English 1

LCBKQ3AV1(E) Booster Unit Installation manual

CONTENTS

1. FIRST OF ALL ......................................................................... 1

1-1 Safety Precautions ........................................................... 1

1-2 Special Notice of Product.................................................. 2

1-3 Disposal Requirements ..................................................... 2

2. BEFORE INSTALLATION........................................................ 2

2-1 Standard Supplied Accessories ........................................ 2

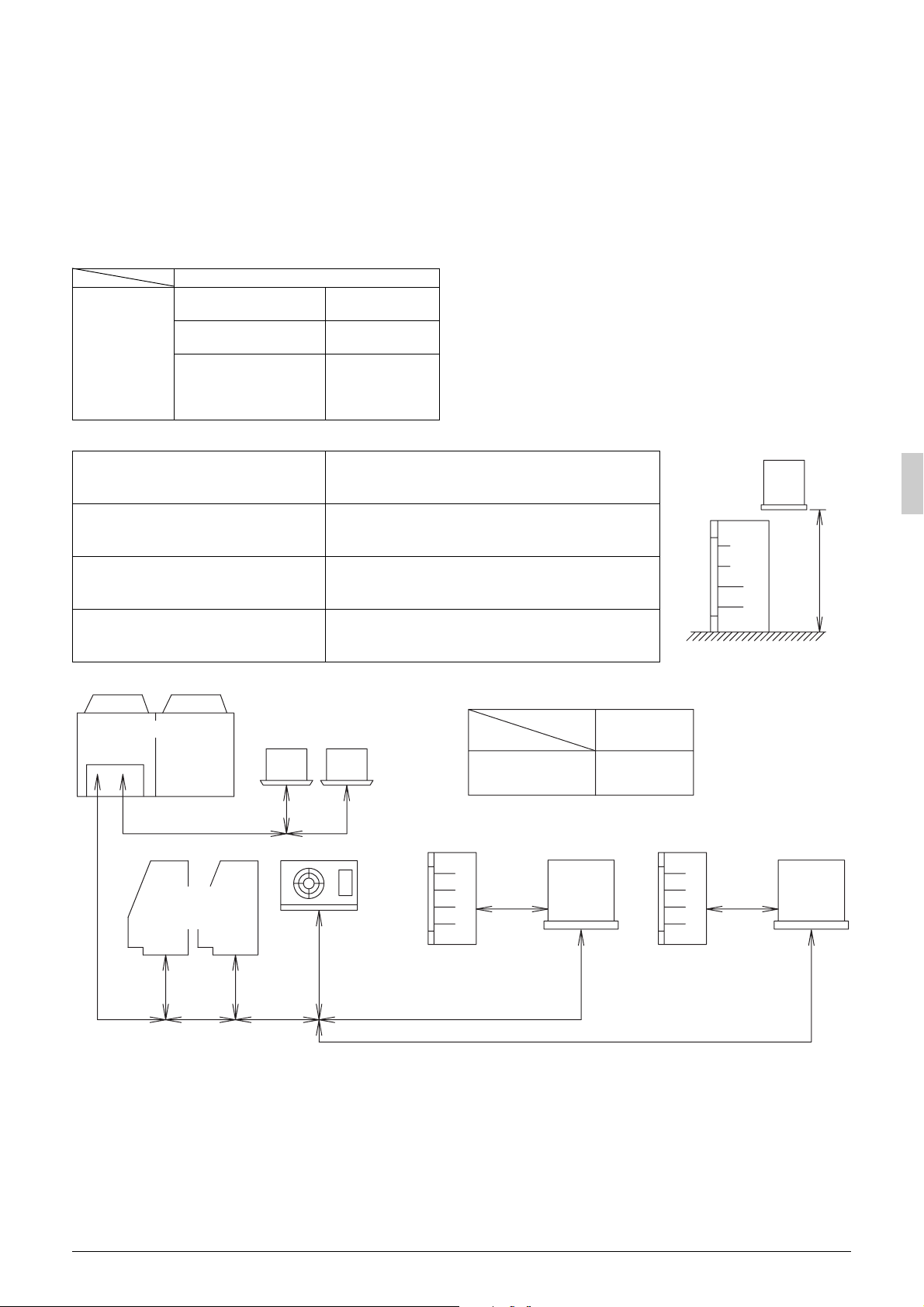

2-2 Example of System Configuration..................................... 2

2-3 Indoor Unit Constraints ..................................................... 3

3. SELECTION OF LOCATION ................................................... 3

4. PLACING THE UNIT................................................................ 3

4-1 Handling The Unit ............................................................. 3

4-2 Installation the Unit ........................................................... 4

4-3 Draining the Unit ............................................................... 4

4-4 Installation Procedure ....................................................... 4

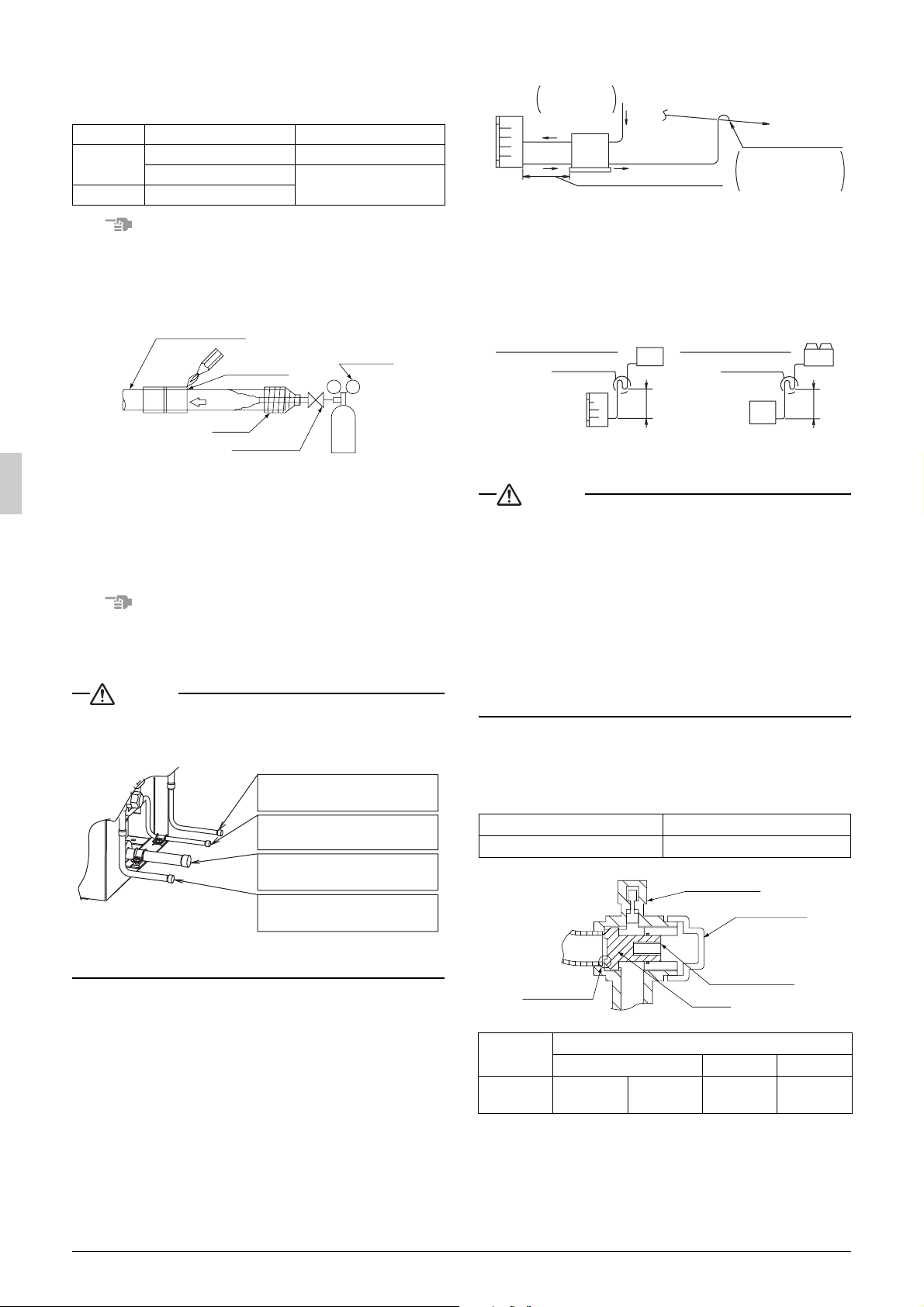

5. REFRIGERANT PIPING .......................................................... 4

5-1 Selection of Piping Material .............................................. 5

5-2 Protection against Contamination when

Installing Pipes.................................................................. 6

5-3 Pipe Connection................................................................ 6

5-4 Connecting the Refrigerant Piping .................................... 6

5-5 Air Tight Test / Vacuum Drying ......................................... 7

5-6 Thermal Insulation for Piping ............................................ 7

6. FIELD WIRING ........................................................................ 8

6-1 Example of Wiring Entire System ..................................... 9

6-2 Procedure for Incoming Wiring ......................................... 9

6-3 Wiring Connection........................................................... 10

6-4 Checking of Device and Installation Conditions .............. 10

7. CHECKS AFTER WORK COMPLETION .............................. 10

8. REFRIGERANT REPLENISHMENT...................................... 11

9. TEST RUN ............................................................................. 11

1. FIRST OF ALL

• This document is an installation manual for the Daikin Booster

Unit. Before installing the unit, read this manual thoroughly, and

following the instructions contained in it. After installation, do a

test run to make sure the unit runs properly, and then explain how

to operate and take care of the unit to the customer, using the

operation manual.

• Lastly, make sure the customer keeps this manual, along with the

operation manual, in a safe place.

•

This manual does not describe how to install the indoor unit and out-

door unit.

Refer to the installation manual included with the indoor unit and

outdoor unit for that.

1-1 Safety Precautions

Please read these “Safety precautions” carefully before installing the

booster unit and be sure to install it correctly.

After completing installation, conduct a trial operation to check for

faults and explain to the customer how to operate the booster unit

and take care of it with the aid of the operation manual. Ask the cus-

tomer to store the installation manual along with the operation man-

ual for future reference.

Meaning of WARNING and CAUTION notices

WARNING .....Failure to follow these instructions properly may

result in personal injury or loss of life.

CAUTION......Failure to observe these instructions properly

may result in property damage or personal

injury, which may be serious depending on the

circumstances.

WARNING

• Ask your dealer or qualified personnel to carry out installation

work.

Do not attempt to install the booster unit yourself. Improper

installation may result in water leakage, electric shocks or fire.

• Maintenance personnel of the manufacturer or equivalent skilled

personnel should install this unit.

• Install the booster unit in accordance with the instructions in this

installation manual.

Improper installation may result in water leakage, electric shocks

or fire.

• When installing the unit in a small room, take measures against to

keep refrigerant concentration from exceeding allowable safety

limits in the event of refrigerant leakage.

Contact the place of purchase for more information. Excessive

refrigerant in a closed ambient can lead to oxygen deficiency.

• Be sure to use only the specified accessories and parts for instal-

lation work.

Failure to use the specified parts may result in the unit falling,

water leakage, electric shocks or fire.

• Install the booster unit on a foundation strong enough to withstand

the weight of the unit.

A foundation of insufficient strength may result in the equipment

falling and causing injury.

• Carry out the specified installation work after taking into account

strong winds, typhoons or earthquakes.

Failure to do so during installation work may result in the unit fall-

ing and causing accidents.

• Make sure that a separate power supply circuit is provided for this

unit and that all electrical work is carried out by qualified person-

nel according to local laws and regulations and this installation

manual.

An insufficient power supply capacity or improper electrical con-

struction may lead to electric shocks or fire.

• Make sure that all wiring is secured, the specified wires are used,

and that there is no strain on the terminal connections or wires.

Improper connections or securing of wires may result in abnormal

heat build-up or fire.

• When wiring the power supply and connecting transmission wir-

ing, position the wires so that the control box lid can be securely

fastened.

Improper positioning of the control box lid may result in electric

shocks, fire or the terminals overheating.

• If refrigerant gas leaks during installation, ventilate the area

immediately.

Toxic gas may be produced if the refrigerant gas comes into con-

tact with fire.

• After completing installation, check for refrigerant gas leakage.

Toxic gas may be produced if the refrigerant gas leaks into the

room and comes into contact with a source of fire, such as a fan

heater, stove or cooker.

• Be sure to switch off the unit before touching any electrical parts.

• Do not directly touch refrigerant that has leaked from refrigerant

pipes or other areas, as there is a danger of frostbite.

• Do not allow children to climb on the outside unit and avoid plac-

ing objects on the unit.

Injury may result if the unit becomes loose and falls.

•

Be sure to earth the

booster

unit.

Do not earth the unit to a utility pipe, lightning conductor or

telephone earth lead. Imperfect earthing may result in

electric shocks or fire.

A high surge current from lightning or other sources may cause

damage to the booster unit.

• Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric

shocks or fire.

CAUTION

• While following the instructions in this installation manual, install

drain piping to ensure proper drainage and insulate piping to pre-

vent condensation.

Improper drain piping may result in indoor water leakage and

property damage.