– i –

Table of Contents

1 Introduction���������������������������������������������������������������������������������������������������������������������������1

Important Safeguards ..........................................................................................................................1

Resources ..............................................................................................................................................1

Daktronics Nomenclature ...................................................................................................................2

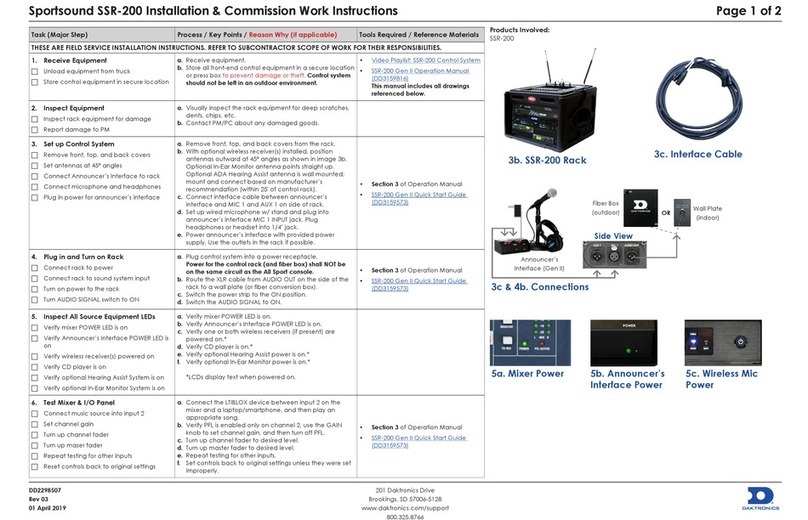

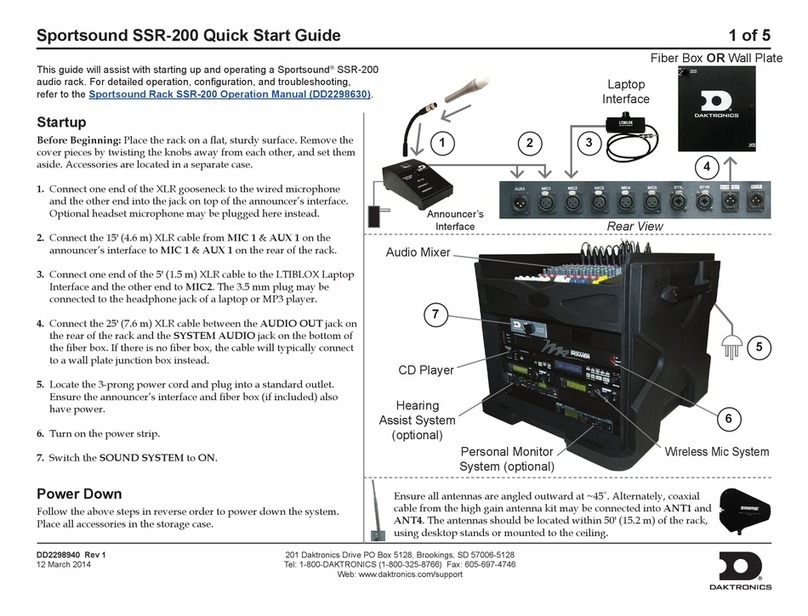

2 Sound System Components ������������������������������������������������������������������������������������������������3

Equipment Overview ...........................................................................................................................3

Sound Cabinet......................................................................................................................................3

Grille���������������������������������������������������������������������������������������������������������������������������������������������������3

Drivers ������������������������������������������������������������������������������������������������������������������������������������������������3

Amplier Components���������������������������������������������������������������������������������������������������������������������4

Fiber Conversion Box............................................................................................................................4

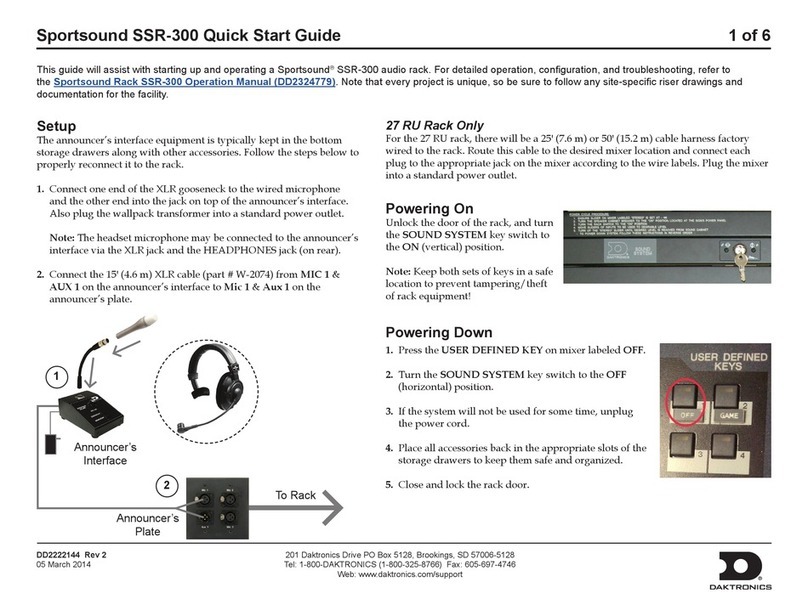

Audio Control Rack..............................................................................................................................4

Signal Cables ........................................................................................................................................4

3 Mechanical Installation �������������������������������������������������������������������������������������������������������5

Cabinet Installation ..............................................................................................................................5

Lift the Cabinet����������������������������������������������������������������������������������������������������������������������������������5

Mount the Cabinet ���������������������������������������������������������������������������������������������������������������������������6

Aim the Speakers �����������������������������������������������������������������������������������������������������������������������������7

4 Electrical Installation ������������������������������������������������������������������������������������������������������������8

Power/Signal Connections..................................................................................................................8

Power IN ��������������������������������������������������������������������������������������������������������������������������������������������9

Signal IN ������������������������������������������������������������������������������������������������������������������������������������������10

Grounding ���������������������������������������������������������������������������������������������������������������������������������������10

Lightning Protection ...........................................................................................................................10

Fiber Conversion Box Connections...................................................................................................10

5 Maintenance�����������������������������������������������������������������������������������������������������������������������12

Grille Maintenance and Cleaning ...................................................................................................12

Grille Mesh Replacement..................................................................................................................12

6 Troubleshooting ������������������������������������������������������������������������������������������������������������������15

Indicator Lights....................................................................................................................................17

Audio Control Rack������������������������������������������������������������������������������������������������������������������������17

Fiber Conversion Box ���������������������������������������������������������������������������������������������������������������������17

System Testing .....................................................................................................................................17

Driver Troubleshooting .......................................................................................................................17

Driver Replacement ...........................................................................................................................19

High-Frequency Driver (A-2302) ���������������������������������������������������������������������������������������������������19

Mid-Frequency Driver (A-2305) ����������������������������������������������������������������������������������������������������20

Low-Frequency Driver (A-2306) ����������������������������������������������������������������������������������������������������21

Amplier Troubleshooting and Replacement .................................................................................22

Media Converters...............................................................................................................................23

Typical Component Settings ���������������������������������������������������������������������������������������������������������23

Verifying Network Activity �������������������������������������������������������������������������������������������������������������23