x.sight - software manual

3 | P a g e

Content

1About this manual .......................................................................................................... 5

2Technical information..................................................................................................... 6

2.1 General information: ........................................................................................................ 6

2.2 Embedded PC information: .............................................................................................. 6

2.3 Data properties:................................................................................................................6

2.4 Third party hardware........................................................................................................7

2.5 Drivers and additional software .......................................................................................7

3Software overview ......................................................................................................... 8

3.1 General handling .............................................................................................................. 8

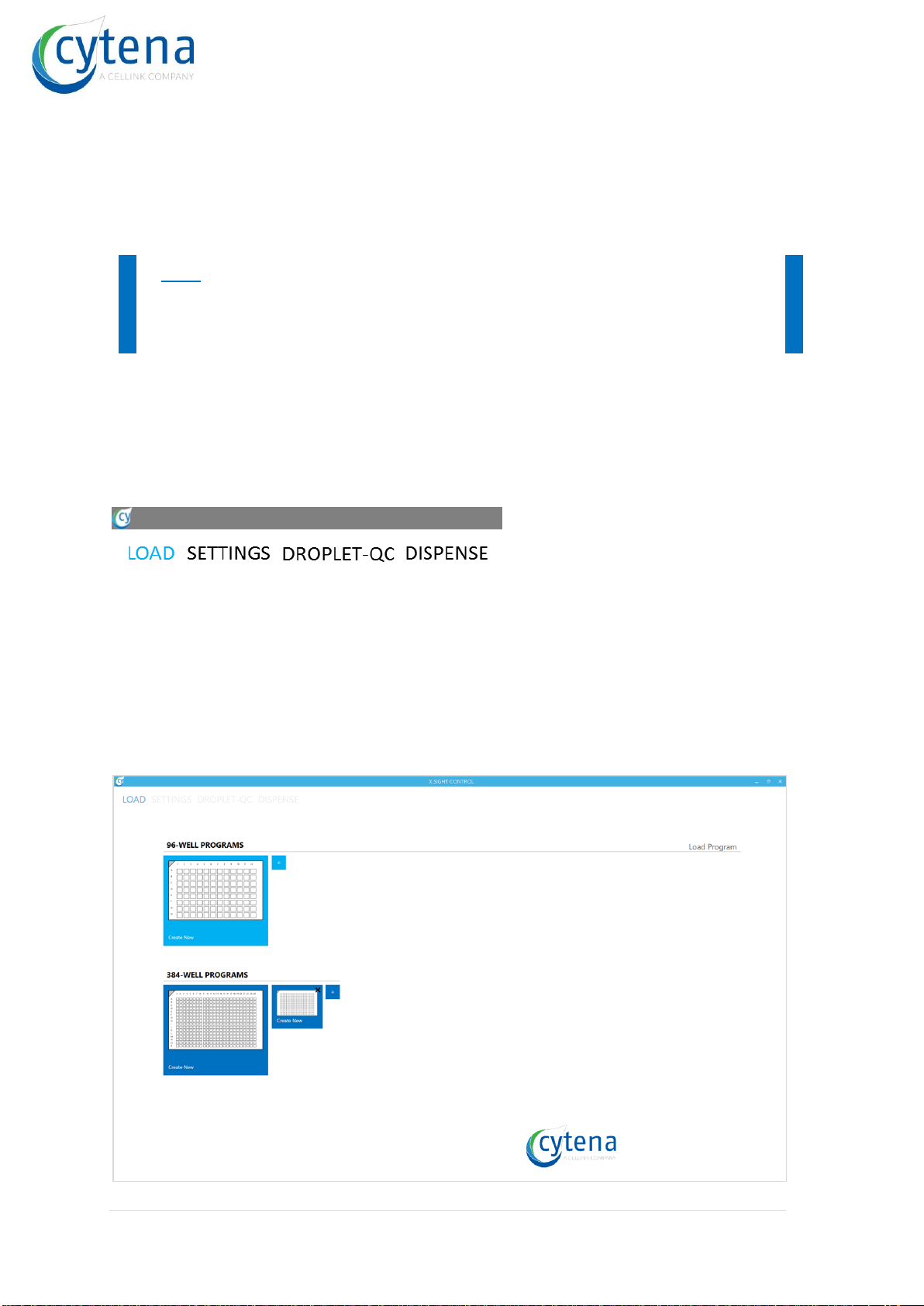

3.2 Start screen (LOAD) .......................................................................................................... 8

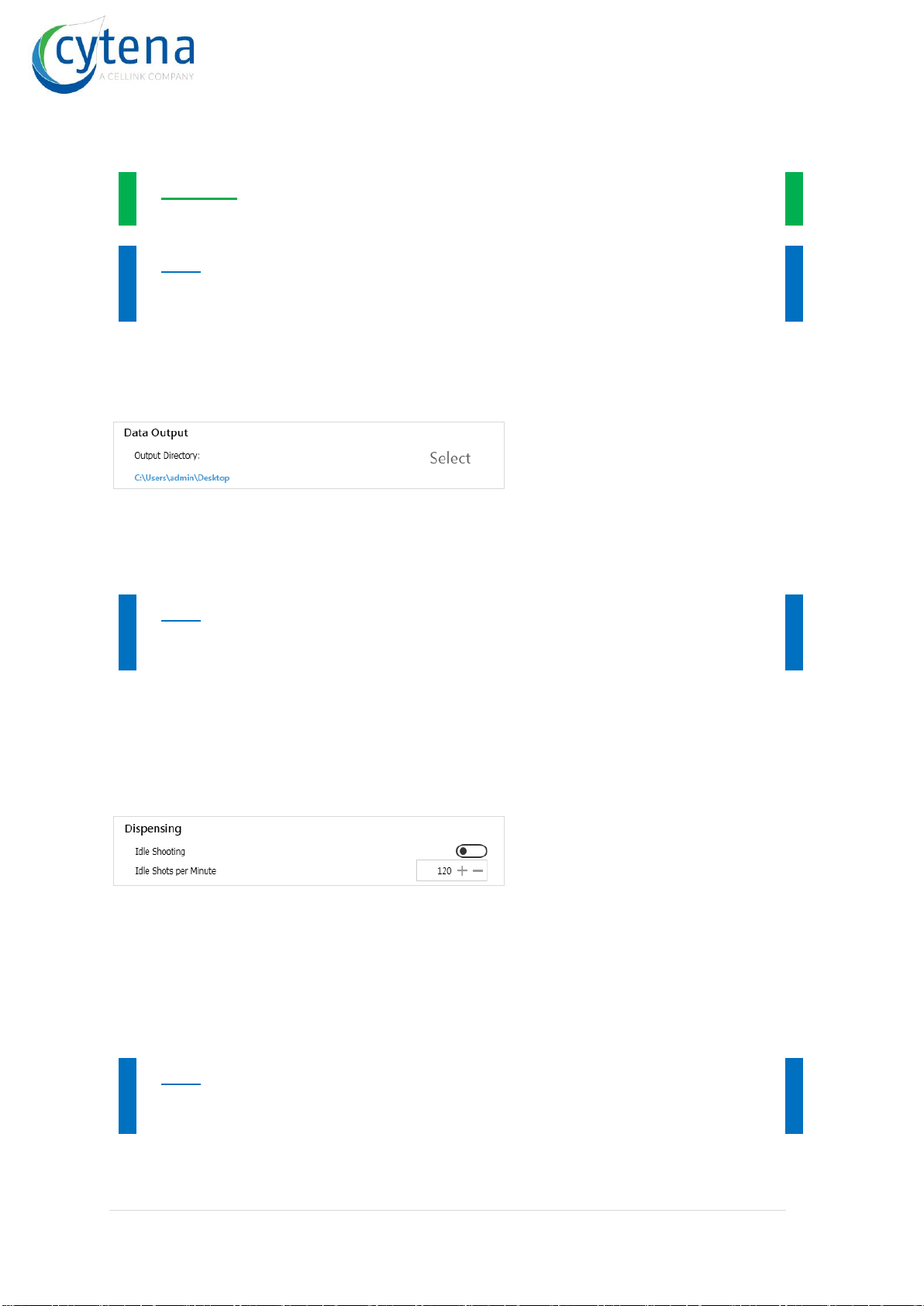

3.3 Settings (SETTINGS) ..........................................................................................................9

3.4 Droplet quality control (DROPLET-QC) ........................................................................... 13

3.5 Main screen (DISPENSE) .................................................................................................15

3.6 Cell Camera & Region of Interest (ROI) ..........................................................................18

3.7 Results ............................................................................................................................21

3.8 Live log window ..............................................................................................................22

4f.sight special ............................................................................................................... 24

4.1 Cell camera modes ......................................................................................................... 24

4.2 Camera alignment mode ................................................................................................25

4.3 Collect sample modes.....................................................................................................27

5Software use ................................................................................................................ 28

5.1 Starting sequence........................................................................................................... 28

5.2 Chose a well plate or load a program............................................................................. 28

5.3 Set up your experiment..................................................................................................28

5.4 Configuring your well plate ............................................................................................28

5.5 Loading cartridge and well plate ....................................................................................31

5.6 Set Region of Interest (ROI)............................................................................................32

5.7 Performing Droplet-QC...................................................................................................32

5.8 Performing the experiment............................................................................................34

5.9 Data ................................................................................................................................ 34

6Configuration & OS....................................................................................................... 35

6.1 Use of antivirus and security software........................................................................... 35