6I.B. 8926-1A

not be used for storage and should have

adequate lighting.

3. Since control centers are assembled at the

factory on smooth and level surfaces to assure

correct alignment of all parts, control centers

should be securely mounted on a level surface.

The foundation furnished by the purchaser must

be true and level, or the bottom frames must be

shimmed to support the entire base in a true

plane. It is recommended that leveled channel

sills under both the front and rear of the control

center be used to provide this level base. Drill an

tap the channel sills for mounting bolts in

accordance with the applicable floor plan

drawing and then either install the MCC level

with, or on top of, the finished floor. If sills are

grouted in concrete, the mounting bolts should

be screwed in place and remain until the

concrete has hardened.

4. For bottom entry, position the motor control

center so that the conduit stubs or floor

openings are located in the shaded areas shown

on the MCC floor plan drawings (refer to pages

31 to 32 for floor plan dimensions). The shaded

areas represent the open space available for

conduit entry through the bottom of each

section. A shaded area may be restricted if large

controllers or autotransformers are mounted in

the bottom of the sections. If optional bottom

plates are supplied, the plates may be removed

and drilled for conduit entry.

5. Install the MCC in its final position, progressively

leveling each section and bolting the frames

together if they are separated. If necessary,

secure the MCC to walls or other supporting

surfaces. Do not depend on wooden plugs

driven into holes in masonry, concrete, plaster,

or similar materials. See NEC 110-13.

6. If two or more shipping sections are to be joined

into an integral assembly or a shipping section is

to be joined to an existing section, refer to

paragraphs below before proceeding with the

installation.

7. Ground and bond the motor control center as

follows:

a) Motor control centers used as service

equipment for a grounded system or as an

incoming line section for a separately-

derived previously grounded system:

i) Run a grounding electrode conductor

(ground wire) having a size in

accordance with NEC 250-94 from the

grounding electrode to the MCC ground

bus or ground terminal provided. See

also NEC 250-91(a) and 92(b).

ii) If the system is grounded at any point

ahead of the MCC, the grounded

conductor must be run to the MCC in

accordance with NEC 250-23(b), and

connected to the ground bus terminal.

iii) Do not make any connections to ground

on the load side of any neutral

disconnecting line or any sensor used for

ground-fault protection. Do not connect

outgoing grounding conductors to the

neutral.

b) Motor control centers used as service

equipment for an ungrounded system or as

an incoming line section for a separately-

derived previously ungrounded system:

i) Run a grounding electrode conductor

(ground wire) having a size in

accordance with NEC 250-94 from the

grounding electrode to the MCC ground

bus terminal. See NEC 250-91(a) and

92(b).

c) Motor control centers not used as service

equipment nor as an incoming line section

for a separately-derived system, and used

on either a grounded or ungrounded system:

i) Ground the MCC ground bus by means

of equipment grounding conductors

having a size in accordance with NEC

250-95 or by bonding to the raceway

enclosing the main supply conductors in

accordance with NEC 250-91(b).

8. When all wiring and adjustments are complete,

close all unit and wireway doors.

9. In damp indoor locations, shield the MCC to

prevent moisture and water from entering and

accumulating.

10. Unless the motor control center has been

designed for unusual service conditions, it

should not be located where it will be exposed to

ambient temperatures above 40°C (104°F),

corrosive or explosive fumes, dust, vapors,

dripping or standing water, abnormal vibration,

shock or tilting.

JOINING COMPATIBLE SECTIONS

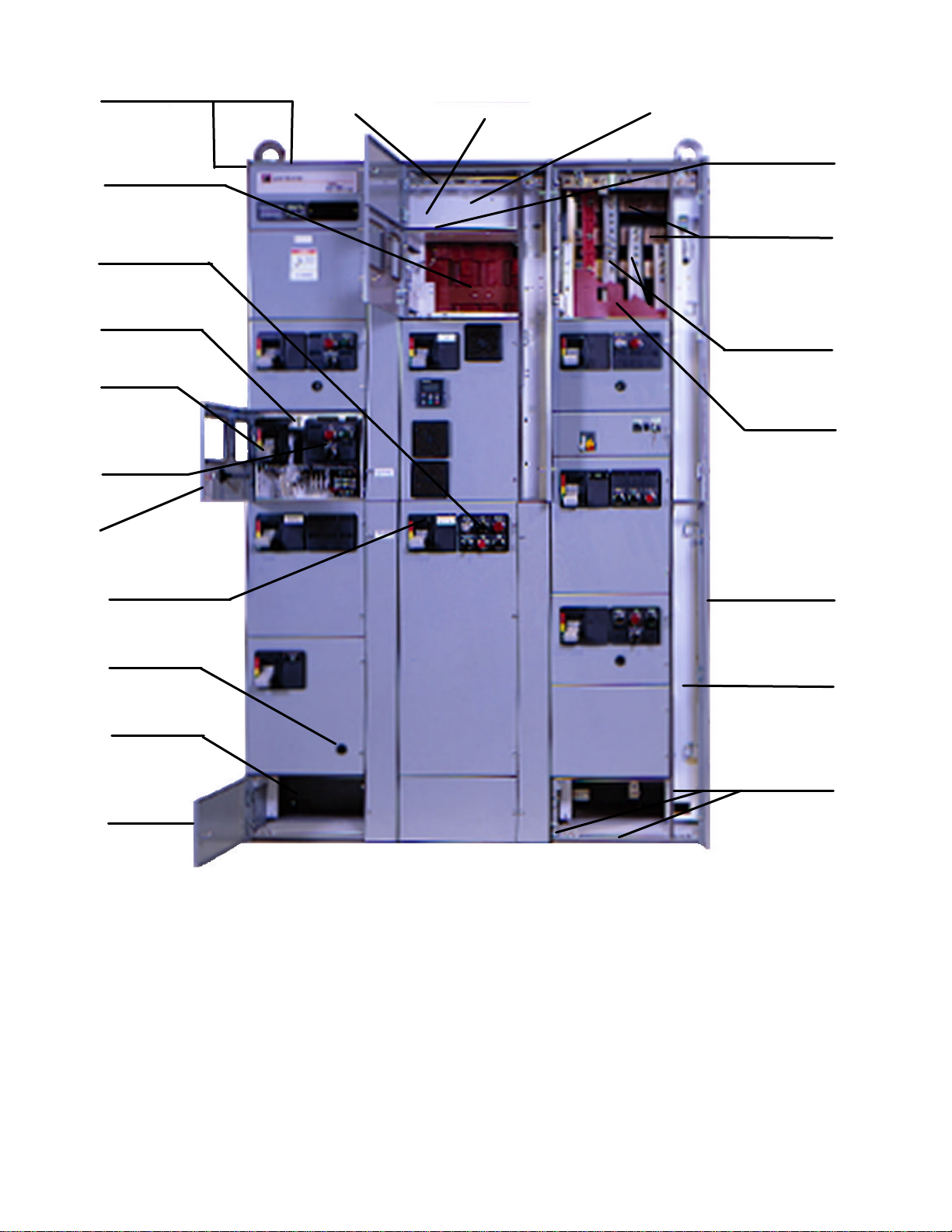

If two more shipping blocks are to be joined into an

integral assembly, or a section added to an existing

installation, splicing or horizontal bus, ground bus,

neutral bus and joining of the adjacent vertical

sections must be planned with the installation.

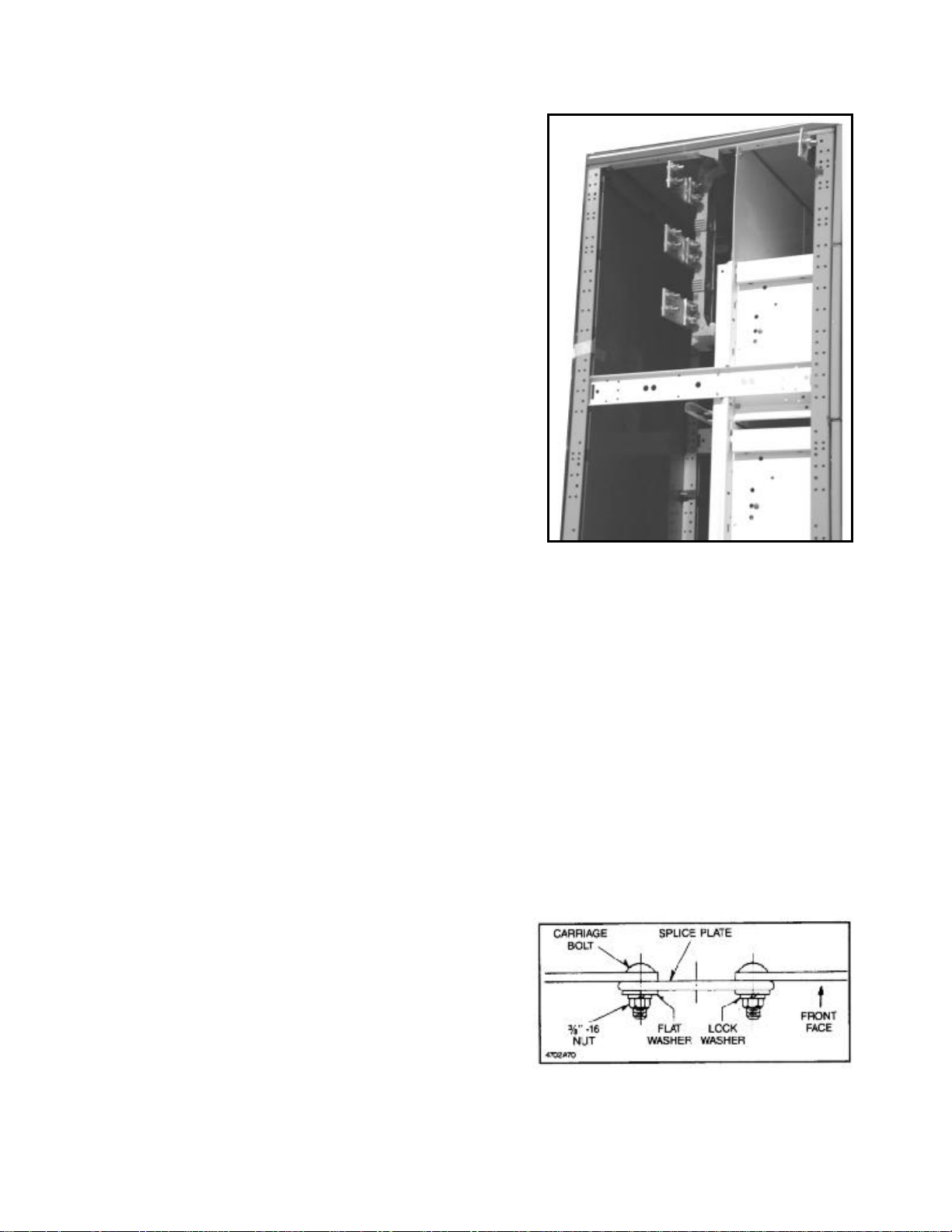

1. Remove the side sheets from adjacent vertical

sections to be joined. (These sheets will have

been removed from factory-assembled

sections.)

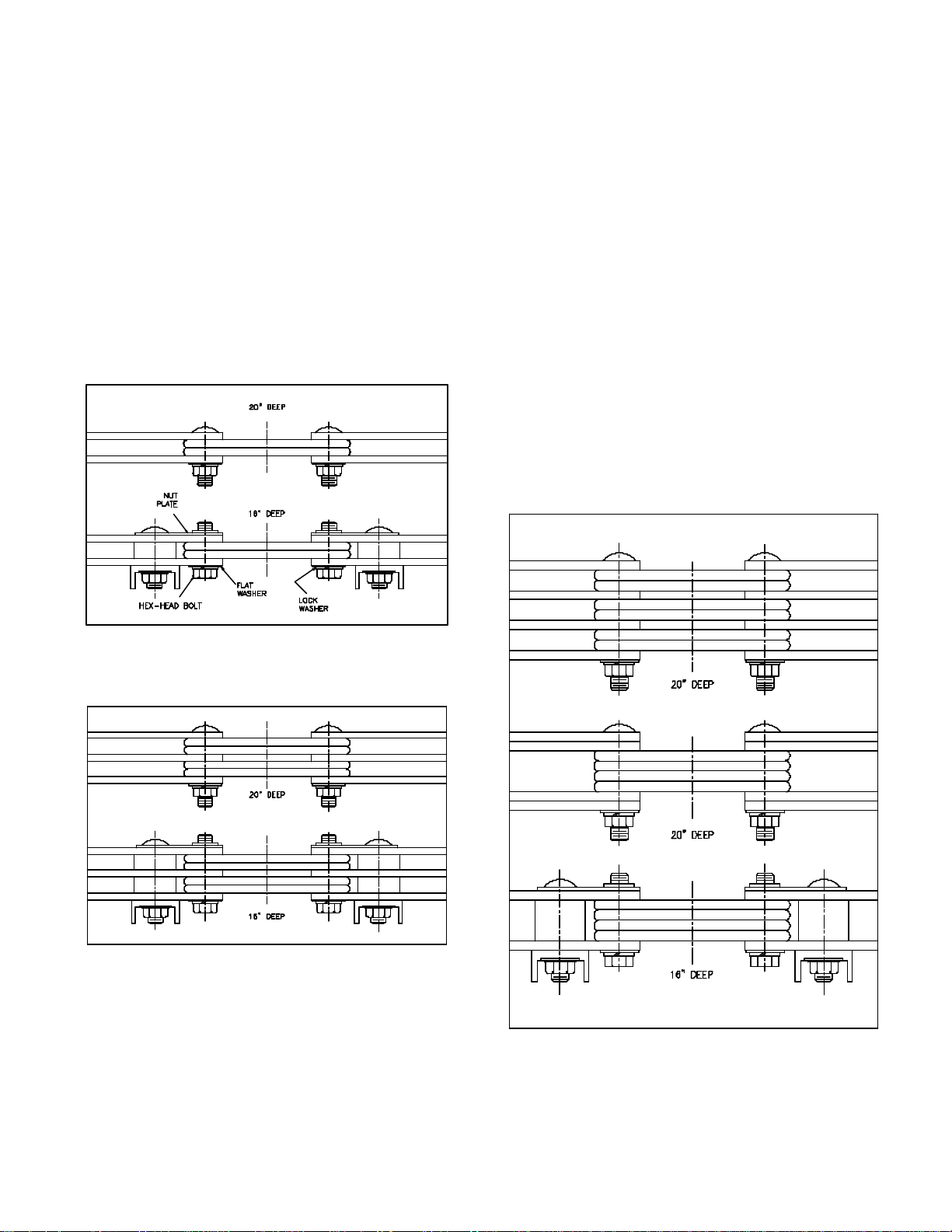

2. The horizontal bus splice plates and connection

hardware will be shipped with the MCC attached

to one end of shipping section. Refer to Figure

4. This method provides the most convenient