ENGINEERING

TOMORROW

Page 1of 4Document number: 700493 REV L © Copyright Danfoss | 2019.05

TTS/TGS/TTH/TGH Spare Part Instructions

KIT BEARING SENSOR CABLE ASSEMBLY

100064, 100065.

Installation and servicing of Danfoss Turbocor® compressors by qualified and product trained

Follow these instructions and sound refrigeration/electrical/servicing practices

relating to installation,

commissioning, maintenance and service.

Consult the appropriate

Danfoss Turbocor

Compressors Inc. (DTC)

Service Manual on

turbocor.danfoss.com for

detailed service instructions.

Never power compressor

without covers in place and

secured.

Removing the mains input

cover will expose you to a

voltage hazard of up to 575V.

Ensure the mains

is off and locked out before

removing cover.

Before removing top cover,

wait at least 20 minutes after

isolating AC power to allow

the high voltage

discharge.

Always wear appropriately

rated safety equipment when

working around equipment

and/or components

energized with high voltage.

This equipment contains

hazardous voltages that

can cause serious injury or

death.

Recover all refrigerant

from compressor in

accordance with local

codes and ensure pressure

is fully vented before the

removal of refrigerant

containing components.

1 - Introduction

BEARING SENSOR CABLE ASSEMBLY replacement.

This kit contains the Bearing Sensor Cable Assembly. Please refer to our Service Manual for details regarding the

replacement of the cable.

We have made the TTS/TGS/TTH/TGH Service Manual available to anyone. To access the manual, you may scan the

applicable QR code below or you may go to our DTC website at www.turbocoroem.com. At the top of the page there is a

pull-down menu called “Quick Links.” Click this menu and select the appropriate service manual.

Refer to the applicable QR code below to download the TTS/TGS/TTH/TGH Service Manual.

English Chinese

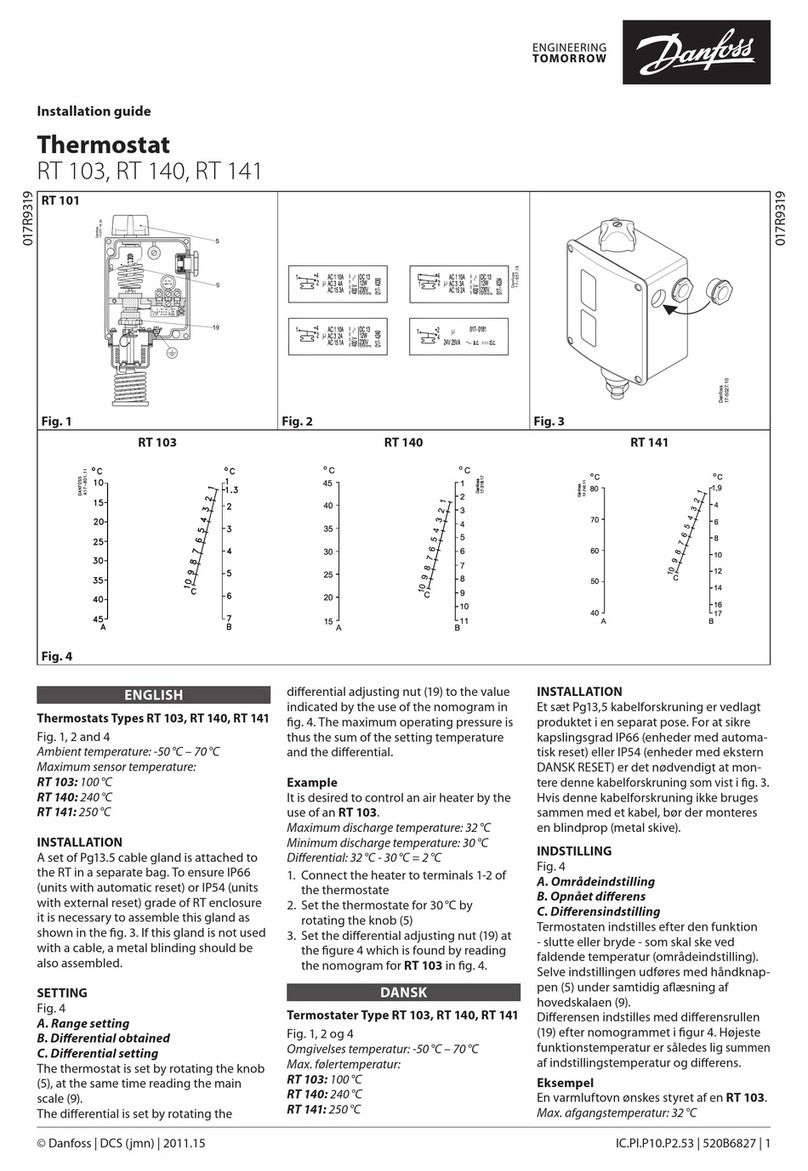

2 - Front Sensor cable Replacement Procedure:

Removal of old cable:

1) Connect cable to connector (J10) on backplane. See Figure 2. Ensure that plug is inserted in correct polarity.

Refer to locating keys on plug and slots in connector. Snap connector retainers into place by gently

squeezing.