MAN-100 Revision 03082022 Page 1 of 22

Scope-Assist Flushing Sink

Operator’s and Maintenance Manual

Table of Contents

1GENERAL INFORMATION ....................................................................................................3

ABBREVIATIONS ................................................................................................................................................3

WARNING/CAUTION STATEMENTS......................................................................................................................3

Warnings .................................................................................................................................................3

Cautions ..................................................................................................................................................4

INDICATIONS FOR USE/INTENDED USE ...............................................................................................................4

PRODUCT DESCRIPTION.................................................................................................................................... 4

Configurations .........................................................................................................................................5

Operating Principle.................................................................................................................................. 5

Physical Characteristics .......................................................................................................................... 5

Interfaces.................................................................................................................................................5

Assembly.................................................................................................................................................6

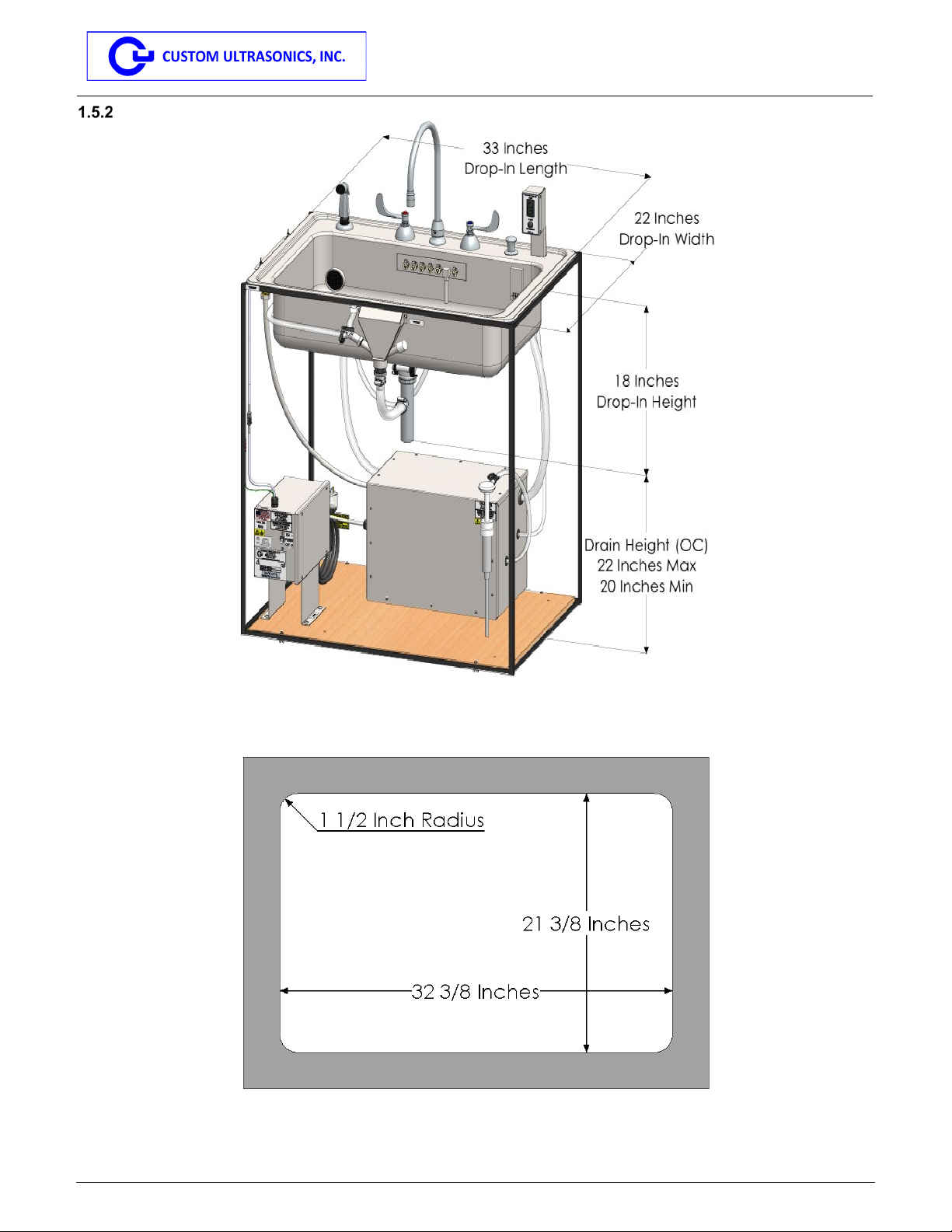

DIMENSIONS AND COMPONENTS........................................................................................................................6

Model S6 Dimensions .............................................................................................................................6

Model S8 Dimensions .............................................................................................................................7

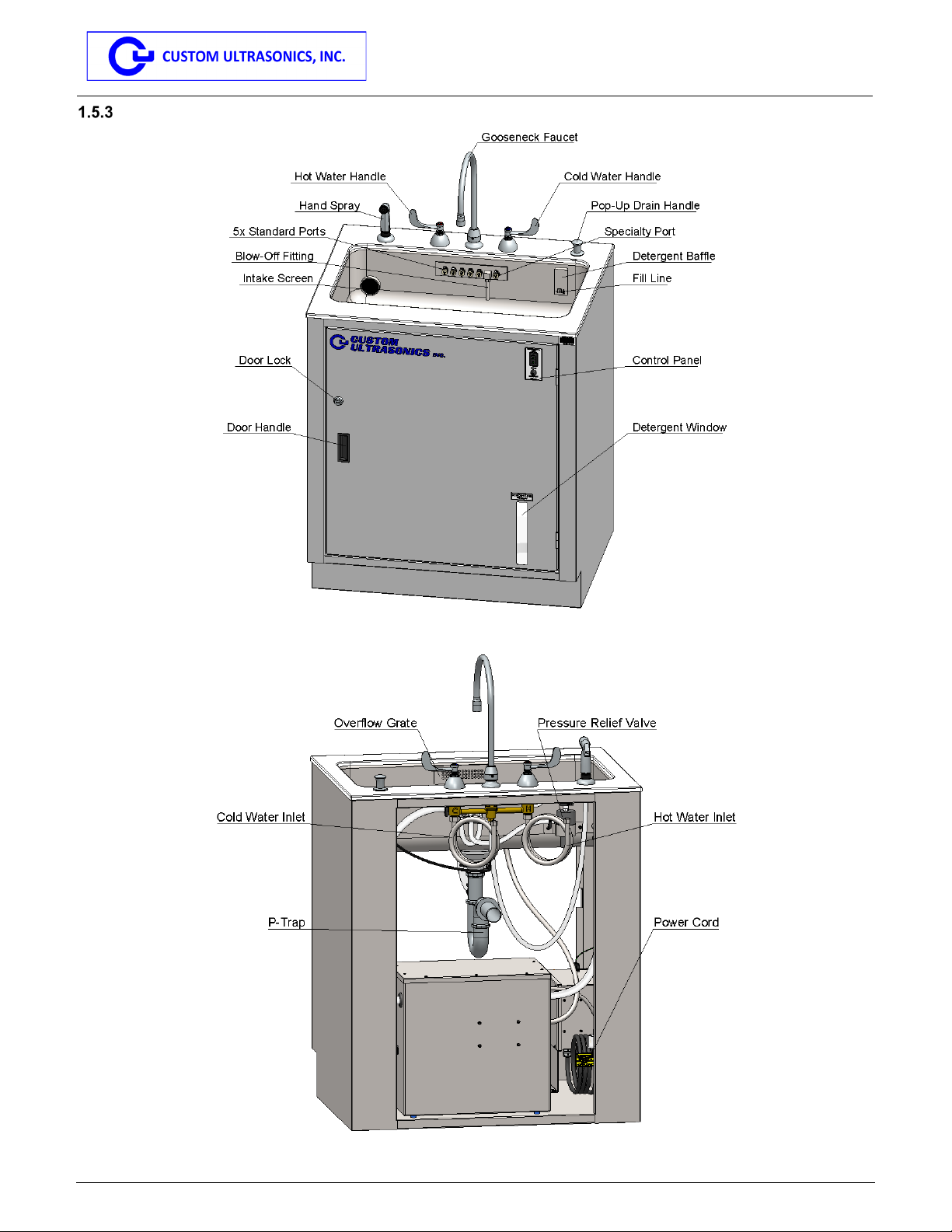

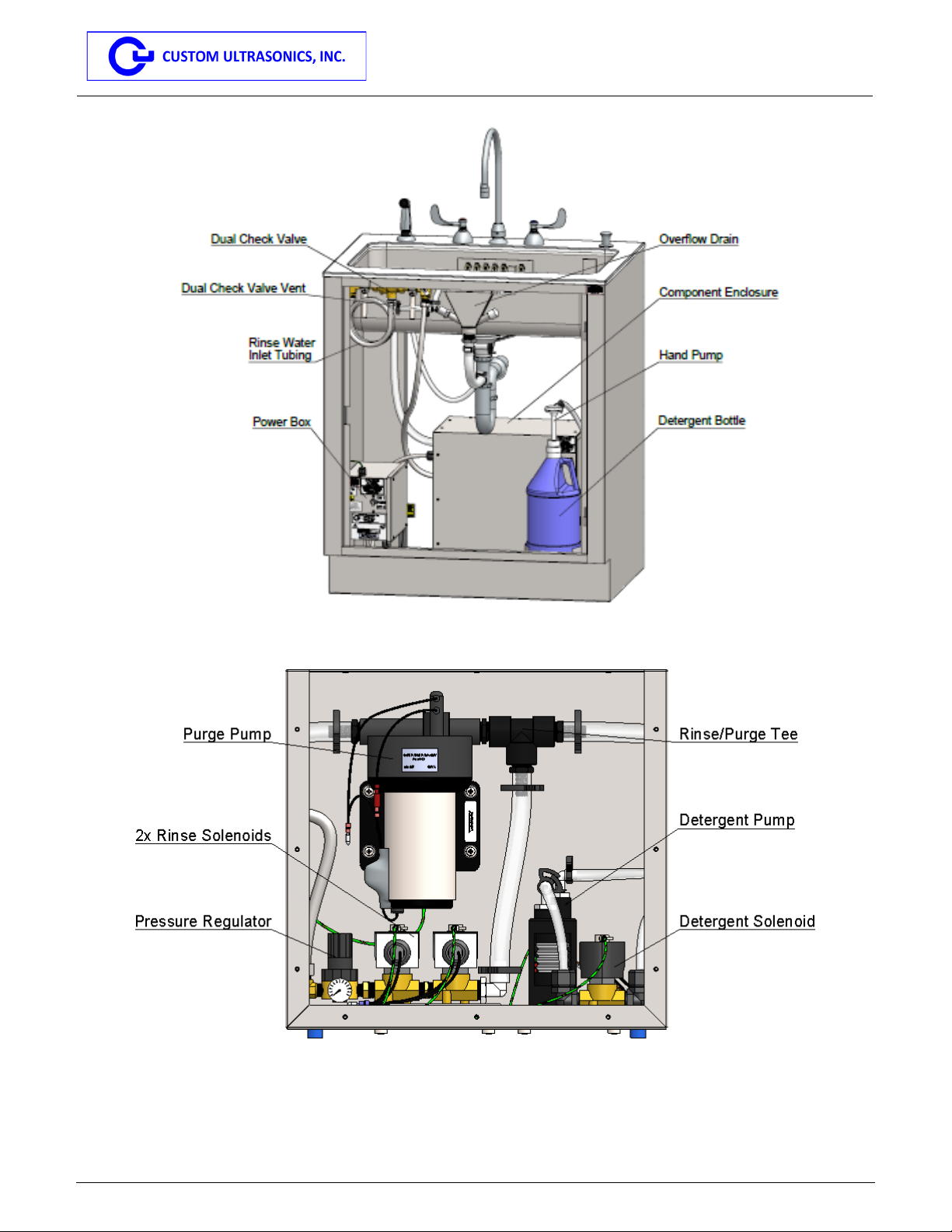

Component Diagrams .............................................................................................................................8

2INSTALLATION ...................................................................................................................10

MODEL S8 INSTALLATION ................................................................................................................................10

Model S8 Installation .............................................................................................................................10

WATER SUPPLY REQUIREMENTS .....................................................................................................................10

Water Supply Installation ......................................................................................................................11

WASTE DRAIN REQUIREMENTS........................................................................................................................11

Waste Drain Installation ........................................................................................................................11

ELECTRICAL SUPPLY REQUIREMENTS ..............................................................................................................11

Electrical Supply Installation .................................................................................................................11

DETERGENT BOTTLE CONNECTION ..................................................................................................................11

Detergent Bottle Installation ..................................................................................................................11

3POST-INSTALLATION INSPECTION..................................................................................12

WATER INLET SYSTEM ....................................................................................................................................12

DRAINAGE SYSTEM .........................................................................................................................................12

DETERGENT SYSTEM ......................................................................................................................................12

PURGE SYSTEM..............................................................................................................................................12

RINSE SYSTEM ...............................................................................................................................................12

4OPERATING INSTRUCTIONS.............................................................................................13

CAUTIONS ......................................................................................................................................................13

OPERATING THE SAFS ...................................................................................................................................13

Performing the Leak Test......................................................................................................................13

Filling the Sink Basin .............................................................................................................................13

Brushing/Wiping the Endoscope Channels...........................................................................................13

Connecting an Endoscope to the SAFS ...............................................................................................13

Flushing Channels with Detergent Solution ..........................................................................................14

Drain the Detergent Solution.................................................................................................................14

Rinsing Channels with Clean Rinse Water ...........................................................................................14

Draining the Rinse Water ......................................................................................................................14

Rinsing the Endoscope Exterior and Sink Basin...................................................................................14

5MAINTENANCE ...................................................................................................................15

DAILY MAINTENANCE ......................................................................................................................................15

Operator’s Daily Checklist.....................................................................................................................15

Daily Cleaning and Decontamination ....................................................................................................15

QUARTERLY MAINTENANCE AND INSPECTION ...................................................................................................16

Visual Inspection ...................................................................................................................................16

Intake Screen Inspection.......................................................................................................................16

Adapters and Channel Flushing Port Inspection...................................................................................16

Solenoid Inspection ...............................................................................................................................16