Dear clients!

Aer making the decision of buying a greenhouse you received a carefully made item. Its

framework is made from special (1mm of thickness and 78mm width) proles produced

from galvanized metal which are extremely strong.

Due to uncomplicated instruction this greenhouse is easy to construct.

Because of additional items, you will be able to accomplish your ideas.

We keep the rights to make variations associated with the improvements of technolo-

gies. Some pictures and instructions may be dierent because of that.

We wish you a lot of joy and success with our greenhouse.

Attention!

Always use protective work measures (safety gloves, clothes) when constructing the

framework of the greenhouse and working with polycarbonate cover.

Tools you will need for the construction:

• Hexagon wrench with the diameter of 8 mm or wrench with open end.

• Cross-head screwdriver or screwdriver for battery

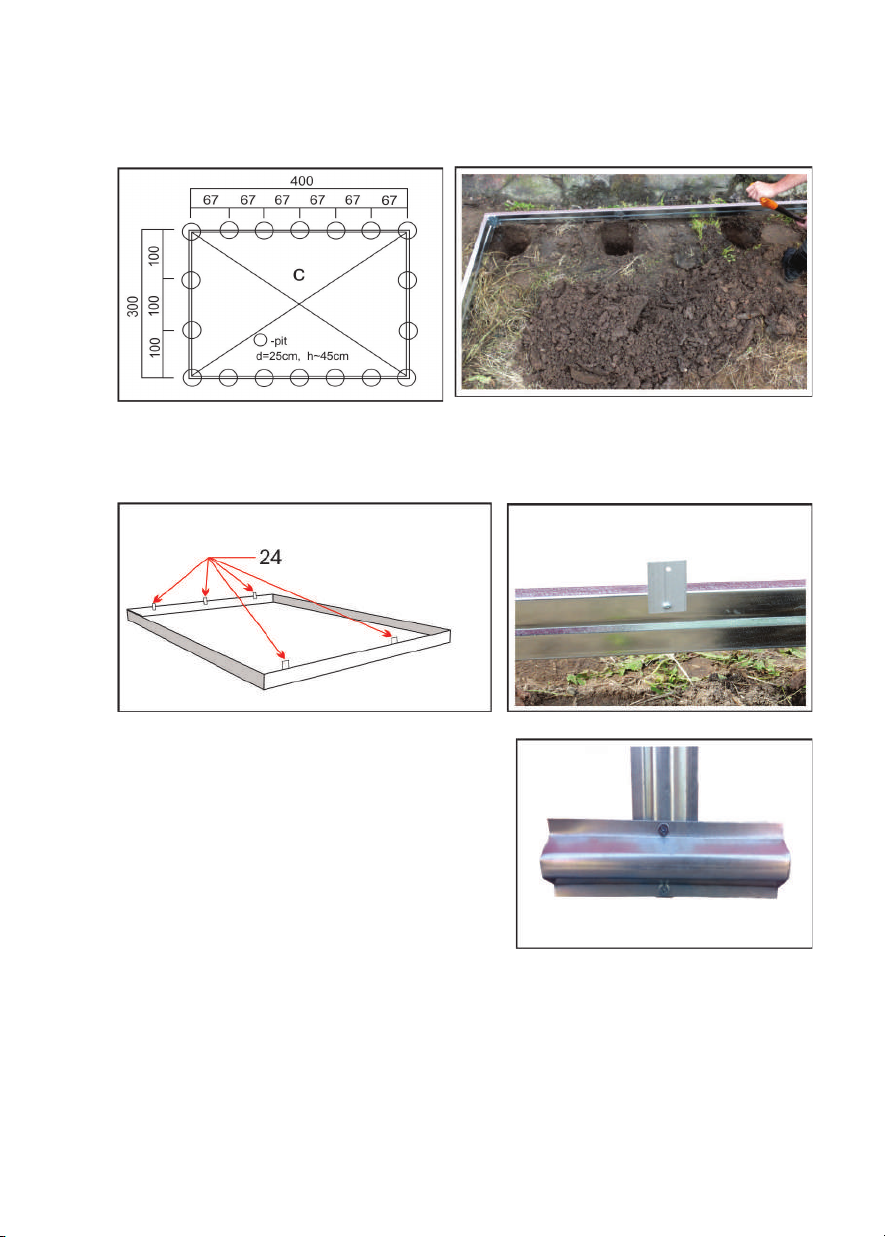

• Shovel to dig pits

• Spirit level to measure equability of the ground.

• Rope to measure the diagonal

• Knife to cut polycarbonate sheets

If necessary, follow the instructions from local building area.

In case of strong wind or storm close the windows and doors.

Before starting the construction, you should read all the instruction at least once and

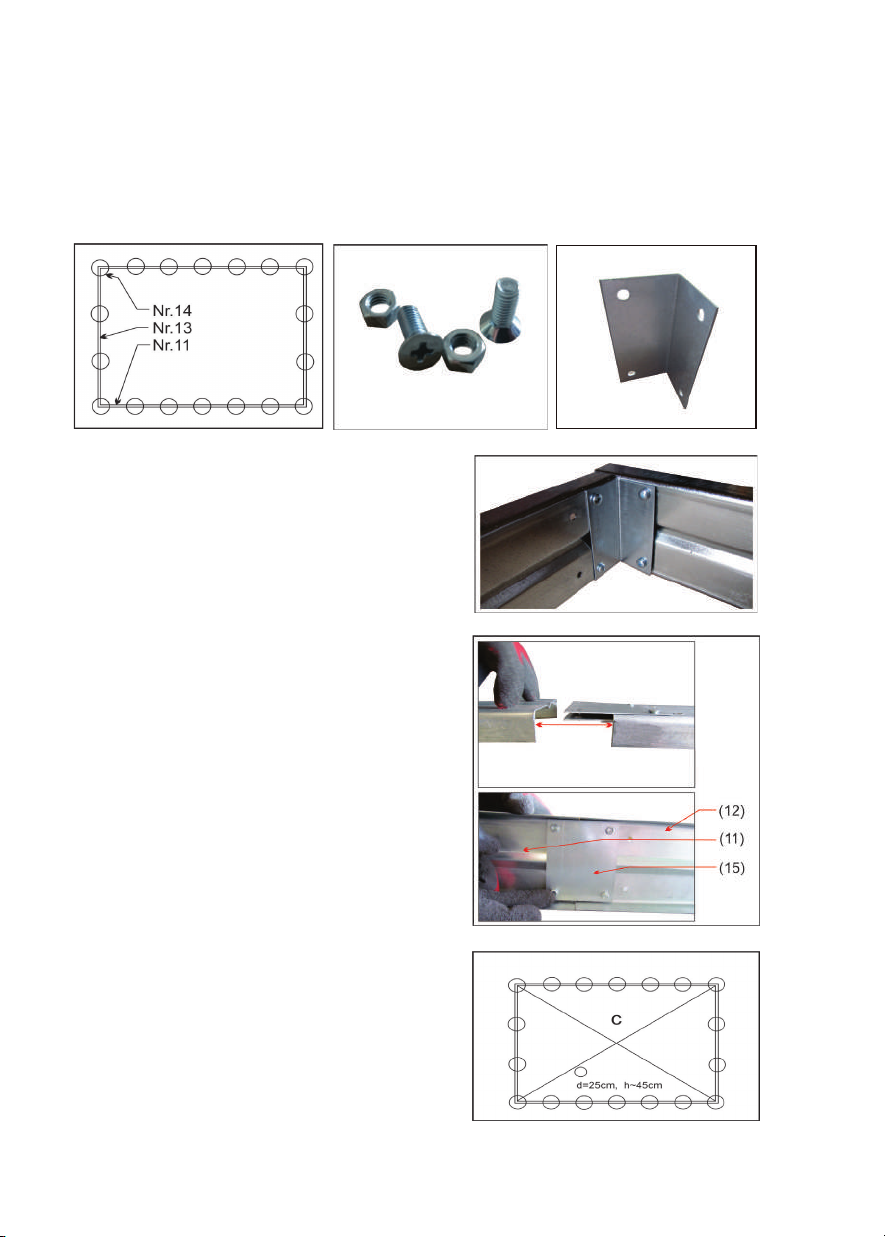

understand dierent sections and proles. is is a helpful guide for you. Compare the

list of parts with the parts in the package. en sort out the sections and leave them in

separate places.

It is highly recommended to screw the screws easily with hands at rst – if needed, you

will be able to rotate sections. Aer the construction, you should measure equability of

the framework and only then tighten the screws.

1