Introduction

1

1 Introduction

This manual explains the installation and maintenance of Daktronics Locker Room Clocks.

For additional information regarding safety, installation, operation, or service, refer to

the telephone numbers listed in Section 4: Daktronics Exchange and Repair & Return

Programs (p�6). This manual is not specic to a particular installation. Project-specic

information takes precedence over general information found in this manual.

Important Safety Instructions

• Read and understand all instructions before beginning the installation process.

• Disconnect power to the display when not in use or when servicing.

• Disconnect power to the display before servicing power supplies to avoid electrical

shock. Power supplies run on high voltage and may cause physical injury if touched

while powered.

• Do not disassemble control equipment or electronic controls of the display; failure to

follow this safeguard will make the warranty null and void.

• Do not drop the control equipment or allow it to get wet.

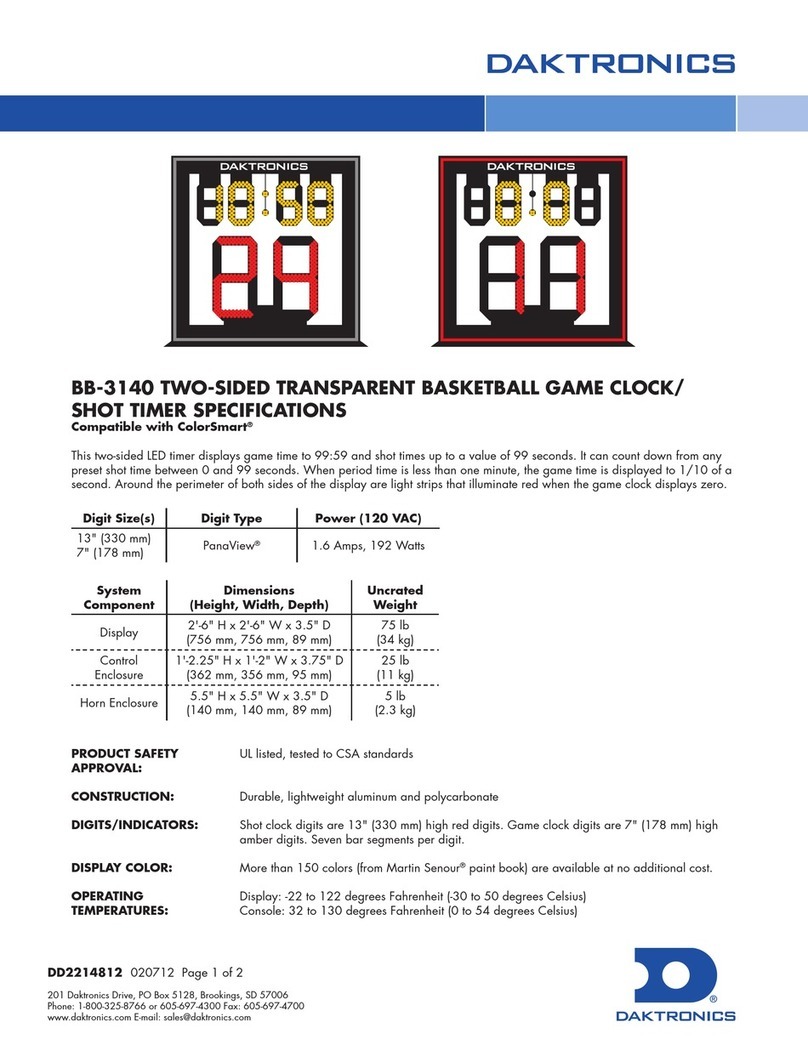

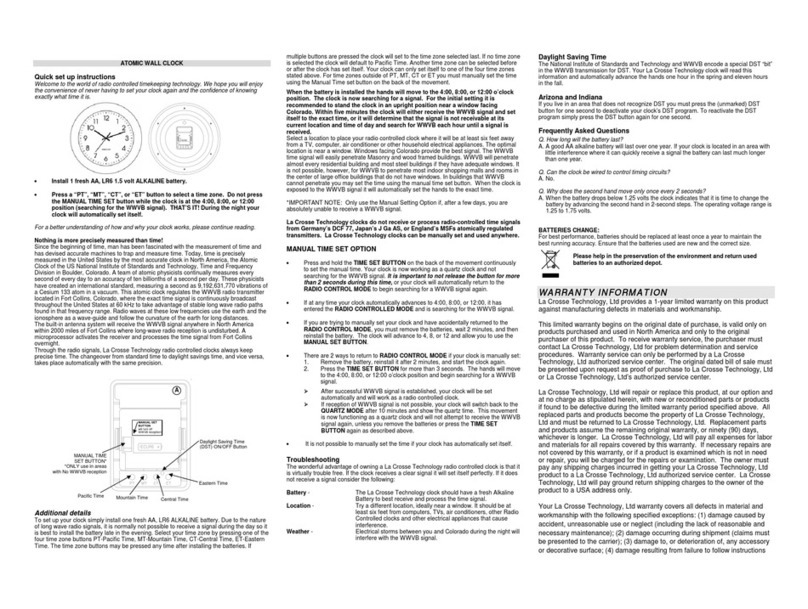

Specications Label

Power specications as well as serial and model number information can be found on an

ID label on the display, similar to the one shown in Figure 1.

ASSY NO.

SER. NO.

MFG DATE

BROOKINGS, SD 57006-5128 PHONE 800-325-8766 LL-2306 R01

201 DAKTRONICS DR.

DAKTRONICS

Figure 1: Specications Label

Please have the assembly number, model number, and the date manufactured on hand

when calling Daktronics customer service to ensure the request is serviced as quickly as

possible. Knowing the facility name and/or job number will also be helpful.

Resources

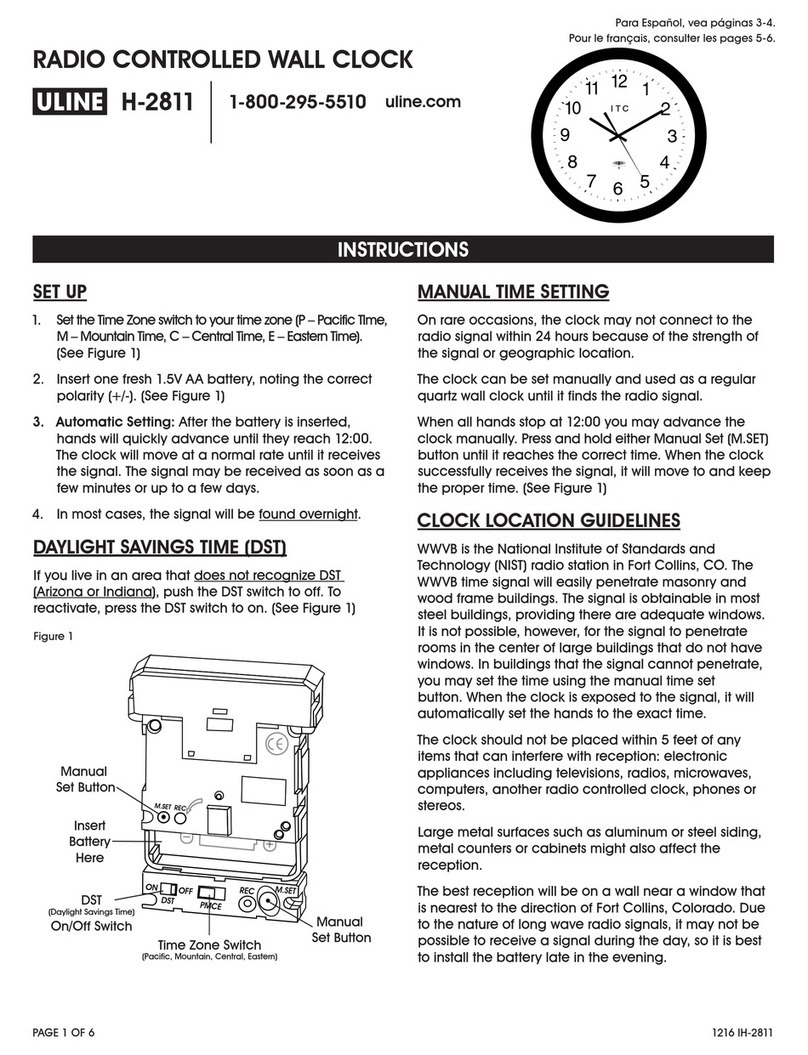

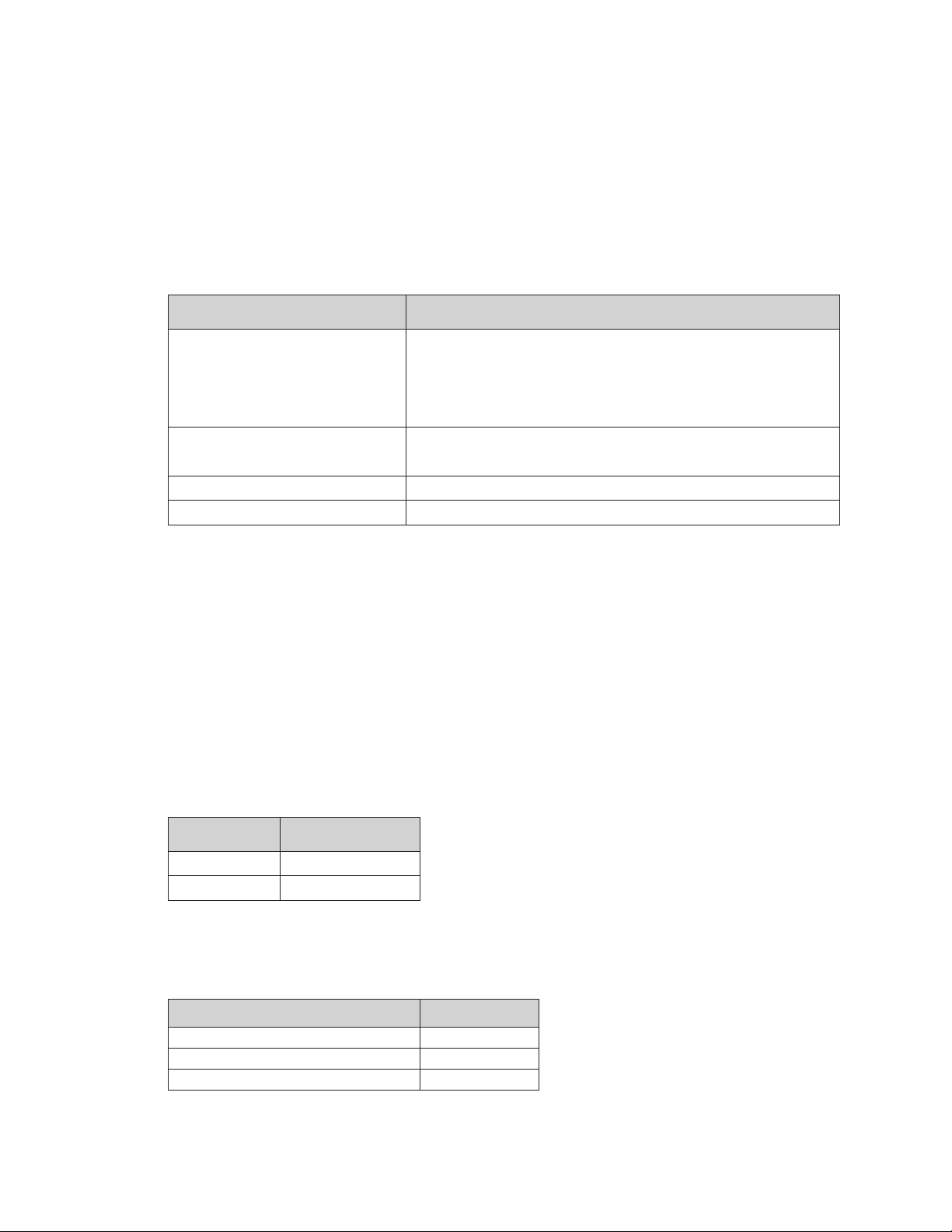

Figure 2 illustrates a Daktronics drawing label.

This manual refers to drawings by listing the last

set of digits. In the example, the drawing would

be referred to as DWG-1007804. All references to

drawing numbers, appendices, gures, or other

manuals are presented in bold typeface.

Any drawings referenced in a section are listed

at the beginning of it as shown below:

Reference Drawing:

System Riser Diagram....................................................................................... DWG-1007804

Daktronics identies manuals by the DD or ED number located on the cover page.

Ensure all applicable materials have been gathered before beginning the installation.

Contact a Daktronics sales coordinator or project manager.

Figure 2: Drawing Label