Franke F3Dn Twin User manual

Other Franke Dispenser manuals

Franke

Franke RODX625 User manual

Franke

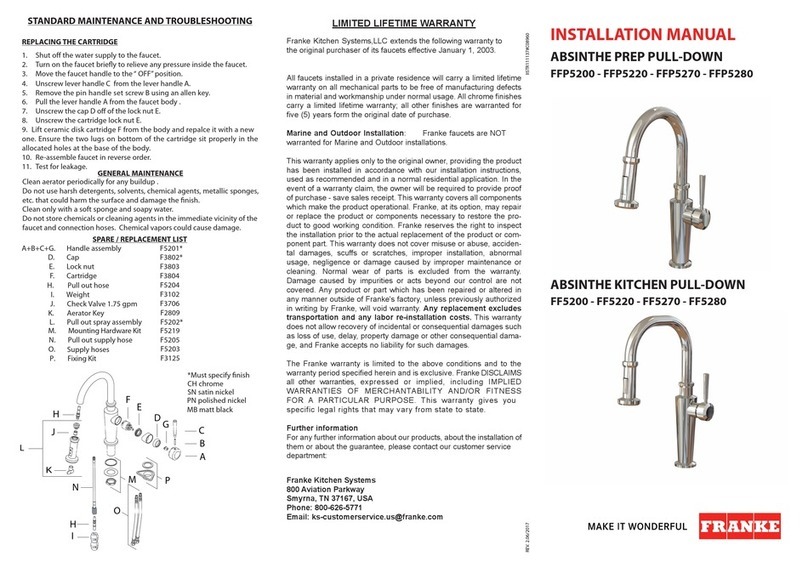

Franke FFP5200 User manual

Franke

Franke SD300 User manual

Franke

Franke RODX619 User manual

Franke

Franke HBD191 User manual

Franke

Franke 7612210006425 User manual

Franke

Franke EXOS618X User manual

Franke

Franke SD80 User manual

Franke

Franke KEMWSBF User manual

Franke

Franke EXOS618EX User manual

Franke

Franke EXOS618X User manual

Franke

Franke STRX672 User manual

Franke

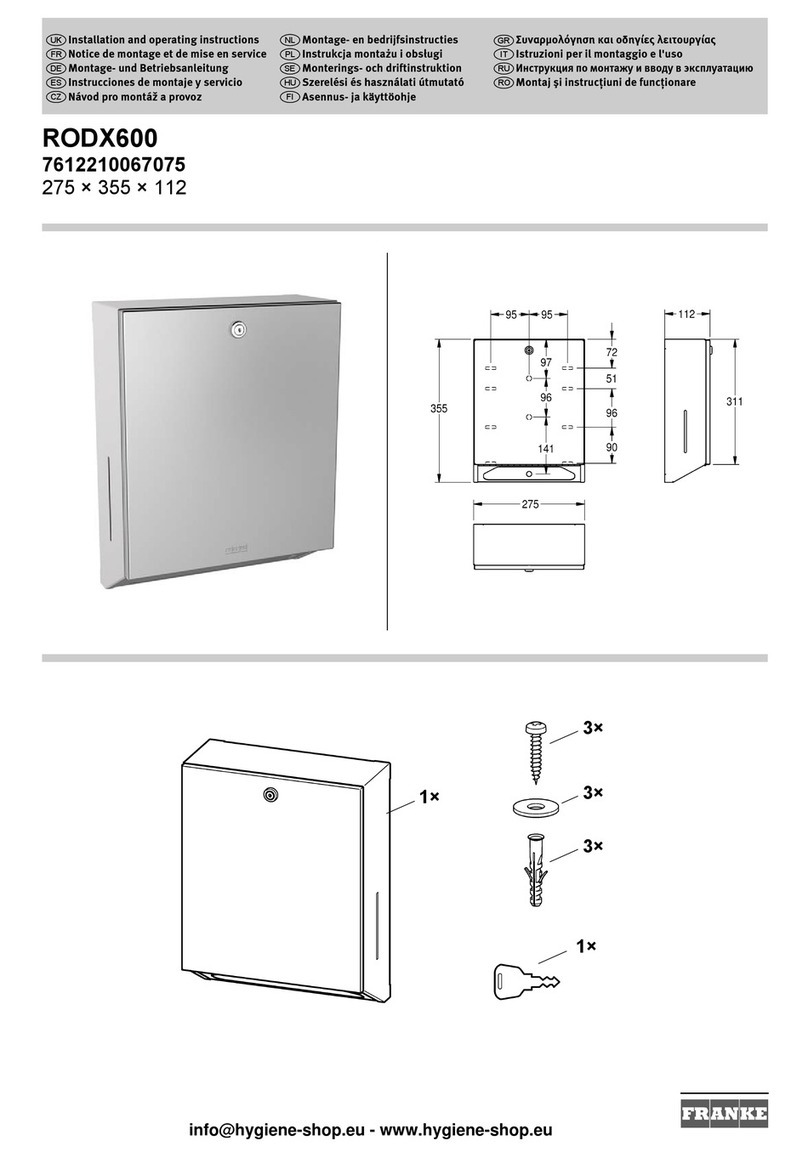

Franke RODX600 User manual

Franke

Franke RODAN RODX600 User manual

Franke

Franke EXOS629X User manual

Franke

Franke FRK202067N User manual

Franke

Franke F3D3S User manual

Franke

Franke STRATOS STRX635B User manual

Franke

Franke STRX635B User manual

Franke

Franke RODX191 User manual

Popular Dispenser manuals by other brands

Silver King

Silver King Majestic SK12MAJ Technical manual and replacement parts list

STIEBEL ELTRON

STIEBEL ELTRON UltraHot Plus Operation and installation instructions

DAN DRYER

DAN DRYER 282 installation guide

Essity

Essity Tork 473208 manual

CBS

CBS SD300BU-88 COMPONENT MAINTENANCE MANUAL WITH ILLUSTRATED PARTS LIST

Sealey

Sealey MK77 manual