p. 7 of 12

middle

side bolt

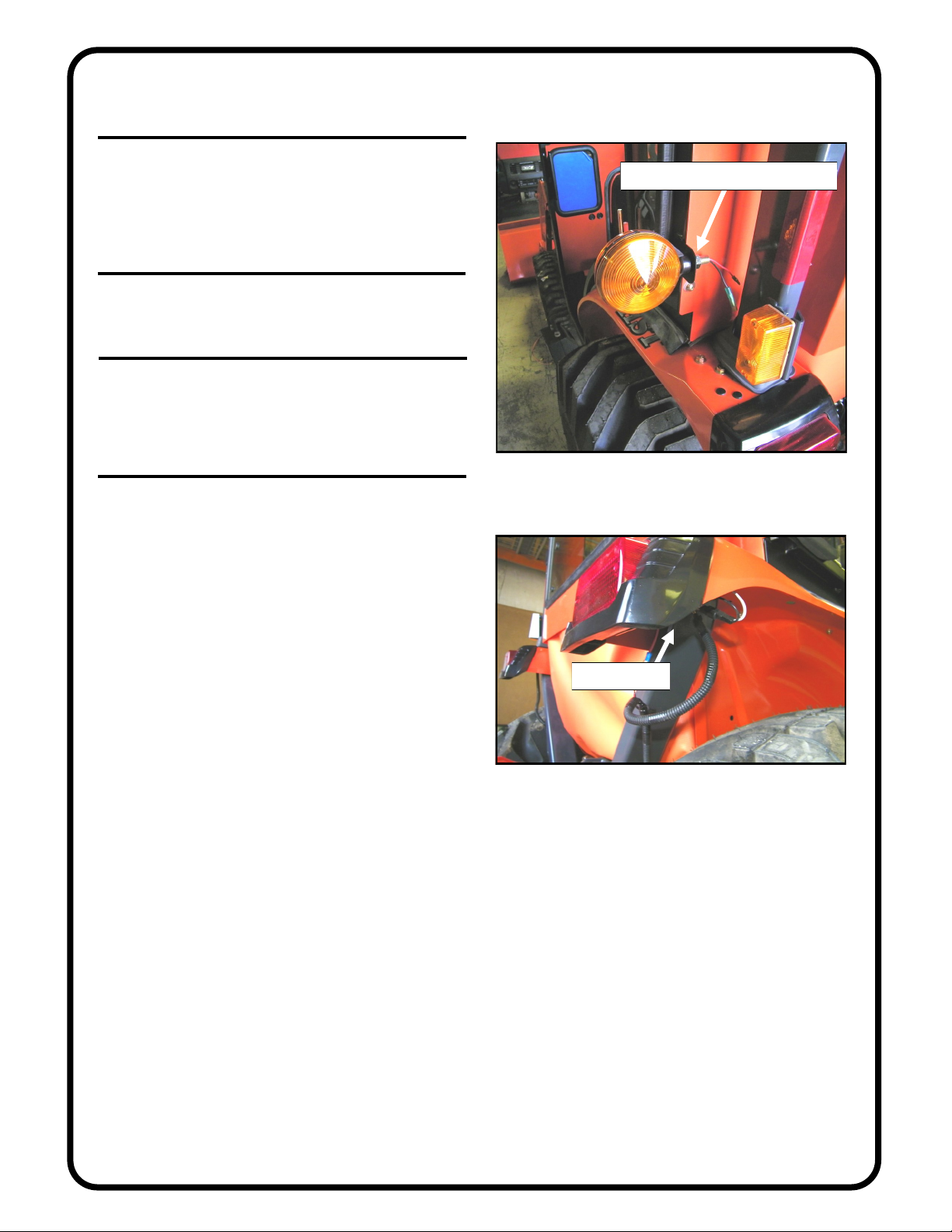

Fig. 9.3 (view from front left side of tractor)

rear corner bolt

ref.: reflectors are back here

Fig. 10.2.1 (view from left side of tractor)

heads of

bolts up top

9. ROOF

9.1 Use a Phillips head screwdriver to punch a hole

through the headliner at any of the covered bolt hole lo-

cations (8 places). Punch holes from the inside out to

avoid having the headliner pull away from its glued sur-

face.

9.2 Install the roof oriented so the reflectors are to-

wards the rear of the vehicle. Use the following hardware

in the two front corners: one 5/16-18 x 1” long button

head bolt, two steel washers, one nylon washer, and one

locknut (locknuts on the inside surface). Install the bolt

through the roof, windshield support, and mounting tab.

See the helpful hints section on page two for placement

of nylon washers.

9.3 See fig. 9.3. The middle side and rear corner bolt

location on both the left and right sides uses the follow-

ing hardware per side: two 5/16-18 x 3/4” long button

head bolts, two steel washers, and two nylon washers.

These bolts are installed into factory installed threaded

inserts in the top of each side frame. NOTE: use caution

to avoid damaging the internal threads on the factory

installed threaded inserts.

9.4 The remaining two holes in the middle front use the

following hardware: two 5/16-18 x 3/4” long button head

bolts, four steel washers, two nylon washers, and two

locknuts. Locknuts to be on the inside surface.

10. TIGHTEN ALL BOLTS

10.1 Tighten all bolts at this time including the carriage

bolts on the roll bar brackets, etc.. Note: the roll bar

brackets should end up parallel and/or perpendicular to

the R.O.P.S. tubing.

10.2 Per figures 10.2 and 10.2.1, use the two holes in

the side frame floorboard as a guide to drill 3/8” diameter

holes through the floor of the tractor. WARNING:

check underneath for obstructions before drilling.

With assistance, depress the inner-most brake pedal to

gain clearance for the drill to be vertical when drilling

the front right bolt hole. Install the following hardware

per side: two 5/16-18 x 1” long button head bolts, four

steel washers, and two locknuts. Locknuts to be under-

neath the tractor. Tighten these bolts.

Fig. 10.2 (view from seat of tractor)

drill a

3/8” hole