TABLE OF CONTENTS

TO YOU THE OWNER.............................................................................................................................. 1

LIMITED WARRANTY STATEMENT........................................................................................................... 2

NEW MACHINE CHECKOUT..................................................................................................................... 3

OPERATION AND SAFETY......................................................................................................................... 4

LUBRICATION SCHEDULE......................................................................................................................... 5

LUBRICATION DETAIL ............................................................................................................................. 6

BOLT TORQUE CHART.............................................................................................................................. 7

MACHINE ADJUSTMENT.......................................................................................................................... 8

SPECIFICATIONS....................................................................................................................................... 9

SPREAD ADJUSTMENT AND APPLICATION RATES.................................................................................... 10

SPREAD PATTERN DETAILS....................................................................................................................... 11

60’ SPREAD SETUP................................................................................................................................... 12

90’ SPREAD SETUP.................................................................................................................................... 13

DISTRIBUTOR BLADE TUNING.................................................................................................................. 14

60’ SPREAD PATTERN DECAL.................................................................................................................... 15

90’ SPREAD PATTERN DECAL.................................................................................................................... 16

60’ OR 90’ SPREAD PATTERN DECAL, VARIABLE RATE.............................................................................. 17

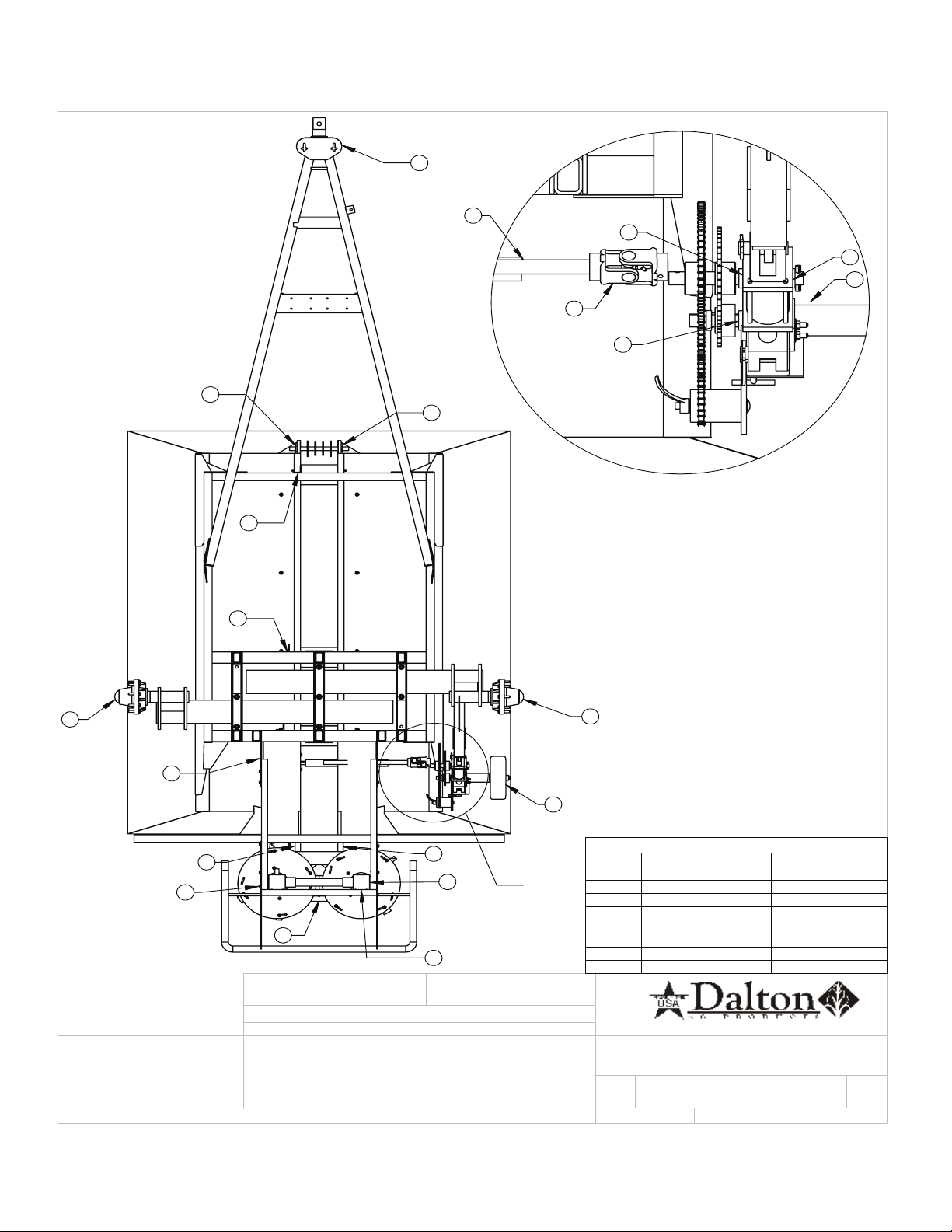

FRAME AND DRIVELINE............................................................................................................................ 18

540 PTO.................................................................................................................................................... 19

1000 PTO.................................................................................................................................................. 20

8 TON AXLE/HUB PARTS........................................................................................................................... 21

10 TON AXLE/HUB PARTS......................................................................................................................... 22

GROUND DRIVE ASSEMBLY....................................................................................................................... 23

FRONT TANK ASSEMBLY............................................................................................................................ 24

GATE JACK ASSEMBLY............................................................................................................................... 25

REAR AREA ASSEMBLY.............................................................................................................................. 26

IDLER MOUNT, CHAIN BELT...................................................................................................................... 28

DISTRIBUTOR GEAR BOX.......................................................................................................................... 29

HYDRAULIC SPINNER GEAR BOX.............................................................................................................. 30

TRACTOR HYDRAULIC DRIVEN SPINNERS................................................................................................ 31

HYDRAULIC SPINNER DRIVE LAYOUT....................................................................................................... 32

DIGITAL READOUT.................................................................................................................................... 33

VARIABLE RATE CONTROL, ELECTRICAL PLAN.......................................................................................... 34

VARIABLE RATE CONTROL, HYDRAULIC PLAN.......................................................................................... 35

SPREADER CONSTANT VALUE................................................................................................................... 36

CALIBRATION NUMBERS FOR VARIABLE RATE SPREADERS 360 ENCODER............................................... 37

SCALE DETAIL............................................................................................................................................ 38

GATE MARKER DECAL............................................................................................................................... 39

DECAL LAYOUT.......................................................................................................................................... 40

PARTS ORDERING PROCEDURE................................................................................................................ 42