Installation manual

4

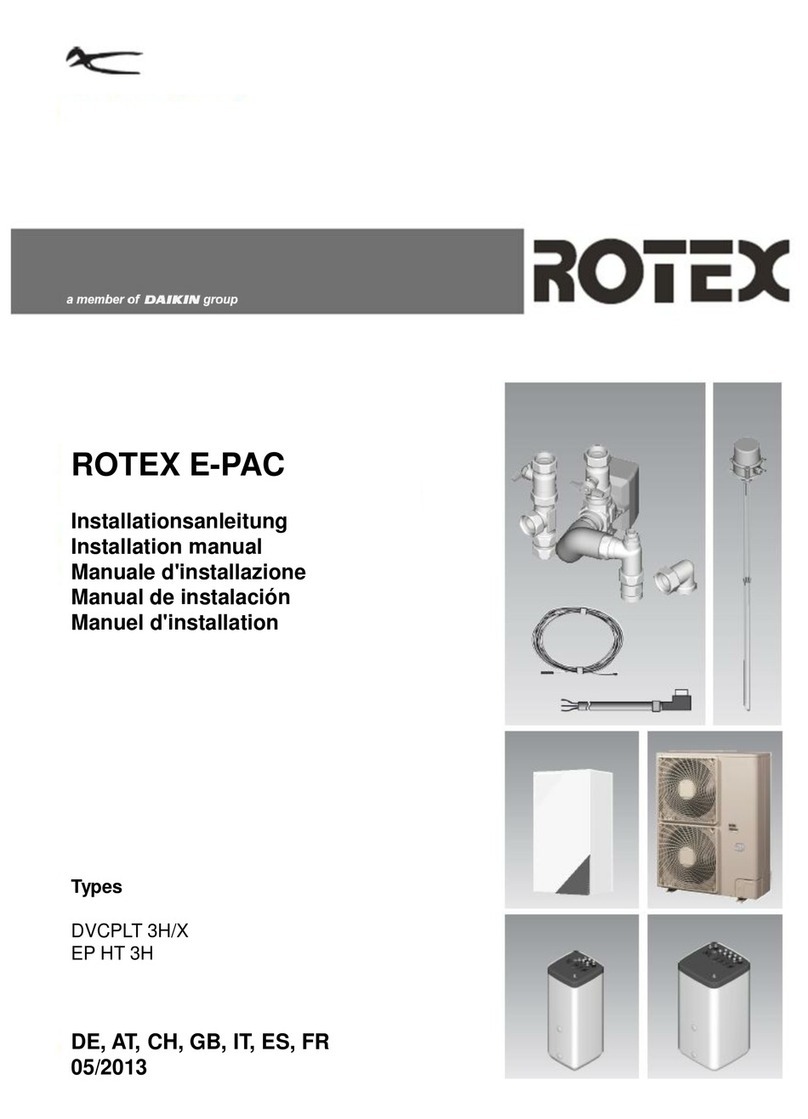

EKHTSU200+260AA + EKUHWHTA

Domestic hot water tank with UK kit for air to water heat pump system

4PW53247-1B

I

NSTALLATION

OF

THE

EKHTSU

DOMESTIC

HOT

WATER

TANK

If required by relevant local and national regulations, connect a

recirculation pump in between the hot water end point and the

recirculation connection of the domestic hot water tank.

Installation guidelines

Keep in mind the following guidelines when installing the domestic

hot water tank:

■

The installation location is frost-free.

■

Standard installation location of the domestic hot water tank is

on top of the indoor unit.

■

The domestic hot water tank can be floor mounted as well. In

that case, the dedicated EKFMAHTA connection kit for

installation of the domestic hot water tank next to the indoor unit

is required and to be ordered separately.

■

Locate the domestic hot water tank in a suitable position to

facilitate ease of maintenance. Refer to the grey-coloured zones

indicated in the outlook diagram figure and to the installation

manual of the EKHBRD indoor unit.

■

To avoid back siphonage it is advised to install a non-return

valve on the water inlet of the domestic hot water tank in

accordance with local and national regulations.

■

Take care that in the event of a leak, water can not cause any

damage to the installation space and surroundings.

■

If installing an EKHTSU* domestic hot water tank, installing the

kit EKUHWHTA is obligatory. Refer to the UK Building

Regulation G3.

Installing and commisioning the domestic hot water tank

Installing the hot water tank on top of the indoor unit

1

Unpack the domestic hot water tank according to the

instructions mentioned on the unpacking instruction sheet.

2

Check if all domestic hot water tank accessories are enclosed

(see "Accessories" on page 2).

3

Remove front and top plate of the indoor unit.

To take away the front decoration panel, remove the 2 bottom

screws and then unhitch the panel.

Mount the top plate of the indoor unit on the domestic hot water

tank module.

4 Connect the 3-way valve

1

Remove drain plate on top of the

indoor unit before installing the

3-way valve.

2

Installation position.

The 3-way valve must be installed in the indoor unit.

3

Unpack the 3-way valve body and 3-way valve motor.

Verify that following accessories are provided with the motor.

■

Installation shall be done by a licensed technician, the

choice of materials and installation shall comply with

local and national regulations.

■

The equipment is not intended for use in a potentially

explosive atmosphere.

■

Domestic hot water quality must be according to EU

directive 98/83 EC.

■

For safety reasons, it is not allowed to add any kind of

glycol to the water circuit.

■

To avoid stagnation of water, it is important that the

storage capacity of the domestic hot water tank meets

the daily consumption of domestic hot water.

In cases where during longer periods of time there is

no consumption of hot water, the equipment must be

flushed with fresh water before usage.

The disinfection function provided on the equipment is

specified in the operation manual of the indoor unit.

■

It is advised to avoid long runs of piping between the

domestic hot water tank and the hot water end point

(shower, bath, ...) and to avoid dead ends.

■

The installation must be in compliance with local and

national regulations and may require additional

hygienic installation measures.

■

For compliance with UK Building Regulations,

thermostatic mixing valves must be installed.

■

Immediately after installation, the domestic hot water

tank must be flushed with fresh water. This procedure

must be repeated at least once a day the first 5

consecutive days after installation.

If available service space to left and/or right side is

limited, carefully consider all indoor module

installation steps first.

3

4

12

1Recirculation connection

2Hot water connection

3Shower

4Recirculation pump

1

Sleeve

2

Valve motor cover

3

Screw

4

Turn knob

1

2

3

2x

1

1

1

2x

2x

2x

2x

4x

1

3

2

1From indoor unit

2To domestic hot water tank

3To room heating

123 4