– i –

Table of Contents

1 Introduction���������������������������������������������������������������������������������������������������������������������������1

Important Safety Instructions...............................................................................................................1

Specications Label .............................................................................................................................1

Resources ..............................................................................................................................................1

Daktronics Nomenclature ...................................................................................................................2

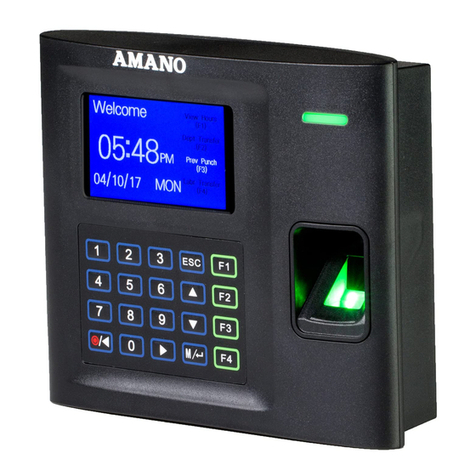

Control Console....................................................................................................................................2

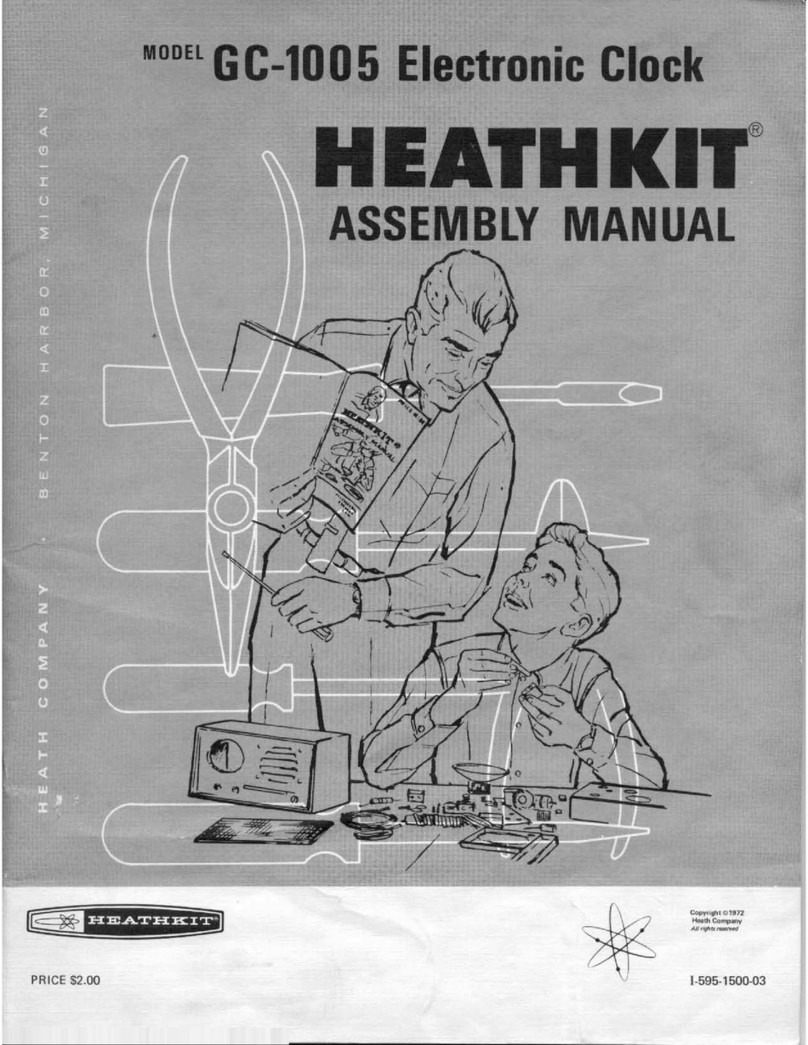

Specications........................................................................................................................................2

2 Mechanical Installation �������������������������������������������������������������������������������������������������������3

Lifting the Display..................................................................................................................................3

Shot Clock Mounting............................................................................................................................3

Control Enclosure Mounting................................................................................................................3

Remote Horn Enclosure Mounting......................................................................................................3

Camera Mounting................................................................................................................................3

3 Electrical Installation ������������������������������������������������������������������������������������������������������������4

Warnings and Disclaimers....................................................................................................................4

Installation Overview............................................................................................................................4

Power .....................................................................................................................................................4

Grounding �����������������������������������������������������������������������������������������������������������������������������������������4

Power-On Self-Test (POST)....................................................................................................................5

Radio Settings �����������������������������������������������������������������������������������������������������������������������������������5

Signal Connection................................................................................................................................5

Radio Control........................................................................................................................................5

Backboard Light Strips..........................................................................................................................6

Tenth-Second Shot Time ......................................................................................................................6

4 Troubleshooting ��������������������������������������������������������������������������������������������������������������������7

Troubleshooting Table..........................................................................................................................7

Component Access and Digit Replacement ...................................................................................9

Schematics............................................................................................................................................9

LED Driver...............................................................................................................................................9

Replacing a Driver��������������������������������������������������������������������������������������������������������������������������10

Setting the Driver Address �������������������������������������������������������������������������������������������������������������10

Switch Settings ��������������������������������������������������������������������������������������������������������������������������������10

Replacement Parts.............................................................................................................................11

5 Daktronics Exchange and Repair & Return Programs ����������������������������������������������������12

Exchange Program ............................................................................................................................12

Repair & Return Program...................................................................................................................13

Daktronics Warranty & Limitation of Liability ...................................................................................13

A Reference Drawings �����������������������������������������������������������������������������������������������������������15

B Daktronics Warranty & Limitation of Liability��������������������������������������������������������������������29