date

page

10/2010

8 of 13

20050 SW 112th Ave. Tualatin, Oregon 97062 phone 503.612.2300 fax 503.612.2380 www.cui.com

PART NUMBER: DESCRIPTION:

AMT203 DEMO KIT USER GUIDE

© 2010 CUI Inc. All rights reserved.

Information in this document is subject to change without notice.

TROUBLESHOOTING THE SERIAL CONNECTION

This latter issue where the serial port is in the “used” state is not unique to the AMT-DMBD drivers or the Demo

Board, it is a Windows serial port problem, and we have supplied the “comdisable” utility to free up serial ports just

in case. If you have that problem, please install the comdisable utility and either try using it with help screens or

go online to Microsoft and look up instructions. Basically you have to disable those “used” ports then reboot to free

them up.

Another way to disable and reenable the port is to use device manager to unload and reload the com port driver

including the USB serial driver. This works for example if you exit Hyperterm abruptly and it will not start again

because the port is “unavailable”. Once again this is because the COMM.db is set in the wrong state. Normally

Hyperterm expects you to disconnect the port before exiting which will prevent this awkward setting.

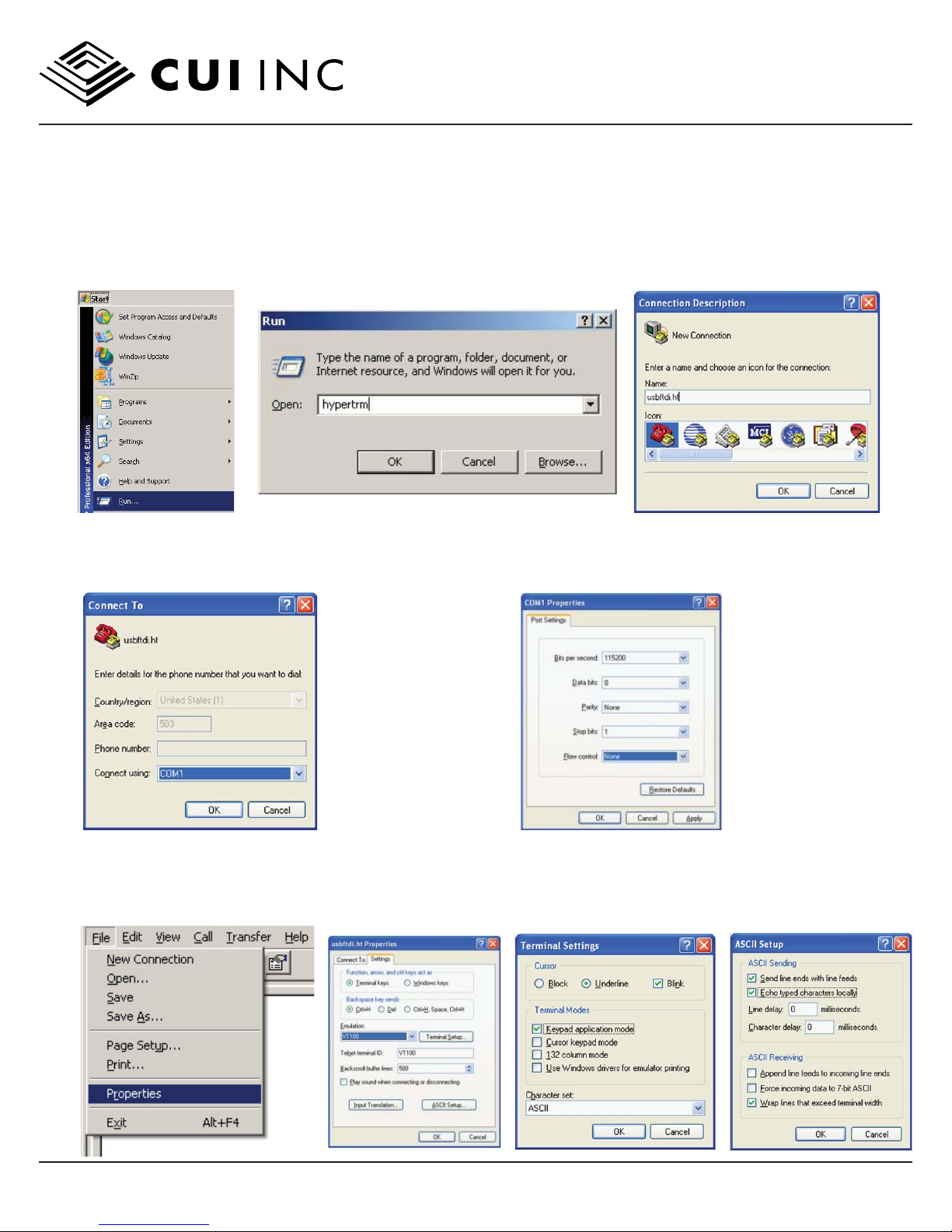

RUNNING COMMANDS UNDER HYPERTERM

Once the Hyperterm is up you can type:

p<cr>

and you should see the position information, for example see Figure 6.

The AMT-DMBD board returns <cr><lf>$ so you see the $ prompt after each command is processed.

The D1 LED turns on when the first character is received by the AMT-DMBD board, and the LCD display shows

“USB Active” and the buttons go inactive.

Any AMT-DMBD serial command can be given from the Hyperterminal. However the USB/Serial port is intended for

automation and after initial bringup of the serial port the user is encouraged to use [the supplied] TCL procedures

or create serial access procedures using Vbasic, C or some other language.

Figure 6: Hyperterminal reading position data