2.1

2.1

2.1

2.1

Description

Description

Description

Description

of

of

of

of

Constant

Constant

Constant

Constant

-

-

-

-

Voltage

Voltage

Voltage

Voltage

Mode

Mode

Mode

Mode

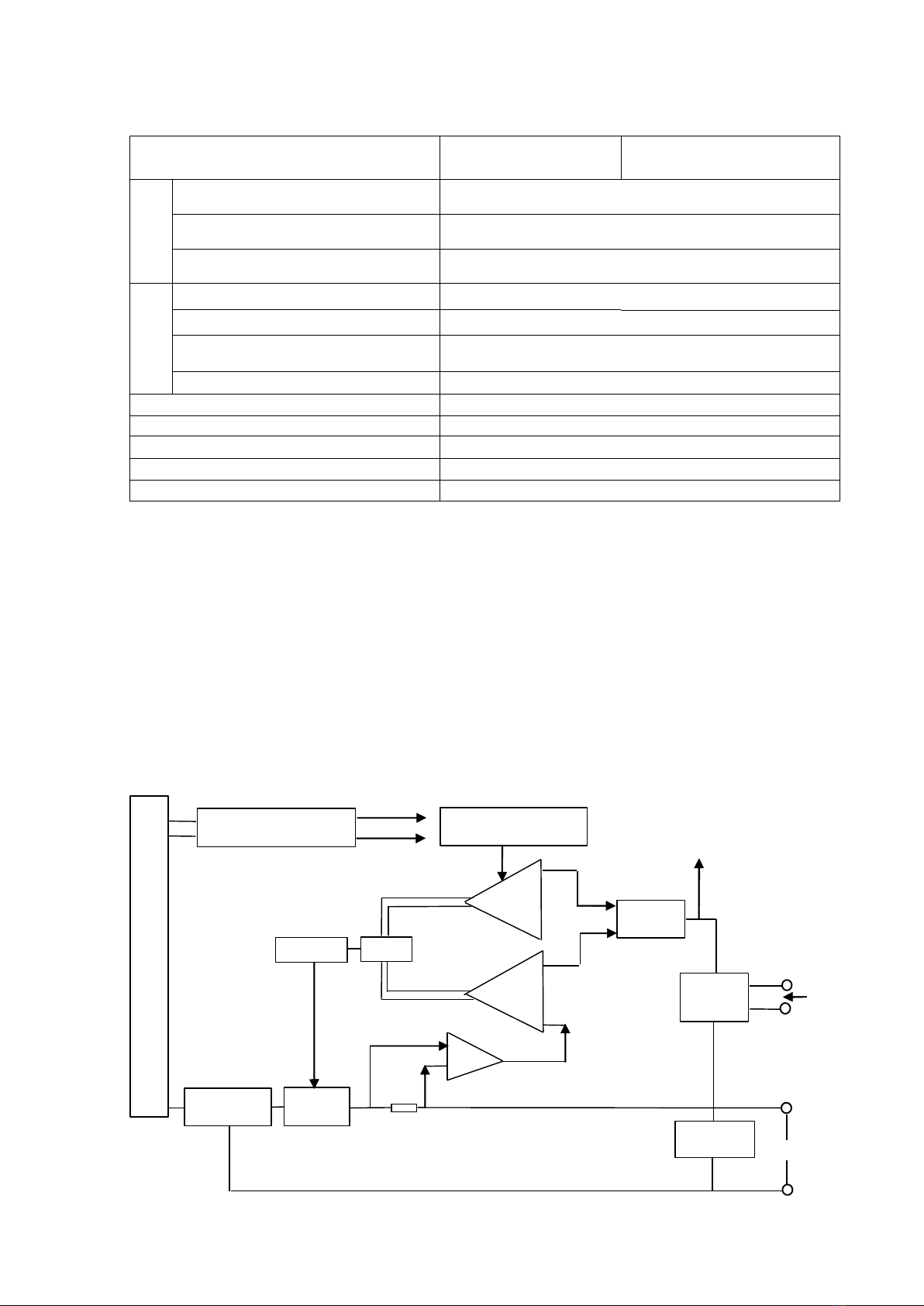

The reference output voltage circuit is applied to the negative input terminal of a CV error

amplifier, the error voltage from the voltage sampling resistor is applied to the positive input

terminal of the CV error amplifier. The error signals of both vol tages are compared each

other and via the gate circuit by amplify then applied to the base of a regulated tube. The

base current of the regulator tube is changed, then a stabilized output voltage can be obtained ,

the adjustment of the output voltage is re alized by setting the voltage potentiometer on the

front panel.

2.2

2.2

2.2

2.2

Description

Description

Description

Description

of

of

of

of

Constant

Constant

Constant

Constant

-

-

-

-

Current

Current

Current

Current

Mode

Mode

Mode

Mode

The reference voltage from the control circuit is applied to the negative input terminal of a

CC error amplifier, the current signal from A/V conversion is applied to the positive input

terminal of the CC error amplifier. Both signals are compared each other and then amplified

to control the base voltage of the regulator tube to reach a stable current output.

2.3

2.3

2.3

2.3

CV/CC

CV/CC

CV/CC

CV/CC

Conversion

Conversion

Conversion

Conversion

-

-

-

-

CV

CV

CV

CV

mode

mode

mode

mode

into

into

into

into

CC

CC

CC

CC

mode

mode

mode

mode

Setting CC potentiometer, a preset current value is provided as required, the resistor load is

reduced, the output current is increased. When the output current reaches the preset constant -

current value, the output voltage is reduced. When the power supp ly is power supply is

operating in the constant - current mode, even of the resistor load value is reduced to zero ( in

short circuit state), the output current can not be increased, it always keeps pre - setting value

constantly; that means this instrument can automatically be converted from constant - voltage

mode to constant current mode so as to protect the load from over - current. It is an automatic

CV/CC crossover system type of power supply.

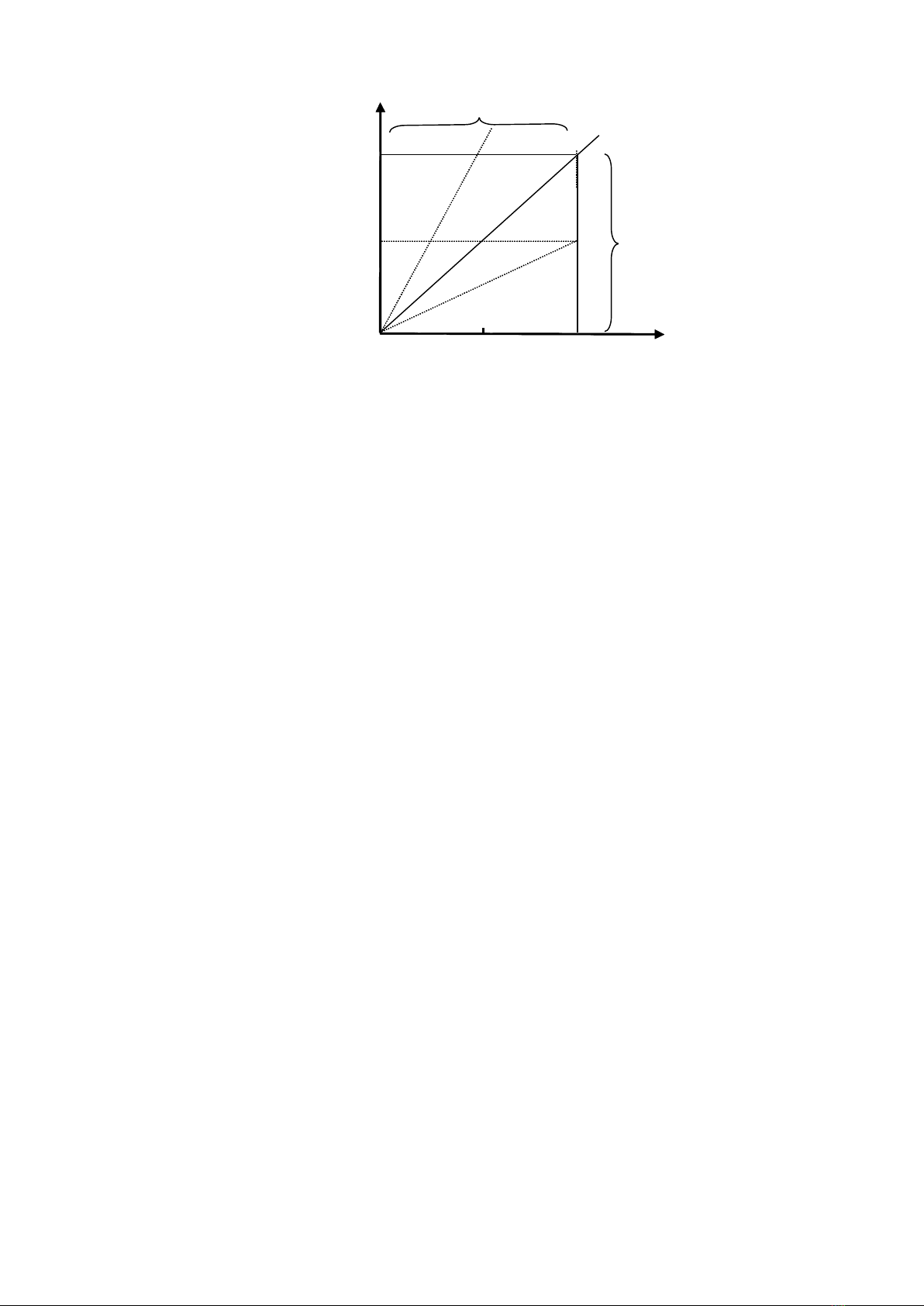

The Figure 2 shows operating points and operating domain related to the load lines. The

preset output voltage is

10V,

the limited current is 2A, the operating point in non--load is at

A

,

when RL=10 Ω

,

operating point B, and when RL=5 Ω , operating point is at C. The

operating point moves from C to D ,if the resistor load is reduced from RL=5 Ωto 2.5 Ω,the

instrument operation is changed from the constant-voltage domain into the constant — current

domain. Point C is called “ Crossover Point ” owing to change modes.

Wen

the resistor load

(RL) is 2.5 Ω , the output voltage is I. RL=2 × 2.5=5V.

2.4

2.4

2.4

2.4

CC/CV

CC/CV

CC/CV

CC/CV

Conversion-Constant

Conversion-Constant

Conversion-Constant

Conversion-Constant

Current

Current

Current

Current

Mode

Mode

Mode

Mode

into

into

into

into

Constant-Voltage

Constant-Voltage

Constant-Voltage

Constant-Voltage

Mode

Mode

Mode

Mode

Setting CV potentiometer, a preset value applied as required. When the output voltage

reaches the preset constant voltage value, then output current is reduced.

When the output current is 2A the resistor load is 0 Ω , operating point is E. While the resistor

load is increased to 2.5 Ω , the operating point moves from E to D. When the operating point

is increased to 5 Ω

,

the operating point moves from D to C. While the resistor load further is

increased to 10 Ω , the operating point moves from C to B. In this case, the instrument is

converted to the constant - voltage domain. When the resistor load is increased continuously

to an open circuit, the operating point moves from B to

A

. Generally, the voltage applied to

the load is not more than the preset voltage. The instrument can convert from the CC mode

to the

V

mode in order to protect the load. The point C serves as a crossover point.