The following manual is only a guide to assist you and is not a complete or comprehensive manual

of ali aspects of maintaining and repairing your generator. The equipment you have purchas d is a

complex piece of machinery. We recommend that you consult with a dealer if you have doubts or

concerns as to your experience or ability to properly maintain or repair your equipment. You will

save time and the inconvenience of having to go back to the store if you choose to write or call us

concerning missing parts, service question ,operating ad vice, and/or assembly questions.

Our air-cooled diese) generators have sorne of the following feature:

• Lightweight construction

• Air cooled

• Four-stroke diesel internal combustion engine

• Direct fuel injection system

• Recoil starter or an optional electric starter

• Large fuel tank

• Automatic voltage stabilizer

• NFB circuit protector

• AC and DC outputs

• Low oil pressure sensor

The air-cooled diese! generators are widely used when electrical power is scarce. Our generators

provide a portable mobile solution in supplying power for field operations during project construc-

tion. Sorne other known applications include pipeline construction and metal welding when electri-

cal power is not available.

This manual will explain how to operate and service your generator set.

lf you have any questions or suggestions about this manual. please contact your local dealer or us

directly. Consumers should notice that this manual might differ slightly from the actual product as

more improvements are made to our products. Some of the pictures in this manual may differ slight-

ly Jrom the actual product as well. We reserves the right to make changes at any time without notice

and without incurring any obligation.

1. TECHNICAL SPECIFICATIONS AND DATA

Engine type: Single cylinder, Vertical, 4 Stroke, Direct injection, Air-cooled

Displacement: 418 cc

Max power: 5.5 kw

Rated power: 5.0 kw

Engine power: 10 hp / 3000 rpm

Bore×stroke: 86×72 mm

Fuel tank capacity: 15 L

Fuel tank capacity: 1.65 L

Compression ratio: 19:01

Starting system: Electric start

Starting motor capacity: 12 V - 0.8 kW

Charging generator capacity: 12 V - 8.3 A

Battery capacity: 12V - 30 Ah

Fuel consumption: ≤370 g/kW.h

Insulation Grade: F

Power factor: 1

Noise level at 7M: 72 dBA

Phase NO.: Single phase

Continuous running time: 6 hr

2. OPERATING THE DIESEL GENERATOR

2-1 General main points of safety during operation of the generator set.

In order to operate the generator set safely,please follow all the instructions provided in this manual

carefully . Doing so otherwise may lead to accidents and or equipment damage.

2-1.1 Fire prevention

The proper fuel for the diesel generator set is light diese! fuel . Do not use gasoline, kerosene and or

other fuels other than light diesel fuel. Keep all flammable fuels away from the generator as the

generator may spark and ignite these gases. In order to prevent fires from occurring and to provide

enough ventilation for people and the machine ,keep the diesel generator at least 1.5meters or 5 feet

away from buildings and or other equipment.Always operate your diesel generator on a level site .lf

the generator is operated on an incline , the lubricating system within the engine will not perform

well and may lead to failure of the engine.

2-1.2 Prevention from inhaling exhaust gases

Never inhale exhaust gases emitted by the engine. The exhaust gases contain toxic carbon monoxi-

de.Never operate your generator in places with poor ventilation.ln order to operate this machinery

indoors , a suitable ventilation system for the building is required to draw the poisonous exhaust

gases out.

2-1.3 Prevention from accidental bums

Never touch the muffler and its cover when the diesel engine is running .Never touch the muffler and

cover after the diesel engine has been used, as the muffler remains hot for a good period of time.

2-1.4 Electris shock and short circuits

Never touch the generator if the generator is wet.Also never touch the generator if your hand is

wet.Never operate your generator if the weather conditions call for any type of precipitation such as

rain ,snow or fog .To prevent electrical shocks,the generator should be grounded. U se a lead to

connect the grounding end of the generator to the grounding surface of choice.

NOTE: When connection devices to the generator, make sure all other devices are rated lower than

the generators output. Any generator socket should not be overloaded over its regulated limit.

2-1.5 Other safety points

Before operating this generator, all operators should have a good knowledge of how to break the

circuit if any accidents occur .Also,all operators should be familiar with all the switches and func-

tions of the generator before using tkis machine .While operating the generator , wear safe shoes

and suitable clothes during operation.Always keep children and animals away from the generator.

2-1.6 Battery

The electrolytic liquid of the battery contains sulfuric acid .In order to protect your eyes,skin and

clothing ,wear protective gear when working with the battery.lf you come in contact with the elec-

trolytic liquid, wash it immediately with clean water.Also, if the electrolytic liquid comes in contact

with your eyes,see a doctor immediately.

2-2 Preparation before operation

2-2. l Fuel choices and fuel treatment

Fuel tank

Use only light diesel fue l. The fuel should be filtered clean. Never Jet dust and water mix with fuel in

the fuel tank. Otherwi se it will clog the fuel lines and oil nozzles. It may also damage your pressure

pump.

NOTE: lt is dangerous to overfill the fuel tank. Never exceed the red piston in the filter.

a. After purchasing fuel, put it into a drum and let it sit for 3-4 days.

b. 3-4 days later, insert half of the fuel sucker into the drum (water and impurities stay in the lower

portion of the drum).

Air filter element

Do not wash the air filter. The element is made of dry material, which does not permit washing.

When the output of the diesel engine is bad or the color of the exhaust gas is abnormal, replace the

air filter element. Never start the diesel engine without the air filter.

NOTE: Never smoke near the opening of the fuel tank. Do not let sparks get near the fuel or fuel tank

and do not overfill tank. After filling, tighten the fuel cap.

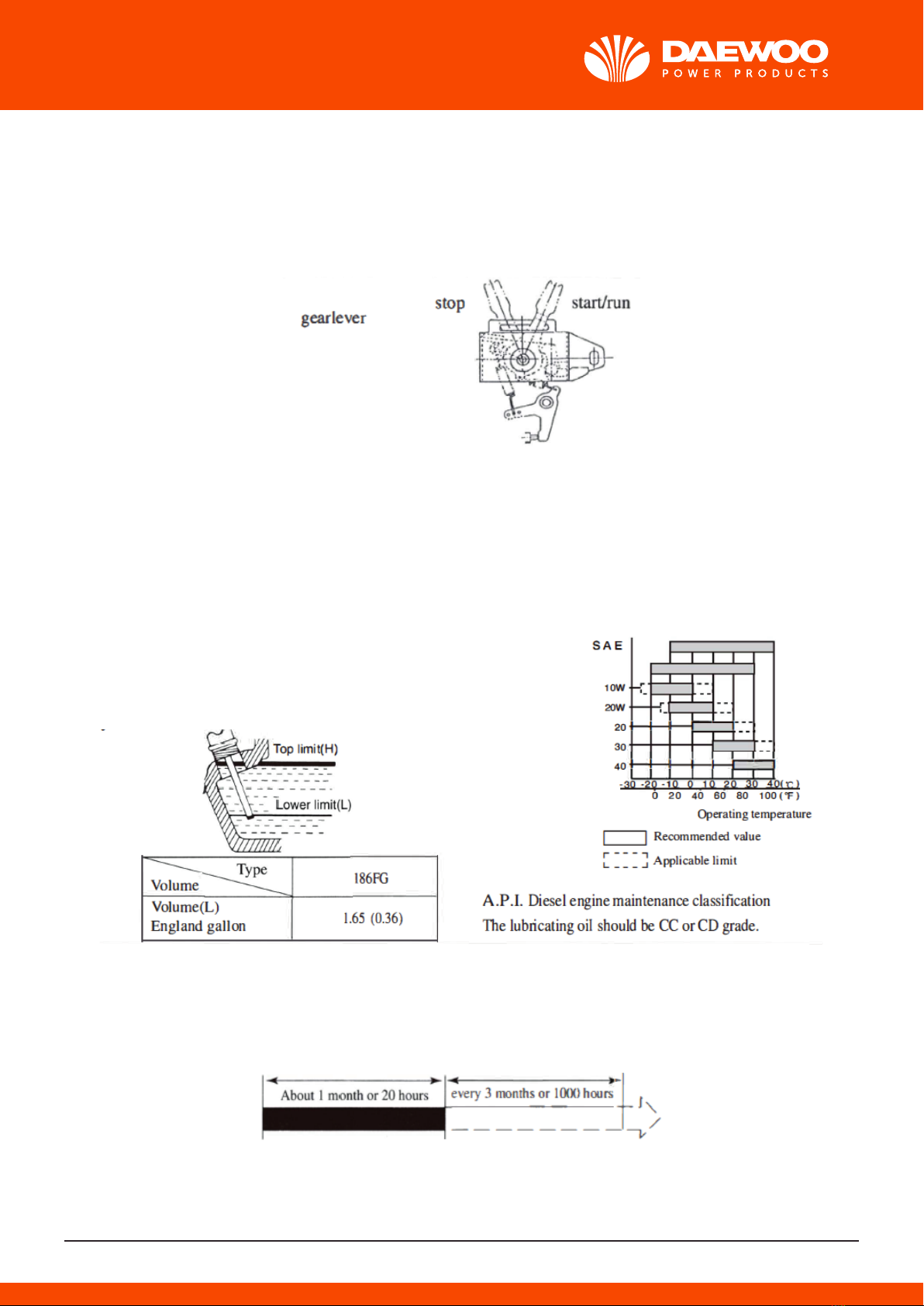

2-2.2 Fill engine oil

Fubrication Oil Filling Inlet

Put the generator set in level state. Fill the oil into the oilfilling inlet. At the time of checking the oil

level, it is necessary only to lightly insert the oil ruler. Please pay attention to that you should not

rotate the oil ruler.

Engine oil is the most important factor in deterrnining the life of your generator engine.If you

use poor engine oil or if you don't change the oil regularly,the piston and cylinder will wear

easily or seize up.Also,the life of the other parts in your engine such as bearings,and other

rotating parts will shorten considerably.

Although there is an alarm system to check for low oil pressure, it is always a good idea to check

the amount of oil inside the engine. lf the oil level is low, fill it before starting the engine. A good time

to drain the oil from the engine is when the diese! engine is still hot. If the engine is fully cooled, it is

more difficult to drain all the oil out or sorne impurities will remain in the engine.

WARNING: Don't fill engine oil when diesel is operating.

2-2.3 Check air filter

(1) Loosen the butterfly nut, take the cover of the air filter off and take the air filter element out.

Do not use detergent to wash the air filter element. When the performance of the engine decreases

or when the color of the exhaust gases is bad,exchange the filter element. Never start the engine

without the air filter as foreign objects may enter the intake and damage the engine.

(2) After replacing the air filter element, replace the cover and tighten the butterfly nut firmly.

2-2.4 Checking the generator welder

Before starting the generator,make sure the air switch is in the "off" position. Starting the generator

with the switch in the "on" switch is very dangerous. The generator should be grounded in order

to prevent electric shock. Use dry compressed air(with pressure about (1.96 x 105 Pa)to blow the

dust out in the electric control cabinet and at the surface of the generator.Check to see how clean

the surfacc of the sliding ring is. Check the pressure of the carbon bmsh.Also,check whether

the position of the carbon brush at the slide rig is correct and the fixture is reliable with a good

contact.

According to the electric wiring diagram, check to see whether the connecting wire is correct and

the connected place is firm. Use a 500 MΩmeter to measure the insulation resistance of the electri-

cal part.The resistance should be less than 2MΩ. When measuring devices ,make sure the capacitor

is turned off.Otherwise, it will burn tpe capacitor.(For silent set,the inspection may not be carried

out).

2-2.5 The fuel and oil in a new engine is drained before sold.

Before you start the engine, please fill the fuel tank snd oil first. Then,check to see if there are air

bubbles in the engine. If there are, follow these procedures.Loosen the connecting nut between the

oíl injection pump and oil pipe. Bleed the air from the system until there are no more bubbles. Then

replace the connecting nut and tighten it.

2-3 Checking the operation of the diesel engine

2-3.1 Low-pressure alarm system.

The diese! engines have a low-pressure sensor system where if the oíl pressure drops to low ,the

sensor will shut the engine off. The purpose of having this system is to ensure that the engine <loes

not seize up. If there is not enough oil in the engine,the temperature of the oil will be raised too

high.On the contrary,if there is too much oil in the engine,the engine oil can slow the engine down

considerably. (Note: The 2 GF-L model cannot automatically stop itself).

2- 3.2 How to open the case door/cover

(1) Open the case door:turn the handle counterclockwise and open the door. Do these checks daily.

7