2 15JUN98 – 9B8948

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be liable

for any loss or damage, including consequential or special damages, resulting from any use of

this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Warning

To avoid hazardous conditions, keep floors and floor coverings around your

Kodak X-Omat

Processor and

associated drains clean and dry at all times. Any accumulation of fluids from mixing tanks, drain lines, etc., should

be cleaned up immediately. In the event of an accumulation of liquid due to backup, overflow, or other malfunctions

of the drain associated with your

X-Omat

Processor, call a plumber or other contractor to correct any problem with

the drain. Kodak accepts no responsibility or liability whatsoever for the serviceability of any drain connected to or

associated with a

Kodak X-Omat

Processor. Such drains are the sole responsibility of the customer.

Description Page

Table of Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Preventive Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

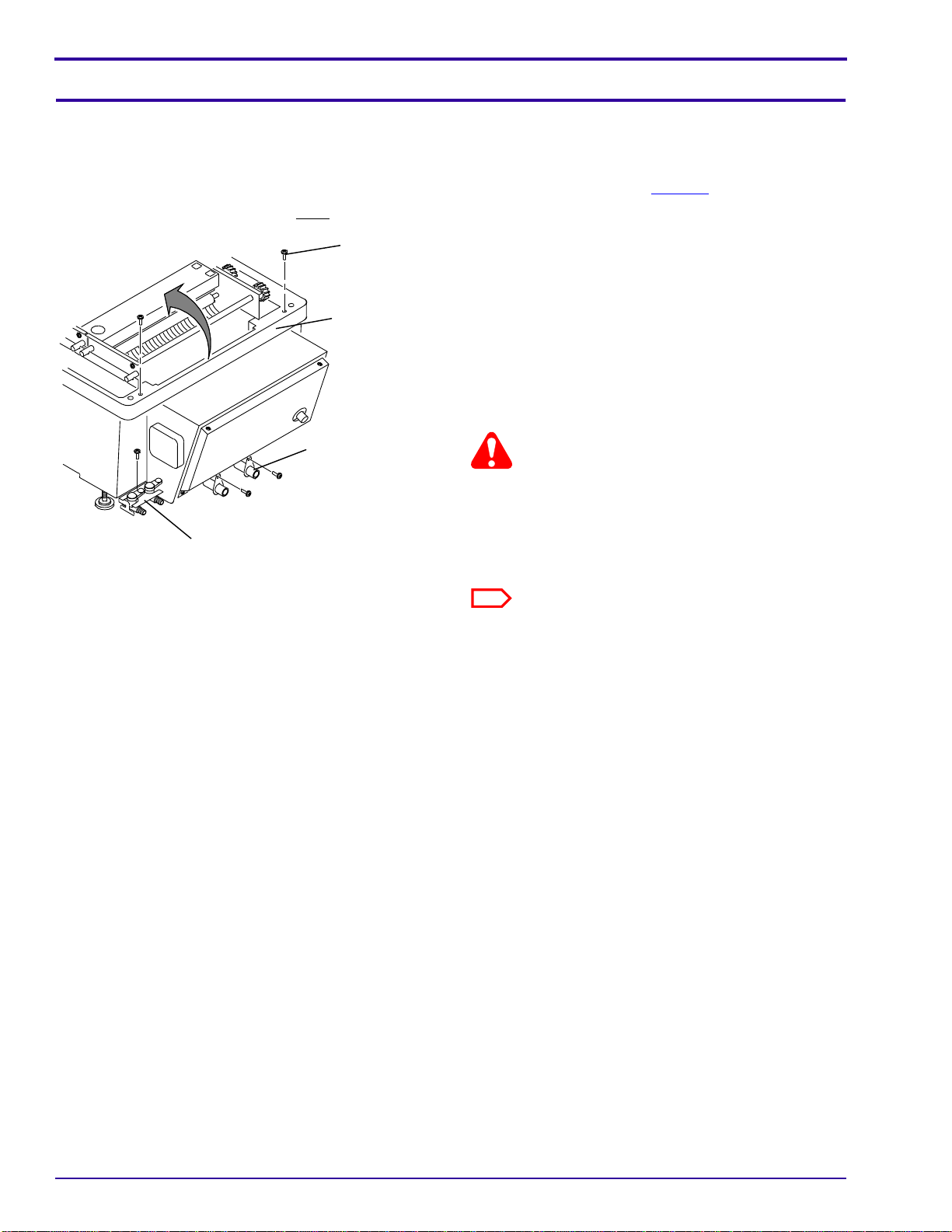

Unpacking the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

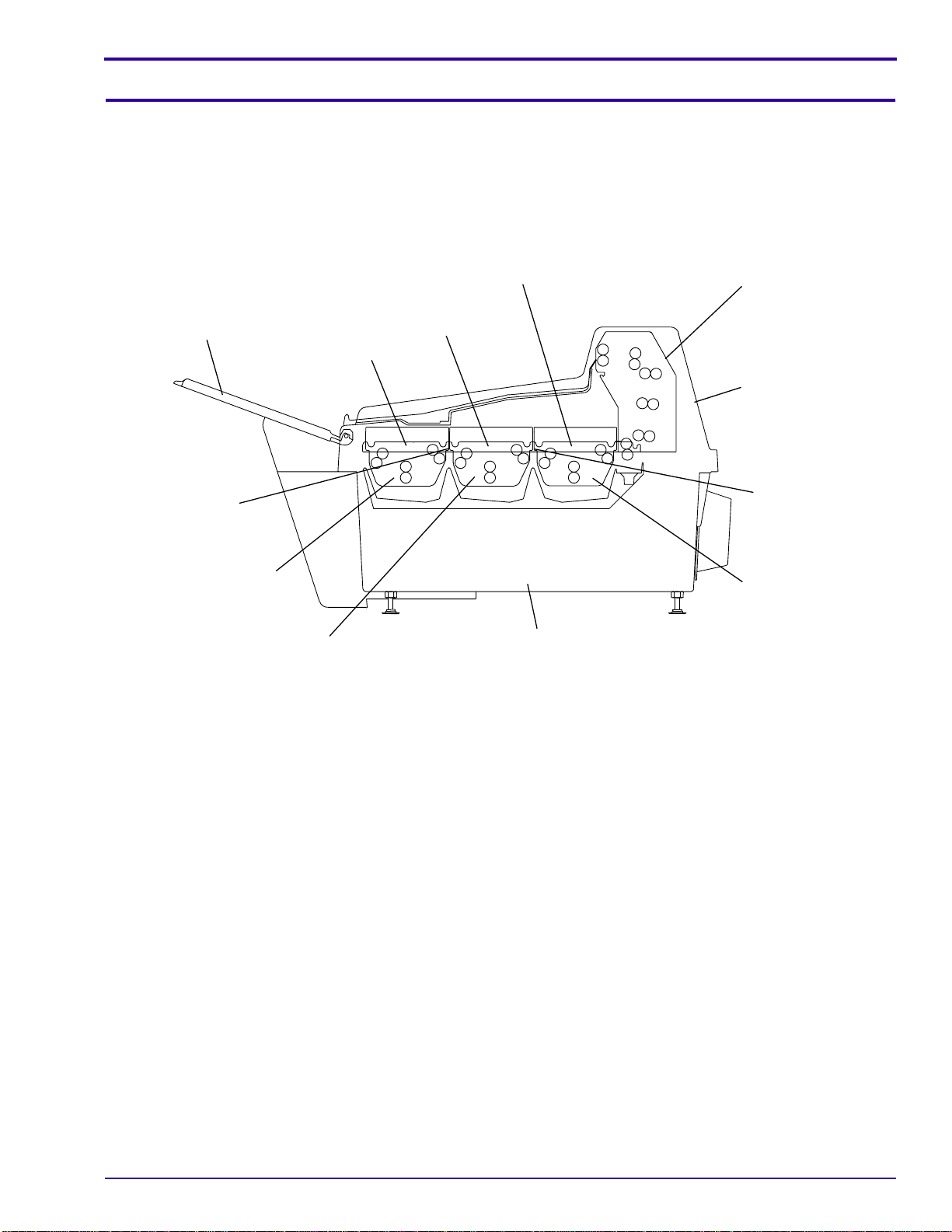

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PROCESSOR Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changing the PROCESSOR Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PROCESSOR Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Checking and setting the PROCESSOR voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting the Plumbing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the FEED TRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Leveling the PROCESSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Function Checkout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the Developer Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting the Developer and Fixer Replenishment Rates . . . . . . . . . . . . . . . . . . . . . . . 16

Setting the Processor to the “Regular” Replenishment Mode . . . . . . . . . . . . . . . . . . 17

Setting the Processor to the “Flooded” Replenishment Mode . . . . . . . . . . . . . . . . . . 17

Setting the DRYER Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Final Pre-Operation Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18