1-7 HOW TO HANDLE THE VEHICLE

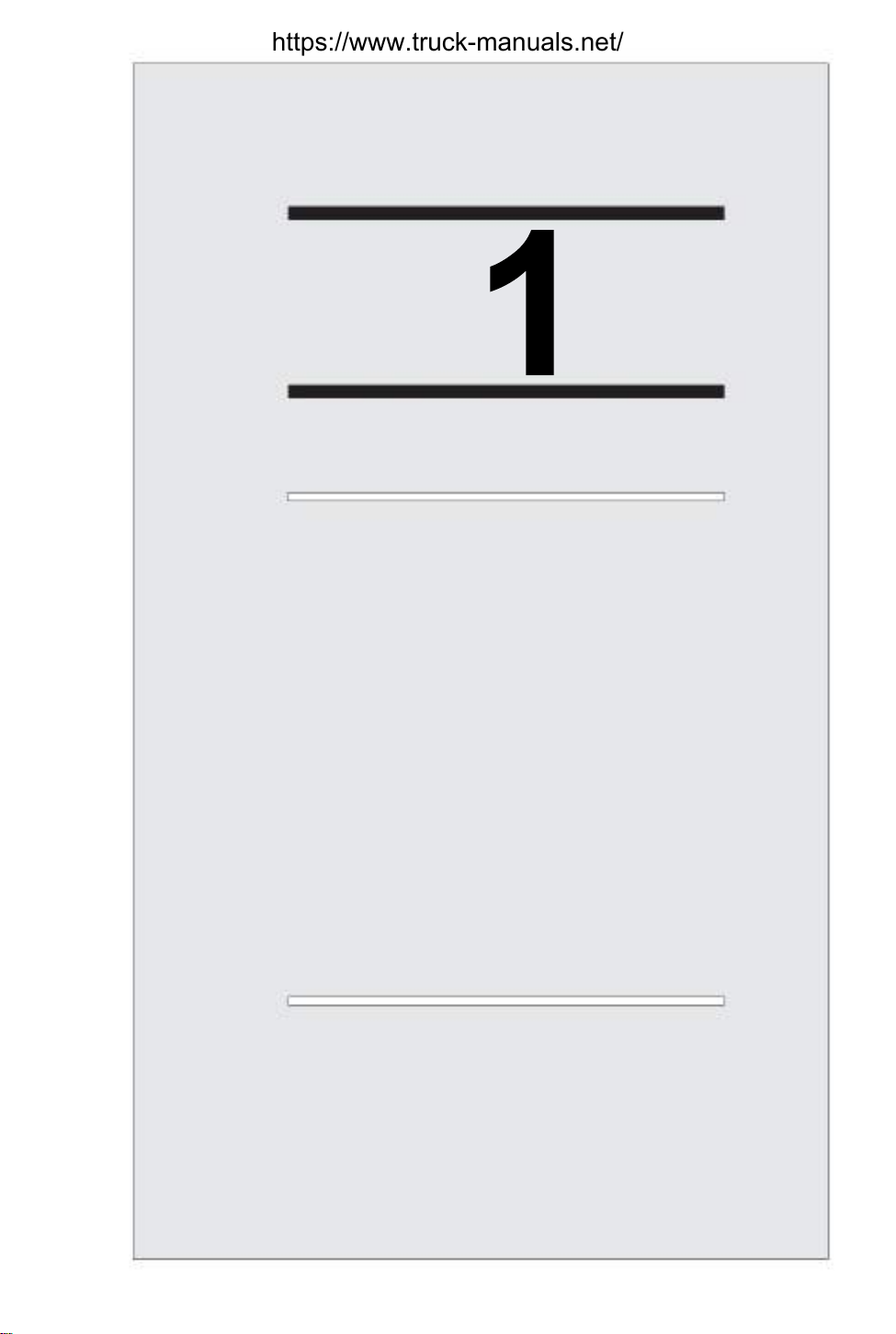

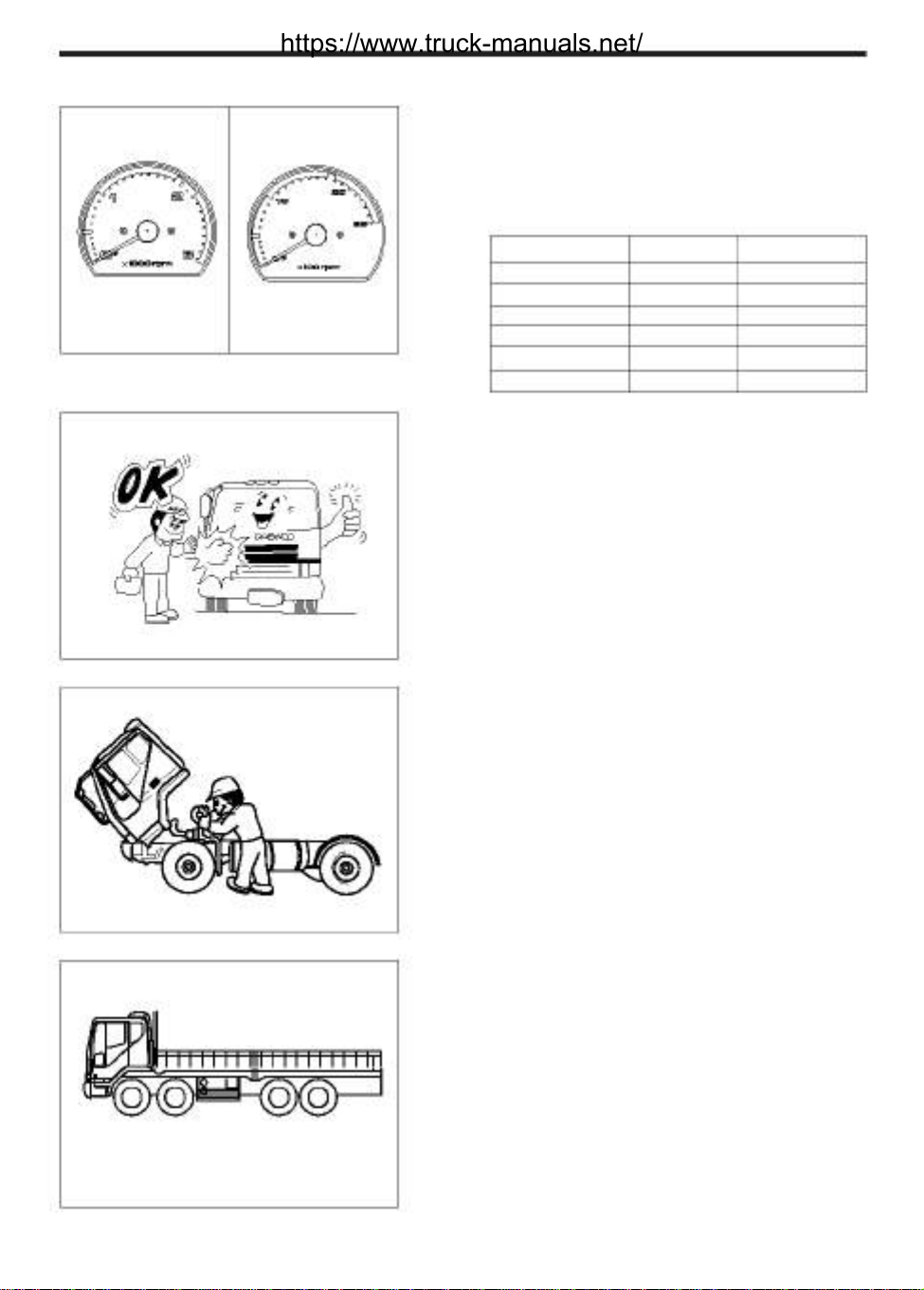

(4) Cab is ascending while pushing the cab-tilt

switch. You can manipulate the switch to adjust

open angle of the cab as desired. Stop pushing

the switch when the cab is tilted over than the

cab weight center, if you keep pushing the

switch on the noise will be increased.

Caution

1. If you want to stop ascending the cab, you

should position the direction change lever in "D"

position.

MTA1220 2. Do not work without tilting the cab completly.

3. Do not start engine when the cab does not tilted

completly or while descending.

4. Never tilt the cab at a sloped hill.

descending

position

MTA1230

5) How to lower the cab (Hydraulic cab latch :

option)

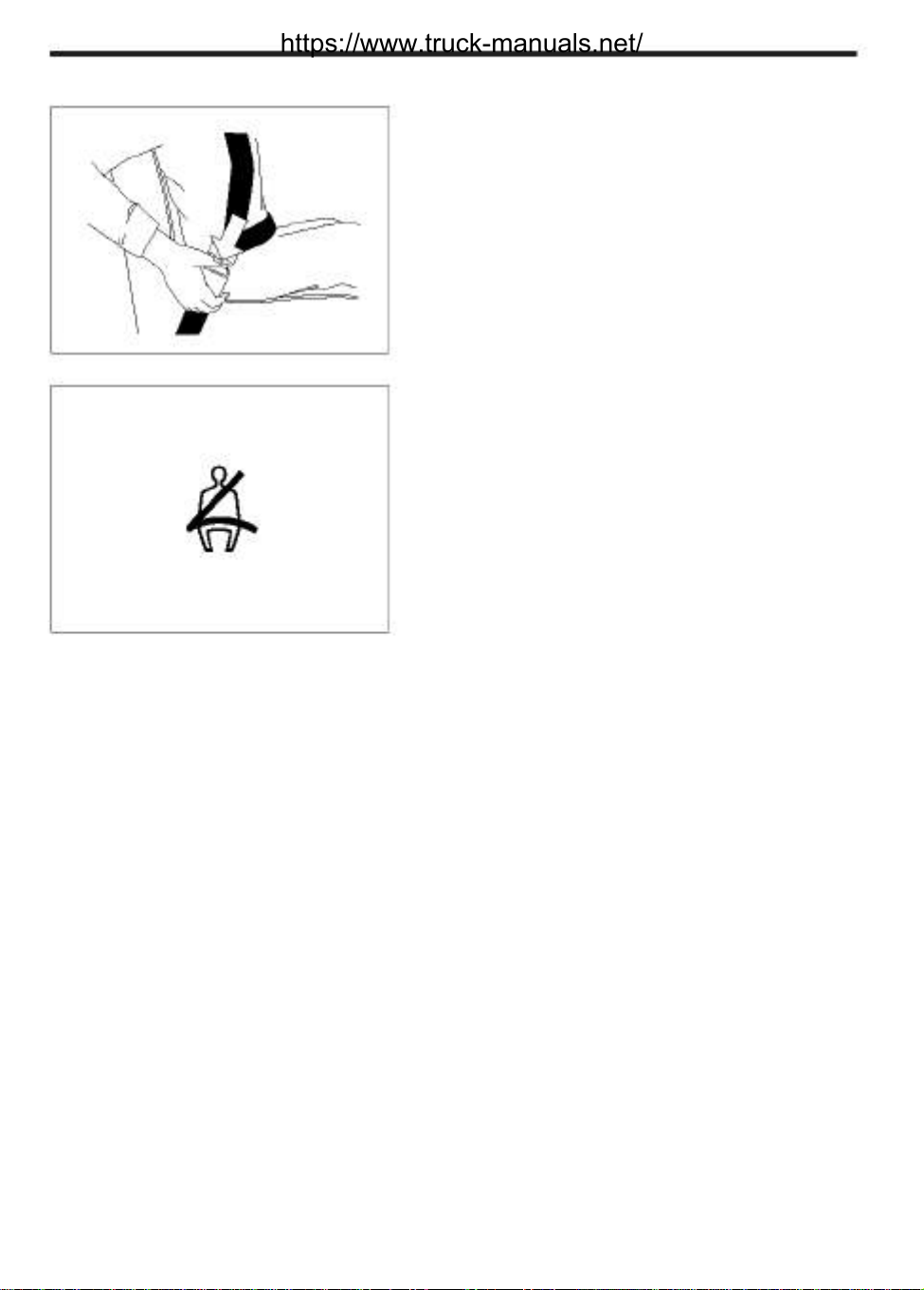

(1) Position the direction change lever in "D" posi-

tion.

(2) Press the switch as shown, and then the pump

works and the cab starts to descend.

(3) Once the cab descended completly, stop push-

ing the switch.

Inside the cab

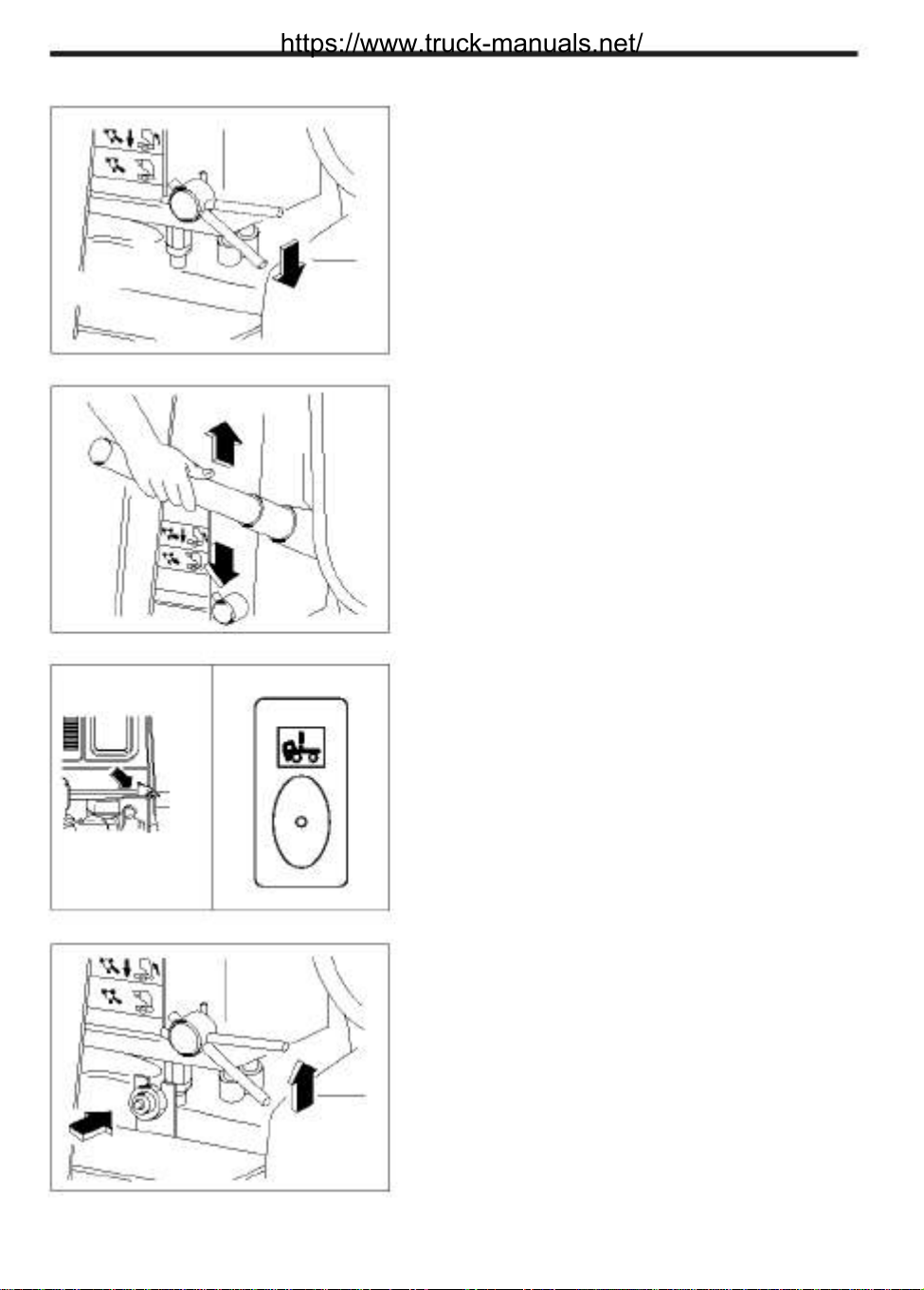

(4) Once the cab descends completely, check that

the lever located at the rear lower right hand

side of the cab is locked into hook.

For hydraulic cabin latch type vehicle, Make

sure that release cab tilt switch to "OFF" and

Hook warning lamp is off before driving.

Lock

lever

MTA1240

MTS0190

Caution

1. While driving you should set the direction change

lever in "D" position.

2. Be sure to check that the lock lever is locked in

hook. In the event of troubles with cab tilting sys-

tem, call for check and necessary services of your

nearest Daewoo dealer.

https://www.truck-manuals.net/