CUTTERS EDGE

9

Cutting Blades

770/970/1270 Model

General

•Cutting blades are available in two basic designs;

abrasive blades and diamond blades.

• High-quality blades are often most economical. Lower quality

blades often have inferior cutting capacity and a shorter service

life, which results in a higher cost in relation to the quantity of

material that is cut.

• Make sure that the right bushing is use d for the cutting blade to

be fitted on the machine. See the inst ructions under the heading

Fitting the cutting blade.

Suitable cutting blades

*Without water

Cutting blades for different materials

Follow the instructions supplied with the cutting blade

concerning the suitability of the blade for various applications, or

consult your dealer in case of doubts.

Cutting blades H Series

Abrasive blades Yes*

Diamond blades Yes

!

WARNING! Never use a cutting blade

for any other materials than what it

was intended to cut.

Never use a diamond blade to cut

plastic material. The heat produced

during cutting may melt the plastic

and it can stick to the cutting blade

and cause a kickback.

Concrete Metal Plastic Cast

iron

Abrasive

blades X X X X

Diamond

blades XX* X*

!

WARNING! A cutting blade may

burst and cause injury to the

operator.

* Only specialty blades.

Hand held, high speed machines

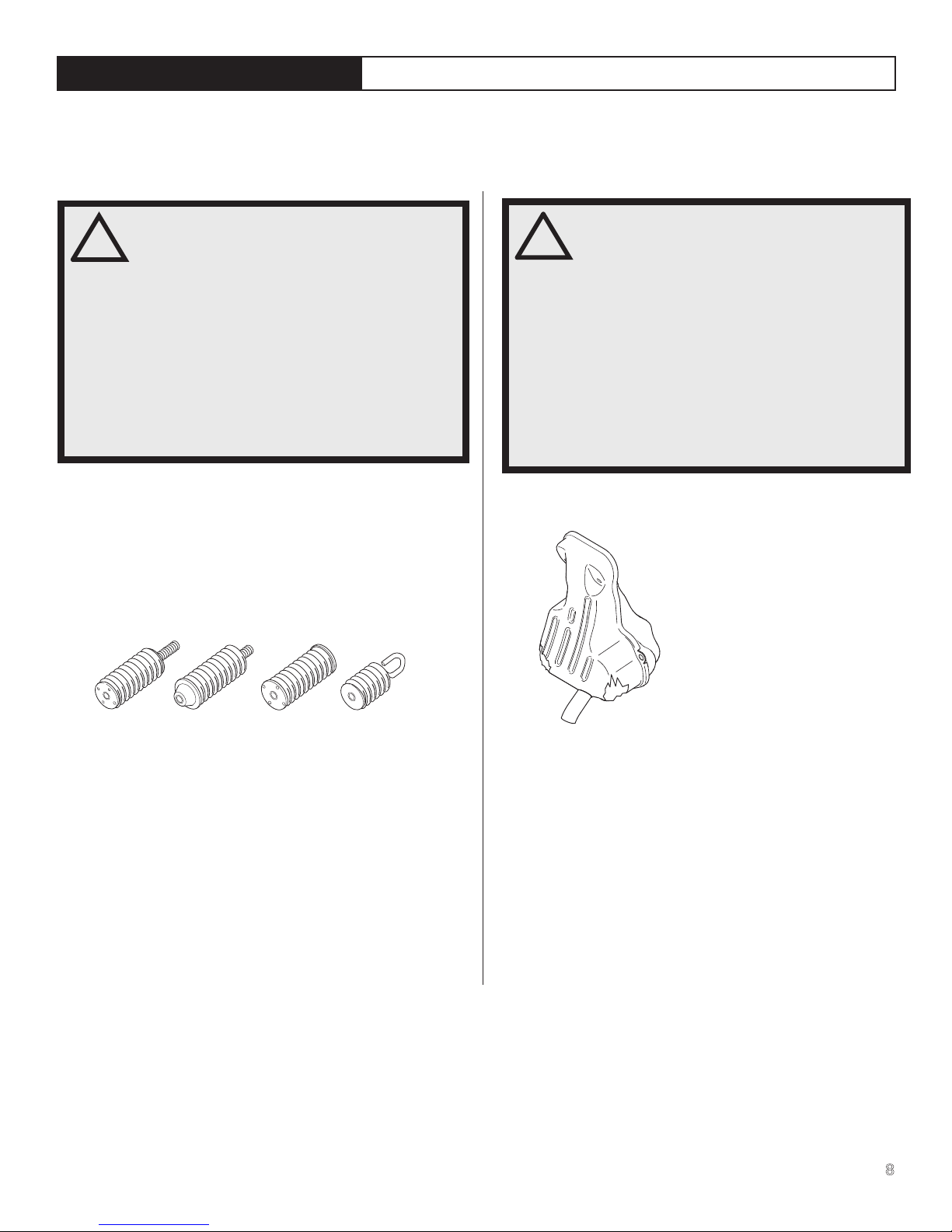

•Many cutting blades t hat might fit this power cutter

are intended for stationary saws and have a lower

speed rating than is needed for this hand-held saw.

Cutting blades with a lower speed rating shall never

be used on this saw.

•Our cutting blades our manufactured for high-speed

portable power cutters.

•Check that the blade is approved for the same or

higher speed according to the approval plate of the

engine. Never use a cutting blade with a lower speed

rating than that of the power cutter.

!

WARNING! Never use a cutting

blade with a lower speed rating

than that of the power cutter.

Blade vibration

•The blade can become out-of-round and vibrate if an

excessive feed pressure is used.

• A lower feed pressure can stop the vibration.

Otherwise replace the blade.

If you use Abrasive Blades

•The cutting material on abrasive blades consists of

grit bonded using an organic binder. ”Reinforced

blades” are made up of a fabric or fibre base that

prevents total breakage at maximum working speed if

the blade should be cracked or damaged.

• A cutting blade’s performance is determined by the

type and size of abrasive corn, and the type and

hardness of the bonding agent.

• Ensure the cutting blade is not cracked or damaged.

• Test the abrasive blade by hanging it on your finger

and tapping it lightly with a screwdriver or the like. If

the blade does not produce a resonant, ringing sound

it is damaged.