Black Bear is a registered trademark of Daekyung Co., Ltd.

1521-6 Dadae-dong, Saha-gu, Busan, Korea Tel: +82)51-264-6611 Fax: +82)51-264-6615

BLACK BEAR HOIST

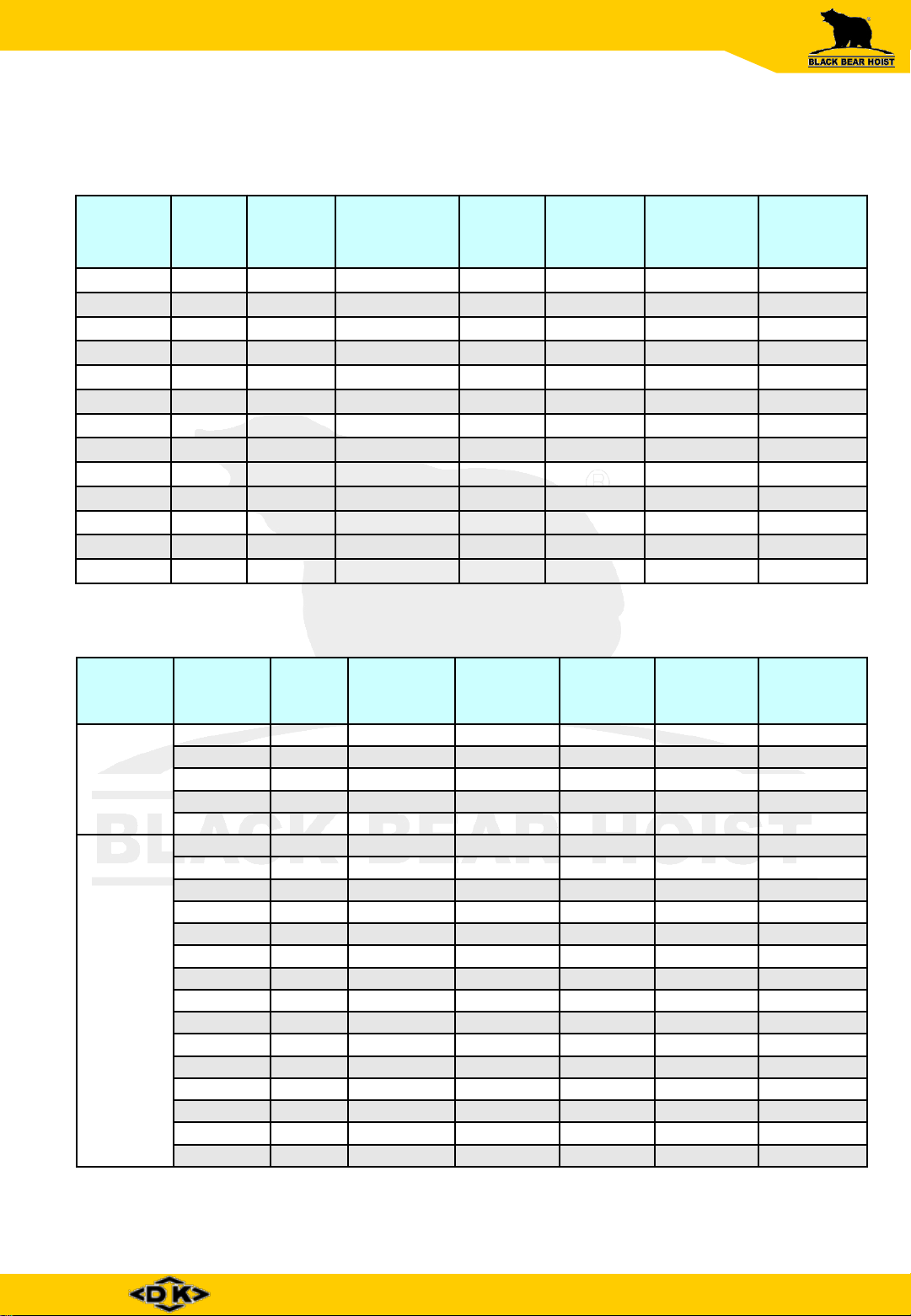

2.2 Specification

- 8 -

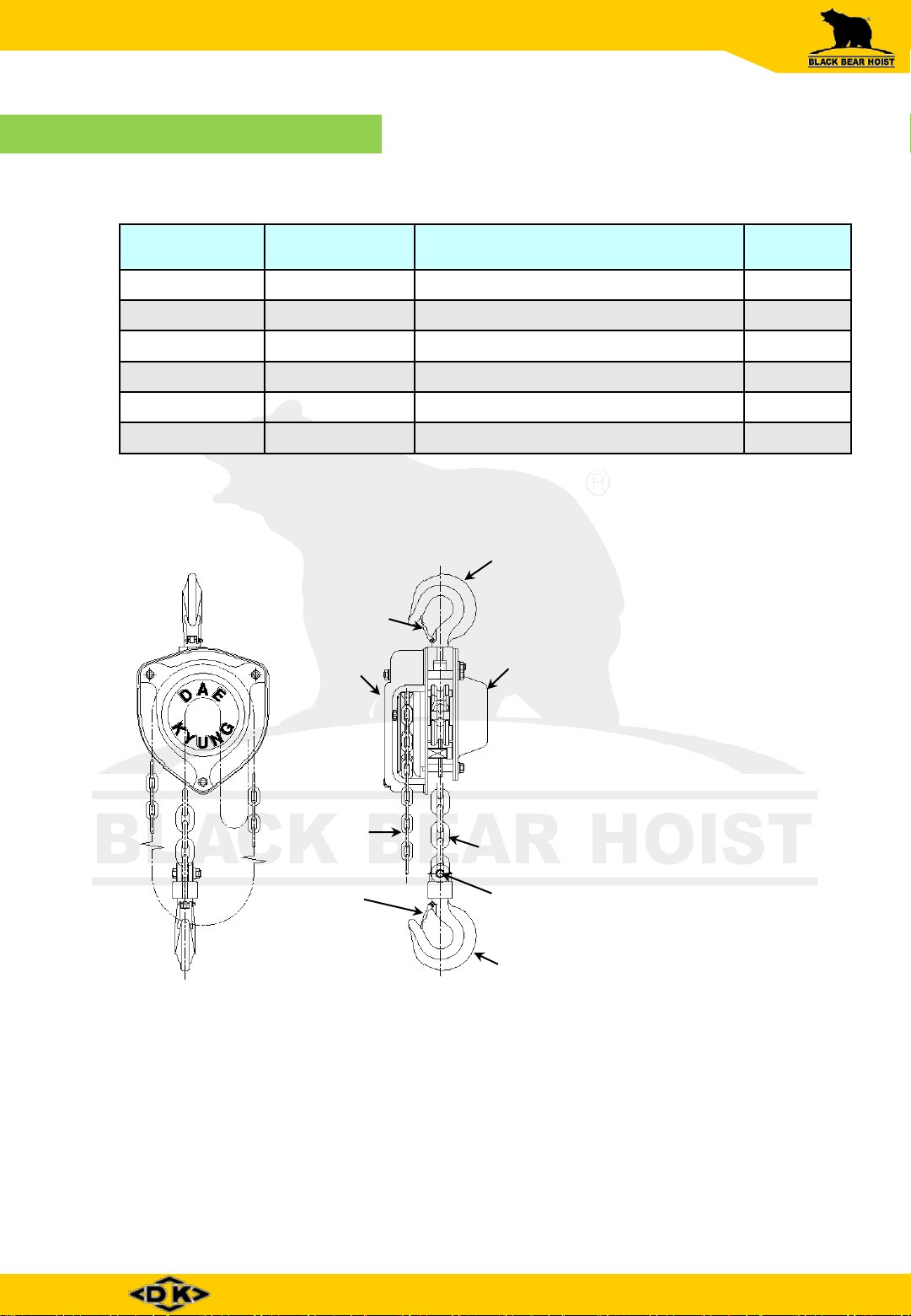

2.2.1 Chain Block

2.2.2 Trolley

Model Capacity

(Ton)

No. of

Chain Falls

Load Chain

Size

(mm)

Lift

[STD]

(m)

Hand Chain

[STD]

(m)

Min. Distance

Hook to Hook

(mm)

Net Weight

(kgf)

DS-005 0.5 1 Ф6.3 x P19.0 2.5 2.0 330 10.5

DH-010 1.0 1 Ф7.1 x P20.2 2.5 2.0 340 12.0

DH-015 1.5 1 Ф7.9 x P23.0 2.5 2.0 400 18.0

DH-020 2.0 1 Ф9.5 x P28.6 3.0 2.5 440 25.5

DH-030 3.0 2 Ф7.9 x P23.0 3.0 2.5 530 28.5

DH-050 5.0 3 Ф7.9 x P23.0 3.0 3.0 670 44.0

DH-080 8.0 3 Ф11.1 x P33.3 3.5 3.5 850 91.0

DH-100 10.0 3 Ф11.1 x P33.3 3.5 3.5 850 91.0

DH-150 15.0 5 Ф11.1 x P33.3 3.5 3.5 1150 181.0

DH-200 20.0 6 Ф11.1 x P33.3 3.5 3.5 1250 235.0

DH-300 30.0 10 Ф11.1 x P33.3 3.5 3.5 1450 492.0

DH-400 40.0 14 Ф11.1 x P33.3 3.5 3.5 1650 750.0

DH-500 50.0 18 Ф11.1 x P33.3 3.5 3.5 1950 930.0

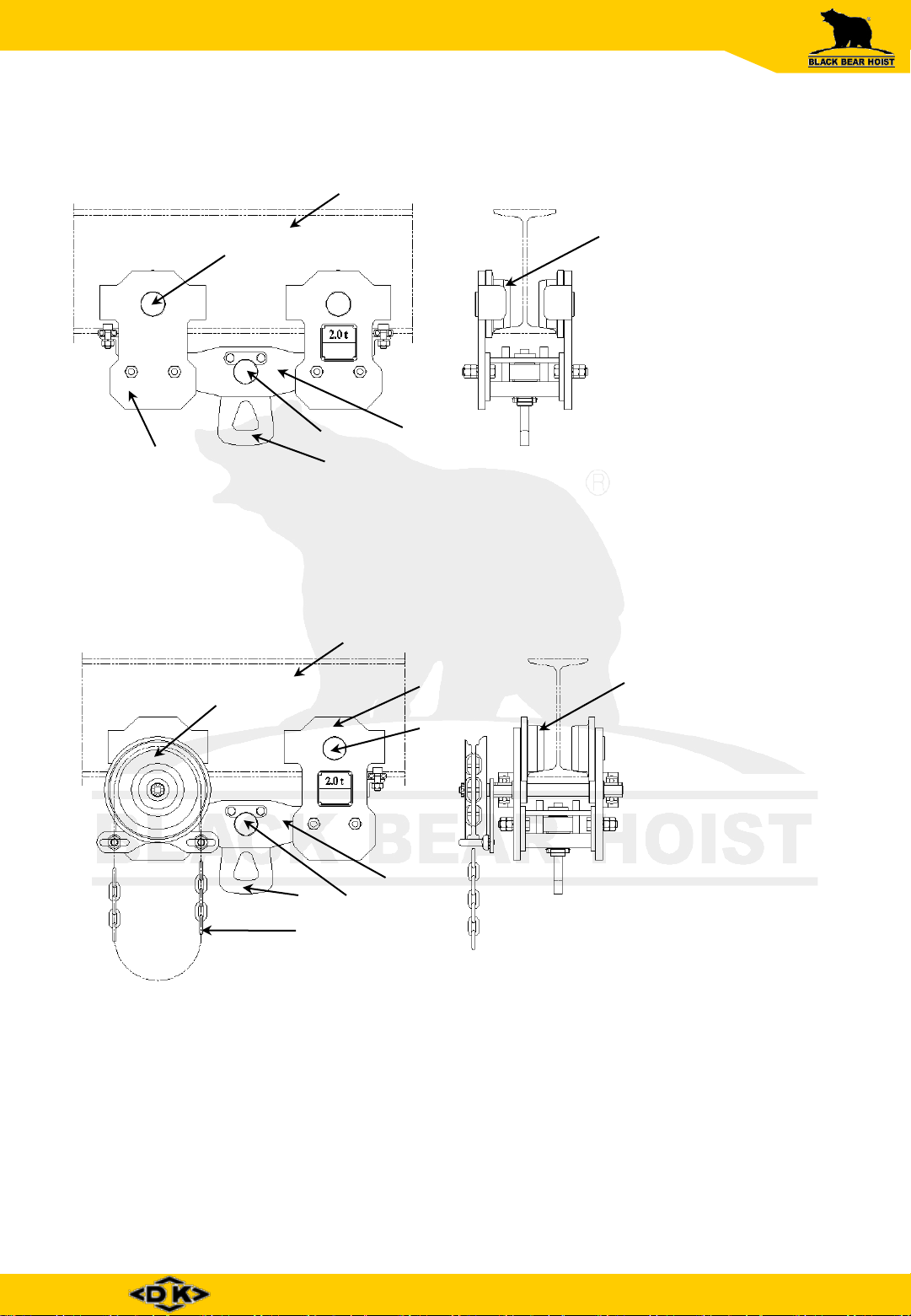

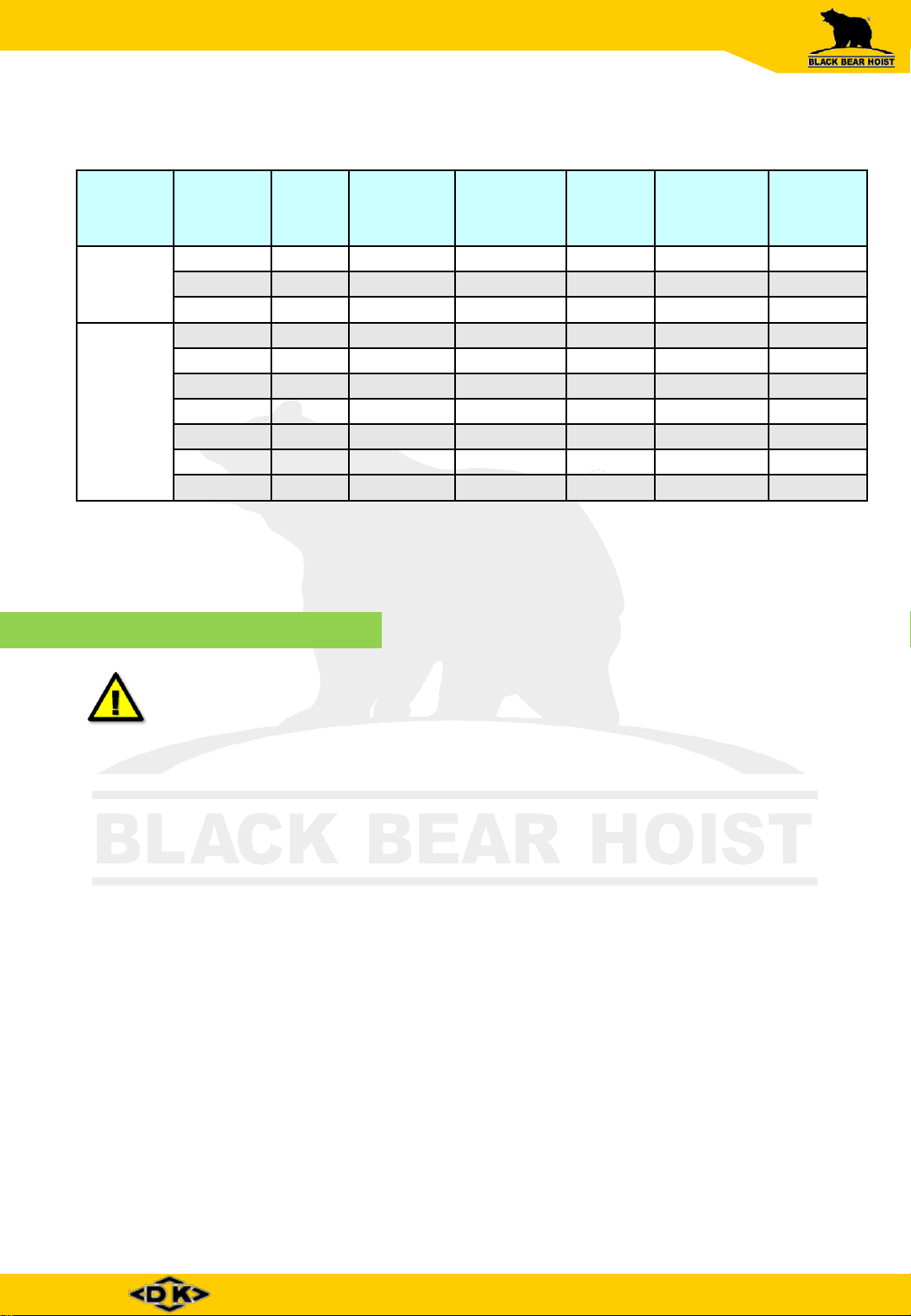

Item Model Capacity

(Ton)

I-Beam

Flange Width

(mm)

Hand Chain

[STD]

(m)

Min. Radius

Curve

(mm)

Min. Distance

Hook to Beam

(mm)

Net Weight

(kgf)

Plain

Trolley

DPT-005 0.5 75~125 - 800 112 7.0

DPT-010 1.0 75~125 - 1200 118 10.0

DPT-015 1.5 75~125 - 1300 157 15.6

DPT-020 2.0 100~150 - 1300 157 15.6

DPT-030 3.0 100~150 - 1500 173 28.0

Geared

Trolley

DGT-005 0.5 75~125 2.5 800 104.5 8.0

DGT-010 1.0 75~125 2.5 1200 115 12.2

DGT-015 1.5 75~125 2.5 1300 147 18.5

DGT-020 2.0 100~150 2.5 1300 147 18.5

DGT-030 3.0 100~150 3.0 1500 173 30.5

DGT-050 5.0 125~175 3.0 1600 197 42.5

DGT-075 7.5 150~190 3.5 2100 242 80.0

DGT-100 10.0 150~190 3.5 2500 262 114.0

DGT-150 15.0 150~190 3.5 3200 413 246.0

DGT-200 20.0 150~190 3.5 - 148 316.0

DGT-300 30.0 175~190 3.5 - 157 560.0

DGT-400 40.0 175~190 3.5 - 162 708.0

DGT-500 50.0 175~190 3.5 - 456 810.0

DGT-700 70.0 175~190 3.5 - 199 1340.0

DGT-1000 100.0 175~190 3.5 - 209 1674.0