Chapter 01 - INSTALLATION

CYANExpert 130 User Manual Rev.02, Feb 2014 Chapter 1, Page 3

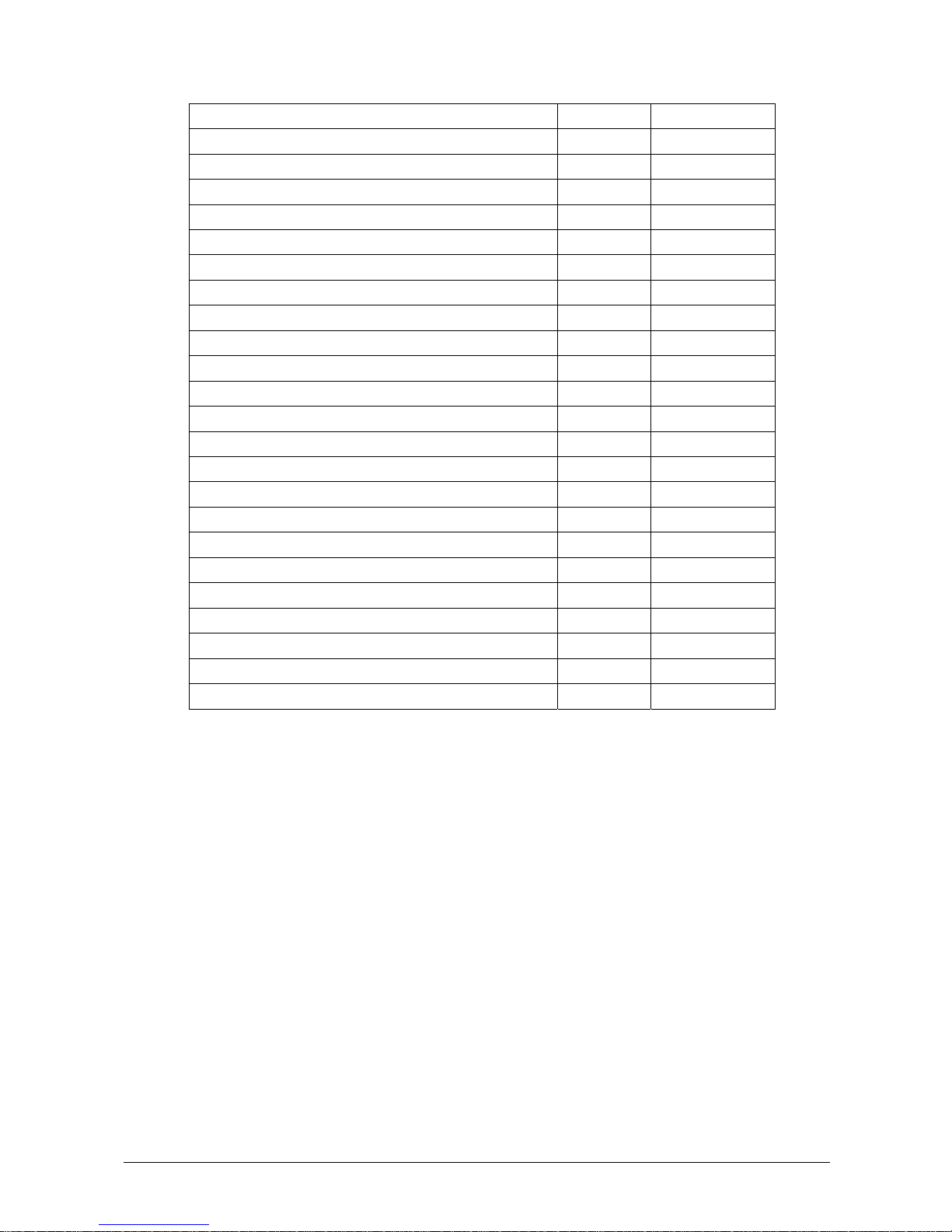

Upon arrival of the box, take out the delivery note and make sure that all the items of the following packing list are

included in the crate and are undamaged:

Code Description Quantity

CY008 CYANExpert 130 Analyzer 1

CY008-BC Barcode reader kit (optional)

- CYANExpert 130 Software 1

- User manual 1

CY008-C08 Reaction tray cover (delivered on the instrument) 1

CY008-C09 Reaction tray without cover (delivered on the instrument) 1

CY008-S33 Sampling probe assembly (delivered on the instrument) 1

CY008-C03 Reaction cuvettes cover 1

CY008-S80 Special key for probe tightening 1

CY008-S08 Power cord 1

CY008-S09A Fuse 6,3 A-T 5x20 2

CY008-S78 Interconnecting serial cable PC analytical module 1

USB-RS232 converter cable with software 1

CY008-C02 Rack for primary tubes (universal) and 3 mL cups 4

CY008-C04 Rack for predilution cups (0.8 mL cups) (optional)

CY008-C22A Pack of 200 short cups (1 mL) – Calibrator and Control cups 1

CY008-C28 Pack of 1000 sample cups for primary tube rack (3 ml) 1

CY008-C21A Pack of 200 predilution cups (0.8 mL) 1

CY008-C25 Pack of reagent container 35 ml + caps (12 pcs) 1

CY008-C26 Pack of reagent containers 6 ml + caps (12 pcs) 1

CY008-S76 Bottle level sensor assembly 4

CY008-S77 Bottles 2 L 4

CY008-S90 Bottles connecting cable 1

CY008-C17 Inlet tubes kit (4 pcs) 1

Waste tubes kit (3 pcs) 1

CY008-C27 Reaction cuvettes (20 pcs per sector/rack) – 6 sectors 1

CY008-WS-I Rinse solution (1 x 50 ml) 1

CY008-WS-III Cleaning solution (5 x 30 ml) 1

CY008- WS-IV Acid solution (5 x 25 ml) 1

Remove the adhesive tape from the cover of the samples and reagents housing, from the front panels and from the

samples and reagents racks.

Before connecting the CYANExpert 130, remove the protective packing material around the sampling arm and under

the washing station.

Warning: In the event that it is necessary to repack any or all of the delivered item(s), the following procedures must

be carefully followed:

Reposition the protective packing material around the sampling arm and under the washing station.

Be very careful not to bend the washing station cannulas when repositioning the protective packing material.

Tape down (using masking tape if possible) the main cover of the samples and reagents housing, the front

panels and the sample and reagent racks.

Remove the probe from the sampling arm and place it inside a primary tube. Then cap the tube and tape the

tube down.

Fill the empty spaces around the accessories packed in the crate using “pluriballs” or other suitable packing

material.