OPERATION

SPREADER SAFETY

Before starting in motion please read the following words of caution.

A. It is recommended that initial spreading be done in as low a range as possible to permit easy break-in.

B. Always shut off or disconnect power to spreader before attempting to repair or adjust the spreader.

C. Do not transport machine with ground drive wheel engaged.

D. NEVER back-up spreader with ground drive wheel engaged.

E. Make sure that the towing vehicle brakes are operating properly and are capable of stopping the towing

vehicle.

F. If a pick-up is used as the towing vehicle, it is wise to add ballast for additional safety and traction. We

recommend that all towing vehicles be ballast loaded to their recommended G.V.W.

G. Hitches should be of heavy construction and should be welded or bolted directly to the towing vehicle

frame. Hitches should be checked routinely for loose bolts, cracked welds, etc.

H. Never tow a spreader with a drawbar pin less than 1” in diameter. Pins should also have a locking de-

vice.

I. Do not tow spreader at speeds in excess of 20 mph loaded or 40 mph empty.

J. Remember, that the stopping and braking distances vary with load and vehicle speed. It is well to famil-

iarize yourself with the characteristics of your machine under different load and speed conditions.

K. Be sure to attach safety break-away chain and the safety chain to towing vehicle to assure control of

spreader in the case of pin or hitch failure.

L. The unit is designed for hitching to vehicles with drawbar heights between 12 and 18 inches above the

ground level. It will operate with all standard tractor hitches and PTO’s. WARNING: Hydraulically

mounted drawbars must be securely and mechanically locked because a fully loaded spreader applies a

load in the order of 2000 lbs. to the hitch.

M. WARNING: Remember this unit is designed for agricultural use only and is primarily an off-the-road

vehicle and should be towed at tractor speeds ONLY, not to exceed 20 mph loaded or 40 mph empty. In-

spect hubs routinely to see if they are heating, which indicates either a need for lubrication or improper

adjustment of brakes or bearings, also check stud nuts for tightness.

N. WARNING: The maximum capacity of this unit is 6 tons (600) or 200 cubic feet, based on a material

density of 60 pounds per cubic foot. DO NOT EXCEED THIS LIMIT!

OPERATING INSTRUCTIONS

Please read the following completely before spreading.

1) Attach spreader to towing vehicle, make sure hitch and hitch pin are sound.

2) Attach PTO shaft to proper rpm PTO.

3) Spinner discs, adjustable chute and conveyor oor should be clean for accurate metering.

4) Set metering gate to desired spread rate according to decal on the back end sheet of tank. Always keep

the machine in the lowest possible range.

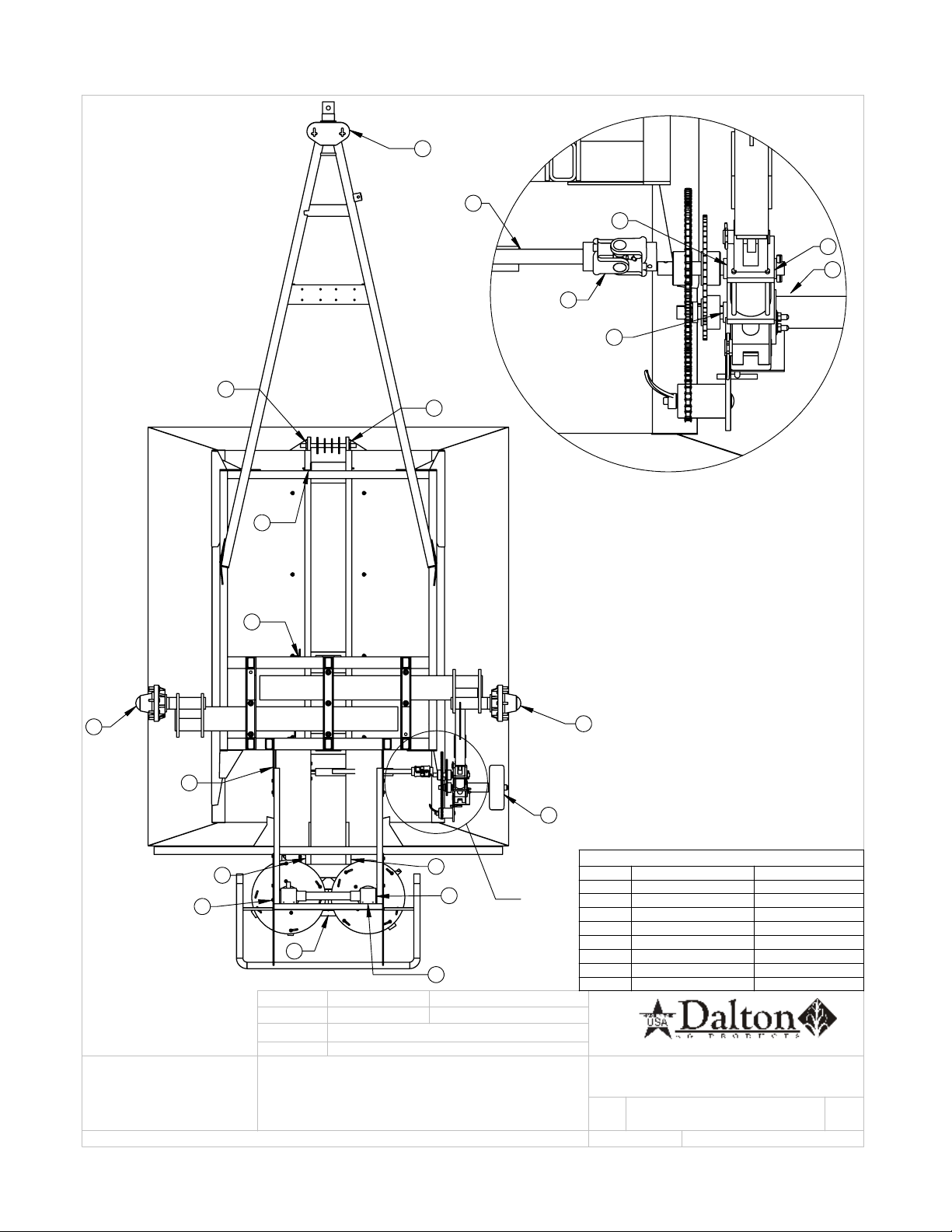

5) Before starting to spread, rotate the ground drive wheel several revolutions by hand to make sure the

conveyor chain is operating freely. If chain is frozen or moves with too much resistance, correct problem

before using spreader.

6) If the ground drive wheel operates properly, check with chain and sprocket arrangement for desired

range setting and chain tension.

7) When spreading is complete, disengage ground drive assembly from the tire and install transport lockup.

4