LOCKZONE Wall

2Swegon reserves the right to alter specications. 20211011

Technical description

Design

Rectangular supply air diffusers for installation in a wall.

The diffuser face is easy to remove and has guide vane

perforations.

Materials and surface treatment

The diffuser face is made of sheet steel and aluminium.

The ALV commissioning box is made of galvanized sheet

steel. The interior and exterior surfaces of the air diffusers

are painted.

• Standard colour:

- White semi-gloss, lustre 40, RAL 9003/NCS S 0500-N

• Alternative standard colours:

- Silver gloss, lustre 80, RAL 9006

- Grey aluminium gloss, lustre 80, RAL 9007

- White semi-gloss, lustre 40, RAL 9010

- Black semi-gloss, lustre 35, RAL 9005

- Grey semi-gloss, lustre 30, RAL 7037

• Non-painted finish and other colours available on

request.

Accessories

Commissioning box:

ALV. Made of galvanized sheet steel. Contains removable

commissioning damper, fixed measurement tapping and

air distribution baffle.

The commissioning box is available with two different

connection options: rear and side connection respectively.

Cover plate:

ALVT 1. For the aesthetic installation of the ALV commis-

sioning box.

Planning

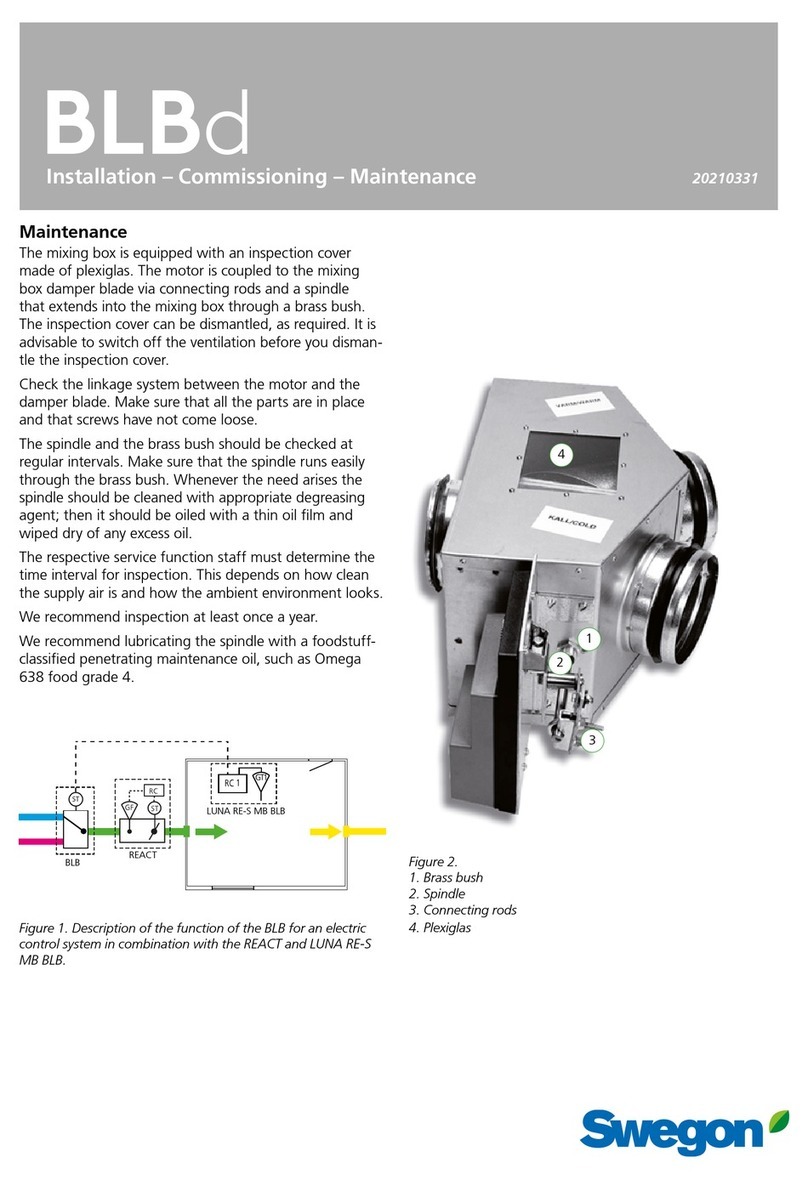

The ALV commissioning box is well-suited for installa-

tion in 1200 mm plasterboard walls (600 mm centre to

centre) and 900 mm plasterboard walls (450 mm centre

to centre). See figure 1.

Installation

• Cut an opening in the wall according to the wall ope-

ning dimensions specified.

• Place the commissioning box in the opening.

• Sealant is applied between the commissionig box and

mounting frame to avoid leakage. Insert the mounting

frame into the commissioning box and secure it by

means of screws in the short sides to the commissio-

ning box and to the wall structure.

• The assembly and dismantling of the component parts

are shown in Figure 1.

• Press the diffuser face to engage it in the mounting

frame.

Commissioning

Commissioning must be carried out with the diffuser face

in place. Pull the measurement hose and damper adjust-

ment cords out of the air diffuser through the perfora-

tion. Connect a manometer to the measurement hose.

Figure 1. Installation.

To secure baffle (4) in bayonet catch and to secure the octagonal

perforated face plate (3) against the duct connection.

1. Commissioning box

2. Damper action, bayonet catch

3. Octagonal air distribution plate

4. Air distribution plate

5. Mounting frame + air diffuser

5

The desired commissioning pressure be computed by

applying the rated coefficient of performance of the air

diffuser. Set the damper to the correct blade position, tie

a commissioning knot in the damper cords to indicate the

damper position. Then lock the cords against the lock-

ing screw in the air distribution baffle. See Figure 1. The

rated coefficient of performance (K-factor) is specified on

the identification label of the product and in the relevant

commissioning instructions at www.swegon.com.

Maintenance

Clean the air diffuser when necessary using lukewarm

water with added detergent. The duct system can be

accessed after opening the diffuser face by pulling it

down from the upper edge, withdrawing the air distri-

bution baffle and lowering the fully open damper. See

Figure 1.

Environment

The relevant building product declaration is available at

www.swegon.com.

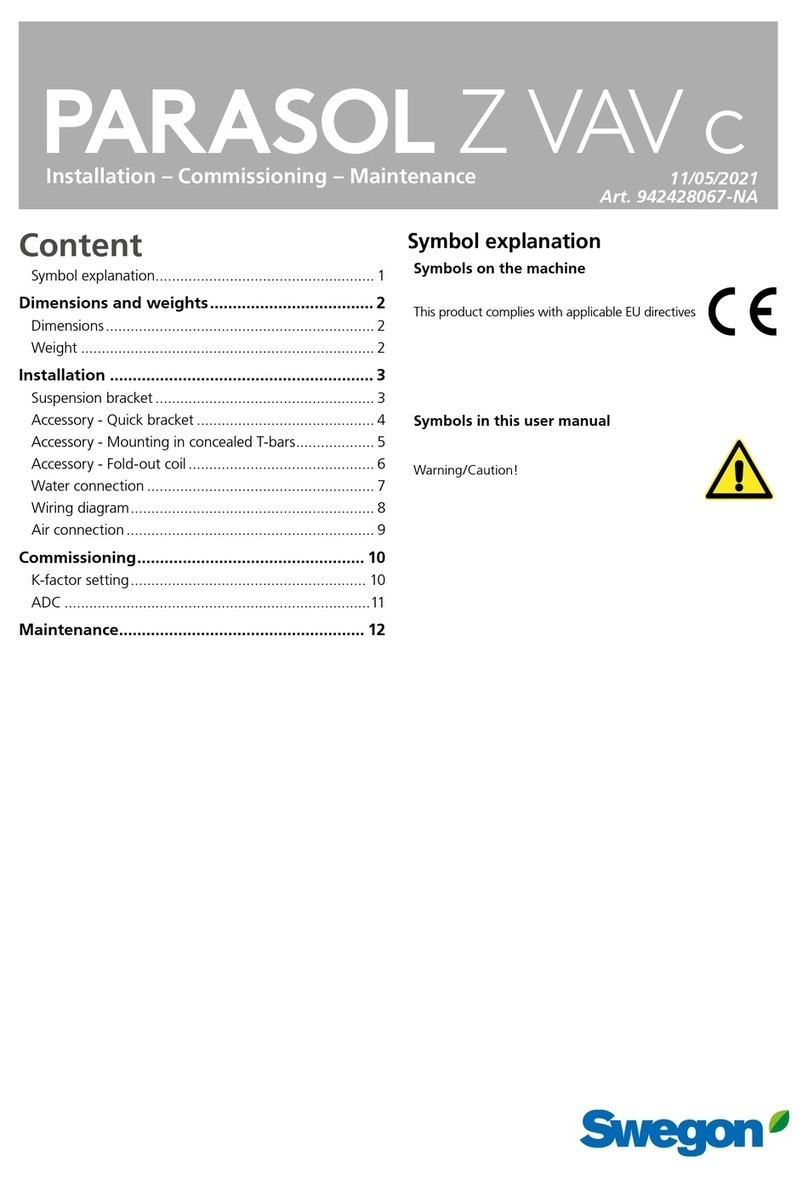

0xD / ±5% 0xD / ±5% 2xD / ±10%

Figure 2. Installation alternatives, applies for all connections (B, K)