BENDER MOUNTING PROCEDURE

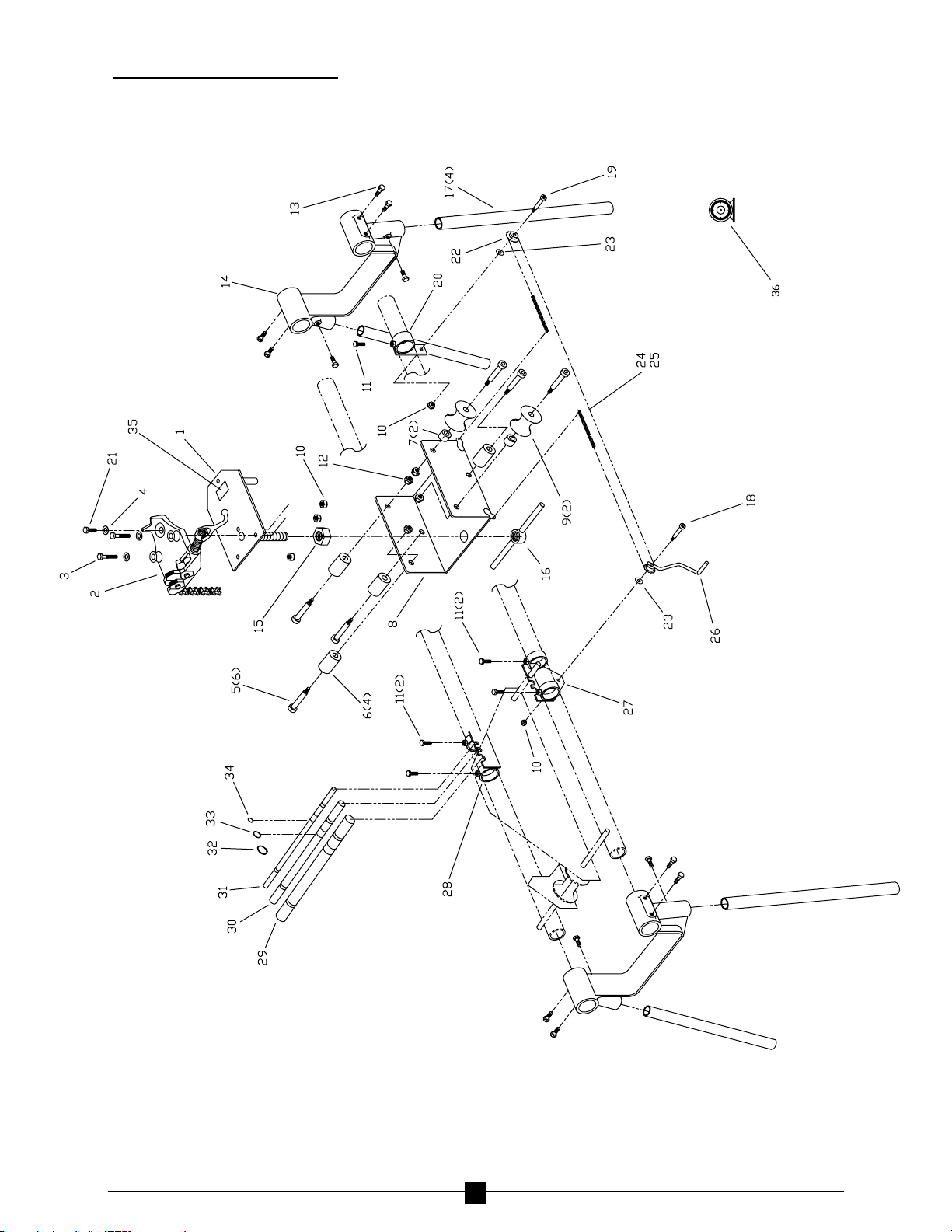

1. Determine the correct size support pins for the bender you are using:

Bender Model # Support Pin Size

Greenlee®880 –3/4”diameter pins

Greenlee®777 –1”diameter pins

Greenlee®884, 885 –1 1/2”diameter pins

Ensley®E –125 –1 1/2”diameter pins

NOTE: The support pins for the 884 and 885 Benders have 2 retaining ring

grooves. Place the retaining ring in the outer groove when using the

885 Bender and place the retaining ring in the inner groove when using

the 884 Bender. See figure below.

2. Place support pins into the bender frame holes that match the size

conduit to be bent. ( Note: Be sure the ram scale is on the hand crank

unit side of the bending table. )

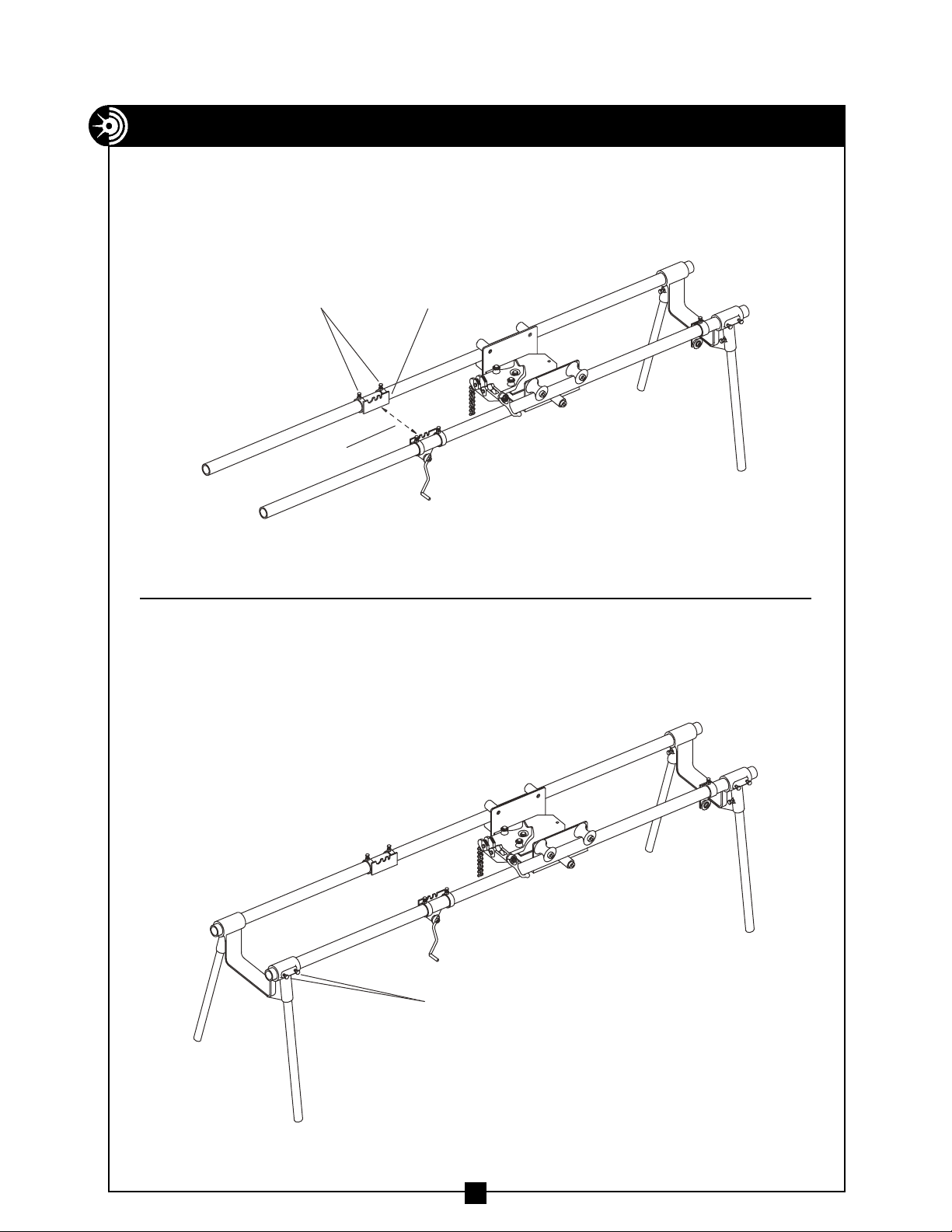

3. Lift bender and set on table as shown with one (front) support pin about

1”from leg support. See figure 7. Next, move the hand crank unit and

the rest plate so that the rear support pin sits in the matching slot of

the hand crank unit and the rest plate. The wide groove on each side of

the support pin should ”sit“in the rest plate and the hand crank unit.

See figure 7. Tighten all bolts on the hand crank unit and the rest plate.

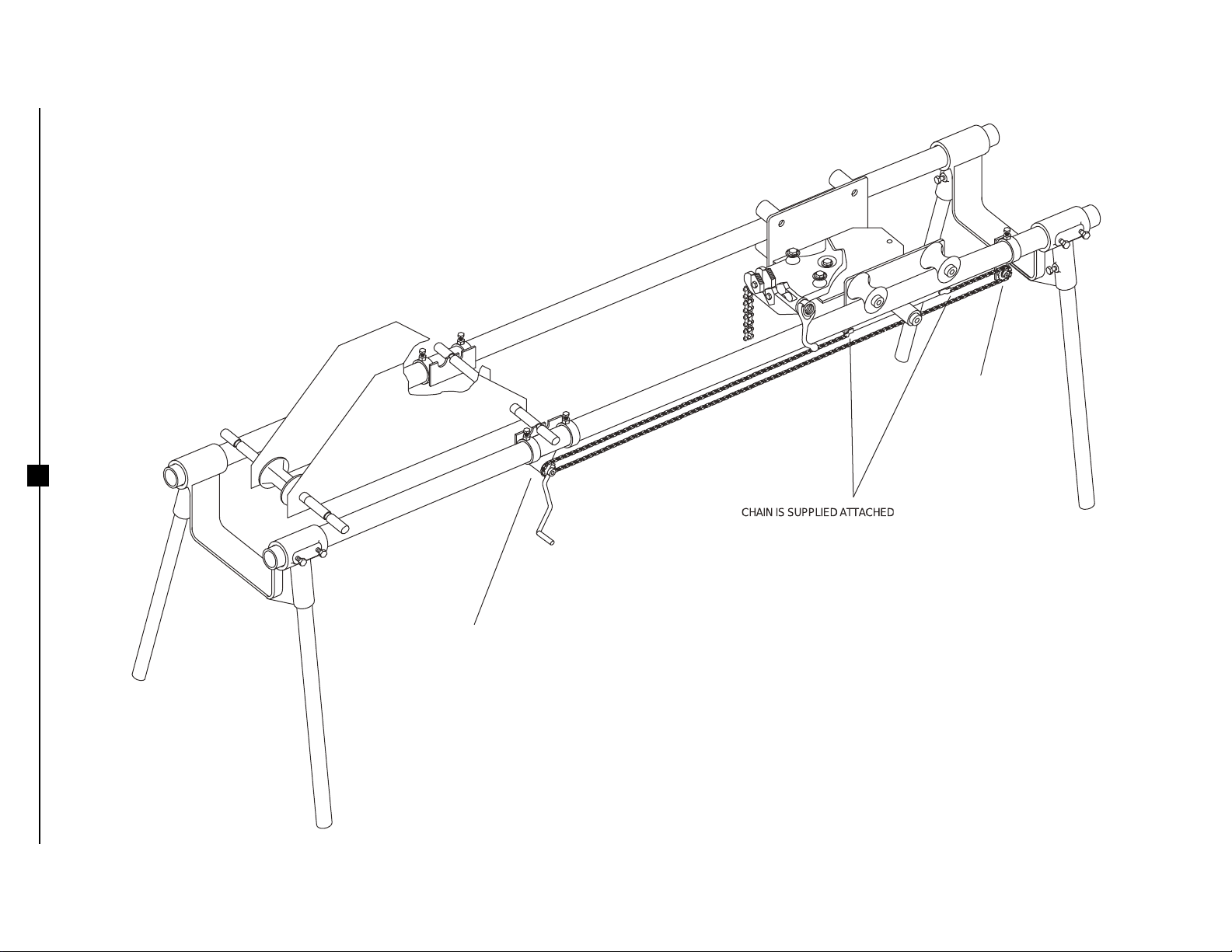

4. Place chain around sprocket on hand crank unit and around idler unit as

shown. See figure 8. Adjust idler unit to tighten chain. Tighten bolt on

idler unit.

NOTE: Before bending, check to ensure all bolts are tightened and the

bending table is level.

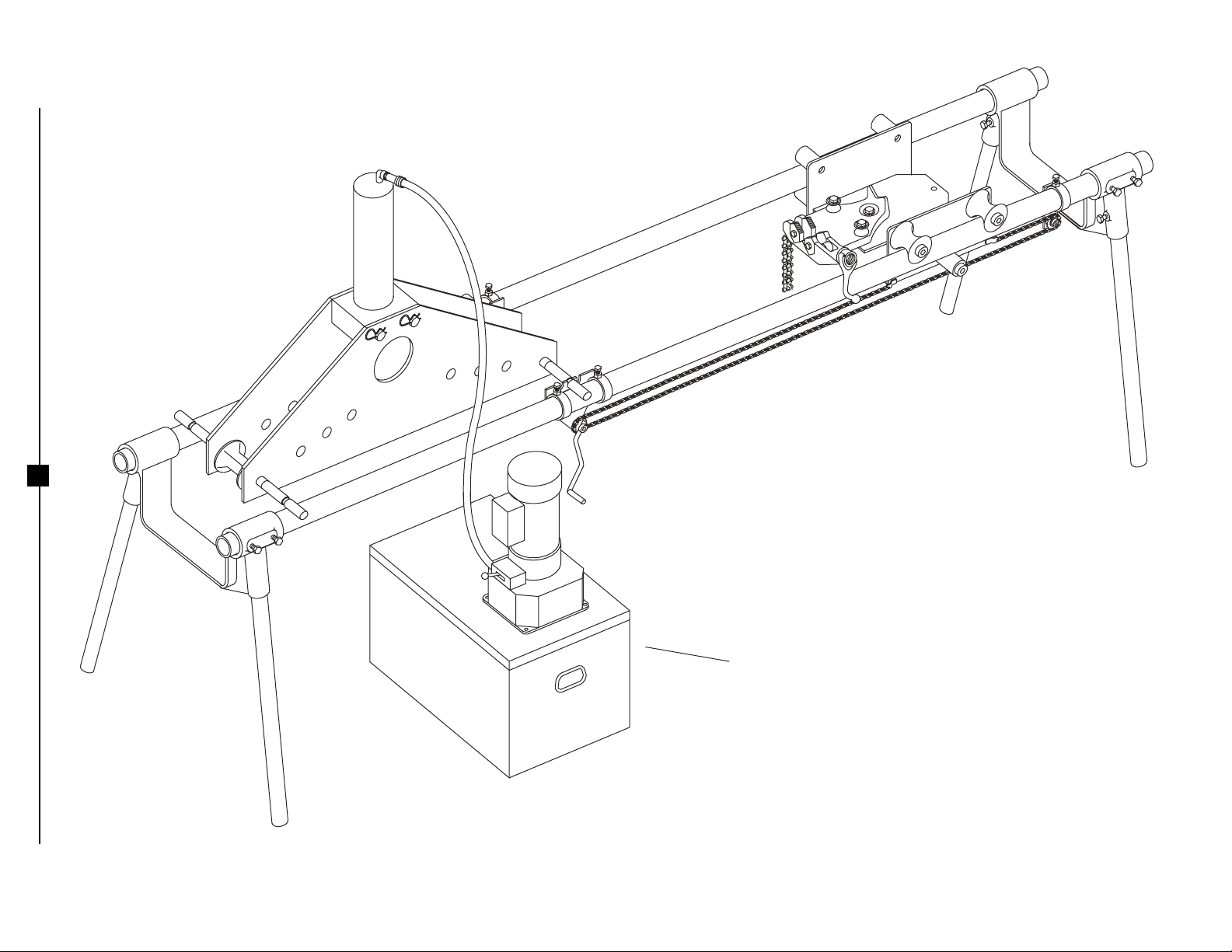

5. The Bending Table is now set-up for bending radii up to 36".

NOTE: When bending 36" and larger radii and to bend 3" and smaller

conduit with the Greenlee®884 and 885 benders, the chain extension kit

( CurrentTools part # 280-9 ) is required.

6

The 280 BendingTable

comes standard with the

1 1/2”diameter pins.

*Greenlee®is a registered trademark of

Greenlee/Textron and Ensley®is a registered

trademark of Rothenberger Group, which

have no affiliation with CurrentTools.