5

DESCRIPTION OF EQUIPMENT

General Description

Compact handpiece, ergonomic design, body made of metal with surface treatment. Rotor supported

on bearings providing a low noise level, speed adjustment in clockwise and counterclockwise

directions, adapts to any contra angle or straight piece handpiece in the INTRA system.

The Alliage handpieces have been planned to oer maximum performance in the most severe clinical

procedures. With a design which caters for ergonomics, torque, sensitivity and lightness. Produced

with technology (MADE IN BRAZIL) and material of the utmost durability.

Internal irrigation System (according to model acquired): without the need for adaptations, the

internal irrigation system allows direct passage of water ow to the counter angle or straight piece

with the power required for the formation of the spray.

To ensure safe operation of your equipment, use only the mounting assembly (chair, equip, water

unit and reector) provided by Alliage Authorized Reseller Service.

Application specication

Alliage Dental Handpieces are designed to perform most routine dental procedures in intraoral

region treatments.

Operation principle

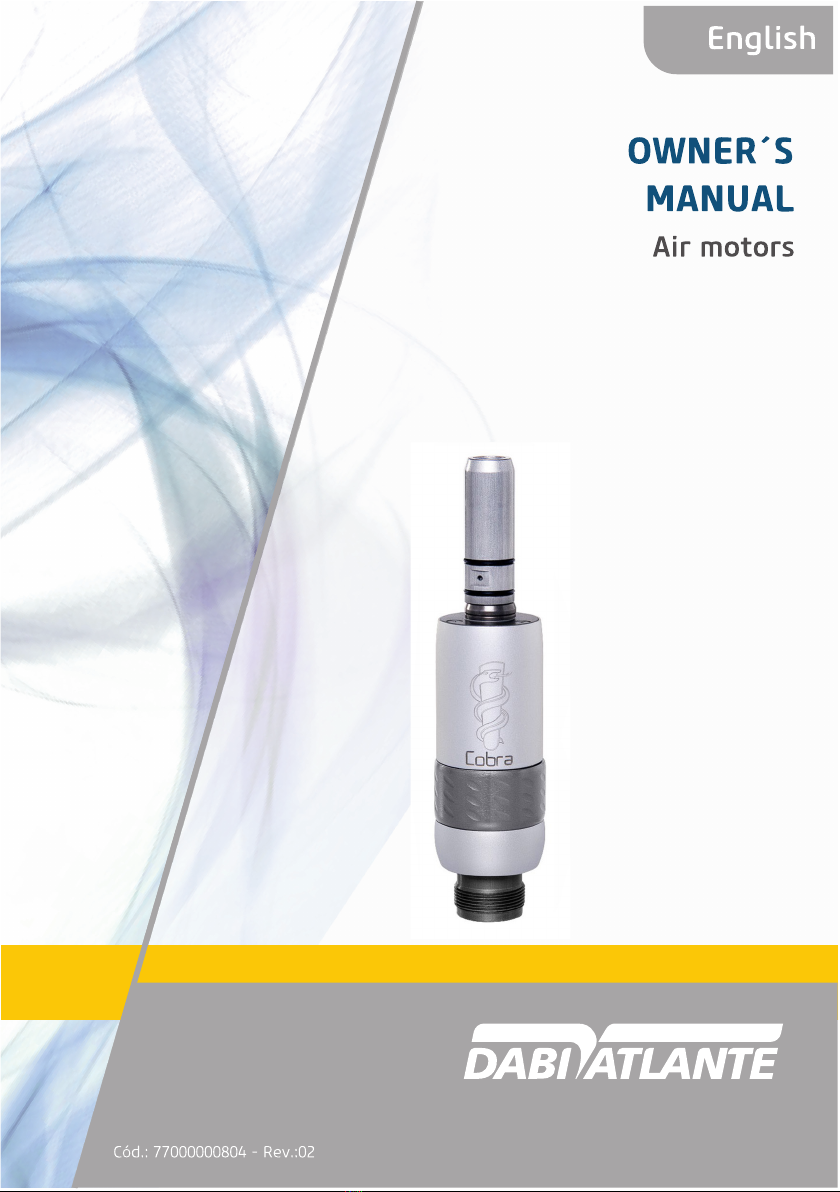

The Air motors operates by pneumatic pressure and has an Intra connection system to be used

with Low Speed Dental Handpieces.

Signicant physical characteristics

The Air motors promotes shaft revolutions in the magnitude of 5,000 to 20,000 revolutions/minute

and has a torque of 0.350 - 1,000 N.cm. Under normal operating conditions, the equipment has a

compressed air consumption of 54 L/min and a water consumption of 42 mL/min.

User prole

Alliage Dental Handpieces can be operated and handled by users of both sexes, with the ability to

read and understand images, symbols, icons, western Arabic characters (Arial font), alpha numeric

characters, knowing how to distinguish intraoral part of the human body, not being able to present

a degree of visual imperfection for reading or seeing and an average degree of impairment of recent

memory, not being in a clear capacity to perform the activities and functions of the product in a

correct manner to the profession.

The user needs to be a qualied health professional and trained with technical competence in the

health and dentistry eld.