ENGLISH

TABLE

OF

CONTENTS

Technical

data

Attention!

General

remarks

Machine

description

Preparation

Mounting

and

filling

the

bottle

Control

of

moistening

and

water

level

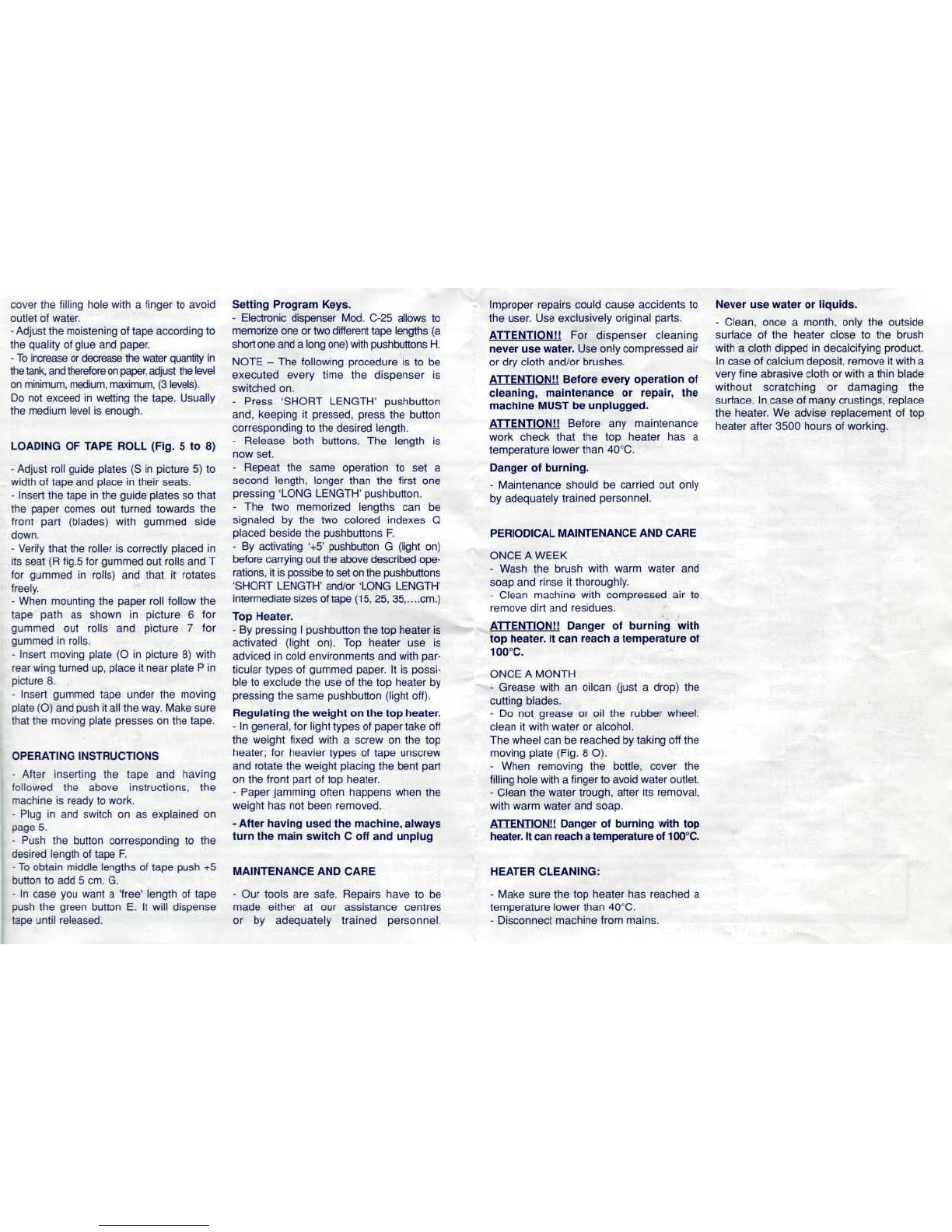

Loading

of the

tape roll

Operating

instructions

Maintenance

and

care

TECHNICAL

DATA

MAINFEATURES

Dimensions

of

machine:

45x29x25

cm.

approx.

Weight

of

machine:

13

Kgs.approx.

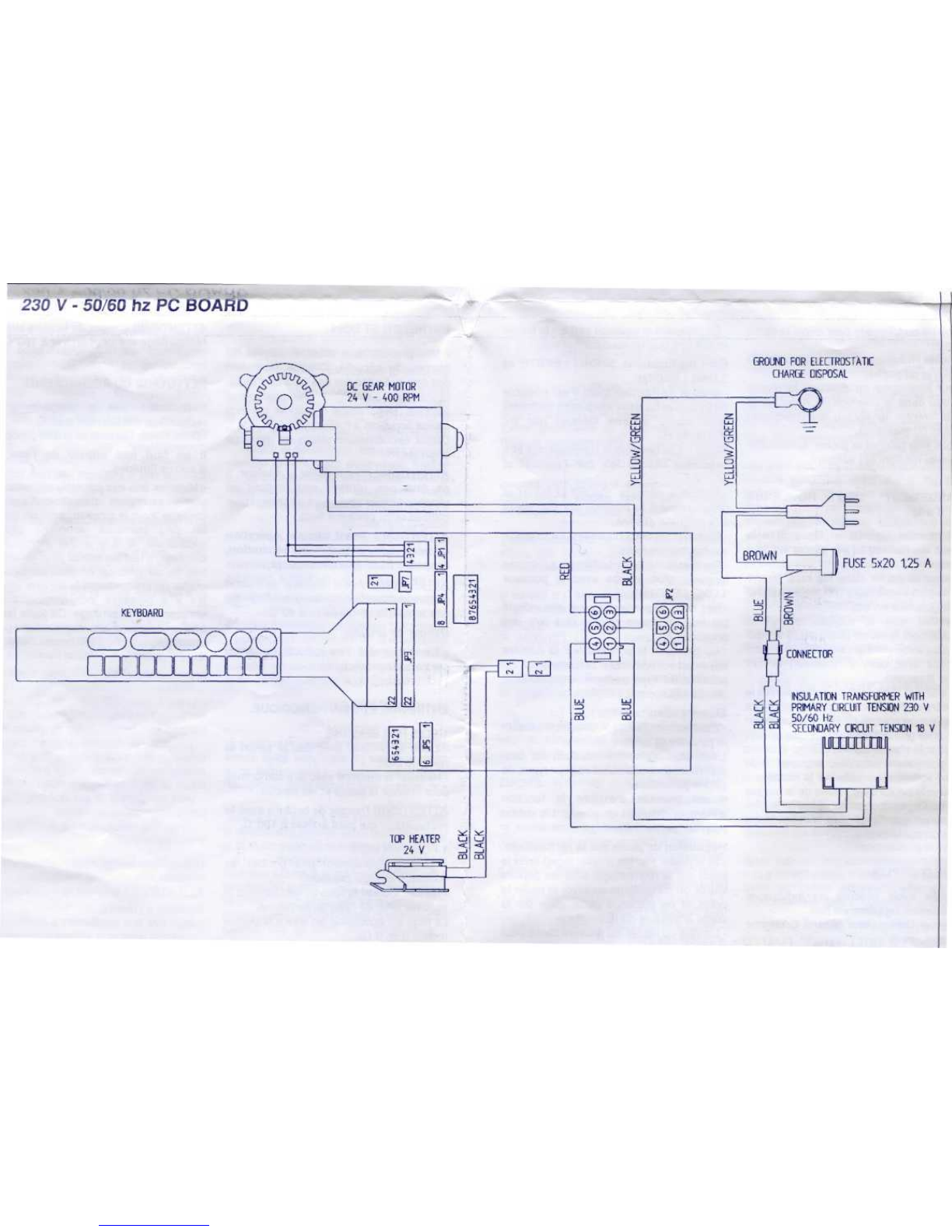

Voltage

and

frequency:

see

machinelabel

Control

circuit

inDC24

Volts

Electricalpower:

100W

Dispensing

velocity:55m./min.

Length:

min.

100

mm./

max.1150

mm.

Sound

levelmeasured

in

room:lessthan

70

dB(A)

TYPES

OF

GUMMED

TAPE

All

PAPER

FEATURES

Width:

min.

20

mm./

max.

100mm.

Maximum

rolldiameter:

200

mm.;

withdevice

for

biggerrolls

(supplied

on

request)

300mm.

ATTENTION!!

-

Before

usingthismachinecarefully

read

the

operatinginstructions.They

contain

importantindications

on

instal-

lation

safety,

useand

maintenance.

-

Keepthisbookletwithcare

forany

further

reference.

It's

customer

responsibility

to

make

surethat

the

personnel

who

will

use

the

machinesreads

and

understandsthis

booklet.

-

The

buildercannot

be

maderesponsible

for

eventualdamage

to

people,animals

or

thingsderivingfrom

non

observation

ofthe

safety

norms

andthe

warningshere

contained.

GENERALREMARKS

-

Follow

the

safety

and

preventionrules

for

accidents

and

fires

issued

bythe

competentauthorities,such

asthe

eventualrecommendations

of

industrial

associations

and

trade unions

in

terms

of

personnelsafety.

-

Thistapedispenser

is

designed

and

manufactured

only

to

dispensegummed

tape.

A

different

use

from

that

advised

is

not

consideredspecific.CYKLOPwill

not

assume

any

responsibilityfollowing

an

improper

useofthe

machine.

-

After

unpackingcheck

the

integrity

ofthe

machine.

In

case

of

doubt

donotusethe

machine

and

enquire

directly

tothe

reseller.

-

Verify

that

the

voltage

ofthe

machine

is

the

same

astheoneyouare

about

to

use.

Otherwise

donotusethe

machine

and

enquiredirectly

tothe

reseller.

-

The

electricalsafety

of

thismachine

is

guar-

anteedonlywhen

itis

correctlyconnected

to

a

groundedelectricalsystem

as

prescribed

by

the

presentelectricalsafetyrules.

-

When

you

disconnect

the

machinefrom

the

electricalplug,alwayspull

by

seizing

the

plug

notthe

cable.

-

Nevertouch

or

operate

the

machinewith

wet

hands

or

barefoot.

-

Donot

leave

the

machine

onfor

long

periods

of

time.Turn

offthe

mainswitch

of

the

machinewhen

itisnot

being

used.

-

Keep

the

machineawayfromchildren

and

from

personnel

whoarenot

authorised

or

adequately

instructed

intheuseofit.

-

Theuseofthe

machine,

as

prescribed

by

the

builder,alsoincludes

the

respect

ofthe

rules

of

inspection,

maintenance

and

repair.

-

Someparts

ofthe

machinereach

dangeroustemperatures

and

thereforethey

shouldNEVER

be

touchedwith

the

hands.

Thetop

heater,

if

functioning,

can

reach

a

hightemperature(100°C).

-

Keep

the

machinealways

in

good

status,

clean

and

dry.

-

The

machineperformsbetter

ina

rather

dry

environment,therefore

we

discourage

usage

in

dampplaces.Workingwith

gummedpaper

in

humidplaces

can

create

problems;

it

performs

better

indry

places.

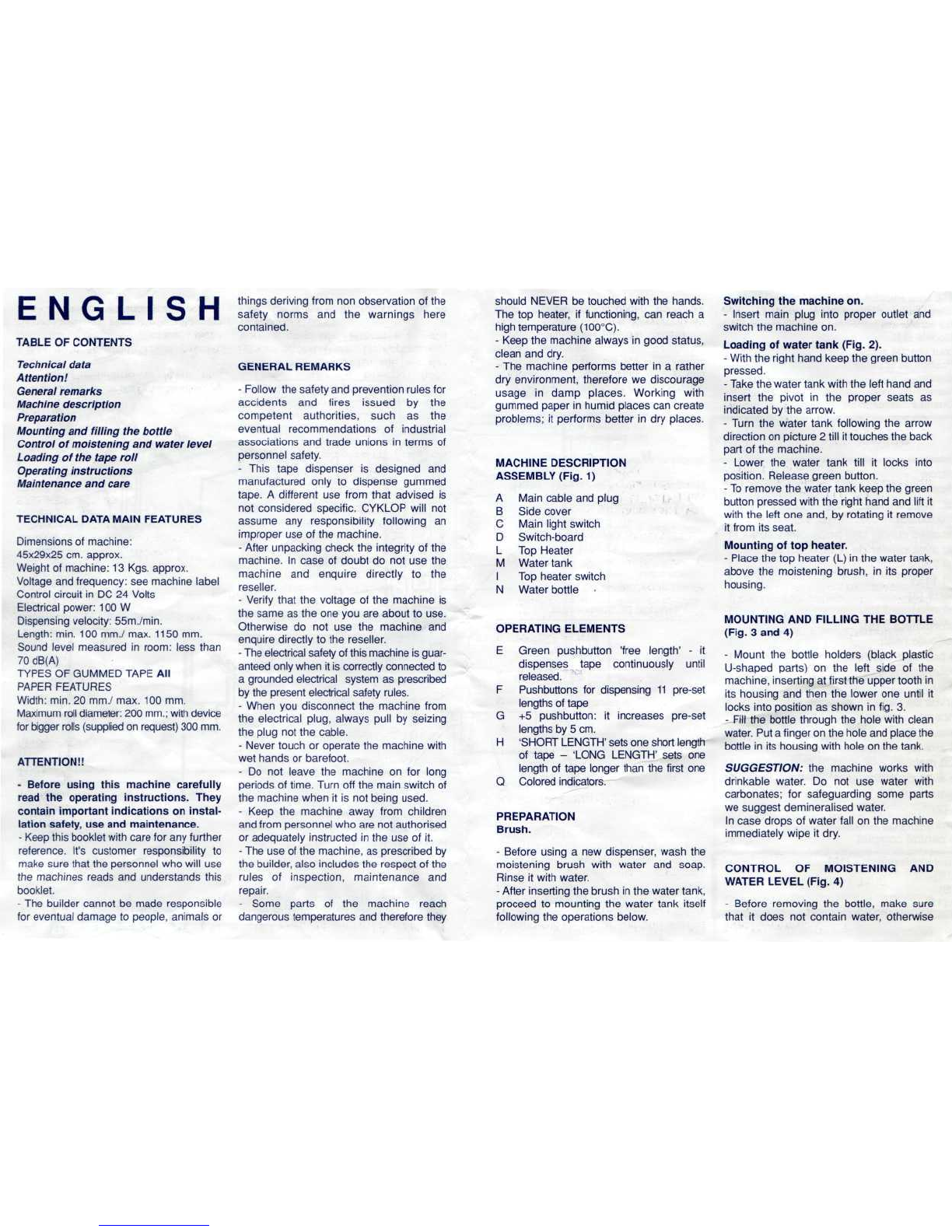

MACHINEDESCRIPTION

ASSEMBLY

(Fig.

1)

A

Main

cable

and

plug

B

Sidecover

C

Mainlightswitch

D

Switch-board

LTop

Heater

M

Watertank

ITop

heaterswitch

N

Waterbottle

•

OPERATINGELEMENTS

E

Green

pushbutton

'free

length'

- it

dispensestapecontinuouslyuntil

released.

F

Pushbuttons

for

dispensing

11

pre-set

lengths

of

tape

G+5

pushbutton:

it

increasespre-set

lengths

by5 cm.

H

'SHORT

LENGTH'

sets

one

shortlength

of

tape

-

'LONG

LENGTH'

sets

one

length

of

tapelongerthan

the

first

one

Q

Coloredindicators.

PREPARATION

Brush.

-

Beforeusing

a new

dispenser,wash

the

moisteningbrushwithwater

and

soap.

Rinse

it

withwater.

-

After

inserting

the

brush

inthe

watertank,

proceed

to

mounting

the

watertankitself

following

the

operations

below.

Switching

the

machine

on.

-

Insertmainplugintoproperoutlet

and

switch

the

machine

on.

Loading

of

watertank(Fig.

2).

-

With

the

righthandkeep

the

greenbutton

pressed.

-

Take

the

water

tank

with

the

lefthand

and

insert

the

pivot

inthe

properseats

as

indicated

bythe

arrow.

-

Turn

the

water

tank

following

the

arrow

direction

on

picture

2

till

it

touches

the

back

part

ofthe

machine.

-

Lower

the

watertank

till

it

locksinto

position.Releasegreenbutton.

-

To

remove

the

watertankkeep

the

green

buttonpressedwith

the

righthand

and

lift

it

with

the

left

one

and,

by

rotating

it

remove

it

from

its

seat.

Mounting

oftop

heater.

-

Place

thetop

heater

(L)inthe

watertank,

above

the

moistening

brush,

inits

proper

housing.

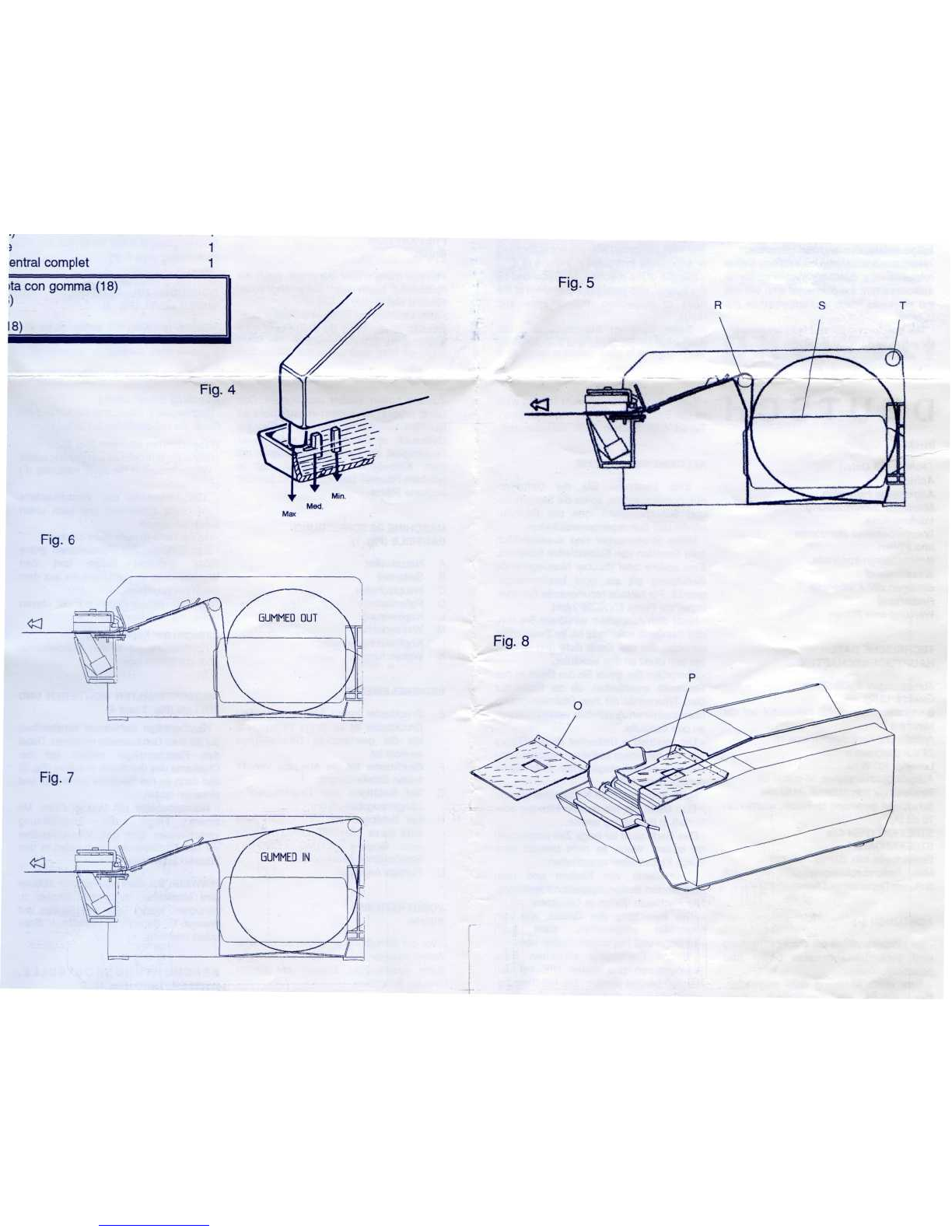

MOUNTING

AND

FILLING

THE

BOTTLE

(Fig.

3 and4)

-

Mount

the

bottleholders(blackplastic

U-shapedparts)

onthe

leftside

ofthe

machine,inserting

at

first

the

uppertooth

in

its

housing

and

then

the

lower

one

until

it

locksintoposition

as

shown

in

fig.

3.

-

Fill

the

bottlethrough

the

holewithclean

water.

Puta

finger

onthe

hole

and

place

the

bottle

inits

housingwithhole

onthe

tank.

SUGGESTION:

the

machineworkswith

drinkablewater.

Donotuse

waterwith

carbonates;

for

safeguardingsomeparts

we

suggestdemineralisedwater.

In

casedrops

of

waterfall

onthe

machine

immediatelywipe

it

dry.

CONTROL

OF

MOISTENING

AND

WATER

LEVEL(Fig.

4)

-

Beforeremoving

the

bottle,makesure

that

it

does

not

contain

water,otherwise