CustomCrimp D205M Series User manual

Other CustomCrimp Crimping Tools manuals

CustomCrimp

CustomCrimp CC150MOB Series User manual

CustomCrimp

CustomCrimp D105 Series User manual

CustomCrimp

CustomCrimp D100 SERIES User manual

CustomCrimp

CustomCrimp CC200 User manual

CustomCrimp

CustomCrimp D205 User manual

CustomCrimp

CustomCrimp D205WB Series User manual

CustomCrimp

CustomCrimp D160-T420 Series User manual

CustomCrimp

CustomCrimp CC15 User manual

CustomCrimp

CustomCrimp D165 Series User manual

CustomCrimp

CustomCrimp CC150 User manual

CustomCrimp

CustomCrimp D160S-T420 User manual

CustomCrimp

CustomCrimp CC1000 User manual

CustomCrimp

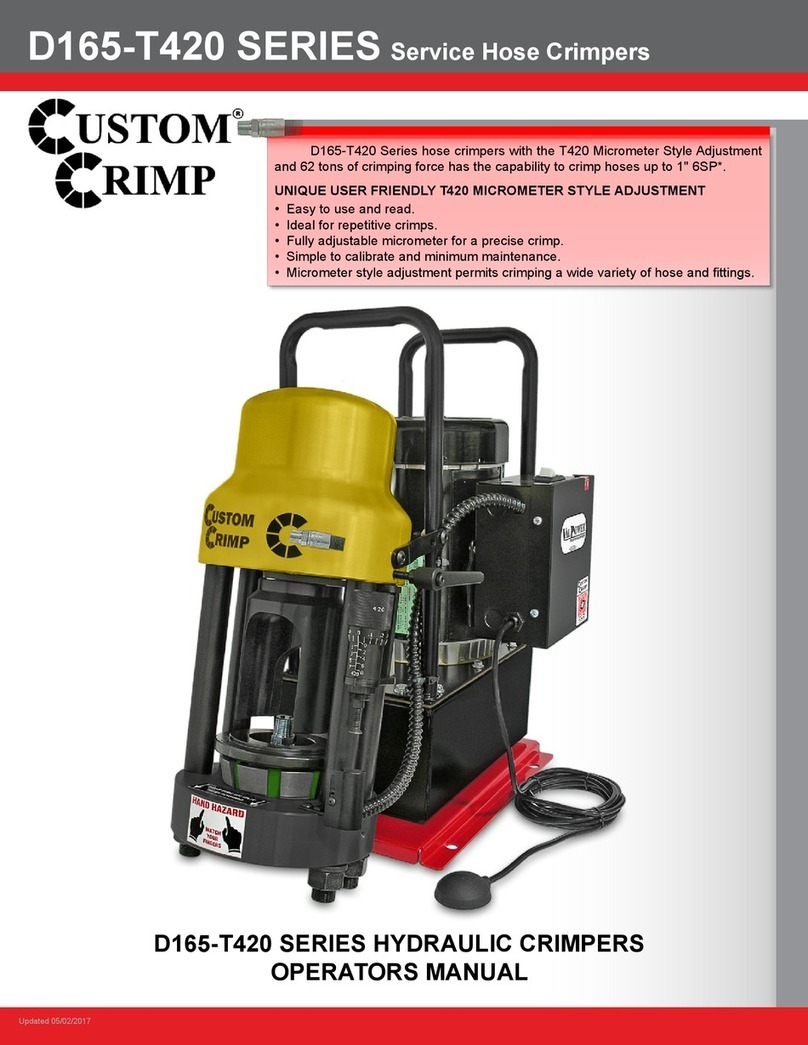

CustomCrimp D165-T420 SERIES User manual

CustomCrimp

CustomCrimp CC25 User manual

CustomCrimp

CustomCrimp CC1200 User manual

CustomCrimp

CustomCrimp D105M Series User manual

CustomCrimp

CustomCrimp CC15 User manual

CustomCrimp

CustomCrimp CC4-50 User manual

CustomCrimp

CustomCrimp D165M Series User manual

Popular Crimping Tools manuals by other brands

Tyco Electronics

Tyco Electronics 90035-3 instruction sheet

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 instruction sheet

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual