Part NO: 212-0024WB 2July 30th, 2019

Applicable Models

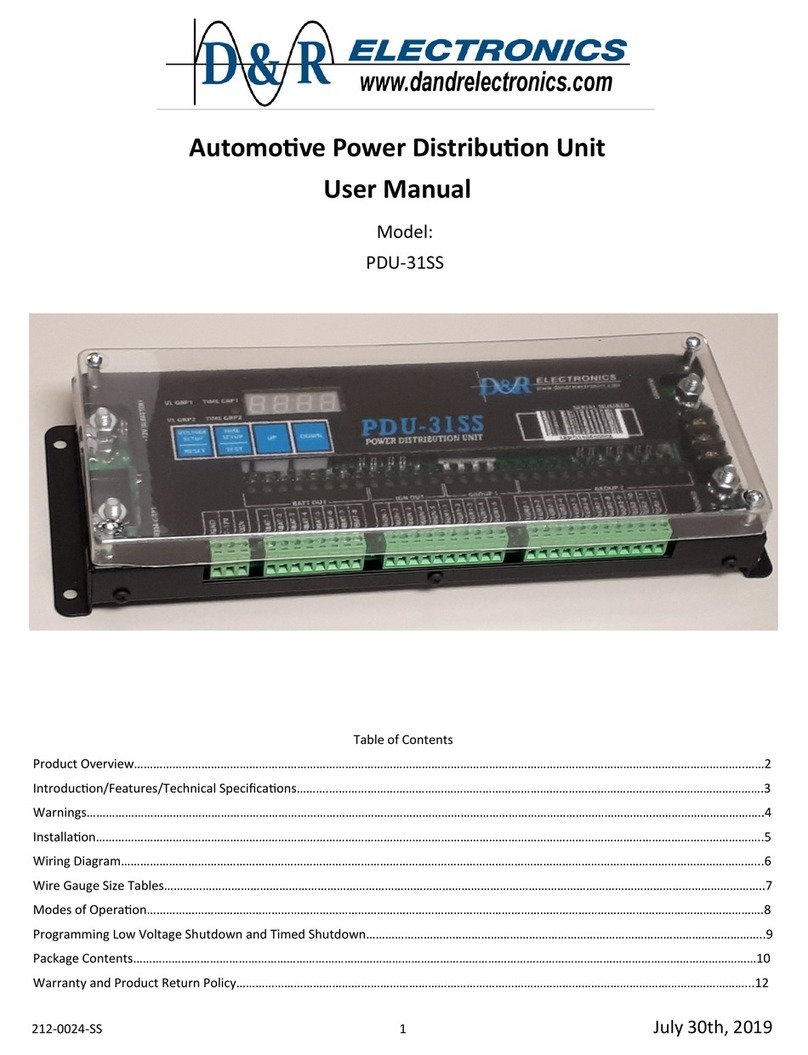

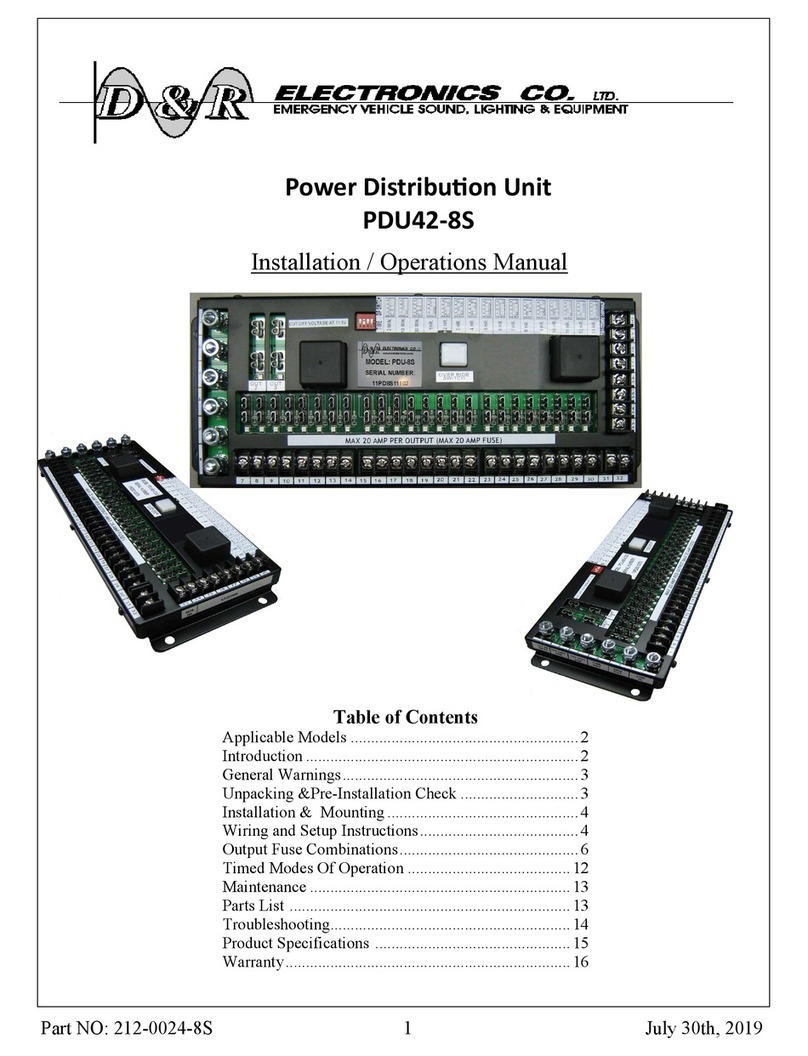

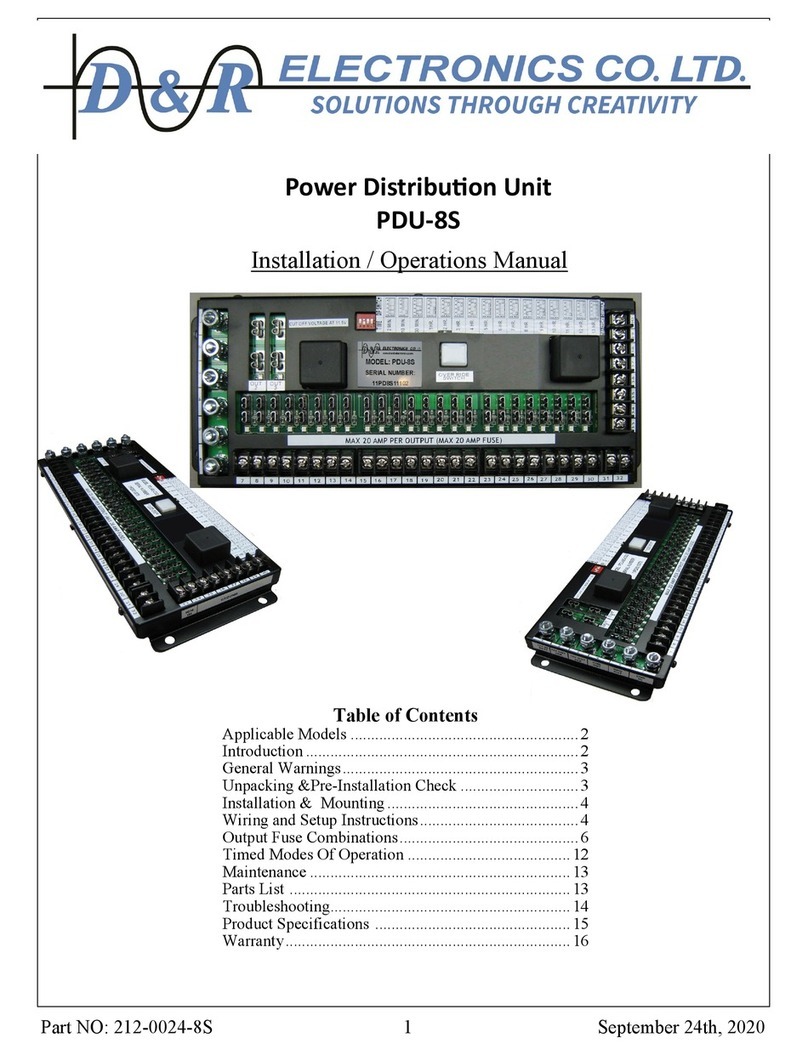

PDU42WB

Introduction

The Power Distribution Unit (PDU) is a compact and convenient point of load power dis-

tribution product for installed electrical devices. By using this device and carefully plan-

ning the distribution of mobile equipment power feeds, complex independent wire runs

and unreliable fuse panel connections can be avoided.

The PDU42WB is directly connected to the vehicle battery and ground, thus providing a

direct easily traceable route to the input power source avoiding interfering with the vehi-

cles factory wiring harness. The specifics for safely connecting the PDU42WB to a vehi-

cles electrical system are outlined in the detailed instructions to follow.

Each circuit can be individually fused further reducing risk of damage to devices from

circuit overload. Each fused output has a red LED to indicate when a circuit fuse is

GOOD.

The PDU42WB unit provides a single 30A high current output and up to 18 additional

outputs divided into “constant/battery”, “ignition controlled” and “timed” outputs to meet

the typical in-vehicle equipment installation requirements. These output features have

the following characteristics;

1) Constant/Battery Outputs:

There are 6 output connections each with individual fuses, that are on at all times

providing the PDU is connected to the battery.

2) Ignition Controlled Outputs;

The 6 output power connections, also individually fused provide +12V output

while the vehicle ignition is on. Power will be immediately turned off at these out-

puts when the vehicle is shut down and the ignition key removed (some vehicles

still maintain and “ignition on” signal when the key is still in the ignition switch)

careful selection of the proper ignition control wire can help avoid this situation..

3) Timed Outputs;

There are 6 output power connections again with individual fuses. These outputs

are on while the ignition control signal is applied to the PDU, and will go through

a pre-set timed off sequence once the ignition is turned off. The time to off is user

selectable and is selected by the installer based on the system design.

This timed off sequence is also controlled by an onboard battery voltage monitor.

If the battery voltage becomes too low the timing sequence is interrupted and a

shut down of the timed outputs will begin. This feature prevents a total discharge

of the vehicle battery while the ignition is off and the equipment is in use.