Deltec skimmers are suitable for use with ozone and will automatically suck the gas through the venturi hose. A

maximum volume of 50 mg/h per pump should be used with special manifolds available for multi pump units. Do not use excessive

ozone, as it is dangerous and can cause severe headaches. Should the skimmer performance deteriorate check the ozoniser for

blockage. Ensure that it is not possible for water to siphon through the ozoniser by installing the unit above the skimmer water level.

Maintenance: The Deltec skimmer range should need very little adjustment and maintenance once set correctly, however due to the

high levels of calcium in marine aquariums and large volumes of air drawn in, it is common for deposits to accumulate requiring

periodical cleaning. Regular introduction of a small amount of RO water into the inlet tap may help to prevent any build up.

The AP Series Skimmers are fitted with two different types of pump depending on the model.

Smaller skimmers are fitted with Aquabee pumps, which have permanent magnet motors.

The drawback of a permanent magnet motor is that the impellor, on start up, can randomly rotate in either a clockwise or anti

clockwise direction. In one direction the full pumping capacity is achieved and in the other a much reduced flow is observed.

In order to counteract this effect the Aquabee pumps are fitted with a little flap inside the outlet of the pump, which flips from one side

to the other depending on the direction of rotation thus ensuring that the pump always operates at full duty.

Larger skimmers are fitted with Eheim Pumps, which are also have permanent magnet motors but have no such flap device, relying

on a symmetrical outlet port design and accepting a lower working efficiency.

It is recommended every 3 months that the pumps are removed from the skimmer having first drained the body of water. Strip down

the pump to check and clean the impellor of debris. On Aquabee pumps ensure that the direction flap moves easily and if necessary

soak the neck of the pump housing in white vinegar or kettle scale remover to dissolve any calcium carbonate deposits.

On older skimmers check for wear on the impeller by holding the two ends of the ceramic shaft between the thumb and first finger

and look for excessive movement (slop). If this is found it should be replaced, as the loss of balance will cause unnecessary noise.

A build up of calcium, dust and salt can restrict or block the venturi inlet on the connecting pipework and also the inlet tap, reducing

the skimming efficiency. This should be checked and carefully cleaned with a toothpick or fine drill rotated between the fingertips.

Check for damage or wear of the sealing ring on the base of the cup and if necessary replace it.

Important Note: Ensure that the air intake pipes are always positioned well above the water level in the skimmer to prevent back

siphoning of water when the pumps are switched off.

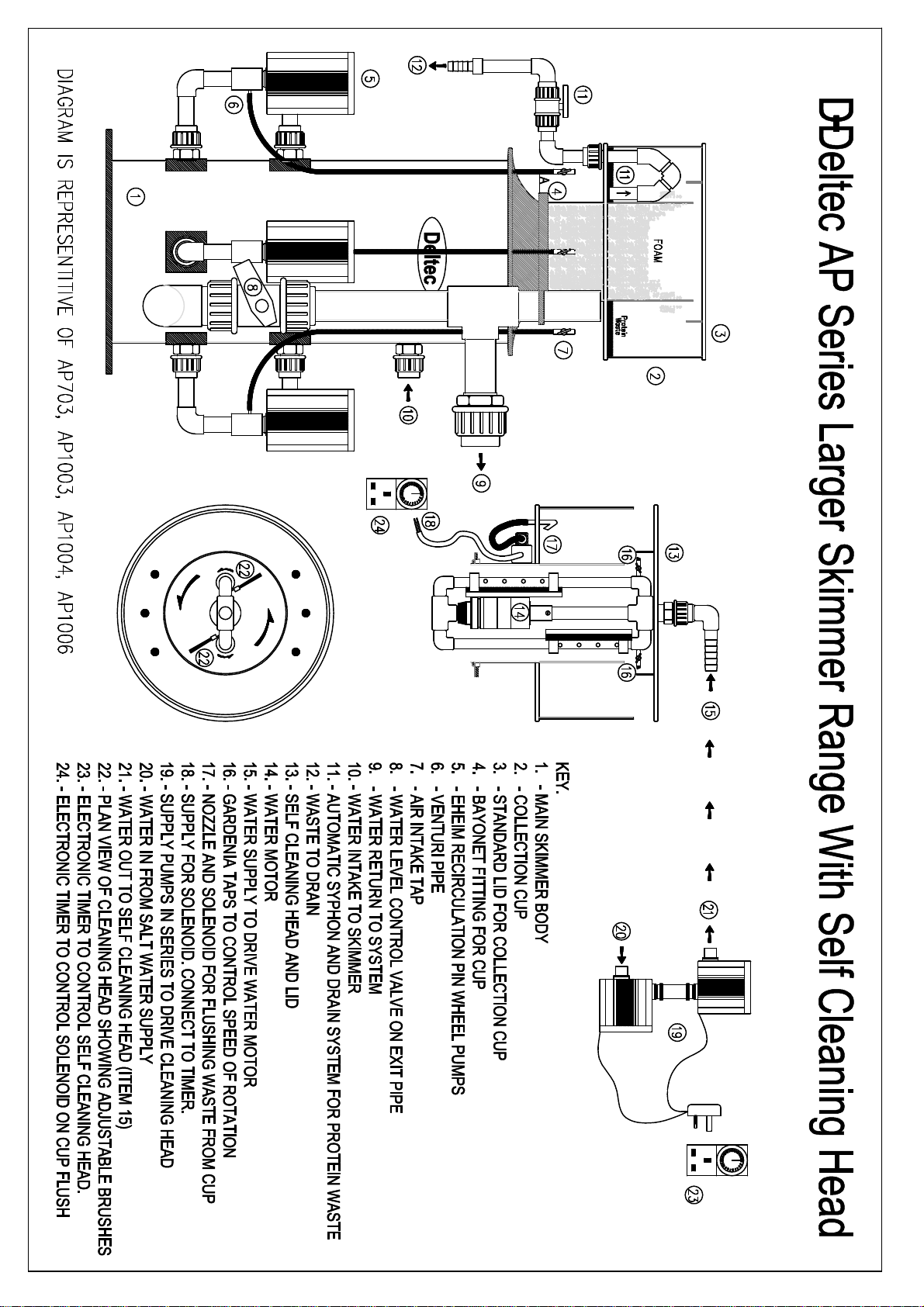

D-Deltec Self Cleaning Head and Auto Flush Systems

It is possible to fit a Self Cleaning Head to some of the larger Deltec Skimmers as indicated above to clean the inside and the outside

of the collection cup. This can be ordered with the skimmer or can be simply retrofitted at a later stage.

Fitting of such a system can increase the efficiency of the skimmer by at least 20% due to the constant removal of fatty deposits on

the riser tube that will otherwise reduce foam production.

Operation: The cleaning head consists of a supply system, modified lid, two sets of brushes on a rotating pipework body and a water

motor to drive it. The details of this can be clearly seen on the attached diagram. In addition there is a flushing system to periodically

wash out the cup and an auto siphon device to remove the waste to drain.

The head operates by forcing water at a relatively high pressure through the pipework and water motor causing it to rotate. Taps on

the end of the brush bars regulate the water throughput and hence the speed of rotation.

Setting up the Cleaning Head:To operate the unit it is necessary to provide a high-pressure supply of salt water to the head.

For this purpose the optional Deltec pump set consists of two Aquabee pumps, which are connected together in series to increase

the achievable pressure to the cleaning head. These are normally piped in flexible hose from a suitable water supply point, through

the pump and then to the hose tail on the skimmer lid. On all new models a drain port is fitted near the base of the body, which can

be fitted with a hose tail allowing it used as a suitable source of supply.

Important Note: Ensure, as with all flexible joints, that the connections onto the hose tail and on the flexi between the two pumps are

suitably clamped as failure of one of these connections could drain down the whole system.

With the supply system fitted as described, switch on the pumps and check that they both operate correctly in supplying water to the

head. Open the taps until the cleaning head is seen to rotate. Rotation is designed to be slow and further adjustment of the taps will

not produce rapid spinning. If the head does not spin it is possible that only one of the two pumps is operating correctly in which case

the directional flap in the pumps should be checked as described under skimmer maintenance.

The angle of the brushes should be adjusted so that they lightly clean the surface of the tube. Excessive contact may cause the

motor to stall. The position of the brushes may need adjusting over time as they gradually wear.

Having commissioned the cleaning head, it will be necessary to control the operation of the supply system with a suitable timer.

Deltec recommend that the timer is set to allow the cleaning head to rotate for 5 -15 minutes every 4 hours.

Setting up the Cup Flushing System: The skimmer cup is fitted with a flushing system, which consists of a directional nozzle; small

bore pipework and a solenoid valve. The drainage side is fitted with an auto siphon device and pipework to drain with a tap.

This is installed to allow a periodic flow of fresh water to flush out the detritus and waste protein from the skimmer cup which

otherwise over a period of time may cause a nuisance smell.

To set up the unit it is necessary to connect the solenoid to a suitable fresh water supply and for the waste to be piped to a drain.

Pipework and connections suitable for R O installations should be used and it is important to fit a non-return valve or preferably a

separate reservoir or other air break device. This will to prevent back siphoning of waste into the water stream should the mains

supply fail. Flushing of the cup with salt water is therefore not recommended as it may result in a gradual reduction in salinity

The auto siphon device that comes fitted with the collection cup will allow the waste water to rise to the top of the 90-degree bend

and then will automatically drain away until empty at which point the siphon will again break.

The solenoid should be connected to a separate timer, which allows the cup to be flushed every 4 hours to prevent waste products

drying on the side of the cup. All waste should be directed to a permanent drain.

Maintenance: This should consist simply of cleaning every 4-6 weeks, maintaining the supply pumps and occasional adjustment of

the brushes so that they keep light contact with the riser tube.

For further information on this or any other D-D product please contact us or visit our website on:

www.d-daquariumsolutions.com Telephone. 020 8501 2492 Fax. 020 8500 9102