D-Box G3 User manual

CONFIDENTIAL

D-BOX – ACM_G3_INSTALLATION GUIDE - 209-914-0002-EN2 Februar 2020

G3 MOTION SYSTEM INSTALLATION MANUAL

I

TABLE

OF

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ........................................................................... III

Introduction ................................................................................................................ 2

Op rating Conditions ................................................................................................... 2

Softwar - Motion Cor ............................................................................................... 2

Softwar – Motion Syst m Configurator ...................................................................... 3

Motion S stem Configuration and Actuator Positioning .......................................................................................4

Communication modul - KCU-1P ................................................................................ 4

KCU-1P Power up....................................................................................................................................................6

Actuator Control Modul ............................................................................................. 6

ACM G3 families and compatibilit ........................................................................................................................6

ACM Connections ...................................................................................................................................................7

ACM G3 LED Status .................................................................................................................................................9

Actuator ...................................................................................................................... 9

Maximum axial load ...............................................................................................................................................9

Weight Distribution ............................................................................................................................................. 10

Actuator Acceleration .......................................................................................................................................... 11

Distance between actuators ................................................................................................................................ 11

Actuator alignment .............................................................................................................................................. 12

Actuator straightness .......................................................................................................................................... 12

Level surface ........................................................................................................................................................ 12

Motion Syst m Acc ssori s ........................................................................................ 13

Power converter .................................................................................................................................................. 13

Pivot ..................................................................................................................................................................... 13

Captive Endings ................................................................................................................................................... 13

II

R moval/Installation proc dur s ................................................................................ 14

H-Bracket for 1.5 in HD Actuator - AC10 ............................................................................................................. 14

H-Bracket for 3in Actuator - AC231 ..................................................................................................................... 15

H-Bracket for 6in actuator - AC360 ..................................................................................................................... 16

Captive ending ..................................................................................................................................................... 17

1.5-inch actuator - AC218 .................................................................................................................................... 19

3-inch actuator – AC231 ...................................................................................................................................... 22

6-inch actuator - AC360 ....................................................................................................................................... 24

AC218 Actuator R plac m nt ..................................................................................... 26

Removal ............................................................................................................................................................... 26

Installation ........................................................................................................................................................... 27

III

IMPORTANT

SAFETY

INSTRUCTIONS

1. Read and follow these instructions step-b -step.

2. Keep them for future reference.

3. Install in accordance with the manufacturer's instructions and heed all warnings.

4. Do not use this apparatus near water.

5. Onl clean with a dr cloth.

6. Do not block an ventilation openings.

7. Do not install near an heat sources such as radiators, heat registers, stoves, or other apparatus (including amplifiers)

that produce heat.

8. Do not defeat the safet purpose of the polarized or grounding-t pe plug. A polarized plug has two blades with one

wider than the other. A grounding-t pe plug has two blades and a third grounding prong. The wide blade or the third

prongs are provided for our safet . If the provided plug does not fit into our outlet, consult an electrician for

replacement of the obsolete outlet.

9. Protect the power cord from being walked on or pinched particularl at plugs, convenience receptacles, and the point

where the exit from the apparatus.

10. Onl use attaching hardware/accessories specified b the manufacturer.

11. Use onl with the cart, stand, tripod, bracket, or table specified b the manufacturer, or sold with the apparatus. When

a cart is used, use caution when moving the cart/apparatus combination to avoid injur from tip-over.

12. Unplug this apparatus during lightning storms or when unused for long periods of time.

13. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been damaged in an

wa , including damage to power-suppl cord or plug, liquid has been spilled or objects have fallen into the apparatus,

the apparatus has been exposed to rain or moisture, does not operate normall , or has been dropped.

14. Do not expose this apparatus to dripping or splashing and ensure that no objects filled with liquids, such as vases, are

placed on the apparatus.

15. To completel disconnect this apparatus from the AC Mains, disconnect the power suppl cord plug from the AC

receptacle.

16. The mains plug of the power suppl cord shall remain readil operable.

17. Do not expose batteries to excessive heat such as sunshine, fire or the like.

The lightning flash with arrowhead s mbol within an equilateral

triangle is intended to alert the user to the presence of

uninsulated "dangerous voltage" within the product's enclosure

that ma be of sufficient magnitude to constitute a risk of electric

shock to persons.

The exclamation point within an equilateral triangle is intended

to alert the user to the presence of important operating and

maintenance (servicing) instructions in the literature

accompan ing the product.

This s mbol indicates that ou must communicate with the

manufacturer for disposal of the equipment.

WARNING: To reduce the risk of fire or electric shock, do not expose this apparatus to rain or moisture.

1

Thank ou for purchasing a D-BOX Motion S stem, the most immersive experience for the simulation and game markets.

We strongl advise that ou read the guidelines before assembling and using our Motion S stem.

Do not hesitate to contact us if ou have questions.

2

I

NTRODUCTION

D-BOX Motion S stems are evolutive and scalable. Integrated into a seat, platform or simulator, the are

designed to simulate a range of textures and scalable axes of movement. Whatever ou require, D-BOX can help

ou select the best arrangement of actuators.

The following components are part of the D-BOX Motion Syst m:

Motion Syst m: a complete architecture of hardware and software providing motion.

Actuator: an assembl of motor and mechanic providing movements and vibrations.

Actuator Control Modul (ACM): provides power and control to the actuators. Controls the power sent

to the motor and adjusts the precise rotation according to the feedback from an encoder within the

actuator.

Communication Modul : electronic component used to transmit motion code, converting a signal

format to another one.

Motion Sourc : various applications generating motion data for the D-BOX Motion S stem.

When integrating our D-BOX s stem, please compl with the following guidelines. If ou must deviate

from the guidelines, please contact us to make sure ou are still using the s stem as prescribed.

O

PERATING

C

ONDITIONS

The D-BOX Motion S stem shall be operated in controlled environmental conditions, per the following

specifications:

Power Requirements 100 – 230VAC, 60Hz, 0.63A, Output: +48VDC,

compatible with CAN – USA and EU power s stems

Operating Temperature Range 0 – 40°C

Operating H grometr 10 – 50%

Maximum Operating Altitude 2000 meters above sea level

S

OFTWARE

-

M

OTION

C

ORE

The D-BOX Motion S stem requires the installation of the Motion Core application on the host PC. The

application is available for download on the D-BOX website (www.d-box.com)

Please follow the Motion Core instructions for installation and use.

3

S

OFTWARE

–

M

OTION

S

YSTEM

C

ONFIGURATOR

NOTE: D-BOX upgrades the ACM firmware on a regular basis. D-BOX therefore recommends that

ou update our equipment to the latest firmware version, upon reception, with the Motion

S stem Configurator

1

.

Each ACM comes with a default configuration based upon the Motion S stem architecture. Here is the list of the

factor configurations. The letters describing the actuator position refers to the next table.

MOTION SYSTEM

ARCHITECTURE

FACTORY

CONFIGURATION

ACTUATOR POSITION

(S figur b low) DESCRIPTION

1 actuator 1 YAW Y

1 ACM

-

MASTER with 1 horizontal

actuator ensuring the YAW movement

of the simulator.

2 actuators 2 BACK BL - BR 1 ACM-MASTER with 2 actuators at the

back of the pivot point on the simulator.

3 actuators 2 BACK/1 YAW BL – BR - Y

1 ACM-MASTER with 2 actuators at the

back of the pivot point on the simulator.

1 ACM-SLAVE with 1 horizontal actuator

ensuring the YAW movement of the

simulator.

4 actuators 2 BACK/2 FRONT BL – BR –FL - FR

1 ACM-MASTER with 2 actuators at the

front end of the simulator.

1 ACM-SLAVE with 2 actuators at the

back end of the simulator.

1

see the Motion S stem Configurator installation and user Manual, D-BOX document number 194-914-0010-EN3

4

You ma have a configuration requirement different from the factor configuration. If this is the case, ou need

to change it using the Motion S stem Configurator

1

to modif the configuration BEFORE ou install our Motion

S stem. The D-BOX Motion S stem Configurator application attributes a specific ACM port to each actuator

position.

A good practice is to replace the sticker on our ACM to reflect the new configuration.

Motion System Configu ation and Actuato Positioning

The letters represent the position of the actuators:

LEGEND POSITION PICTOGRAM REFERENCE

FL Front-Left

FC

F

ront

-

Center

FR

Front

-

Right

BL

Back

-

Left

BC

Back

-

Center

BR Back-Right

SU Surge

SW Swa

Y Yaw

For example: For a t pical roll, pitch, heave configuration with 4 vertical actuators, actuators at positions 1 and 2

connect to the Master ACM and actuators at positions 3 and 4 connect to the Slave ACM. For additional details

on the ACM configuration, please read the Motion S stem Configurator Guide.

C

OMMUNICATION MODULE

-

KCU-1P

The KCU-1P is a communication module that transmits the data from the Motion Source to the first ACM in the

chain.

CAUTION: avoid conn cting th KCU-1P into th USB port of a Windows PC b for th Motion

Cor application has b n install d. Although th application installs its lf as soon as th KCU-

1P is conn ct d to th comput r, it r quir s driv r fil s to compl t th installation proc ss.

5

CAUTION: Th KCU-1P works with a D-BOX G2 or G3 ACM. N v r conn ct th KCU-1P to an

ACM-I (G1).

The KCU-1P comes with an installation bracket and a power suppl . It has 2 ports and a power input jack.

PORTS / JACK RECOMMENDED CABLE COMMENTS

MASTER OUT Use a shielded CAT.5e or CAT.6e cable to

connect the KCU-1P to a D-BOX ACM G3

(Actuator Control Module).

Make sure ou use a shielded CAT.5e or CAT.6e

cable and the RJ-45 at each end features a metal

jacket.

Connect one end of the cable to the MASTER OUT

port of the KCU-1P.

Connect the other end of the cable to the MASTER

IN Port of the ACM G3.

The total length should be 100 ft. (30.5m) or

less – KCU-1P to last seat.

USB Use a USB-A / USB-B cable to connect the KCU-

1P to the Windows base computer.

Connect the USB-B end of the cable to the USB

port of the KCU-1P.

Connect the USB-A end of the cable to the USB

port of the computer.

The total length of the USB cable should be 6 ft

(1

.8m) or less

.

POWER 100 – 230VAC, 50 - 60Hz, 0.63A

Output: +48VDC

Alwa s connect the power cable to a grounded

receptacle.

6

KCU-1P Powe up

At power up, the front LED shows the status of the KCU-1P.

Power up sequence:

● RED: 48V power present but no USB connection.

● ORANGE: Connected to the PC USB port, drivers are installed. The unit is read to operate.

● GREEN: Active Motion.

NOTE: On KCU-1P can provid th motion signal for a maximum of 20 daisy-chain d ACM G3.

A

CTUATOR

C

ONTROL

M

ODULE

ACM

G3

families and compatibility

There exists multiple ACM in the G3 architecture. The following table outlines the ACM G3 compatibilit with

different actuator models.

ACM

G3

TRAVEL MODEL MAX NUMBER OF

ACTUATORS PER ACM

ACM

G3

w DISCHARGE

Master, Slave

1.5 in

250i

2

400i

250HD

400HD

3 in

250i

-

3

2

400i-3

ACM

G3

w DISCHARGE & FAN

Master, Slave

6 in 500HD 2

NOTE: ACMs are programmed to work with a specific actuator model and at a specific place in

the architecture (Master/Slave). Thus, ACMs are not interchangeable.

NOTE: In the G3 architecture, the ACMs are onl compatible with a G3 actuator (motor and

mechanics). Different generations of components are not compatible with each other.

7

ACM Connections

Depending on the ACM position in the s stem, it is programmed either as:

● MASTER: first ACM in a Motion S stem

● SLAVE: all following ACMs

Here are t pical ACM configurations for the connection of a single Motion S stem:

8

The following example shows 3 Motion S stems using 2 ACMs each.

9

ACM

G3 LED Status

ACM

G3

LED STATUS

Off ACM not powered

Green No fault

Flashing green & flashing orange/red (MASTER)

Fault on one ACM

Red

Actuator fault. Manual re

-

initialization required.

Orange

Actuator fault. The unit will reinitialize

b itself after a

few minutes.

A

CTUATOR

Maximum axial load

The following table shows the maximum axial load for each actuator.

TRAVEL

ACTUATOR MODEL

(m chanics nam )

MAX AXIAL LOAD lb

MAX AXIAL LOAD

1

N

D-BOX

– Syst m Monitor

1.5 in

250HD (AC10) 250 1900

400HD (AC10) 400 2400

250i (AC218) 250 1900

400i (AC218) 400 2400

3.0 in

250i-3 (AC231) 250 1900

400i-3 (AC231) 400 2400

6.0 in 500HD-6 (AC360) 500 2800

1

You can find the reference to the maximal axial load in S stem Monitor

-

part of Motion

Core. The Newton units are a reference to the load perceived b each motor but can’t be

converted into actual Newtons. Therefore D-BOX uses the epon m index.

Make sure that the weight on the platform is no higher than the maximum supported weight.

Make sure that the weight is evenl distributed among the actuators of the platform (as centered as

possible).

10

Weight Dist ibution

Each actuator has an individual maximal pa load as previousl mentioned. When integrating the Motion S stem on a

platform, D-BOX recommends balancing the

c nt r of gravity

(CG) of the platform to ensure

ach actuator supports

an qual load

. The following figures show equal distribution of weight with 2, 3 or 4 actuators.

2

actuators

3

actuators

4

actuators

11

Actuato Accele ation

The D-BOX Motion S stem can produce a 1G acceleration or greater. However, to avoid risks of injur for the user or

damage to the equipment, D-BOX recommends calibrating the Motion S stem to produce a maximum of

1G, using

the control panel - see information on Motion Core. An acceleration above 1G can make the platform jump. Jumping

can be observed when the actuator takes off from the ground. The following figures show a piston jumping in its cup.

The shock of a piston falling back down in its cup reverberates on the top bearing of the piston, which takes the hit to

protect the motor. As it progressivel wears, the bearing also becomes noisier, reducing the service life of the ball

nuts and screw. Avoid actuator jumping in the cup.

This behavior is t pical when running the platform with no or light weight. There are no guidelines as to minimum

weight; this is highl dependent on the actuators position, the motion code, the simulator weight, simulator structure

and weight distribution.

Distance between actuato s

Respect the minimum distance between actuators for adequate movement of the platform. Measure the distance

from a

squar surfac nclosing all actuators

- see example below. Respecting the spacing guidelines ensures proper

interaction of the Motion S stem with the actuator endings, and proper lateral force transfer.

TRAVEL MINIMUM SPACING BETWEEN

ACTUATORS (A)

1.5 in 14 in [356 mm]

3.0 in 24 in [610 mm]

6.0 in 36 in [914 mm]

12

Actuato

alignment

When using 4 actuators, install them per a square or rectangular pattern. Avoid other patterns - e.g. trapezoid.

Actuato st aightness

During installation, the actuators should alwa s remain straight to limit radial loading. Radial loading could result

in premature wear of the actuators.

Level su face

All actuators must be level on the same flat surface for optimal operations. Different levels could result in

premature wear of the actuators.

13

M

OTION

S

YSTEM

A

CCESSORIES

Use onl D-BOX certified accessories. Using accessories that are not D-BOX certified voids the warrant and can

result in damages to the Motion S stem.

Powe conve te

Past generation of D-BOX products were 120V native and to be used with a custom step-down transformer

made specificall to respect certification requirements for 230V configurations. The G3 s stems can be ordered

in 120V or 230V version without an external step-down transformer.

CAUTION:

120V and 230V ACM ar NOT THE SAME PRODUCT. Th y n d diff r nt int rnal

compon nts and n d to b ord r d from th factory for th right configuration.

As D-BOX is not providing an external step-down transformer, ou will need to assure power conversion b our

own means if needed. To select our converter, please follow the power requirement listed in the spec sheets

for our specific configuration.

Other than power requirement, D-BOX would like to suggest the use of an isolated converter to avoid risks of

electrical shock. If a non-isolated converter is selected, please make sure to secure ground connection.

Pivot

When using a 2-actuator Motion S stem, D-BOX provides a pivot as a third attachment point to ensure proper

actuator movement. D-BOX suggests locating the pivot near the center of gravit , to support most weight and

allow equal weight distribution on the actuators.

NOTE

: the closer the actuators are to the CG, the larger the movement ou get. A CG that’s ver

close would create strong forces on actuators and might reduce stabilit . Make sure that

actuators are alwa s under charge.

Captive Endings

Go to the Removal/Installation section for details about the captive endings.

14

R

EMOVAL

/I

NSTALLATION PROCEDURES

H-B acket fo 1.5 in HD Actuato - AC10

Removal

1. Remove bolt (9) and pivot (8).

2. Remove bolt (7) and end piston adapter (6).

3. Remove bolt (5), lockwasher (4), stop (3), and H-plate (2) from housing (1).

Installation

NOTE

: Appl one drop of Loctite 243 blue threadlocker on bolts (5), (7) and (9) before

installation.

1. Align holes on H-plate (2) with holes on housing (1) and align holes on stop (3) with holes on H-plate (2),

and then secure with lockwasher (4) and bolt (5). Torque bolt (5) to 98 lbf.in.

2. Align holes on end piston adapter with holes on piston end and secure end piston adapter (6) with bolt

(7). Torque bolt (7) to 40 lbf.in.

3. Secure pivot (8) on end piston (6) with bolt (9). Torque bolt (9) to 130 lbf.in.

15

H-B acket fo 3in Actuato - AC231

Removal

CAUTION: xt nd th piston and lock with a wr nch to avoid br aking th cam follow r.

1. Remove bolt (6) with a 3/8” hex bit, spacer (5) and pivot (4).

2. Remove bolt (3) and H-bracket (2).

Installation

1. Place the H-bracket (3) on the end of the piston bod (1) with the screw holes aligned.

16

2. Appl Loctite 243 (blue) thread locker in the four blind holes (2) on the piston bod .

NOTE

: Appl the thread locker just before the bottom of the blind holes.

3. Use a 5 mm bit to secure the H-bracket plate to the piston bod with 4 screws (item 4, M6 X 1.0 X

14 mm), then tighten the 4 screws to a torque of 133 N m (98 lbf in).

4. Install pivot (4) with spacer (5) and bolt (6).

H-B acket fo 6in actuato - AC360

NOTE

: there are 2 models of H-brackets; one with seven mounting holes, one with 10 mounting

holes. The procedures are the same for both models. Onl the ten holes model is shown here.

Table of contents

Other D-Box Switch manuals

Popular Switch manuals by other brands

Juniper

Juniper EX8200 Series quick start guide

Mellanox Technologies

Mellanox Technologies M2401G user manual

H3C

H3C S5120-EI Series Configuration Commands

Lantronix

Lantronix SISPM1040-582-LRT quick start guide

steute

steute Ex ES Mounting and wiring instructions

axing

axing premium-line SPU 94-03 Operation instructions

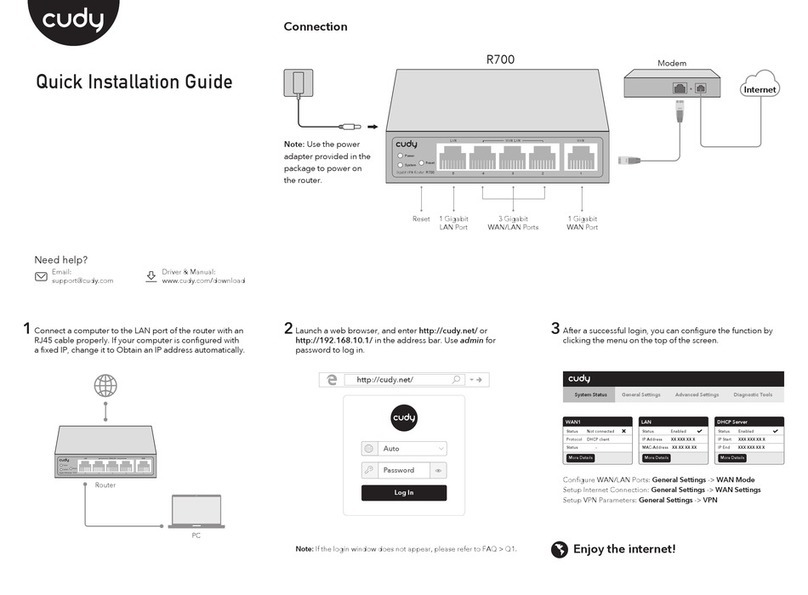

Cudy

Cudy R700 Quick installation guide

IMI NORGREN

IMI NORGREN 33D Mounting and operating instructions

Brocade Communications Systems

Brocade Communications Systems A7990A - StorageWorks SAN Director 4/16 Blade... Reference

Black Box

Black Box SW214A Specifications

Erbe

Erbe 20186-007 manual

Planex

Planex FMX-24NZ user manual