WASHING MACHINE

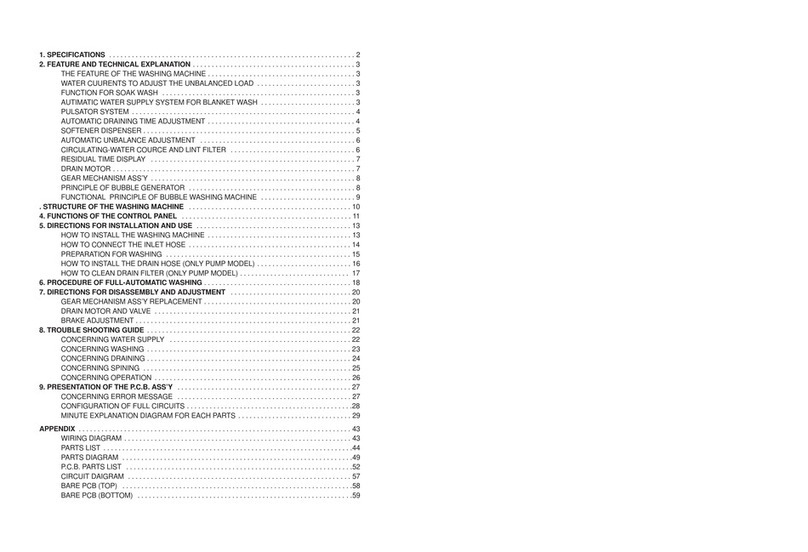

Contents

1. SPECIFICATIONS................................................................................................................... 2

2. STRUCTURE OF THE WASHING MACHINE............................................................................. 3

3. DIRECTIONS FOR INSTALLATION AND USE............................................................................ 4

INSTALLATION OF THE UNDER BASE COVER .......................................................................................4

HOW TO INSTALL ON AN INCLINED PLACE .............................................................................................4

HOW TO CONNECT THE INLET HOSE ..........................................................................................................5

HOW TO CLEAN ......................................................................................................................................................... 6

4. FEATURE AND TECHNICAL EXPLANATION............................................................................... 7

FEATURE OF THE WASHING MACHINE...................................................................................................... 7

WATER CURRENT TO ADJUST THE UNBALANCED LOAD............................................................7

FUNCTION FOR SOAK WASH...........................................................................................................................7

AUTOMATIC WATER SUPPLY SYSTEM FOR WASH........................................................................... 7

AUTOMATIC DRAINING TIME ADJUSTMENT ...........................................................................................8

CIRCULATING-WATER COURSE AND LINT FILTER .............................................................................8

RESIDUAL TIME DISPLAY .................................................................................................................................. 8

5. DIRECTIONS FOR DISASSEMBLY AND ADJUSTMENT............................................................... 9

GEAR MECHANISM ASS’Y REPLACEMENT ...........................................................................................10

DRAIN MOTOR AND VALVE REPLACEMENT .........................................................................................11

6. TROUBLE SHOOTING GUIDE............................................................................................... 12

TEST PROGRAM (TEST WITHOUT WATER).......................................................................................12

7. .................................................................................18USAGE OF THE OPERATION BUTTONS

KEY POINTS IN DISSASSEMBLY ................................................................ ............................... ..............9

METHOD OF DISASSEMBLING THE CONTROL PANEL.................................................................9

CONCERNING NO ACTION (THE INDICATOR IS OFF).......................................................................12

CONCERNING NO ROTATION IN WASHING ................................................................. ............................13

CONCERNING NO SPINNING ........................ ....................................................................... .. ...........................13

CONCERNING NO WATER FILLING .................................................................................... ...........................13

CONCERNING NO DRAINING ................................................................................................ ...........................14

CONCERNING KEEP FILLING WATER ............................................................................ ...........................14

CONCERNING TOO MUCH NOISE IN WASHING ........................................................ ...........................15

CONCERNING TOO MUCH NOISE IN SPINNING ......................................................... ..........................15

CONCERNING TIME-OUT IN BRAKE ............................................................................... ............ ..............16

TROUBLE-SHOOTING TABLE ............................................................................................... ............ ..............17

8. ................................................ ............................ 20CIRCUIT DIAGRAM ..................................................

9. ................................................ ................................. 22PARTS DIAGRAM ............................... ..