2

INTRODUCTIONANDRECOMMENDATIONS

Congratulationsonyourpurchaseofa D.A.C.Egatemotor.D.A.C.Ehasproventobealeaderinthe

automationfieldandstrivestomanufacturehighqualityproductsusingthelatesttechnologyavailable.

D.A.C.E.isconstantlyworkingonupgradingtheirproductstobringyou,thecustomer,aproductofthe

highestquality.OtherproductsmanufacturedbyD.A.C.E.include:

·Infraredsafetybeams

·Remotesandreceivers

·SlidegateoperatorsSPRINT;CONDO

Itisrecommendedthatanexperiencedgateinstallerisusedtoinstallyourgatemotor.Ifyouintendto

installthismotoryourself,pleasereadthismanualcarefullybeforeanyinstallationbegins.

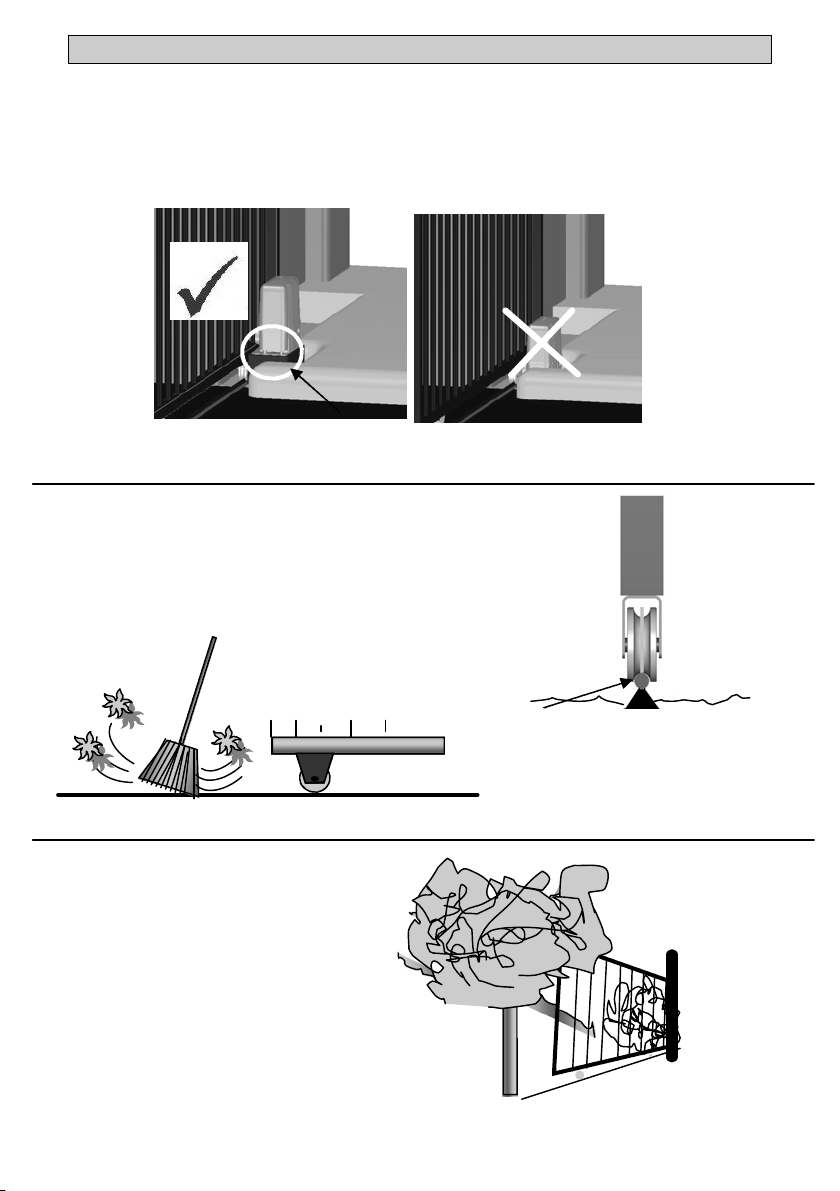

Itisstronglyrecommendedthatsafetybeamsareusedonallinstallations,asthisreducestheriskof

thegateclosingonapedestrianorvehicle.

NOTE:D.A.C.E.suppliesanonboardreceiverwitheverymotor.D.A.C.E.cannotguaranteetherange

ofthereceiverduetointerferenceorobstaclesinthepathofthereceiver.

ThisautomaticgateoperatorisNOTasecuritydevice.Itisdesignedtomakeaccesstoapremises

undemanding.

BMG ImportsofferaStandard Warrantyonthisequipment.ThefollowingtermsandconditionsapplytoALL

warrantyclaims.

BMG ImportswarrantstheORIGINALpurchaser,atthepointofsale,thattheproductisingoodworking

order andisfreefromanydefect.

ANYwarrantyclaimmustbeaccompaniedbytheoriginalinvoice.

Theoriginalpurchaserisresponsible within 24hours of receiving the goods to carry out a physical

inspection and notify BMG Imports in writing if the goods do not comply with the description set out.

Thewarrantyperiodis12monthsfromdateof PURCHASE.

Thewarrantyisa“back to base“warranty.

Theequipmentmustbereturnedtothefactorywiththeoriginalinvoiceforanyrepairor

replacement.

Iftheequipmentwaspurchasedatadealer,merchantoragentofBMG Imports theclaimmustbedirected

to saidmerchant,dealeretc.

Thewarrantywillnotcoveranyofthefollowingcircumstancesinanyway.

·Incorrectinstallationoftheequipment.

·Incorrectwiringoftheequipment.

·Lightning,flooding,powersurge,fire,insectinfestationoranyformofabnormaluseofthe

equipment.

NOTE: thetransformerisnotguaranteedinanymanner,duetopowerfluctuations.

AnywarrantyclaimmustbeinspectedandtestedbyaBMG Importsagentbeforeanyfurther

claimisenteredinto.

WARRANTY