4

GENERAL INFORMATION

LABELING AND TERMINOLOGY

The Transplanter and this manual use the following terms

and symbols to bring attention to the presence of hazards of

various risk levels and important information concerning the

use and maintenance of the Transplanter.

WARNING: Indicates presence of a hazard which can

cause severe personal injury, death, or substantial property

damage if ignored.

CAUTION: Indicates presence of a hazard which will or

can cause minor personal injury or property damage if ignored.

NOTE: Indicates supplementary information worthy of

particular attention relating to installation, operation, or

maintenance of the Transplanter but is not related to a

hazardous condition.

Be sure to follow all instructions and related precautions

as they are meant for your safety and protection. This manual

is considered a permanent part of the Transplanter and must

remain with the Transplanter when sold.

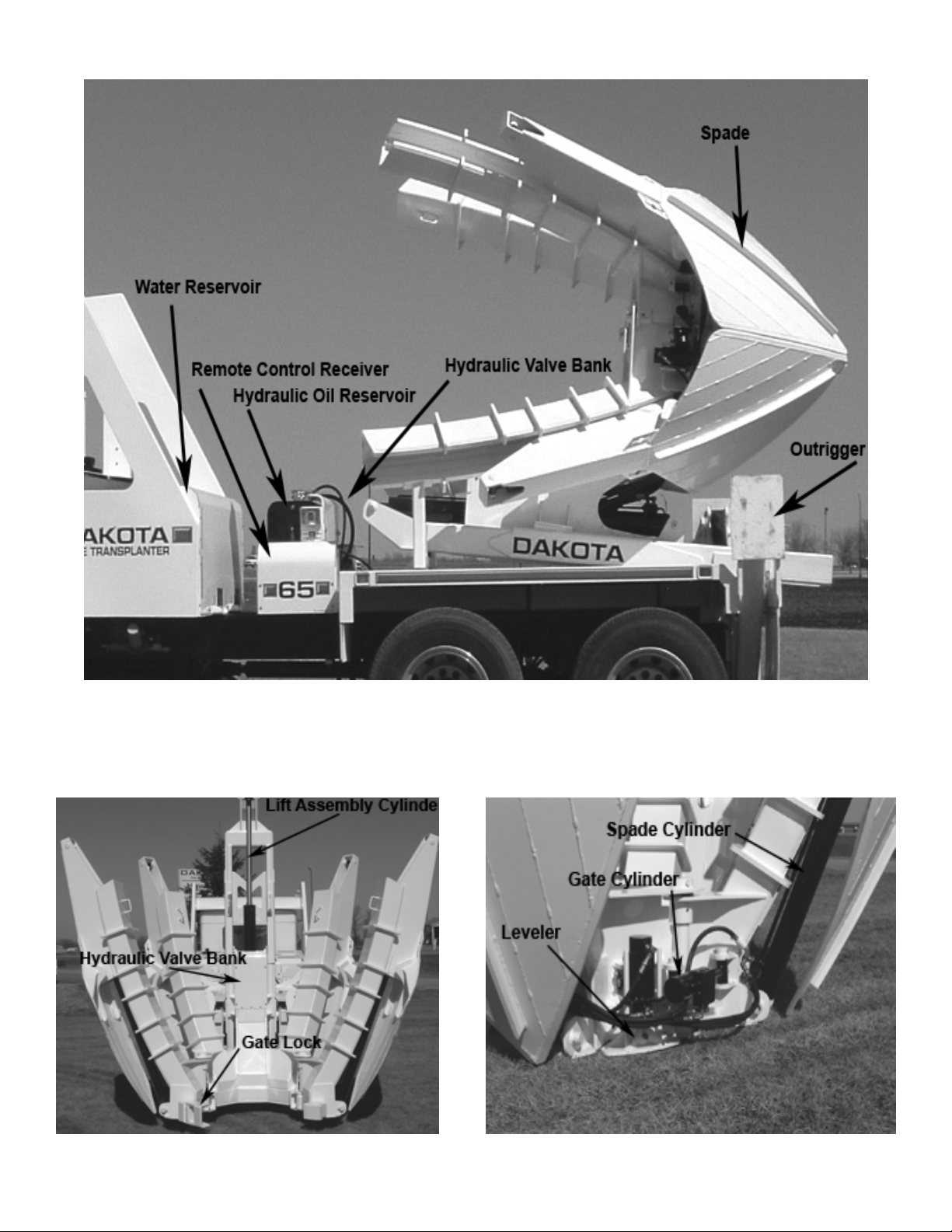

Record the model and serial numbers (found on the left

hand support) in the specifications section so they are readily

available when contacting a dealer for parts or service.

AUTHORIZED MAINTENANCE

Perform only the maintenance described in this manual

that you are qualified to perform. If major repairs are ever

needed or assistance is desired, contact an Authorized

DAKOTA Dealer for their professional service.

POWER OFF MAINTENANCE AND

ADJUSTMENTS

All maintenance and adjustments to the Transplanter must

be made with the transplanter in a secure position and the

truck’s parking brakes set, engine off, and key removed.

Failure to do so could result in injury or even death.

MAINTAIN SAFE OPERATING CONDITIONS

Grease all fittings as described in this manual. Proper

lubrication is essential for the safe operation and longevity

of the Transplanter.

Daily, visually inspect the Transplanter for any

abnormalities. Look for loose or broken hardware; bent or

damaged components; broken or fatigued welds; leaking,

worn or damaged hydraulic hoses and fittings.

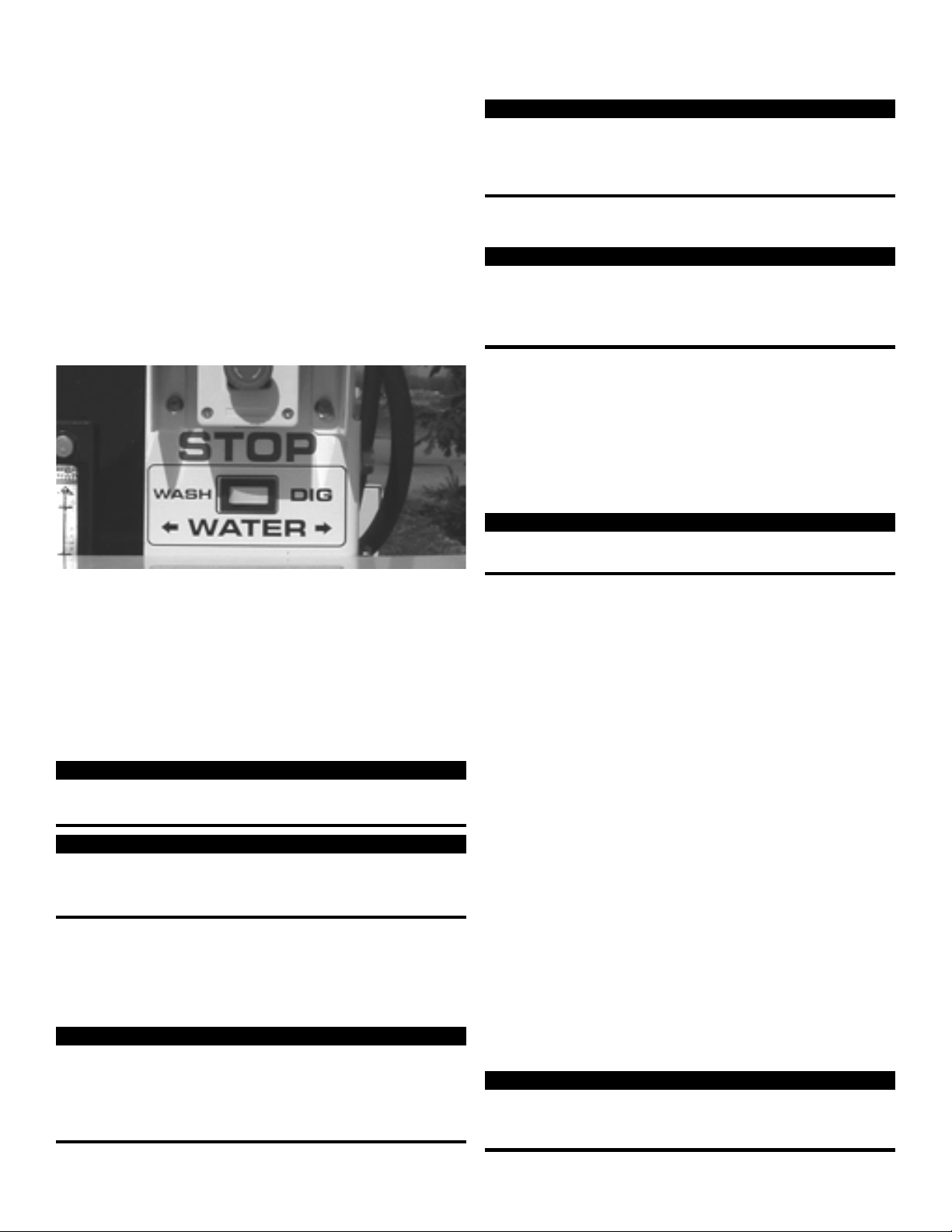

RELIEVE HYDRAULIC PRESSURE

Before performing any work on the hydraulic system, all

pressure in the system must be relieved. Place the Transplanter

either in the transport position or firmly support the area being

serviced. Make sure all parts of the Transplanter actuated by

hydraulic pressure are supported or otherwise restrained to

prevent movement prior to relieving hydraulic pressure.

Disengage the power take off; then turn off the transmitter

and stop the truck engine. Using the special 1/2 in. wrench

found in the manual canister, rotate the hex shaft of the

appropriate valve to both ON positions. Residual hydraulic

pressure may still be present, so care must be taken. Failure

to do so could result in damage, injury, or even death.

KEEP TRANSPLANTER CLEAN

Keep the Transplanter free of excessive grass, leaves, and

accumulations of dirt and sand. Materials such as this can

compromise seals, bearings, and other components.

REPLACEMENT PARTS

To ensure optimum performance and safety, always

purchase genuine DAKOTA replacement parts and

accessories. NEVER USE “WILL-FIT” REPLACEMENT

PARTS AND ACCESSORIES MADE BY OTHER

MANUFACTURERS. Using unapproved replacement parts

and accessories voids the warranty of the DAKOTA

Transplanter. Right and left-hand sides are determined by

sitting in the driver’s seat of the truck.

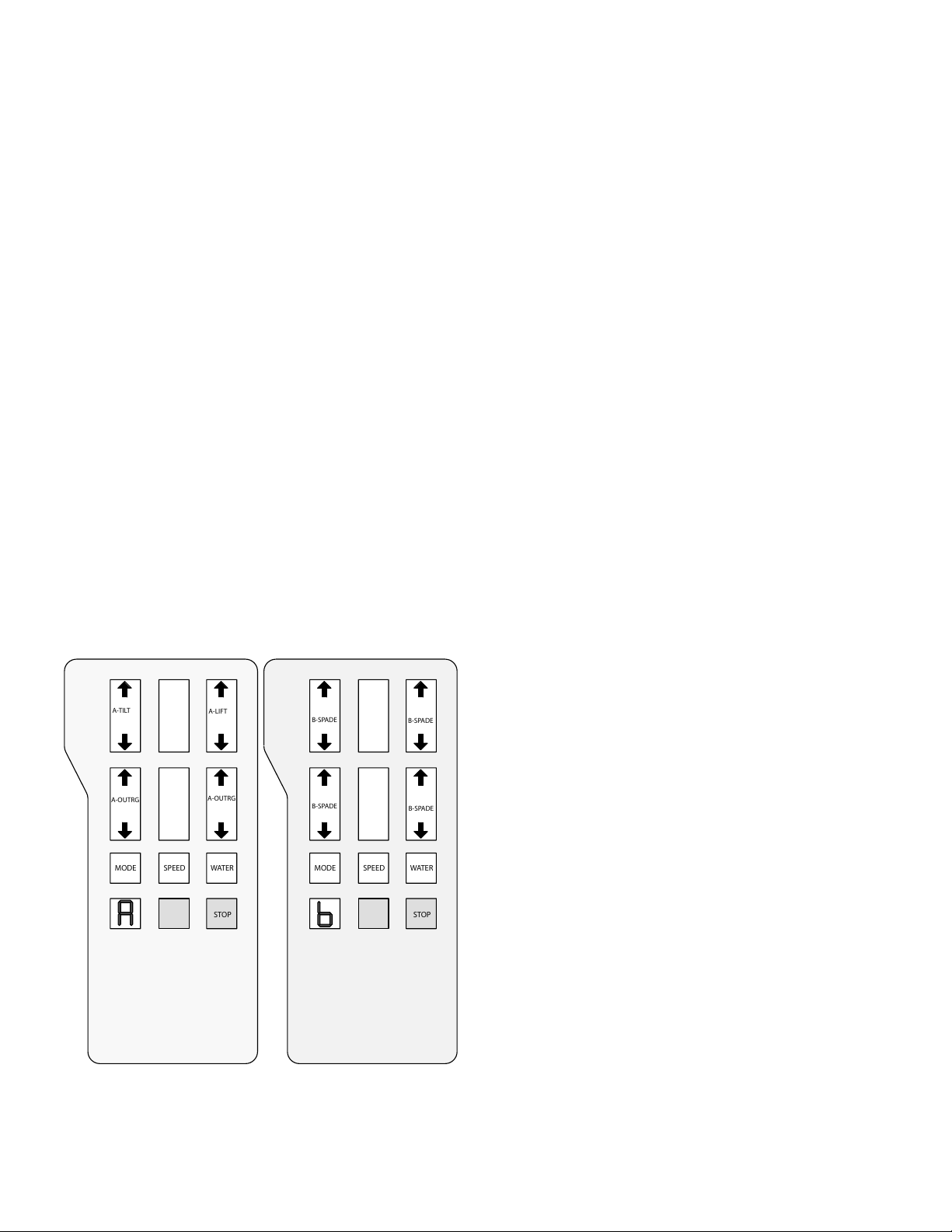

If ever in need of a new remote, please provide DAKOTA

the serial number of either the existing remote or receiver to

ensure proper programming.

READ OPERATOR’S MANUALS

Prior to operating the Transplanter, read and understand

the contents of this Operator’s Manual and the Operator’s

manual of truck. Become familiar with all control functions

and know how to operate the truck and Transplanter safely.

Replacement Manual

A replacement manual is available by sending complete

Model and Serial Numbers to

Dakota, Inc.

833 Gateway Drive, North East

East Grand Forks, Minnesota 56721

UNAUTHORIZED OPERATORS

Never allow children to operate the Transplanter. Do not

allow anyone to operate the Transplanter without proper

instruction or training. Only trained and authorized persons

should operate the Transplanter.

DRUGS AND ALCOHOL

Never operate the Transplanter when under the influence

of drugs or alcohol.

SHIELDS AND SAFETY DEVICES

Keep all shields, guards, and safety devices in place. If a

shield, guard, or safety device is damaged, replace or repair

it prior to operating the Transplanter. If a decal is illegible,

order and install a new one.

LOOSE FASTENERS AND FITTINGS

Although the Transplanter has been designed so that

components will not come loose during normal operation of

the Transplanter, always check the Transplanter prior to start

up and after each use for loose fasteners, fittings, connectors,

and other components. Tighten, repair, or replace as necessary.

This includes electrical and hydraulic system components,

also.

MODIFICATIONS TO TRANSPLANTER

Do not modify the Transplanter in any way. Modifying

the Transplanter will void the warranty.