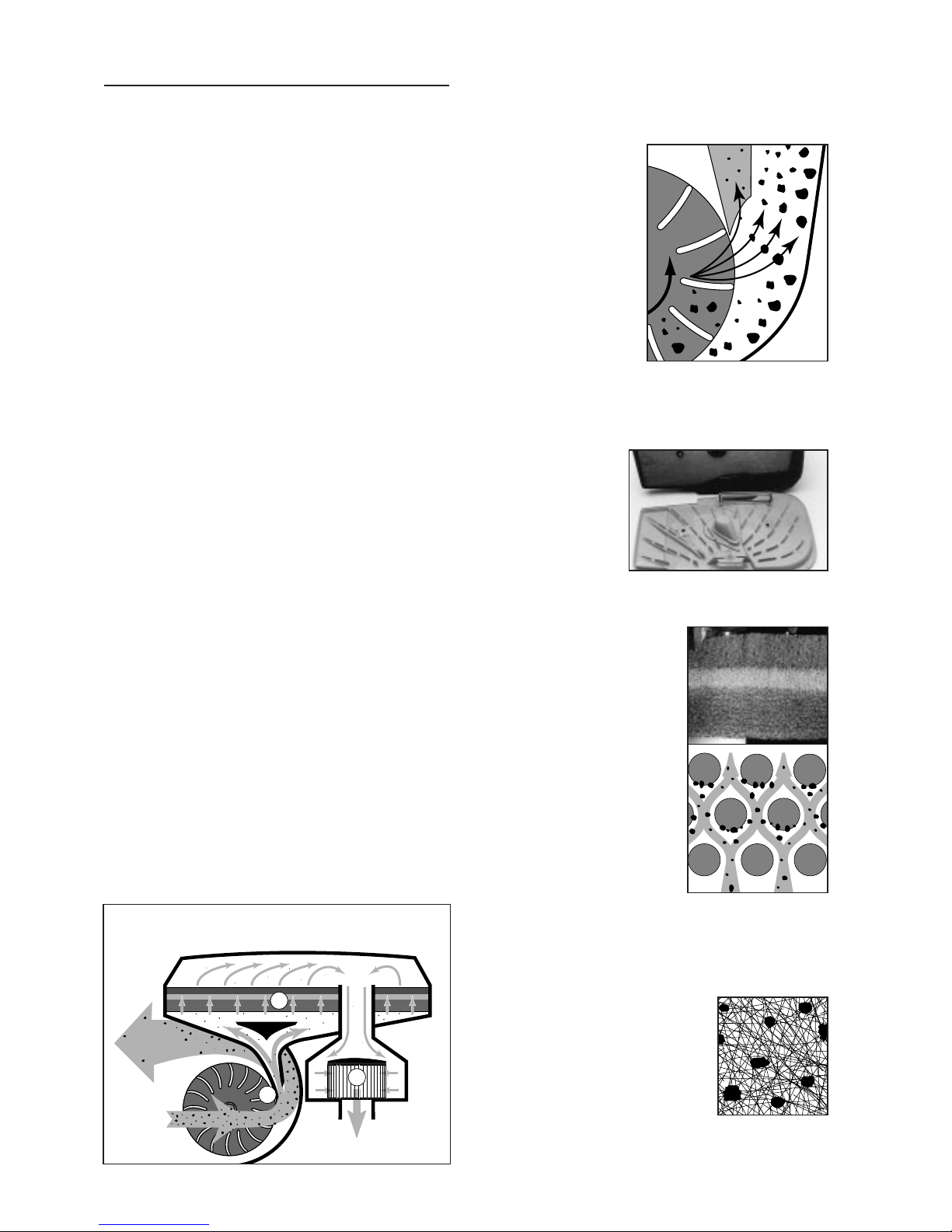

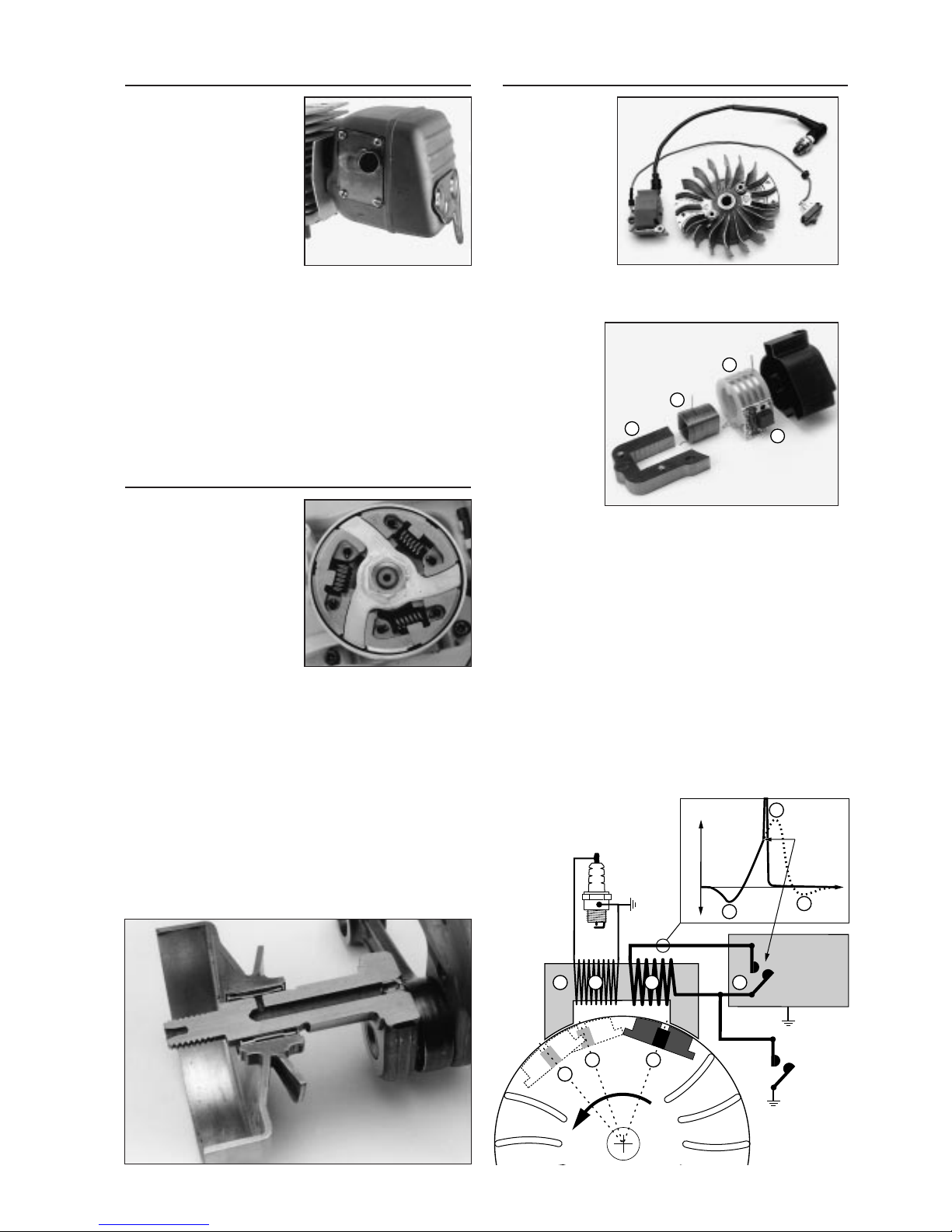

1. Centrifugal force is the first stage in cleaning the

intake air of the K950/K1250 Active. Centrifugal cleaning

was previously only used on larger engines in dusty

environments, for example for construction machines

(cyclone air filter).

The fan vanes on

the flywheel supply the

cylinder with cool air at

the same time as they act

as the active part of the

centrifugal filtering sys-

tem for the engine’s in-

take air. An intake nozzle

is fitted just beside the

fan vanes. Under centri-

fugal force, the larger

particles do not follow

the curved current of air

to the nozzle but are in-

stead thrown against the outside of the nozzle. Only very

small dust particles will be able to follow the current of

air leading into the intake. Tests show that up to 80% of

all dust is removed by the centrifugal cleaning process.

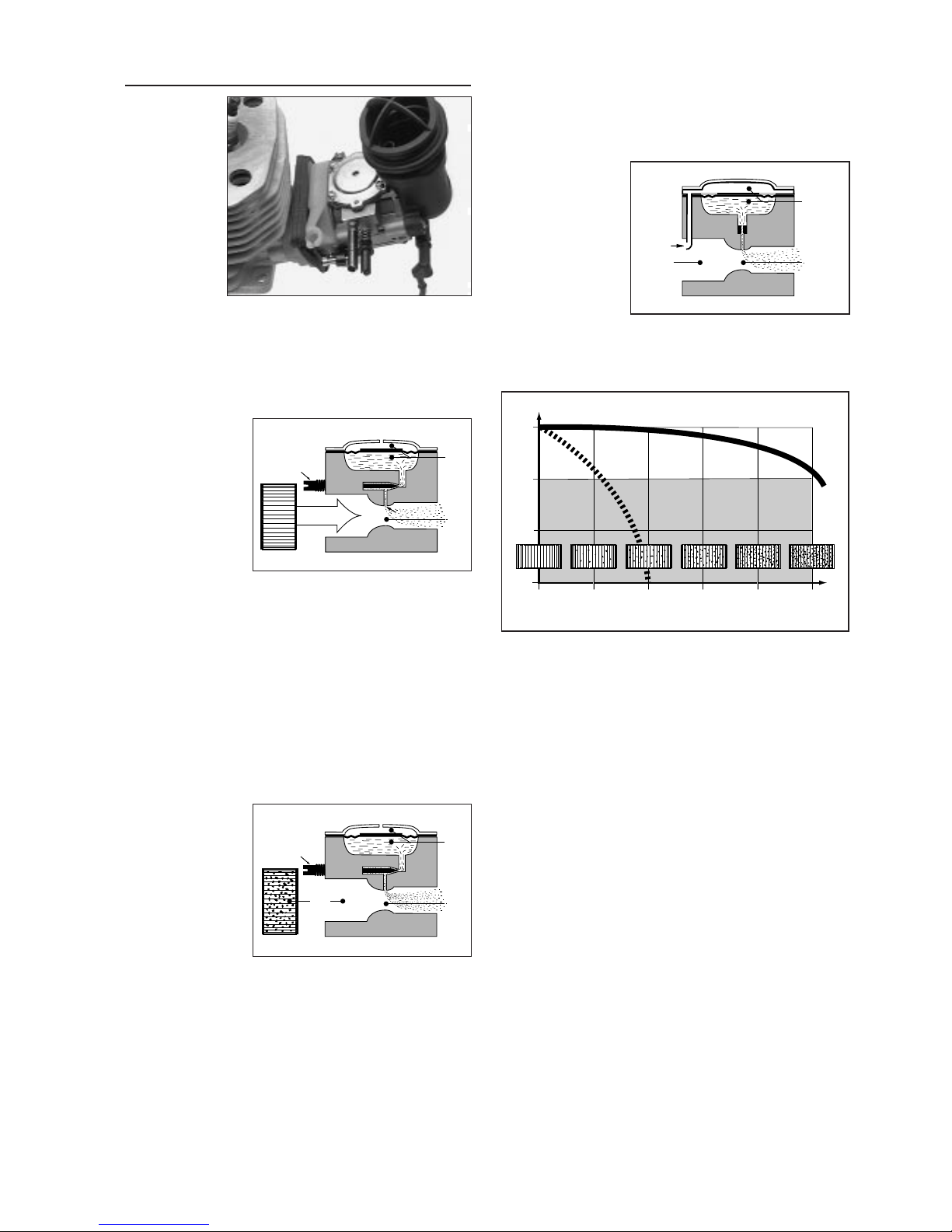

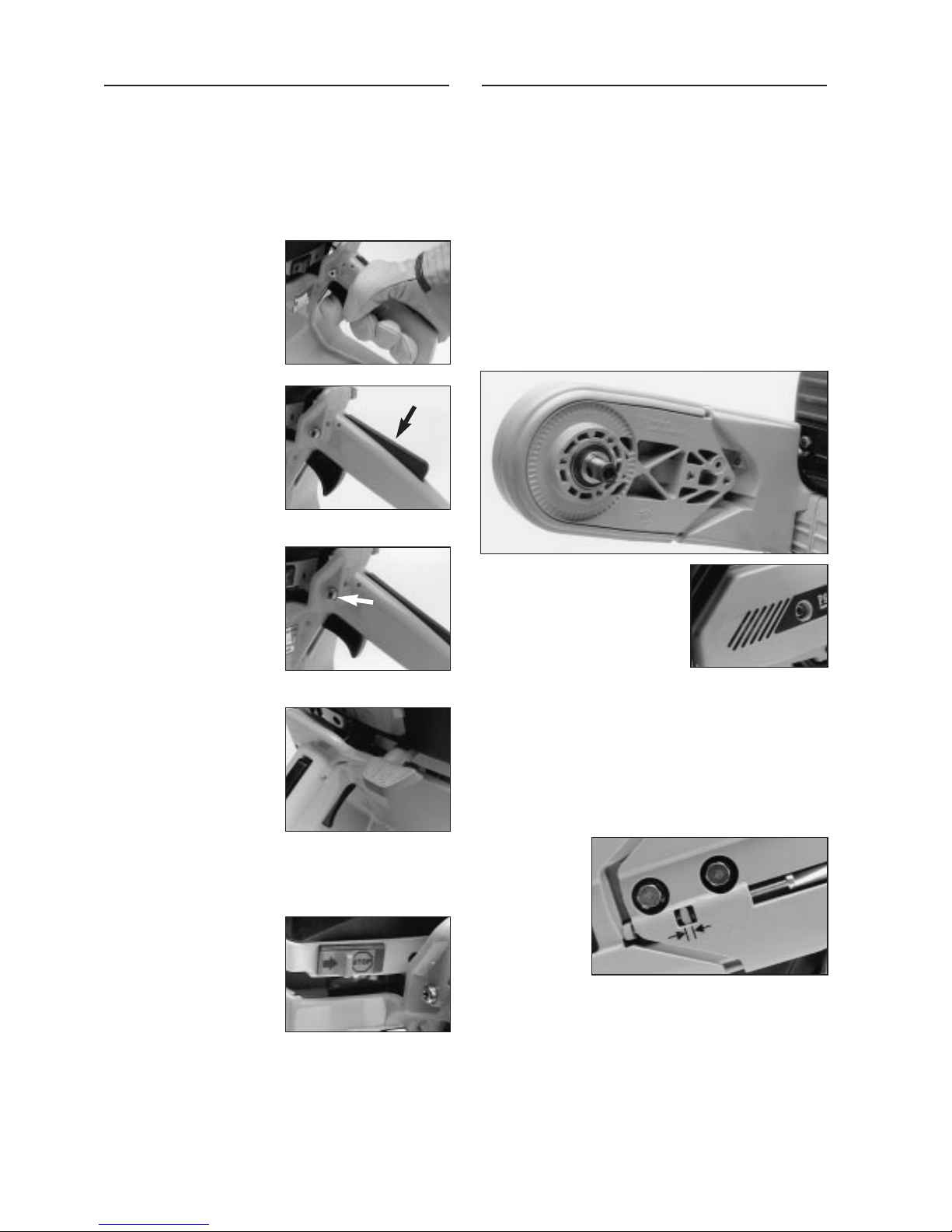

2. The foam filter

is the next stage of

separation in the filtra-

tion process. This filter

covers the housing’s

entire surface, thus

offering a filter surface

of no less than 3.5 dm2

(K950), 3.7 dm2(K1250). The filter’s base distributes air

across the entire filter surface, so the filter performs

uniformly.

The filter is immersed in oil

and is made up of three layers,

each intended for a different

pore size.

Inside the filter, the air flows

through a structure pretty much

like a labyrinth. Dust particles

which strike against the filter

sides do not bounce off but

instead fasten to the sticky oily

surface. A dry foam filter offers

far less efficient cleaning perfor-

mance than an oil-soaked filter.

An oiled foam filter is by far

the most effective filter for clea-

ning of stone dust, since the

entire filter volume is used as a

“dust trap”, not just the surface. The total dust-absor-

bing filter area is accordingly enormous. The foam filter

absorbs about 95% of the total dust volume remaining

after centrifugal filtering. It can be washed clean and

must be oiled at each service.

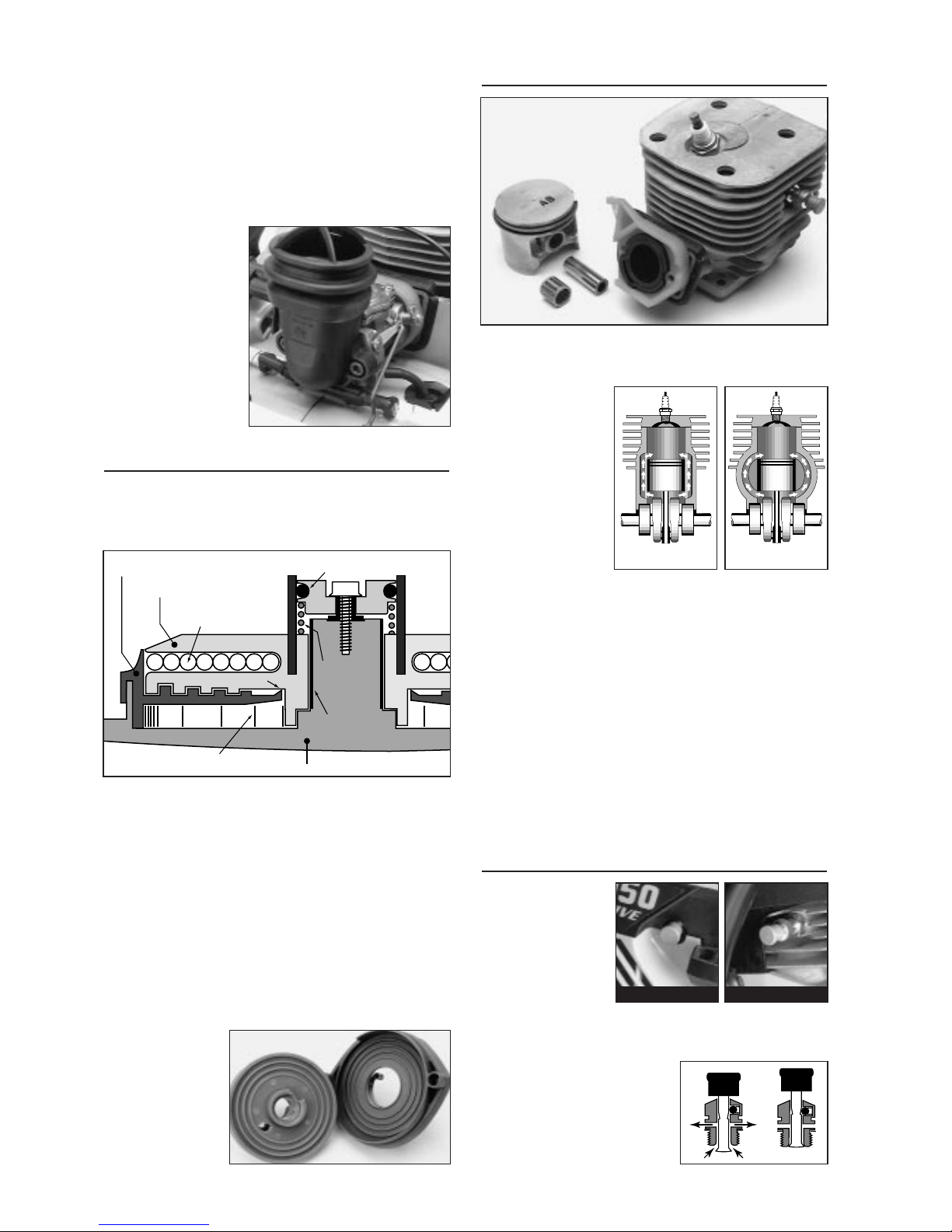

3. The paper filter deals with the

small amount of dust particles which,

more by chance than anything else,

may manage to slip through the foam

filter. Only a tiny amount of extremely

small dust particles will ever get as

far as the paper filter. The filter’s

dense network of cellulose fibres

traps all incoming particles. The paper filter also serves

as a protective barrier during filter services. The paper

filter should be changed at every service.

2

Filter System

Cutting in stone and concrete generates tiny dust parti-

cles which must at all costs be prevented from entering

the engine. The design of the air filter and its maintenan-

ce are the two most important factors governing the ser-

vice life of the cutter. Designing a good air filter system

is a matter of balancing effective filtering with long ser-

vice intervals.

The development of more efficient filters has improved

air-cleaning performance, but service intervals have by

tradition still been inconveniently short in cutting machi-

nes. Machine rental firms inherit the problems caused by

customers who do not carry out the necessary service

during the rental period, or are faced with the cost of tra-

velling frequently to various work-sites to carry out the

necessary service.

Dust consists of extremely fine particles, generally so

small that the individual particle cannot easily be disting-

uished by the naked eye but which in larger quantities

can be seen as a cloud of dust. The stone or concrete

dust which generally results from cutting operations

generates the most damaging kind of particles for an

engine’s sliding or rotating components. Together with

oil, this dust forms a perfect grinding paste which quick-

ly wears down pistons, piston rings, cylinder walls and

engine bearings once it penetrates an engine.

We generally measure dust particles in µm (1 µm =

0.001 mm), thousandths of a millimetre, and the particle

sizes which are dealt with by the filter system generally

measure between 50 µm and 5 µm. (It takes roughly 2

minutes for a stone particle measuring 10 µm to fall 1 m

in wind-still conditions.)

One physical characteristic which is vital to the func-

tion of the Partner Active Air Filtration system is the

behaviour of dust particles in air currents depending on

particle size:

A small particle is more easily affected by a current of

air than a larger particle.

The reason for this is that small particles have a larger

surface in relation to their mass. A small particle can the-

refore be steered and guided more easily by a current of

air while a larger particle succumbs to centrifugal force

or the force of gravity.

Partner Active Air Filtration is a filter system which

effectively cleans the air entering the engine in three

separate stages, utilising three different cleaning princi-

ples. The most immediate practical benefit of Active Air

Filtration is that the service intervals are far longer com-

pared to previous systems.

In

To carburettor

Cylinder

cooling air

2

3

1

Air filtration principle