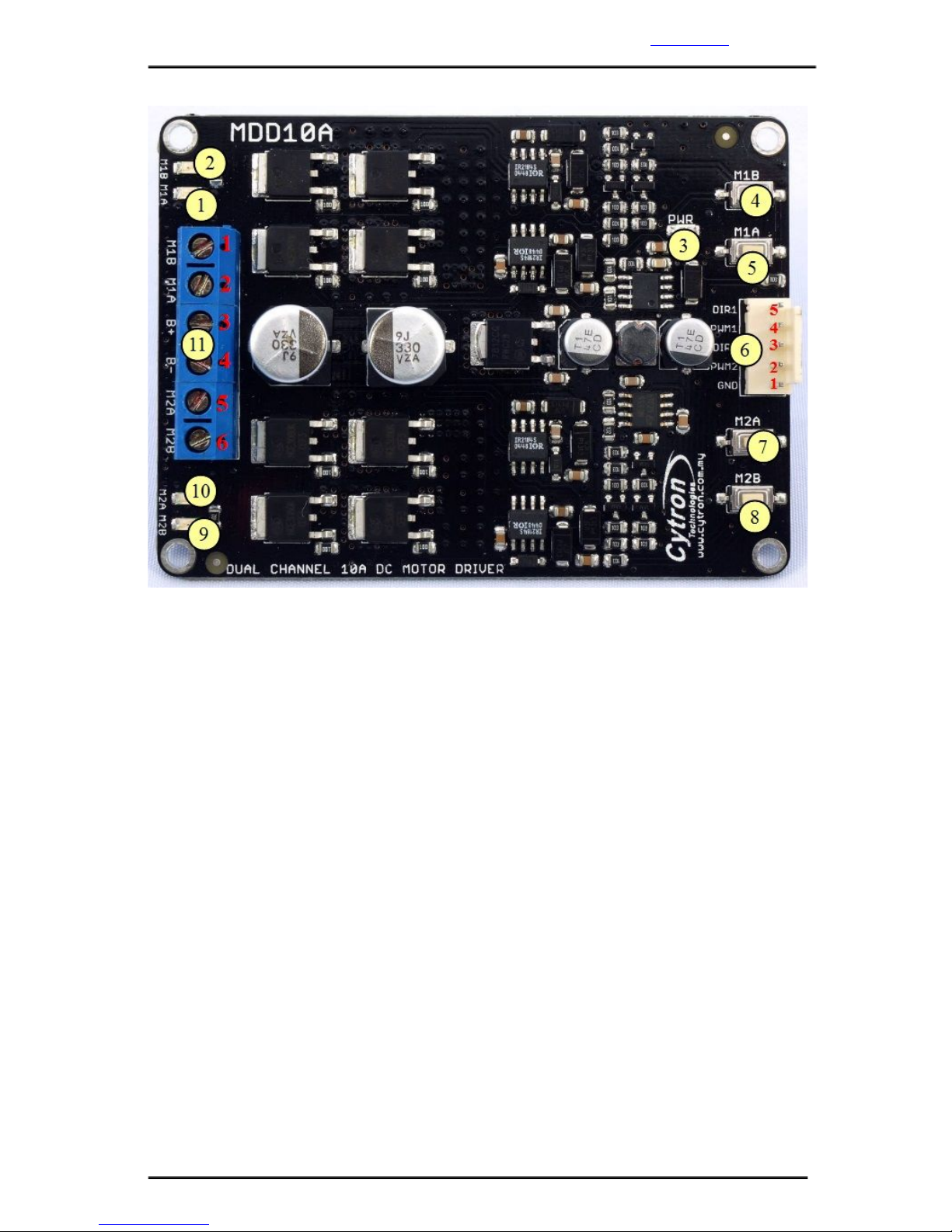

Product User’s Manual – RB-Cyt-153 (MDD10A)

1. INTRODUCTION/OVERVIEW

MDD10A is the dual channel version of MD10C which is designed to drive 2 brushed DC

motors with high current up to 10A continuously. Just like MD10C, the MDD10A also

supports locked-antiphase and sign-magnitude PWM signal. It is also using full solid state

components which result in faster response time and eliminate the wear and tear of the

mechanical relay.

* MDD10A being shipping after Jan 2017 are Rev2.0 which have upgraded to support

maximum motor voltage up to 30V.

MDD10A has been designed with the capabilities and features of:

●Bi-directional control for 2 brushed DC motors.

●Support motor voltage ranges from 5V to 25V 30V (Rev2.0).

●Maximum current up to 10A continuous and 30A peak (10 second) for each channel.

●Solid state components provide faster response time and eliminate the wear and tear

of mechanical relay.

●Fully NMOS H-Bridge for better efficiency and no heat sink is required.

●Speed control PWM frequency up to 20KHz (Actual output frequency is same as

input frequency).

●Support both locked-antiphase and sign-magnitude PWM operation.

●Support TTL PWM from microcontroller, not PWM from RC receiver.

●Onboard push button to control the motor manually.

●Dimension: 84.5mm x 62mm

Note: Please use battery when driving inductive load such as DC brush motor. Due to the

protection circuit of most Power supply (switching), it will shut down when regenerative

current from motor is detected.