US/CA)

www.csunitec.com

+1-203-853-9522 (Intl.)

Other manuals for 5 1217 0020

1

Table of contents

Other CS Unitec Saw manuals