Water Tank Overfills

1. Turn the toggle switch on the back of the brewer ON and OFF. If water continues to flow when the switch is in both positions, replace

the inlet valve.

2. If water stops flowing to the water tank when the switch is turned OFF and continues when the switch is turned back ON, remove the

orange wire from the water probe on the tank. While power is ON, short the end of the orange wire to the metal surface on the

outside of the tank. If the water tank stops filling when the orange wire is shorted, check for a corroded connection to the water

probe.

3. If water does not stop flowing when the orange wire is shorted, check the tank ground connection and the continuity of the orange

wire connecting to the UPM. If both are OK, replace the UPM.

Water Tank Does Not Fill

Note : No water or low water in the tank can cause the tank to overheat, resulting in the thermostat reset switch opening. If after connecting a

tank refill problem there is still no power to the control panel, reset the machine.

1. Check to make sure the water supply is turned on. Check for a plugged water supply line or plugged inlet valve.

2. If there are no plugs, check for power across the inlet valve terminals. If power is being supplied, but there is no water flow, replace

the inlet valve.

3. If power is not being supplied, check the wires between the UPM and inlet valve. Check for corroded connections.

4. If the wiring between the UPM and the inlet valve is OK, but there is no power to the inlet valve, remove the orange wire from the

water tank probe. If the water tank starts to fill, replace the water probe. If the water tank does not start to fill, replace the UPM.

Water Level Error Message

1. Check to make sure that the flow rate from the water supply line meets the minimum flow rate specifications for the brewer. Check

water pressure.

2. Check for blockage at the inlet valve or outlet. Check for blockage in the tubing between the inlet valve and the water tank.

3. Check the water probe wire for an open condition or corroded connection.

4. If the probe connections are OK, cycle power to the unit by turning the rear toggle switch OFF, then back ON. Check to see if power

is applied to the inlet valve terminals. If power is applied to the terminals, but there is not a water flow, replace the inlet valve.

5. Check for power from the UPM to the inlet valve. If the wiring is OK, replace the UPM.

“Internal Error 1” Message

1. Check the wiring harness that connects from pins 4,9, and 11 of the 14 pin connector on the UPM to pins 2, 3, and 6 of the 8-pin

connector to the UCM.

“Internal Error 2” Message

1. The UPM and the UCM have a mismatch in their settings. A firmware update is needed. Refer to manual.

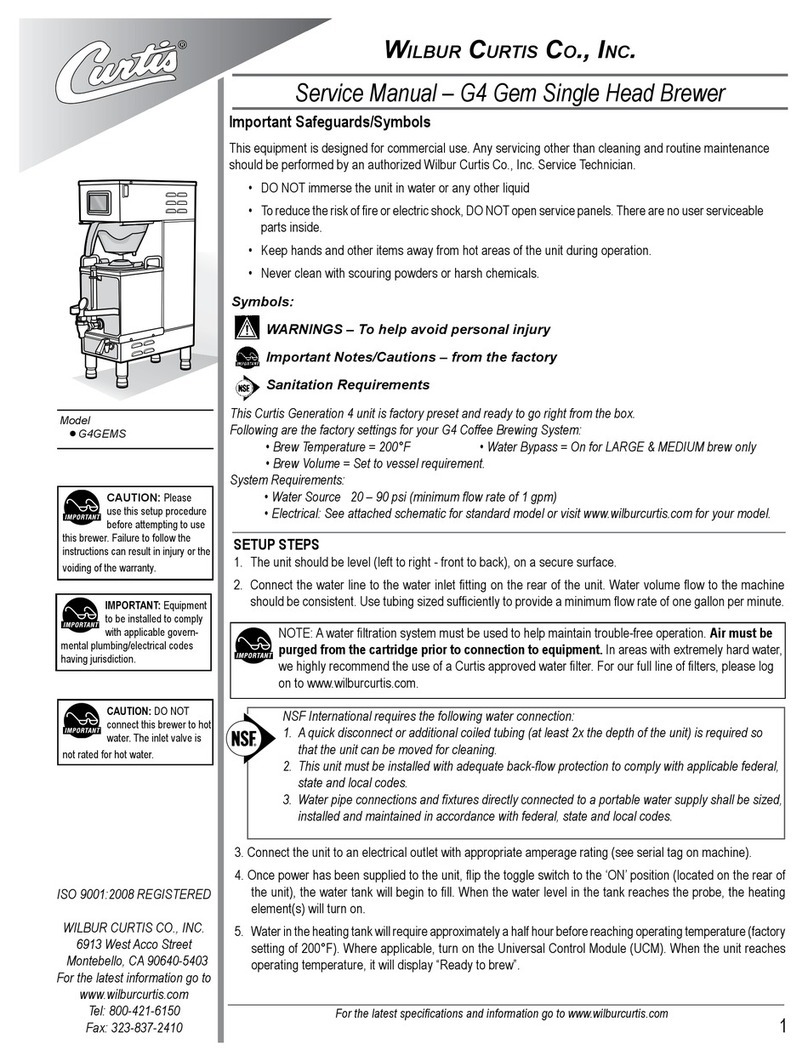

Calibration / Programming / Dial-In

1. Tap the white Curtis logo on the touch screen 5 times to enter programming mode.

2. The ACCESS CODE screen will appear. The default passcode is 1, 2, 3, 4 and once the code is entered press OK. The MAIN MENU

screen will appear. (The access code can be reset in the control settings sub-menu, under Passwords)

3. Open the CONTROL SETTINGS menu on the touchscreen. Press DIAGNOSTICS to run a system auto-test.

4. Press the TEMPERATURE menu. Make sure brewers are set to 200° F.

5. Next check WARMER SETTINGS and confirm with General Manager whether they would like to set an Auto-OFF (options for 1-12

hours).

6. Touch QUALITY TIMER and adjust to 2 hours.