3

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING INSTRUCTIONS COULD

RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO read this entire operator’s manual before operating this

machine and understand all warnings, instructions, and

controls.

DO keep all guards in place and in good condition.

DO wear safety approved hearing, eye, head and respiratory protection.

DO read and understand the symbol definitions contained in this manual.

DO keep all parts of your body away from the blade and all other

moving parts.

DO know how to stop the machine quickly in case of emergency.

DO shut off the engine and allow it to cool before refueling.

DO inspect the blade, flanges and shafts for damage before installing the

blade.

DO use CUTTERS EDGE Diamond Blades, BLACK STAR

DIAMOND BLADE or BLACK LIGHTNING DIAMOND

BLADE. Specifically rated with a maximum operating speed of

5400 RPM on 14” (350mm) or 6200 RPM on 12” (300mm).

DO use CUTTERS EDGE Diamond blades marked with a 1”

(25.4mm) hole for a 1” (25.4mm) flange, or a 20mm hole for a

20mm flange.

DO use Cutters Edge diamond blades marked for use with gasoline-

powered, hand-held, portable, abrasive cut-off machines.

DO read all safety materials and instructions that accompany any blade

used with this saw.

DO inspect each blade carefully before using it. If there are any signs of

damage or unusual wear, DO NOT USE THE BLADE.

DO verify the blade arbor hole matches the machine spindle before

mounting the blade.

DO make sure the blade and flanges are clean and free of dirt and debris

before mounting the blade on the saw.

DO use the correct blade for the type of work being done. Check with

blade manufacturer if you do not know if blade is correct.

DO always hold the machine with both hands when the engine is

running. Use a firm grip with thumbs and fingers encircling the

handles.

DO keep all parts of the body away from the cut-off blades when the

engine is running.

DO keep the handles dry, clean, and free of oil or fuel.

DO always carry the machine with the engine stopped and the muffler

away from the body.

DO use caution and follow the instructions when loading the saw.

DO operate this machine only in well ventilated areas.

DO instruct bystanders on where to stand while the saw is in operation.

DO establish a training program for all operators of this machine.

DO clear the work area of unnecessary people. Never allow anyone to

stand in front of or behind the blade while the engine is running.

Do use caution when handling fuel!

DO move the machine at least 10 feet away from the fueling point

before starting the engine and make sure the gas cap and the fuel cap

on the saw are properly tightened.

DO use caution when lifting and transporting the machine.

DO always check for buried electrical cables before sawing.

If unsure, contact the local utilities.

DO have all service, other than items in this manual, performed by

competent service personnel.

DO always tie down the Rotary Saw when transporting.

DO use caution and follow instructions when setting up or transporting

the machine.

DO clean the saw after every use.

DO always give a copy of this manual to the equipment user.

DO NOT Operate this saw unless you have read and understand

this operators manual.

DO NOT Operate this saw without the blade guard, or other

protective guards in place

DO NOT stand behind or in front of the blade path while the

engine is running.

DO NOT leave this saw unattended while the engine is running.

DO NOT operate this machine when you are tired or fatigued.

DO NOT use abrasive blades that are less the 1/8” (3.17mm) thick.

DO NOT exceed maximum blade speed shown for each blade size.

DO NOT use damaged equipment or blades.

DO NOT try to stop a moving blade with your hand.

DO NOT use an abrasive blade that has been dropped.

DO NOT not use Carbide tipped or toothed type blade of any kind.

DO NOT use segmented diamond blades unless they are

specifically designed for high speed, hand-held saws.

DO NOTplace 1 inch (25.4mm) arbor hole blades on 20mm

flanges.

DO NOT grind on the side of a cut-off blade.

DO NOT cock, jam, or wedge the blade in the cut.

DO NOT operate a cutting machine if the blade does not stop

rotating when the throttle trigger is released.

DO NOT start cutting until you have a clear work area and secure

footing.

DO NOT allow other people to be near the machine when starting,

refueling, or when the saw is operating.

DO NOT operate the machine in the vicinity of anything that is

flammable. Sparks could cause a fire or an explosion.

DO NOT allow bystanders or animals in the work area while using

a cut-off saw.

DO NOT touch a dry cutting diamond blade immediately after use.

These blades require several minutes to cool after each

cut.

DO NOT use damaged or worn blade flanges.

DO NOT operate this machine in an enclosed area unless it is

properly ventilated.

DO NOT allow blade exposure for the guard to be more than 180

degrees.

DO NOT operate this saw without both hands on the handles.

..............................................................................................................................

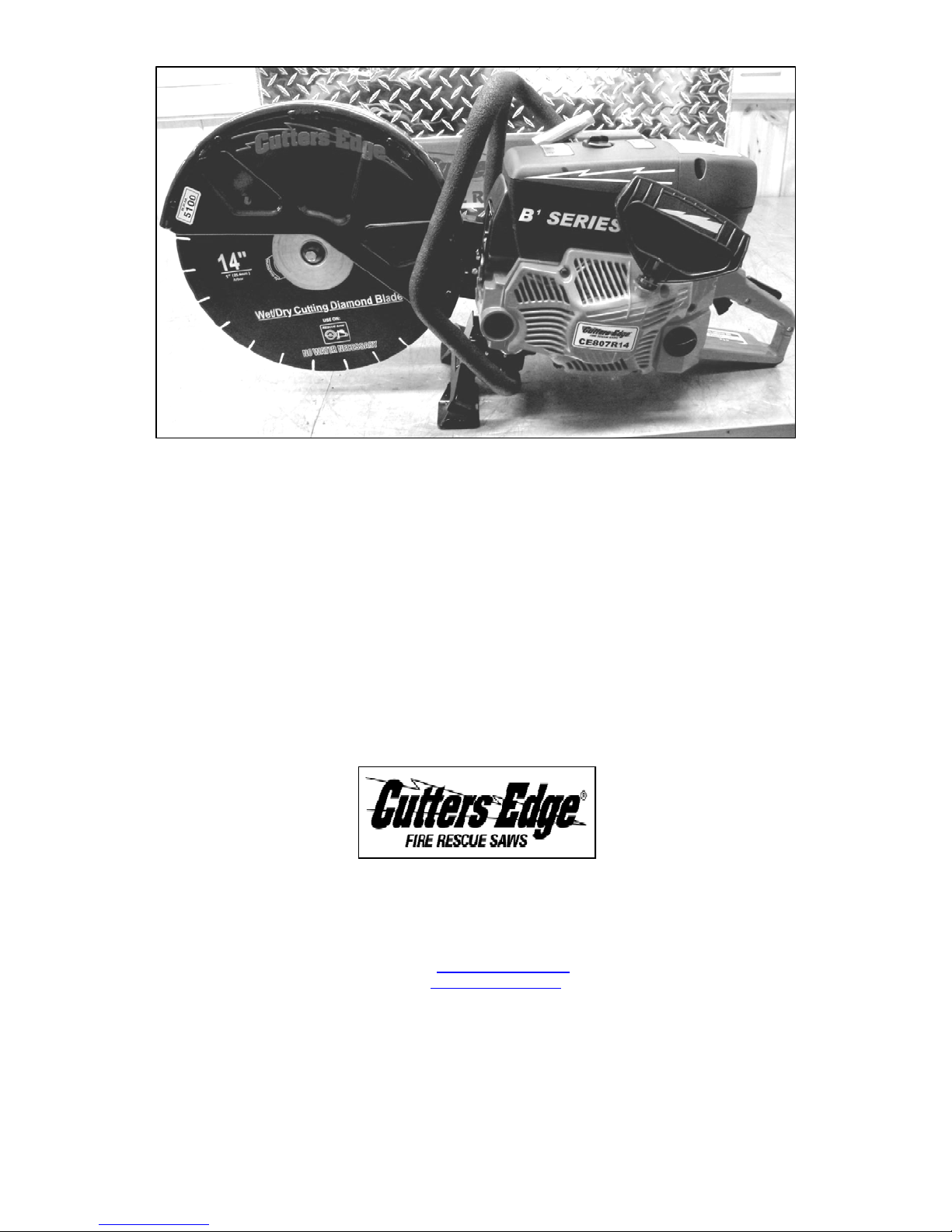

This saw has been designed specifically for Fire Rescue cutting applications.

Do not modify or use this saw for any purpose other than Fire Rescue

cutting. If you have any questions relative to its intended application, do not

use the saw until you have been advised regarding an application in question.

WARNINGS