2/64 NT00000850-UTBS-ECOWATT-PRO-REG-ETD2-AN-230623

SOMMAIRE

1. GENERAL........................................................................................................................................... 4

1.1 Warnings .................................................................................................................................. 4

1.2 Safety instructions .................................................................................................................... 4

1.3 Reception – Storage................................................................................................................. 5

1.4 Warranty ................................................................................................................................... 5

2. PRODUCT RANGE PRESENTATION................................................................................................ 5

2.1 Range....................................................................................................................................... 5

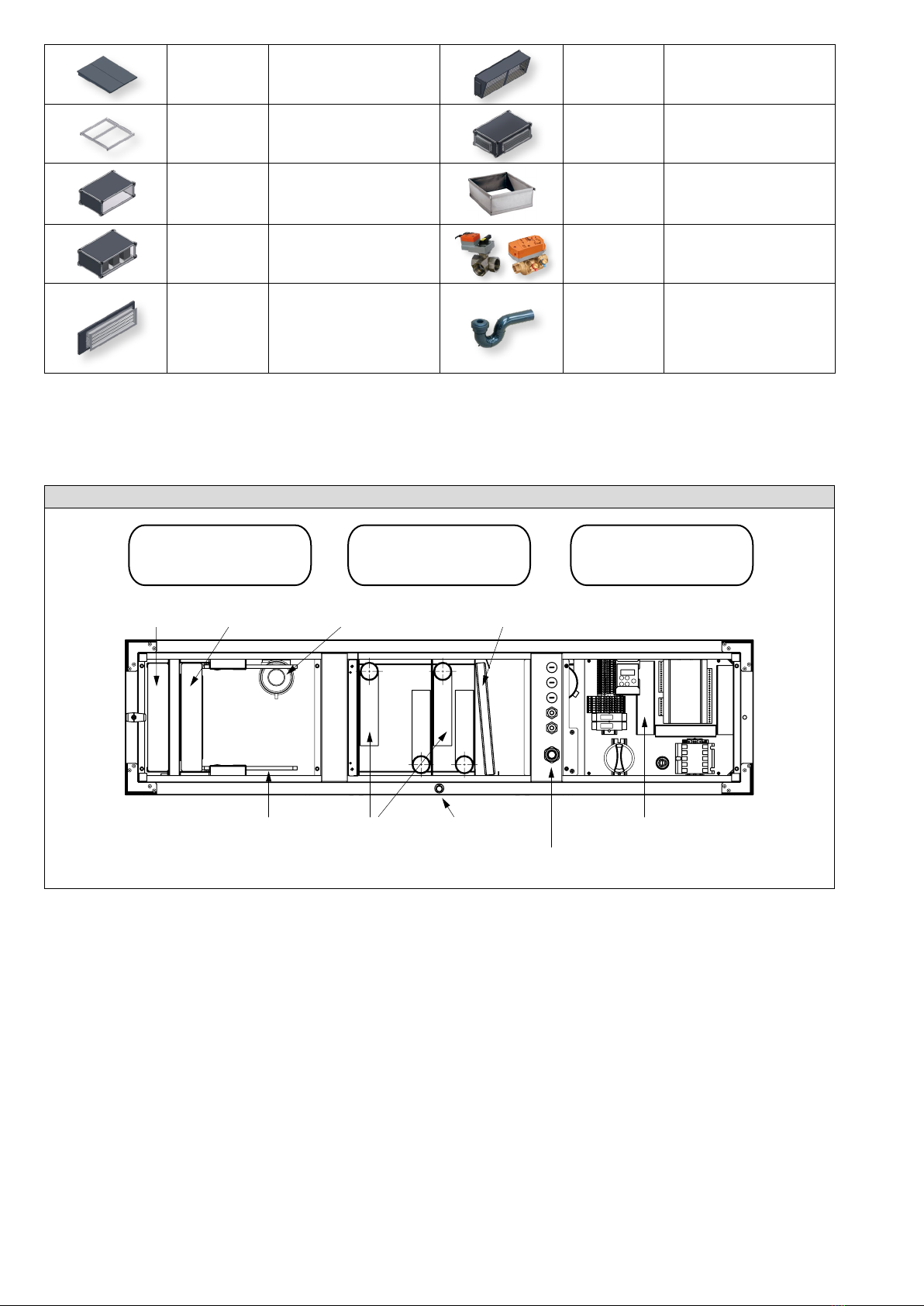

2.2 Main components ..................................................................................................................... 7

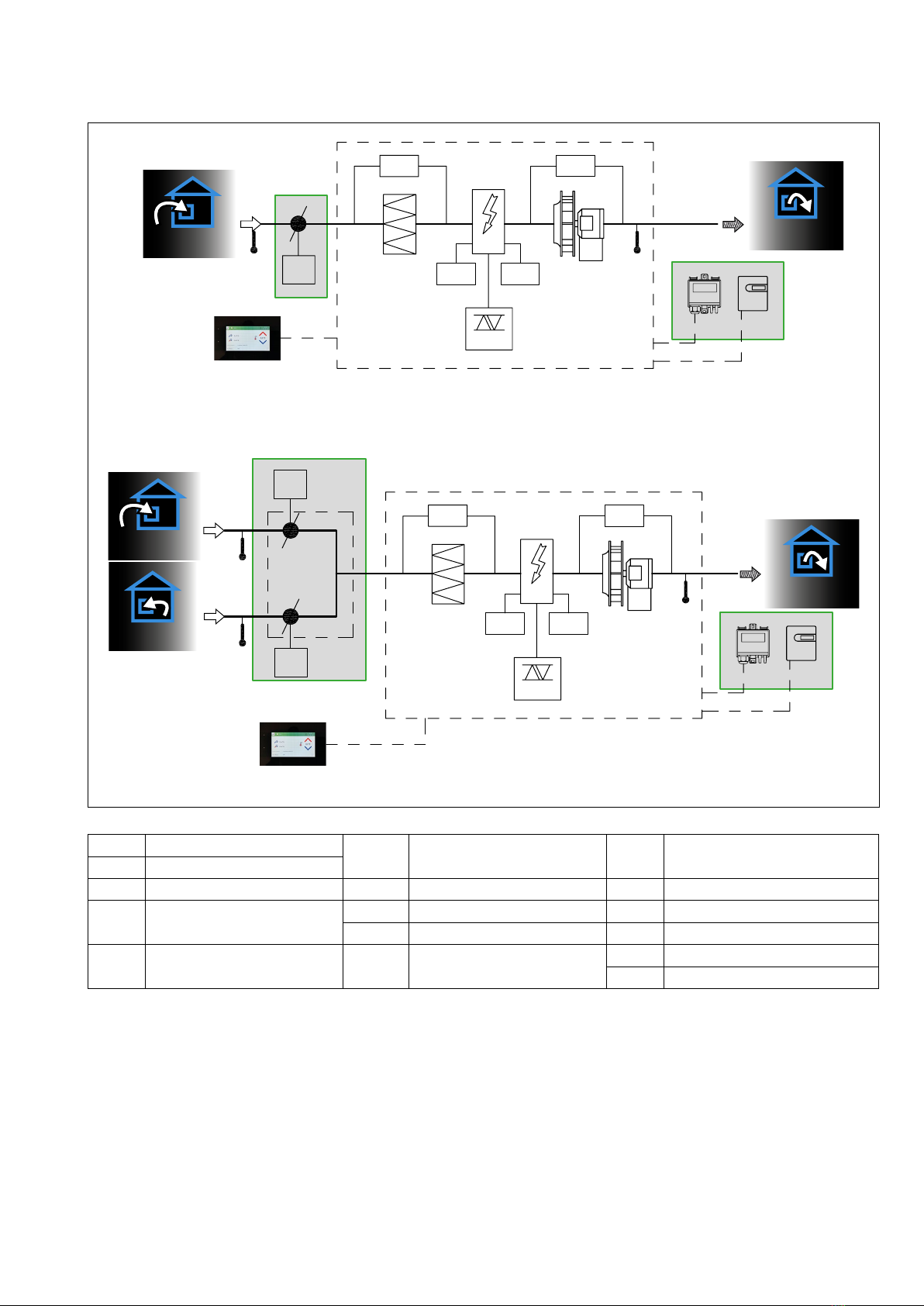

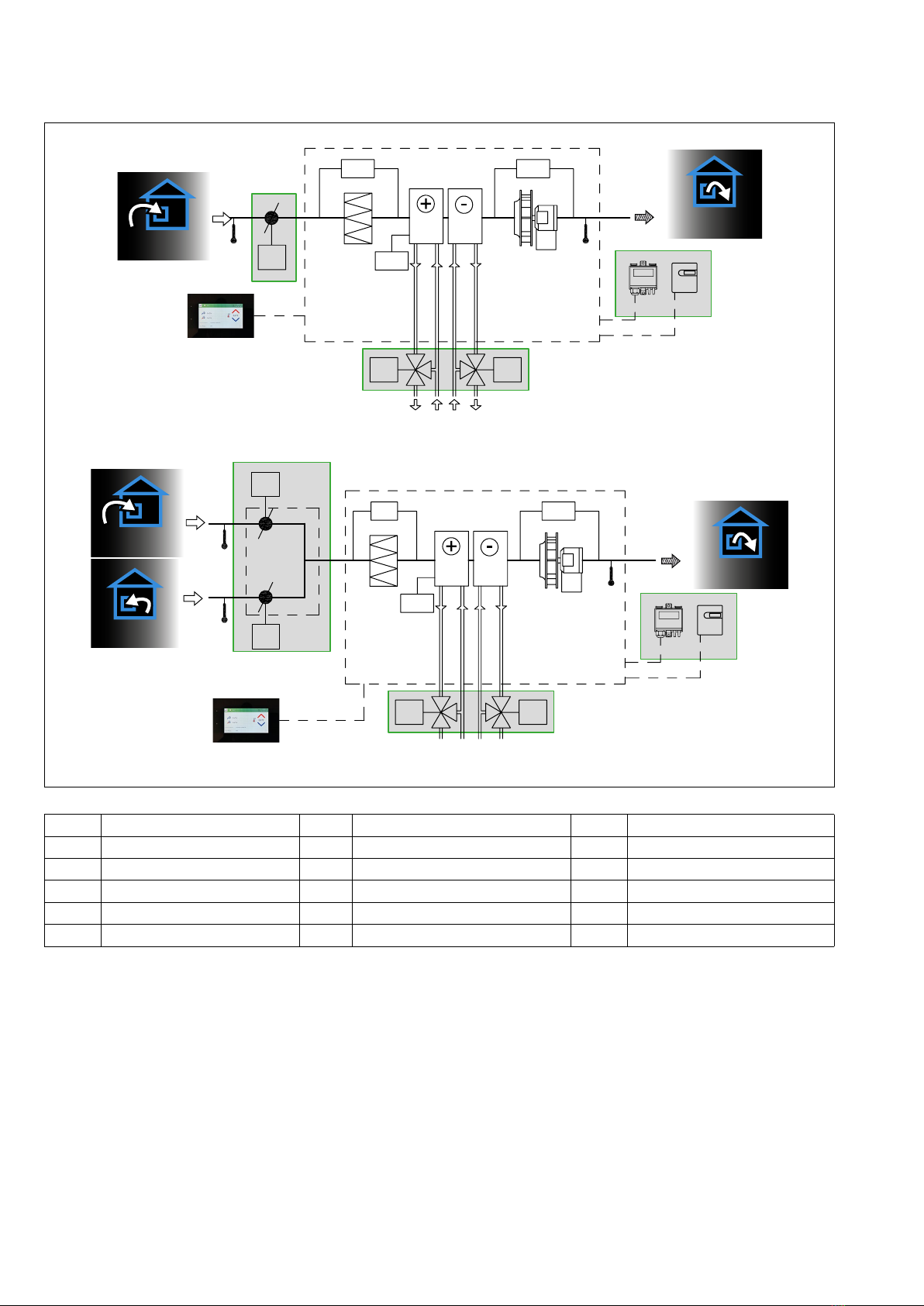

2.3 Functional synoptics (examples) .............................................................................................. 8

3. INSTALLATION ................................................................................................................................ 12

3.1 Machine identication............................................................................................................. 12

3.2 Dimensions and weights......................................................................................................... 12

3.3 Handling and lifting................................................................................................................. 18

3.4 Location and mounting ........................................................................................................... 18

3.5 Fitting accessories.................................................................................................................. 20

4. HYDRAULIC AND FLUID CONNECTION ....................................................................................... 22

4.1 Connecting the water coils ..................................................................................................... 22

4.2 Connection of hydraulic accessories...................................................................................... 23

4.3 Connection of direct expansion coils (DX).............................................................................. 24

4.4 Condensate drain ................................................................................................................... 25

4.5 Temperature sensors.............................................................................................................. 25

5. AIR DUCT CONNECTION................................................................................................................ 26

5.1 Duct connection...................................................................................................................... 26

5.2 Accessories connection.......................................................................................................... 27

6. ELECTRICAL CONNECTIONS AND FEATURES ........................................................................... 27

6.1 Electrical connections............................................................................................................. 27

6.2 Electrical features................................................................................................................... 27

6.3 CORRlGO controller - Technical datas................................................................................... 28

6.4 Remote control with ETD2 display - Connection.................................................................... 28

6.5 Internal electrical board - Description and connection............................................................ 30

6.6 External components connection diagrams (examples)......................................................... 32

6.7 Connecting accessories for temperature control with internal coil ......................................... 34

7. CONTROL - FUNCTIONAL ANALYSIS ........................................................................................... 35

7.1 Main elements of control ........................................................................................................ 35

7.2 Airow control fan................................................................................................................... 36

7.3 Temperature control................................................................................................................ 37

7.4 Special case: temperature control with EX direct expansion coil ........................................... 38

7.5 Heating water coil frost protection (EC / ECF / ER versions) ................................................. 39

7.6 AHU start and stop sequences............................................................................................... 39

7.7 Input for external re signal .................................................................................................... 40

7.8 Clock and time programming.................................................................................................. 40

8. USE OF REMOTE CONTROL ETD2 ............................................................................................... 41

8.1 Presentation of the ETD2 remote control ............................................................................... 41

8.2 Stop the air handling unit........................................................................................................ 42

8.3 Main settings .......................................................................................................................... 42

8.4 Specic settings for ventilation modes CAV/VAV/COP........................................................... 45

8.5 Time schedule ........................................................................................................................ 49

8.6 Setting the communication protocol ....................................................................................... 51

8.7 Save and restore .................................................................................................................... 52

8.8 Expert level settings ............................................................................................................... 53

9. BMS COMMUNICATION .................................................................................................................. 53

9.1 Communication in Modbus protocol ....................................................................................... 53

9.2 Communication in BACnet protocol........................................................................................ 56

10. COMMISSIONING ............................................................................................................................ 56

10.1 AHU factory settings............................................................................................................... 56

10.2 Factory control of air handling units........................................................................................ 57

10.3 Recommendations.................................................................................................................. 57