TABLE OF CONTENTS

CHAPTER 2

GENERAL DESCRIPTION

CHAPTER 1

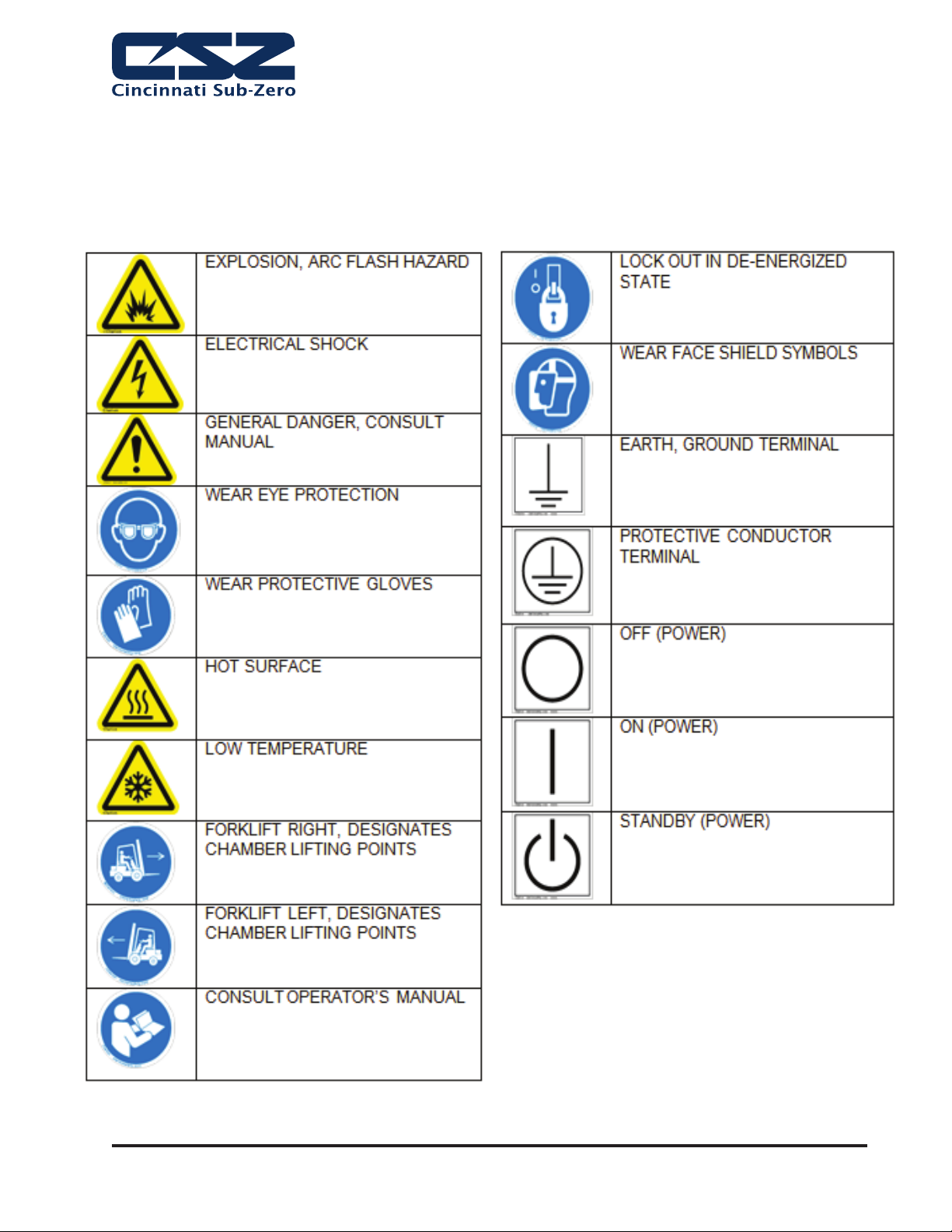

SAFETY PRECAUTIONS-FEATURES

INTRODUCTION......................................................................................................................................... 1-1

GENERAL SAFETY PRECAUTIONS......................................................................................................... 1-1

ELECTROSTATIC DISCHARGE SENSITIVE DEVICES............................................................................ 1-4

SAFETY FEATURES .................................................................................................................................. 1-5

ELECTRICAL PROTECTION ..................................................................................................................... 1-5

REFRIGERATION SYSTEM PROTECTION............................................................................................... 1-5

OVER-TEMPERATURE PROTECTION ..................................................................................................... 1-5

PRODUCT HIGH LIMIT (OPTIONAL EQUIPMENT)................................................................................. 1-5

FIGURES AND TABLES

FIGURE 1. COMMUNICATION PLATES ..................................................................................................................... 1-6

SYSTEM DESCRIPTION ........................................................................................................................... 2-1

CONTROLLER............................................................................................................................................ 2-1

CHAMBER .................................................................................................................................................. 2-1

REFRIGERATION/HEATING COMPONENTS ........................................................................................... 2-2

HUMIDITY ................................................................................................................................................... 2-5

PEN RECORDERS (OPTIONAL EQUIPMENT)....................................................................................... 2-11

REDUNDANT HIGH/LOW LIMIT CONTROL (OPTIONAL EQUIPMENT)............................................... 2-11

IEEE-488 SYSTEM (OPTIONAL EQUIPMENT)....................................................................................... 2-11

LN2/CO2 BOOST COOLING SYSTEM (OPTIONAL EQUIPMENT)........................................................ 2-11

PROGRAMMABLE DOOR LOCK (OPTIONAL EQUIPMENT)................................................................ 2-12

GN2 PURGE SYSTEM (OPTIONAL EQUIPMENT) ................................................................................. 2-12

DRY AIR PURGE (OPTIONAL EQUIPMENT).......................................................................................... 2-12

LIMITED TEMPERATURE SHEATH HEATERS (OPTIONAL EQUIPMENT) .......................................... 2-12

GAS MONITOR (OPTIONAL EQUIPMENT) ............................................................................................ 2-12

CHAMBER PERFORMANCE................................................................................................................... 2-13

SEQUENCE OF OPERATION .................................................................................................................. 2-18

FIGURES AND TABLES

FIGURE 1. CHAMBER COMPONENTS LOCATION ................................................................................................... 2-3

FIGURE 2. ZPRC CHAMBER - SIDE VIEW ................................................................................................................ 2-4

FIGURE 3. ZPRC CHAMBER - TOP VIEW.................................................................................................................. 2-4

FIGURE 4. ACHIEVABLE HUMIDITY POINTS ............................................................................................................ 2-6

FIGURE 5. OPTIONAL RECIRCULATING WATER/DEMINERALIZER FILTER.......................................................... 2-7

FIGURE 6. HUMIDITY PANEL LOCATION & COMPONENTS.................................................................................... 2-8

FIGURE 7. CHAMBER INTERIOR............................................................................................................................. 2-10

FIGURE 8. SHELF AND BRACKET........................................................................................................................... 2-13

FIGURE 9. SHELF IN PULLED OUT POSITION....................................................................................................... 2-13

TABLE 1. ZP(H) SPECIFICATIONS ........................................................................................................................... 2-14

TABLE 2-4. ZP LOAD CAPACITY AND ELECTRICAL REQUIREMENTS................................................................. 2-14

TABLE 5. ZP SINGLE STAGE SPECIFICATIONS ..................................................................................................... 2-16

TABLE 6. ZP CASCADE SPECIFICATIONS.............................................................................................................. 2-16

TABLE 7. ZP TUNDRA SPECIFICATIONS ................................................................................................................ 2-17